Intelligent winter jujube sorting device

A sorting device and technology of winter jujube, applied in the directions of sorting, grading, solid separation, etc., can solve the problems of individual differences in color discrimination and size discrimination of winter jujube, labor cost delaying enterprise development speed, hidden dangers of product hygiene and safety, etc. The effect of operation and maintenance, promoting intelligence, and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

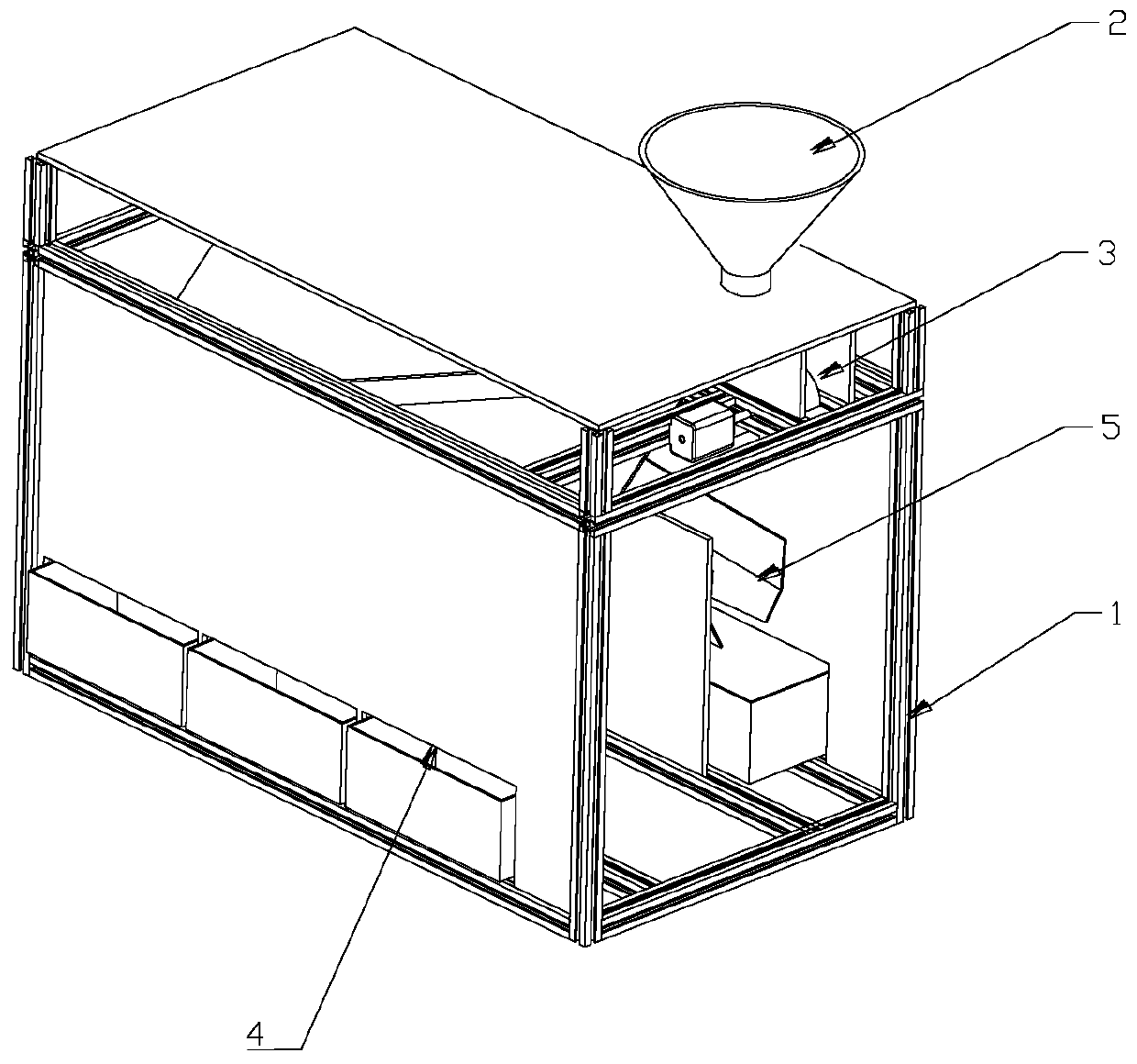

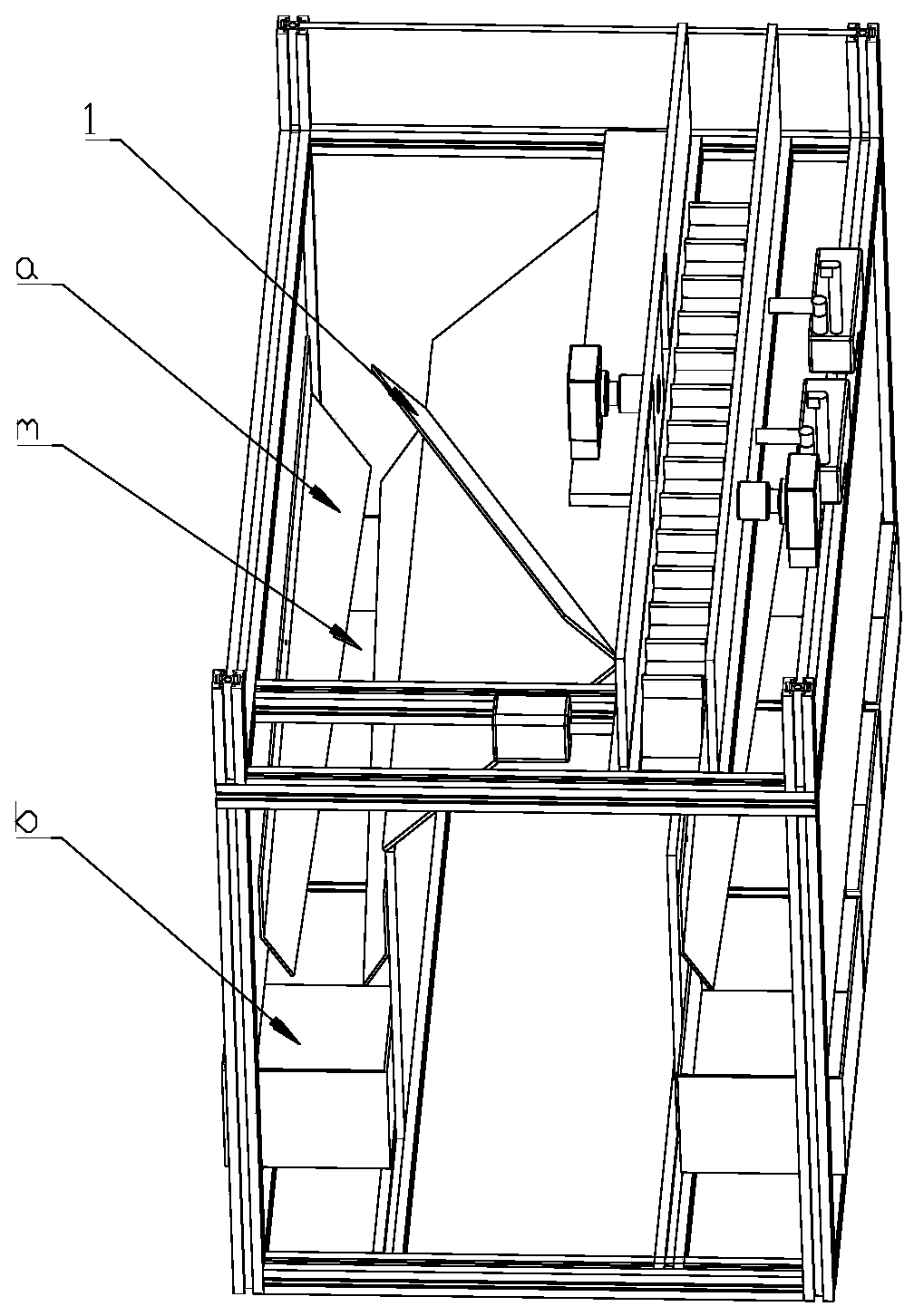

[0045] See attached Figure 1-3 , a winter jujube intelligent sorting device, comprising a device frame 1, a feed port 2, a color sorting mechanism 3, a first size sorting mechanism 4 and a second size sorting mechanism 5; the feed port is arranged on the top of the device frame, and the winter jujube It enters the color sorting mechanism from the material inlet, and the color sorting mechanism completes the color sorting of winter jujubes. After color sorting, the winter jujubes enter the first size sorting mechanism and the second size sorting mechanism respectively, and are separated by the first size sorting mechanism and the second size sorting mechanism. The second size sorting mechanism sorts the winter jujubes that have been color-sorted by size.

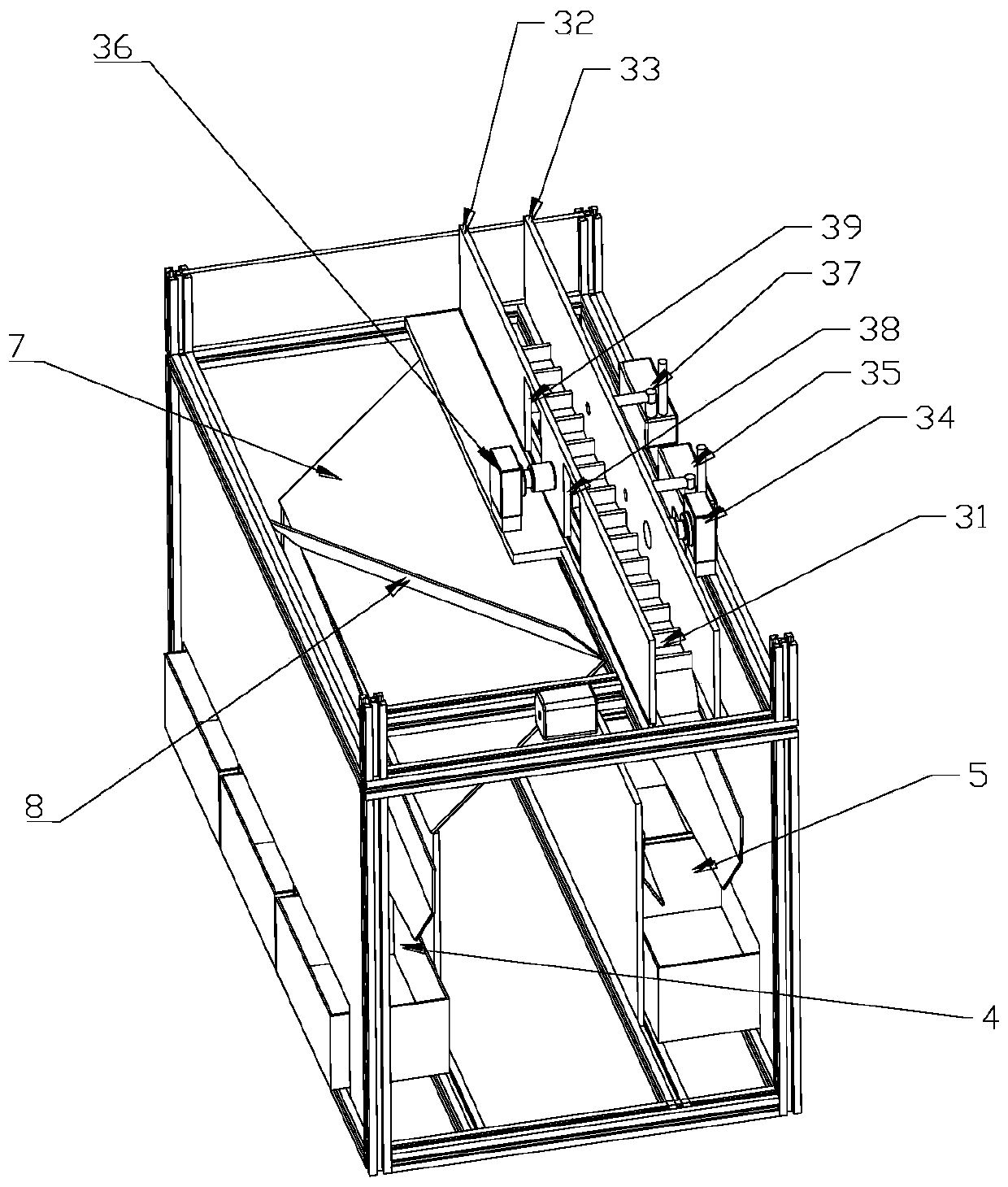

[0046] The color sorting mechanism 3 includes a conveyor belt 31, a first baffle plate 32, a second baffle plate 33, a first camera 34, a first blowing nozzle 35, a second camera 36, and a second blowing nozzle 37. The con...

Embodiment 2

[0059] See attached Figure 4 , on the basis of Embodiment 1, in order to ensure that the winter jujubes can enter the jujube space of the conveyor belt 31 one by one as much as possible, the present embodiment adds a feeding and coding mechanism, which includes a feeding funnel 11 , the screw rod 12 and the channel 13, the screw rod is vertically arranged at the central position of the feed funnel, the screw rod has a spiral guide plate, and the winter jujube can move downward along the spiral guide plate of the screw rod, the described channel is arranged obliquely, and the channel The higher end is connected to the bottom of the screw rod, and the lower end of the channel is connected to the feed port 2. The width of the channel is slightly greater than the maximum diameter of the winter jujube, preferably 50mm. The feeding and coding mechanism can effectively ensure that the winter jujubes fall into the feeding port 2 one by one.

Embodiment 3

[0061] On the basis of the second embodiment, further speaking, the screw rod is an active component, which is connected with a driving motor and can drive the screw rod to rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com