Patents

Literature

87results about How to "Simplify the sorting process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

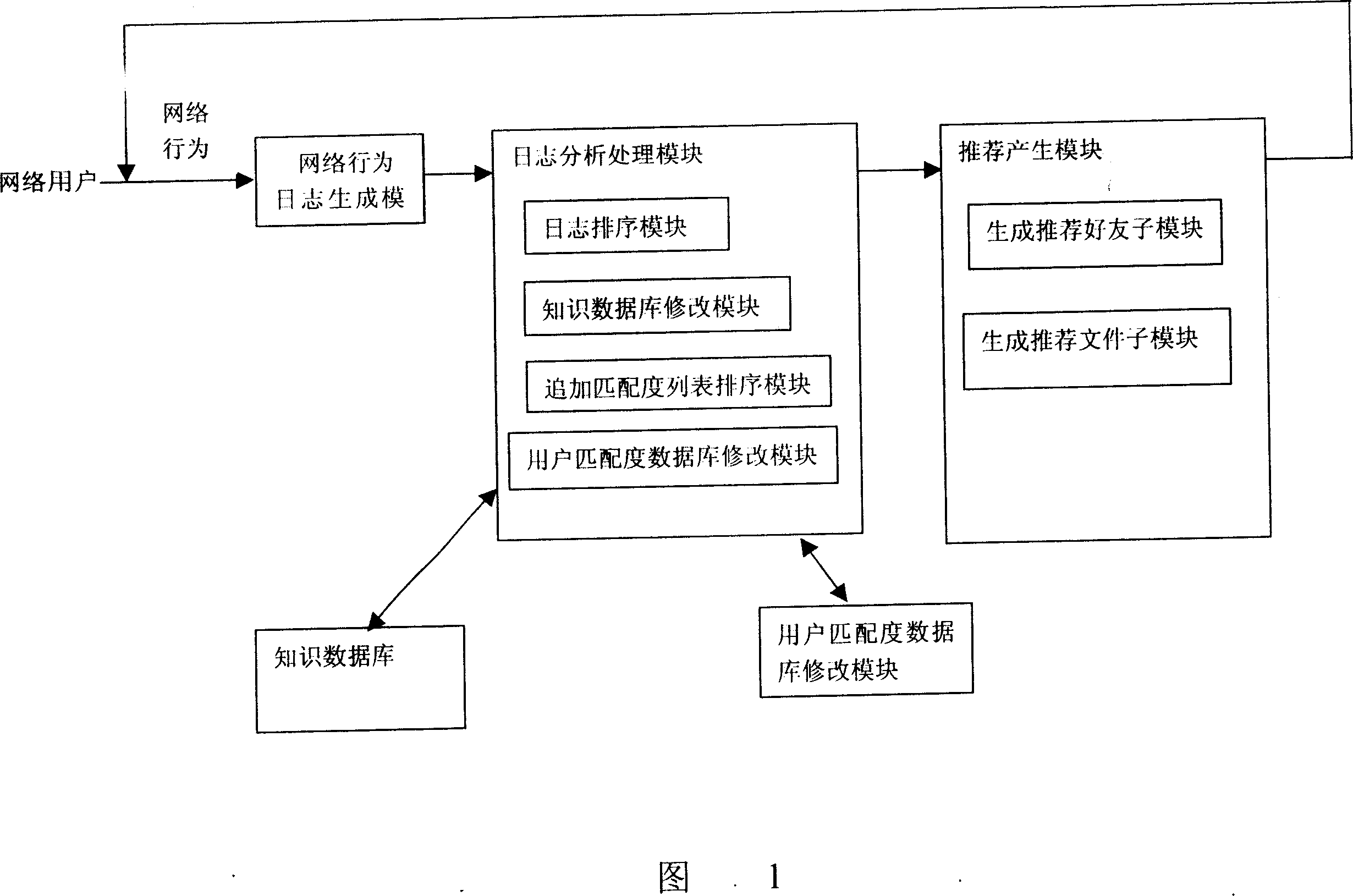

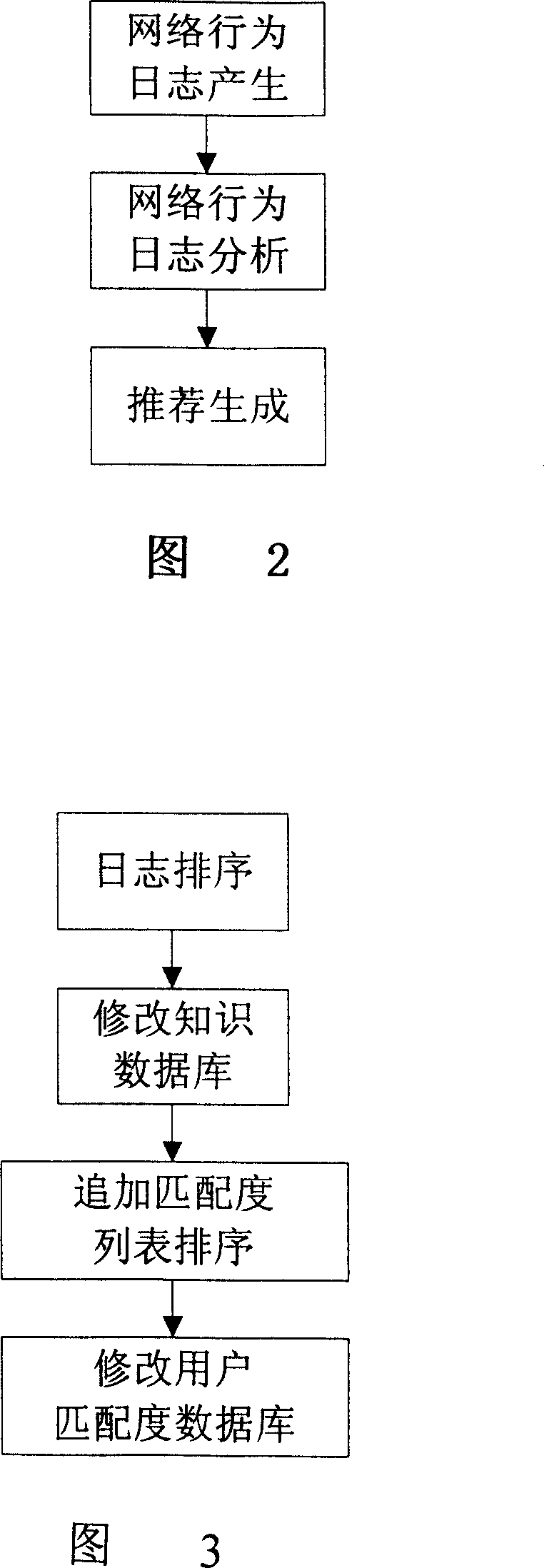

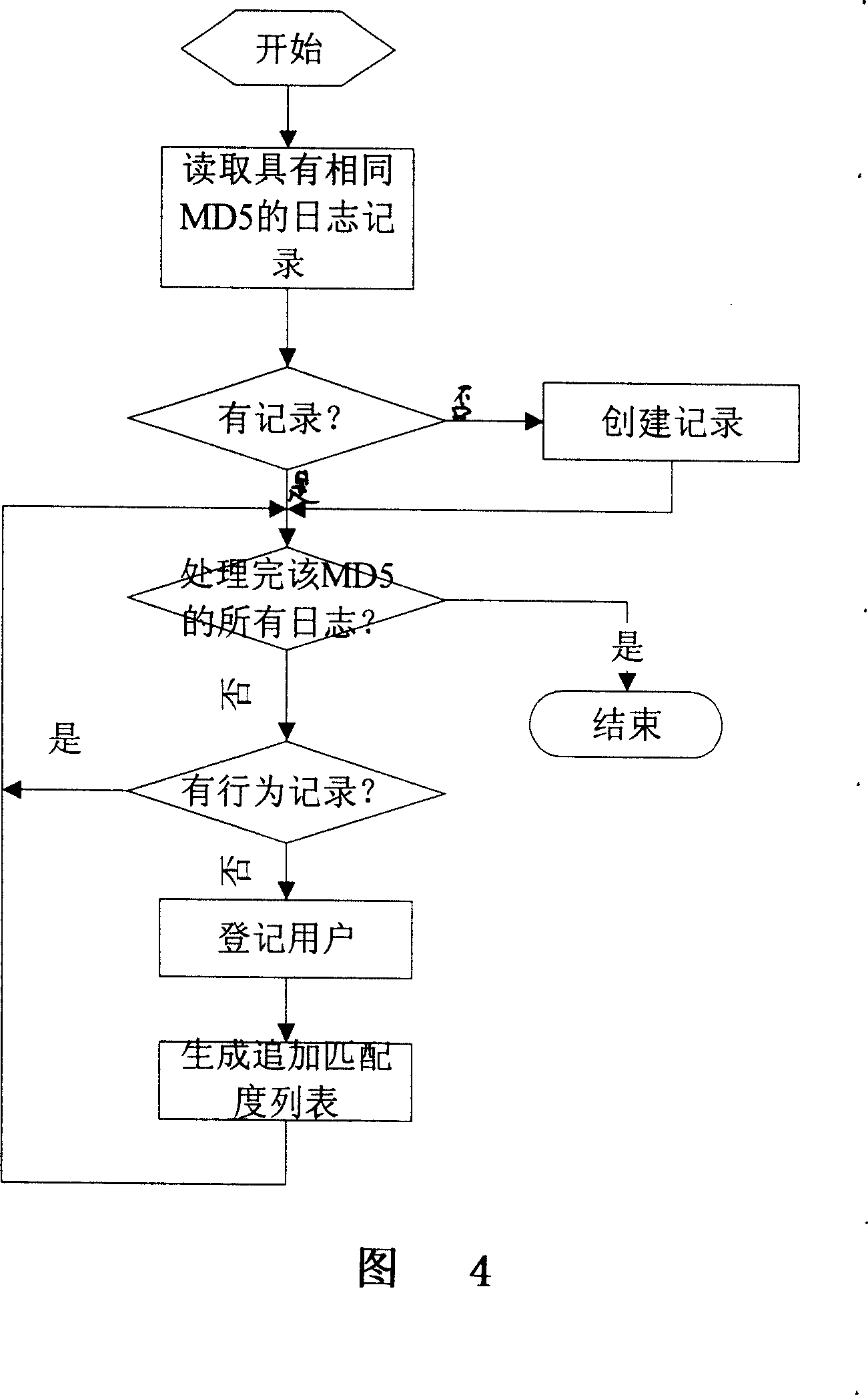

Network behavior based personalized recommendation method and system

InactiveCN101105795AImprove operational efficiencyThe result is highly usableData switching networksSpecial data processing applicationsPersonalizationNetwork behavior

The invention discloses an individualized recommendation method based network behaviors. The method includes the following steps: (A). Generate the corresponding network behavior log of the user according to the search request sent by the users to the server and the report on the completion of document download, and record the keyword searched by users and downloaded document; (B). Analyze and clean up network behavior log, and modify system knowledge database and user matching database; (C). Find out users with the same interest from the modified user matching database and introduce them to users, and take the documents that users are interested in as the recommended document resource for users. The invention also discloses an individualized recommendation system based on network behaviors, which consists of network behavior log generating module, log analysis handling module, recommendation generating module, knowledge database, and user matching database. The invention has the advantages of high operating efficiency, strong usability of results, easy maintenance and expansion of the system, and capability to trigger users' interest.

Owner:钟惠波

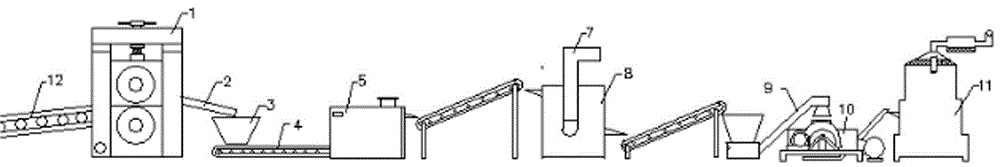

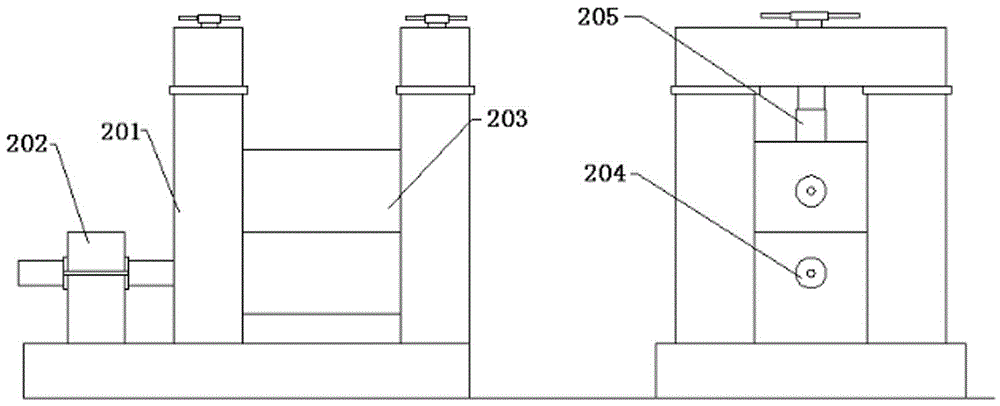

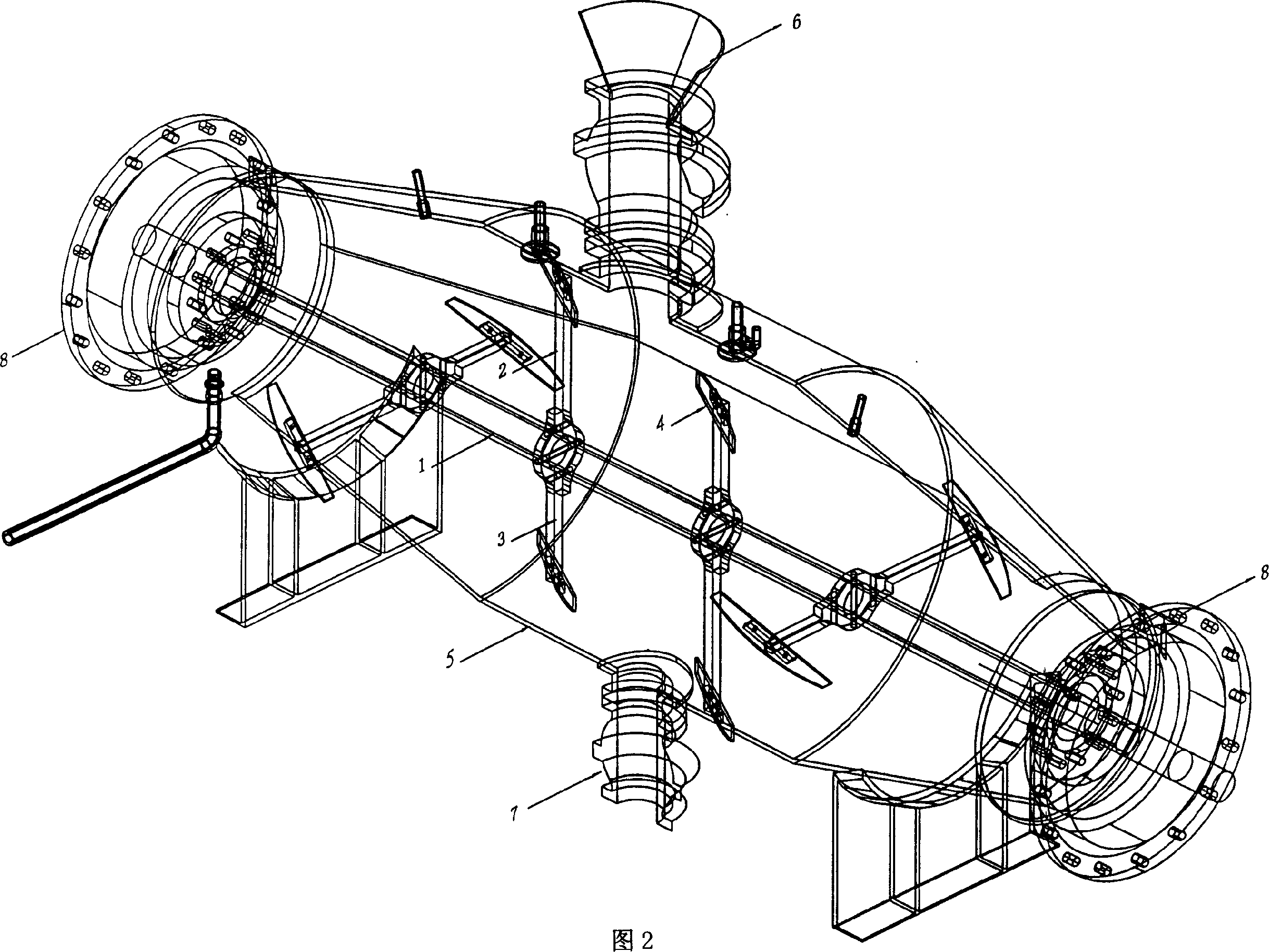

Municipal refuse handling method and equipment

The invention relates to a municipal refuse handling method and equipment. The handling method includes the steps of squeezing for water removal, magnetic separation sorting, first-stage smashing, blasting separation, second-stage smashing, biomass fuel adding, pelletizing and particle burning heating and steam generation or power generation; and the handling equipment comprises a feeding conveying device, a magnetic separation conveying device, a material collecting hopper, a discharging plate, a magnetic separation device, an air blower, a mixing and stirring machine, a refuse water removal roller press, a biomass particle machine, a refuse smashing machine and a smokeless burning device. According to the municipal refuse handling method and equipment, the refuse handling process is simple, a bonding assistant does not need to be added during pelletizing, and manufactured municipal refuse combustible particles are smooth in surface, compact in structure, higher in calorific value, high in drying degree and free of pollution during burning.

Owner:黎汉东

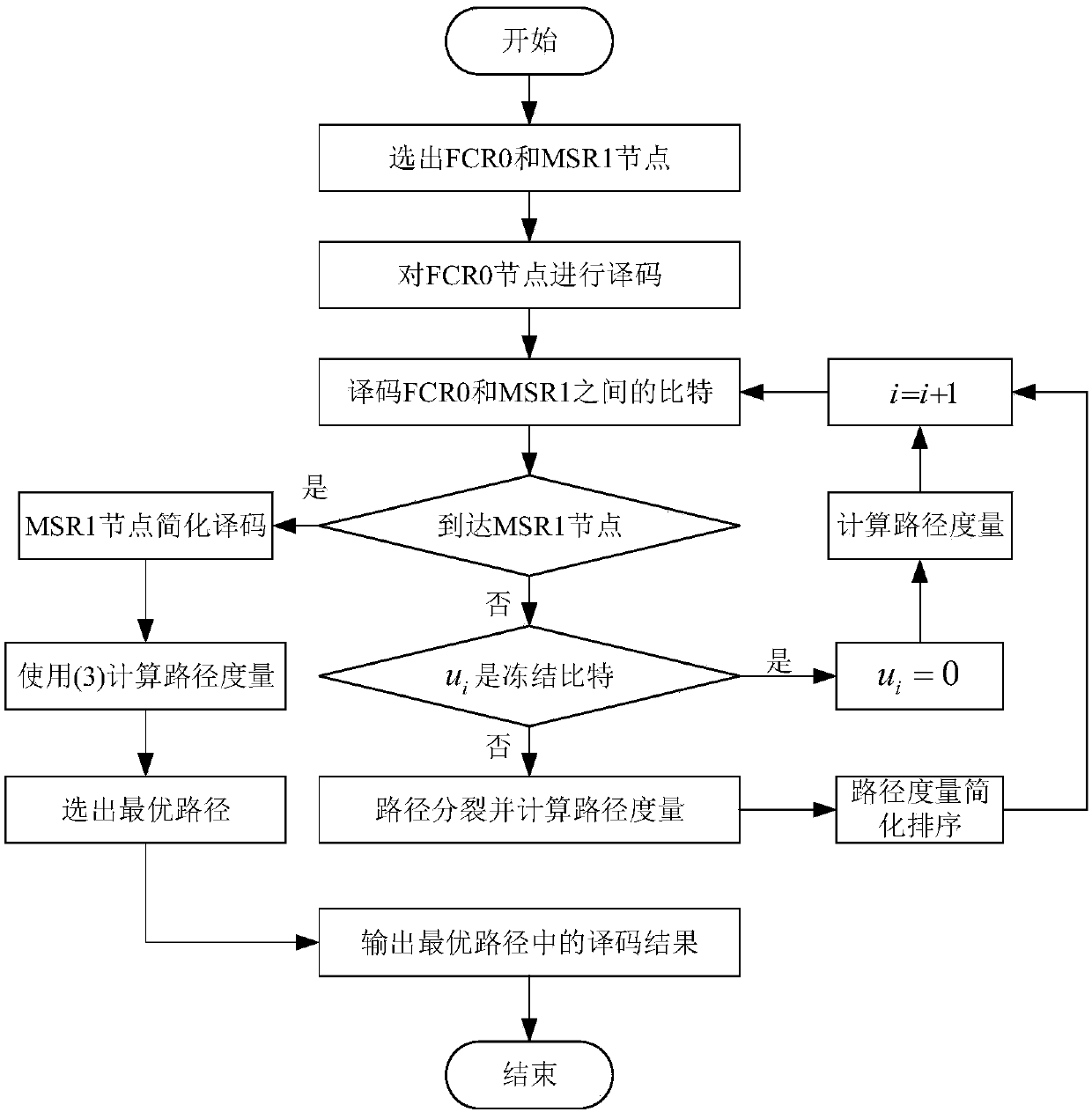

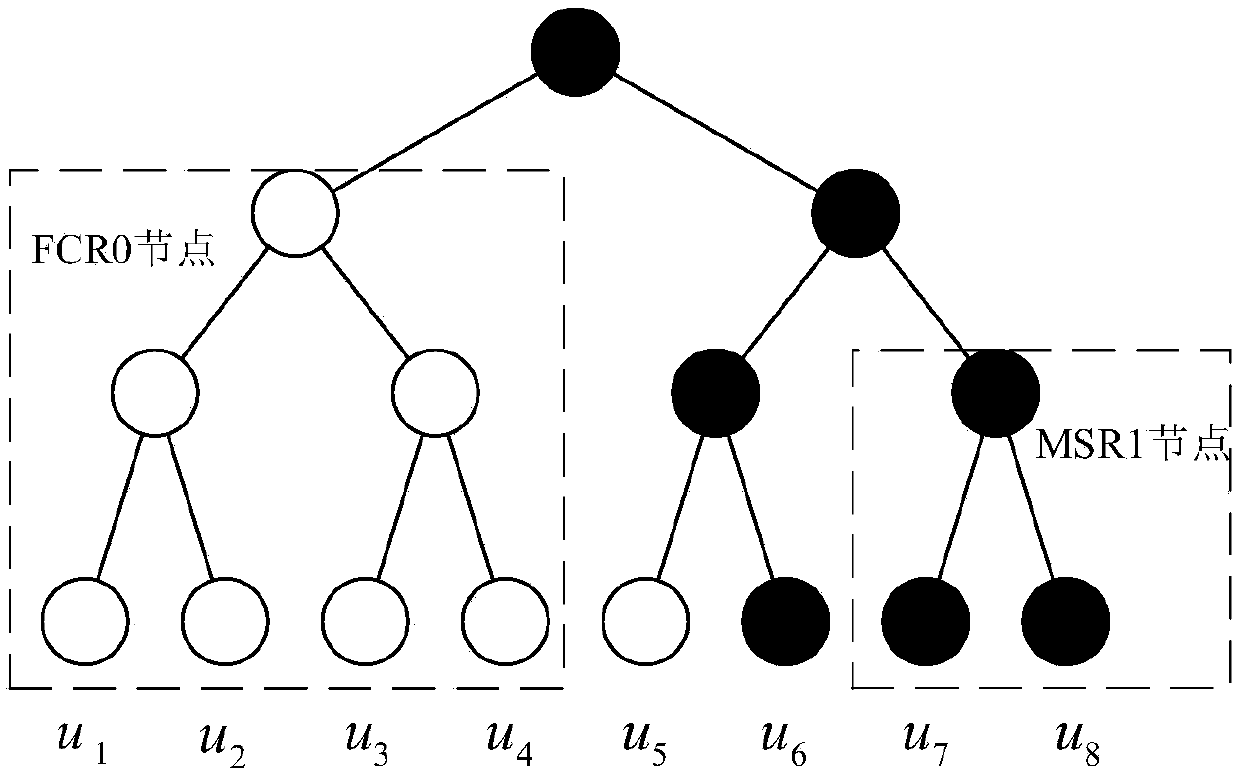

Polar code decoding method with low delay and complexity

ActiveCN108063649ASimplified decoding calculationReduce decoding delayError preventionOther decoding techniquesDecoding methodsLow delay

The invention discloses a polar code decoding method with low delay and complexity. The polar code decoding method adopts an SCL method for decoding and comprises the following steps of (1) selectingan FCR0 node and an MSR1 node from a bit sequence to be coded; (2) for the FCR0 node, directly acquiring a decoding result according to a value of a freezing bit stored by a receiver; (3) for a bit sequence between the FCR0 node and the MSR 1 node, if the current bit sequence to be coded is the frozen bit, connecting a path in the step (2) and directly acquiring a decoding result according to a value of the freezing bit stored by the receiver, and if the current bit sequence to be coded is an information bit, connecting a freezing bit decoding path, and reserving a path with a smaller path metric through path splitting and simplified path metric; (4) for the MSR1 node, carrying out direct judgment decoding by using an LLR, and connecting to the step (3), and connecting to all paths reserved in the step (3); and (5) for the path in the step (4), selecting a decoding sequence corresponding to a path with the minimum path metric as decoding output. The polar code decoding method has lowerdelay and complexity.

Owner:白盒子(上海)微电子科技有限公司

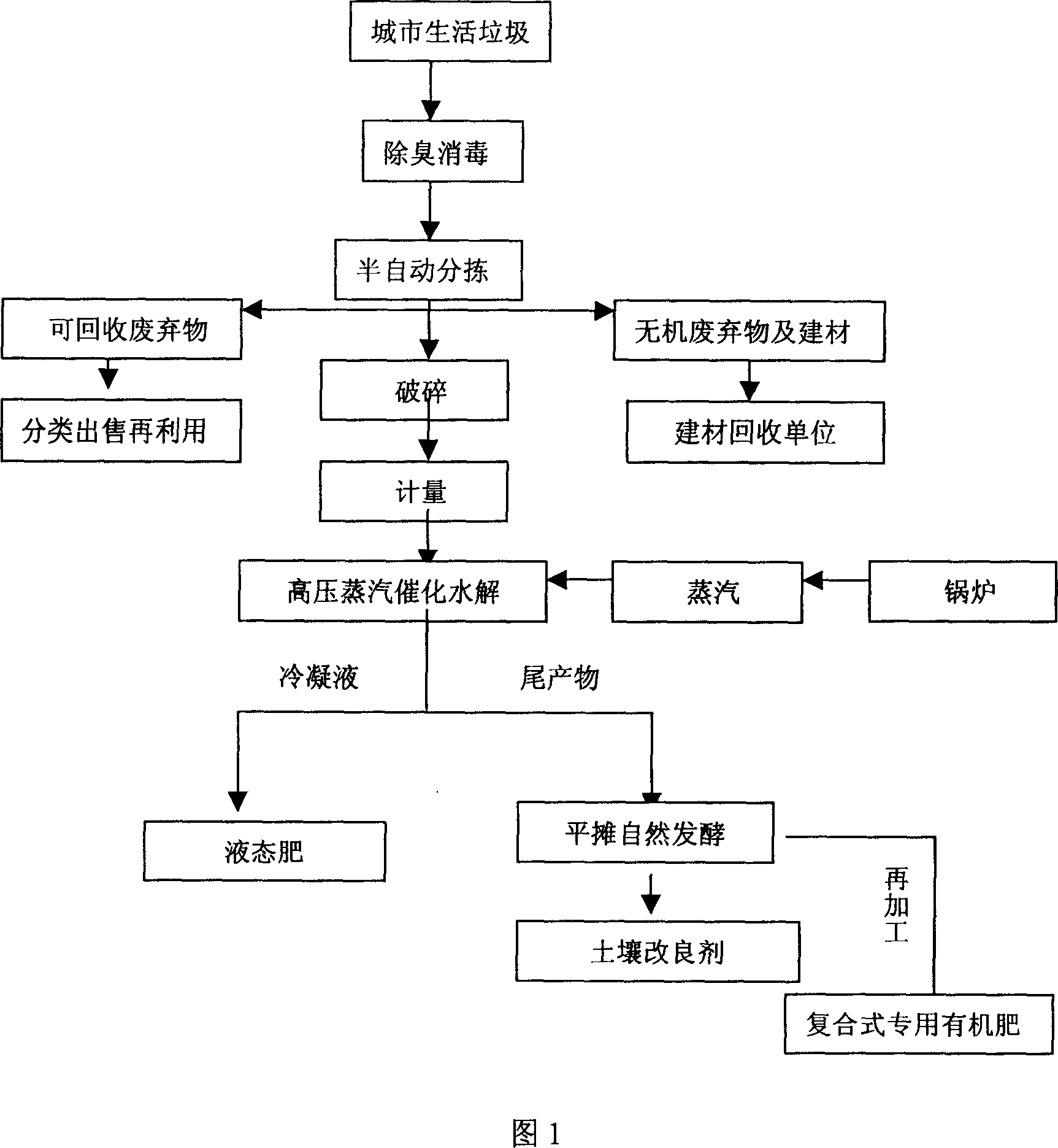

High pressure steam catalysis hydrolysis process for treating domestic refuse

InactiveCN1923383AReach the goal of reducingAchieve the goal of harmlessSolid waste disposalClimate change adaptationChemical reactionSaturated water vapor

The invention relates to a method for treating life waste. Wherein, it uses high-pressure steam catalyst hydrolysis processor; and the treatment comprises that: first using high-pressure steam treated chip condensed liquid to disinfect the waste; then classifying and selecting to picking the un-treated waste as glass, metal and rubber, and the ones which can be recycled; breaking left organic waste and feeding into high-pressure steam catalyst hydrolysis processor; chemically reacting at certain pressure, temperature and saturated steam, the energy generated in water molecule structure change will break off the molecule chain of macromolecule polymer, to reduce it into micromolecule polymer which can be absorbed by plant.

Owner:周钜洸

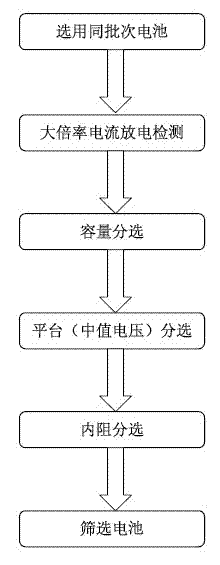

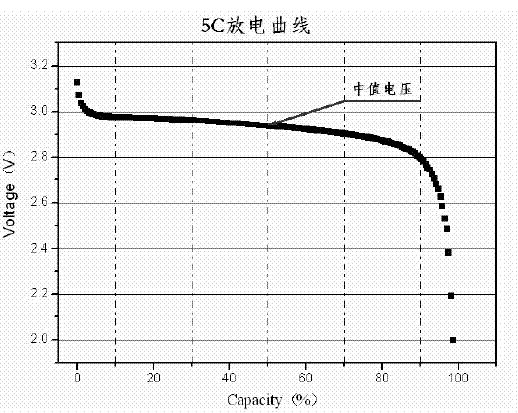

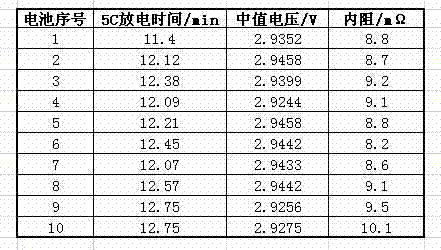

Method for separating secondary batteries

ActiveCN103084342ASimplify the sorting processSimplify sorting equipmentSortingElectrical batteryInternal resistance

The invention relates to a method for separating secondary batteries. The method comprises the following steps: (1) selecting a batch of secondary batteries in a full energy state, placing the batch of secondary batteries in a charge-discharge detection device for a lithium ion battery, discharging the secondary batteries in a 3C-10C rate, and recording discharge data by using a computer; (2) setting the low limit of discharge time according to the capacity range of the selected secondary batteries, and classifying the batteries with the discharge time longer than the low limit of discharge time according to a setting range; (3) setting a low limit discharge platform or a low limit mid-value voltage for the selected secondary batteries in the capacity range according to needs to obtain the batteries more than the low limit discharge platform or the low limit mid-value voltage; and (4) carrying out internal resistance separation on the batteries obtained in step (3), and selecting the batteries with satisfactory internal resistances. After the technical scheme is adopted, a separation process is simplified, separation equipment is reduced, the separation speed is increased and the separation quality is improved, the production cost is reduced, and the production efficiency is improved.

Owner:OPTIMUM BATTERY CO LTD

Method for removing magnesium from phosphate ore

The invention provides a method for removing magnesium from phosphate ore. The method comprises the following steps: grinding raw phosphate ore until particles in the particle size of -0.074mm account for 60 to 80 mass percent to make monomers forming the ore separated; adding 1 to 20kg of aqueous solution of polyvinyl alcohol into each ton of raw phosphate ore, uniformly stirring, and adding an acid solution until the pH value is 3-5; and stirring, reselecting ore pulp, discharging calcite and dolomite as tailings in an overflow way, and discharging the phosphate ore as magnesium-removed phosphate concentrate in a bottom current way. A separation process is simple in flow; and compared with the traditional flotation and reverse flotation, the separation process has the characteristics of high separation accuracy, good separation index, high production capacity and the like, and the content of magnesium oxide in the phosphate concentrate can be effectively reduced.

Owner:KUNMING UNIV OF SCI & TECH

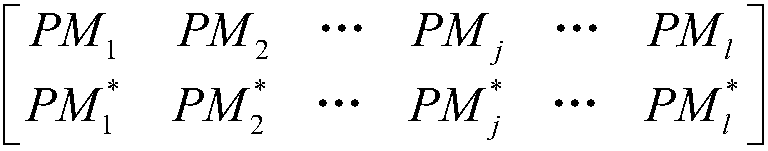

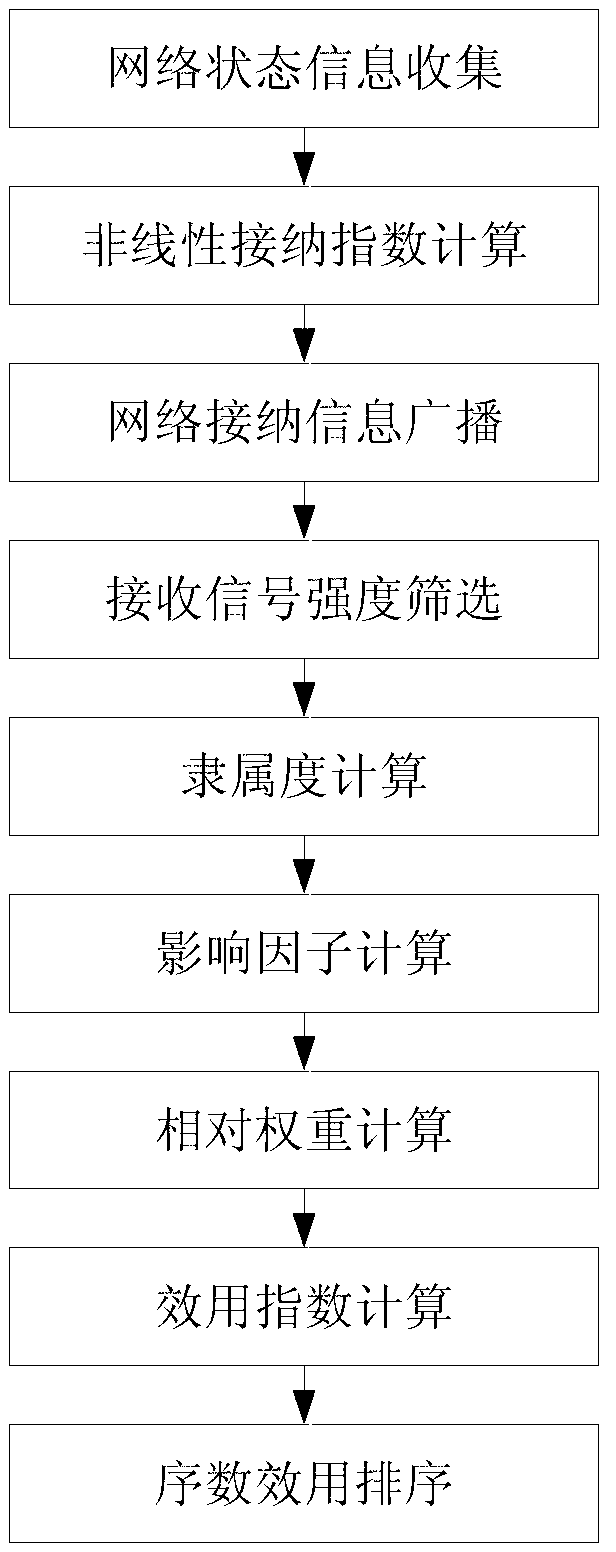

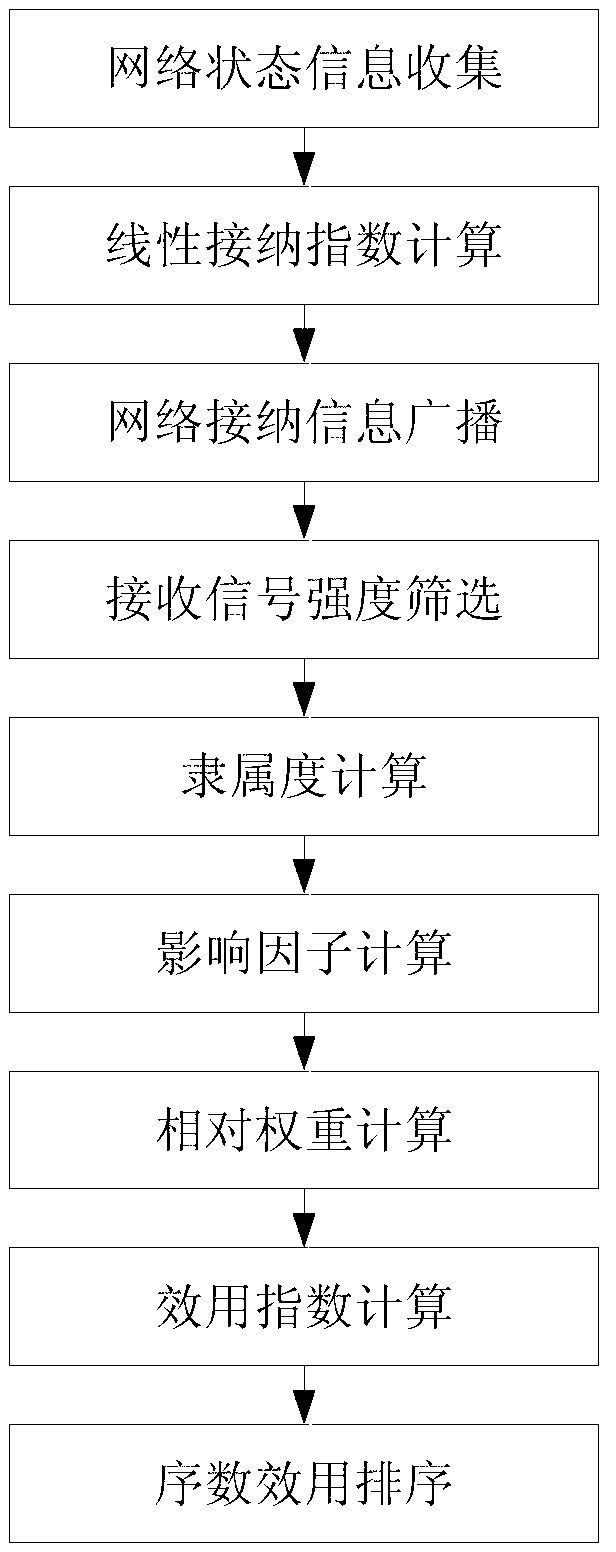

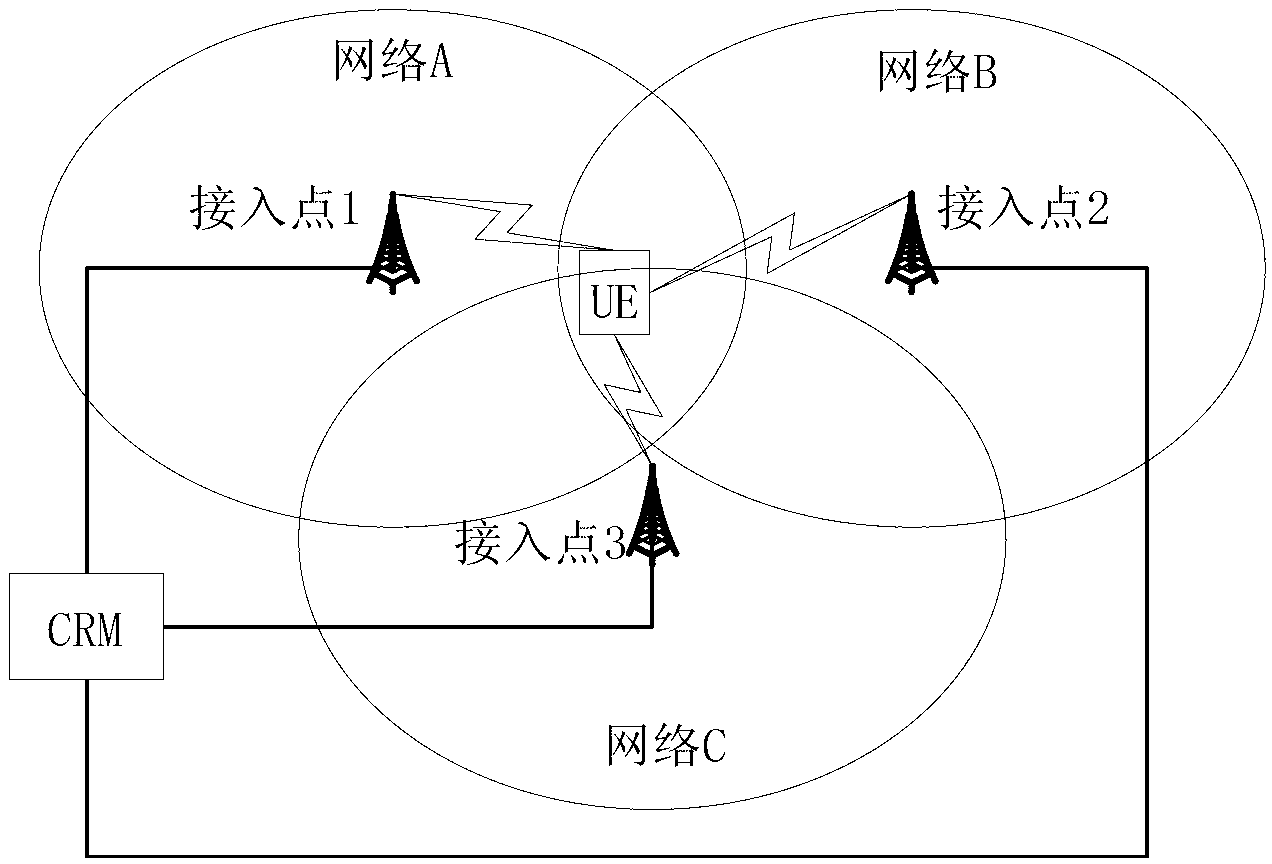

Network selection method based on user experience QoE

InactiveCN102802204AImprove experienceSatisfy preference requirementsNetwork traffic/resource managementResource utilizationNetwork key

The invention discloses a network selection method using ordinal utility to evaluate user experience QoE, and mainly solves problems that user experience QoE is neglected and that network resource utilization rate is low in former network selection methods. Steps to realize the method are as followed: collecting state information of each network to form a network original information list; calculating service acceptance indexes of the network to form a network acceptance information list; user equipment receiving the network acceptance information list broadcasted by the network, and screening signal strength; calculating grade of membership of the service to form a network grade of membership information list; calculating impact factors of key quality indexes on the service to form a network key quality index information list; recording user preference information; calculating utility indexes of the network on the service to form a network utility information list; and using the ordinal utility method to obtain a candidate access network information list. The method can improve user experience QoE, equalize network load and increase utilization rate of network resources. The method can be used in network selection in a heterogeneous wireless network scenario.

Owner:XIDIAN UNIV

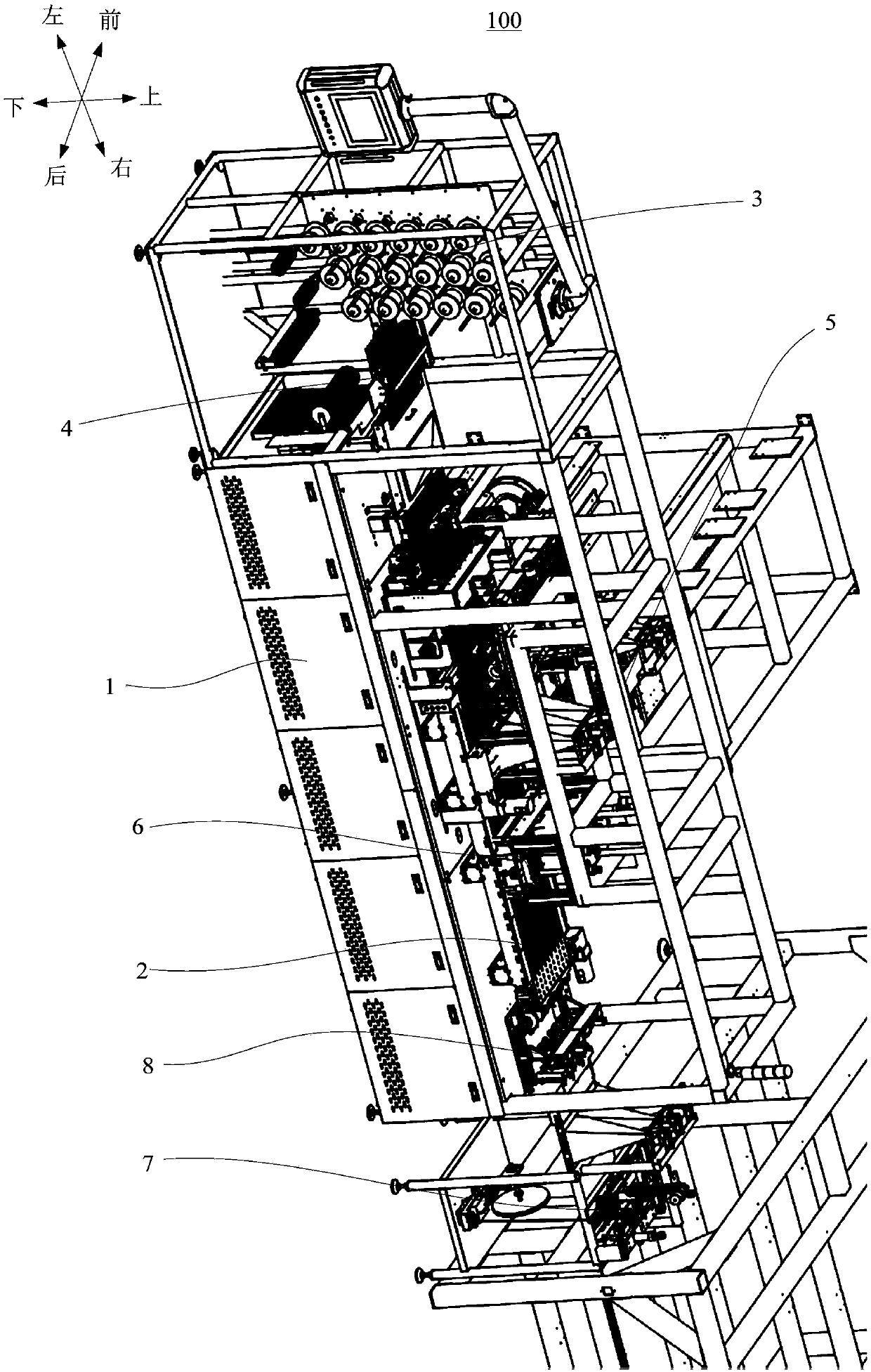

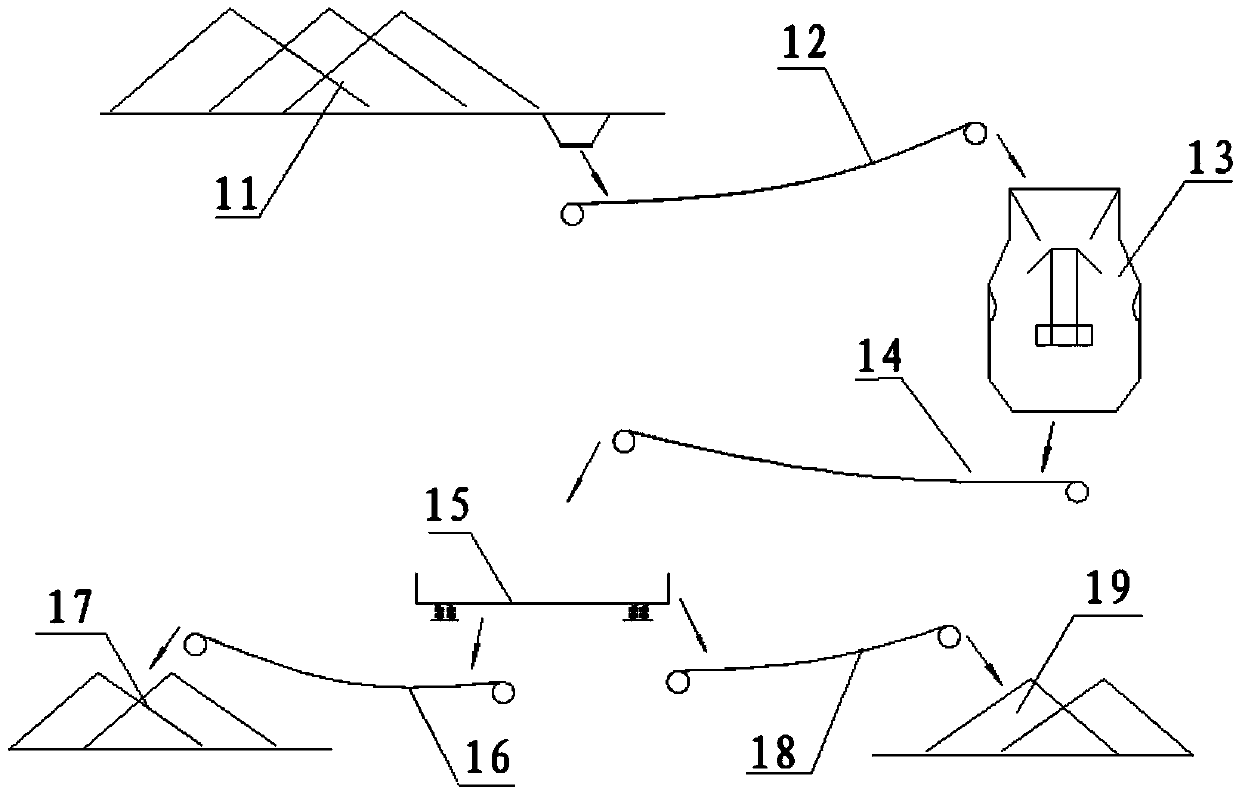

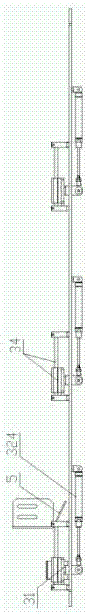

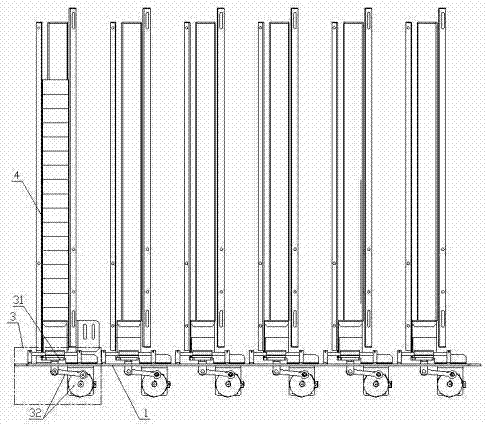

Solar cell welding machine

PendingCN109623218ARealize automatic weldingClosely arrangedFinal product manufactureWelding/cutting auxillary devicesCell interconnectionWelding

The invention discloses a solar cell welding machine. The solar cell welding machine comprises a machine base, a conveying assembly, a first welding strip feeding device, a second welding strip feeding device, a cell feeding and discharging device, an interconnection welding device and a confluence welding device; the machine base is provided with a cell paving station, a waiting station, an interconnection welding station and a confluence welding station; the conveying assembly conveys a plurality of solar cells to the interconnection welding station via the cell paving station successively;the first welding strip feeding device conveys a first welding strip to the cell paving station; the second welding strip feeding device conveys a plurality of second welding strips to the waiting station and the cell paving station; the cell feeding and discharging device conveys solar cells to the cell paving station; the interconnection welding device welds and forms a plurality of interconnected solar cell strings; and the confluence welding device welds and forms a cell interconnection plate. Simultaneous welding of the multiple solar cell strings and automatic welding of the solar cell interconnection plate are achieved, the production efficiency is improved, and the conversion efficiency of a photovoltaic module is improved.

Owner:WUHAN SUNIC INTELLIGENT EQUIP MFG CO LTD

Recycling method for valuable element in waste lithium ion battery electrode material

InactiveCN108023134AReduce lossReduce consumption costWaste accumulators reclaimingBattery recyclingRecovery methodSlag

A recycling method for a valuable element in a waste lithium ion battery electrode material comprises the following steps of roasting the waste lithium ion battery electrode material in air to obtainroasting slag, wherein the roasting temperature is 400-900 DEG C, and the heat preservation time is 30-300 minutes; and mixing the roasting slag and an acid solution with [H+] concentration being 0.5-9mol / L according to a mass ration being 1:(2-10), performing leaching under a leaching temperature being 30-95 DEG C and leaching time being 1-9 hours, and performing filtering to obtain a leaching liquid and leaching slag, wherein the leaching liquid is used for recycling nickel, cobalt, manganese, aluminum and lithium, and the leaching slag is used for recycling a carbon material. According to the recycling method, a positive electrode material and a negative electrode material of a battery are not needed to be separated, no extra leaching reduction agent is added, the recycling cost is reduced, the positive electrode material and the negative electrode material can be simultaneously recycled, and the recycling economic benefit of the lithium battery is improved.

Owner:GUANGDONG INST OF RARE METALS

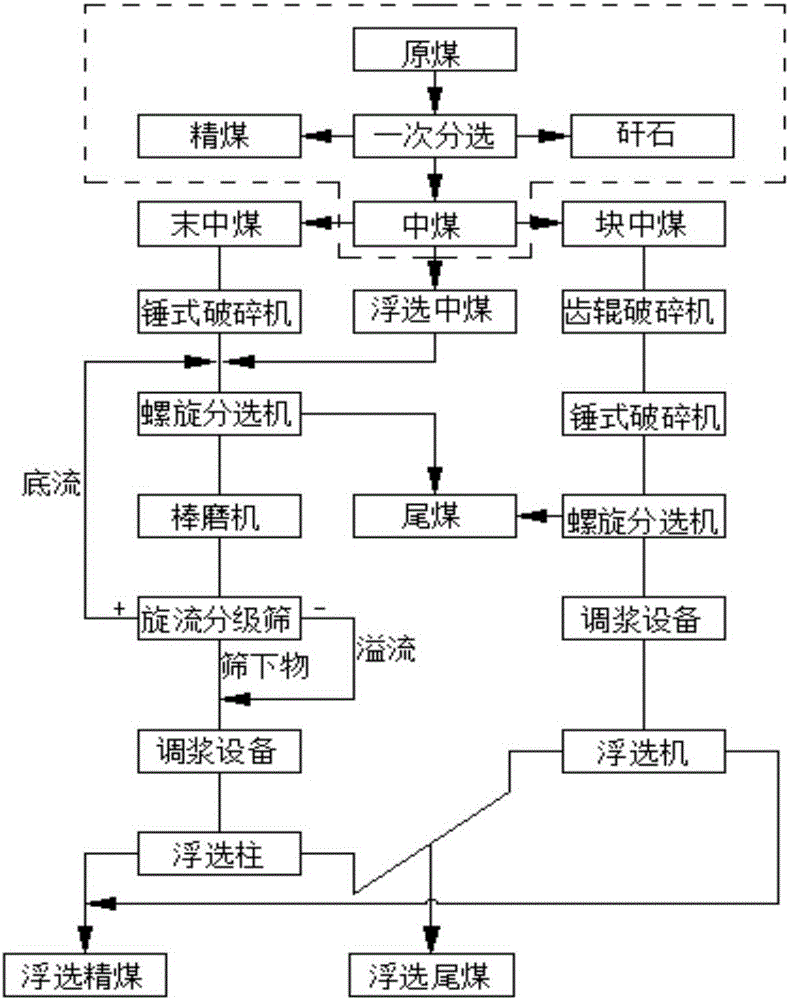

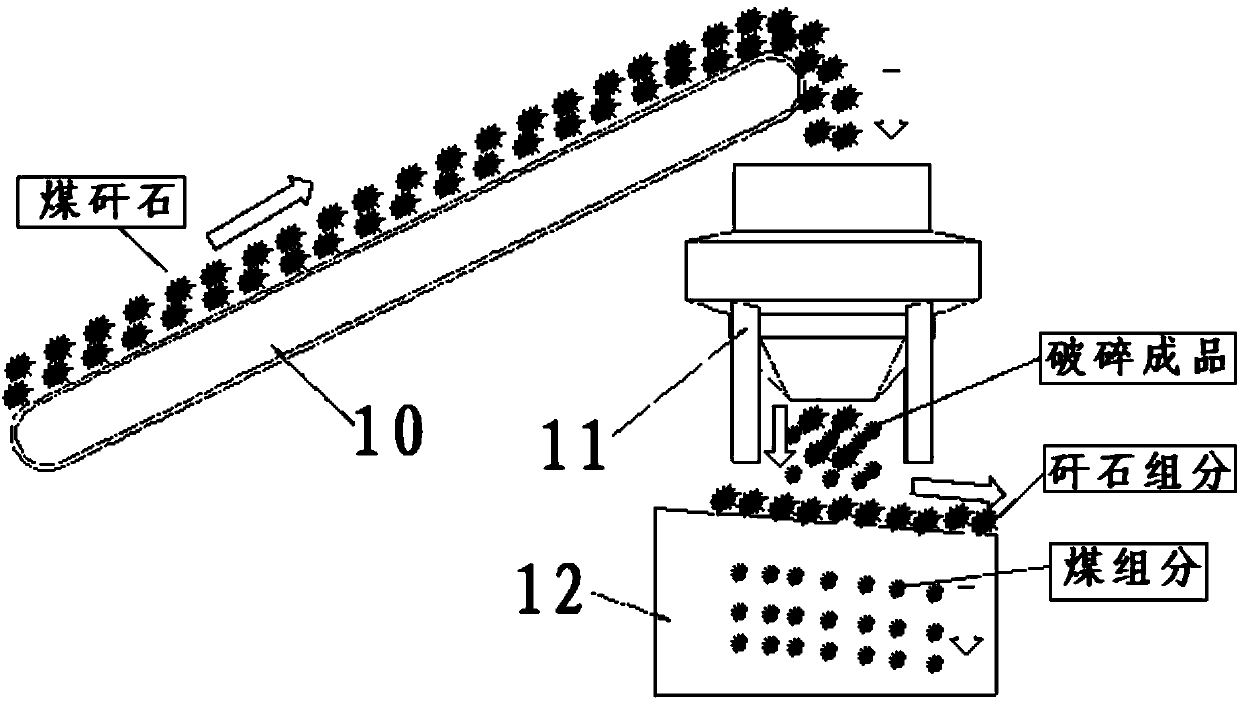

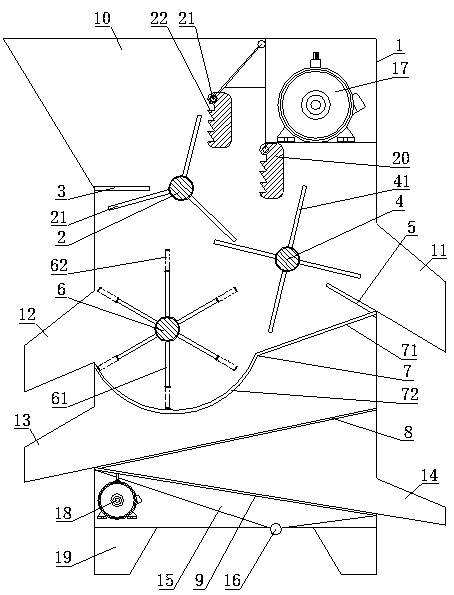

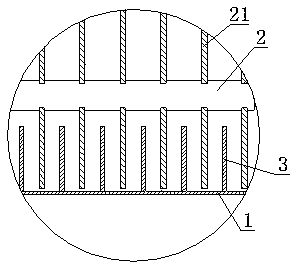

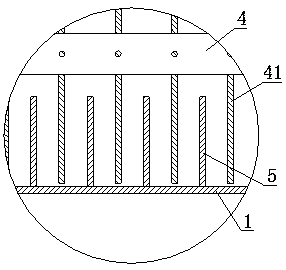

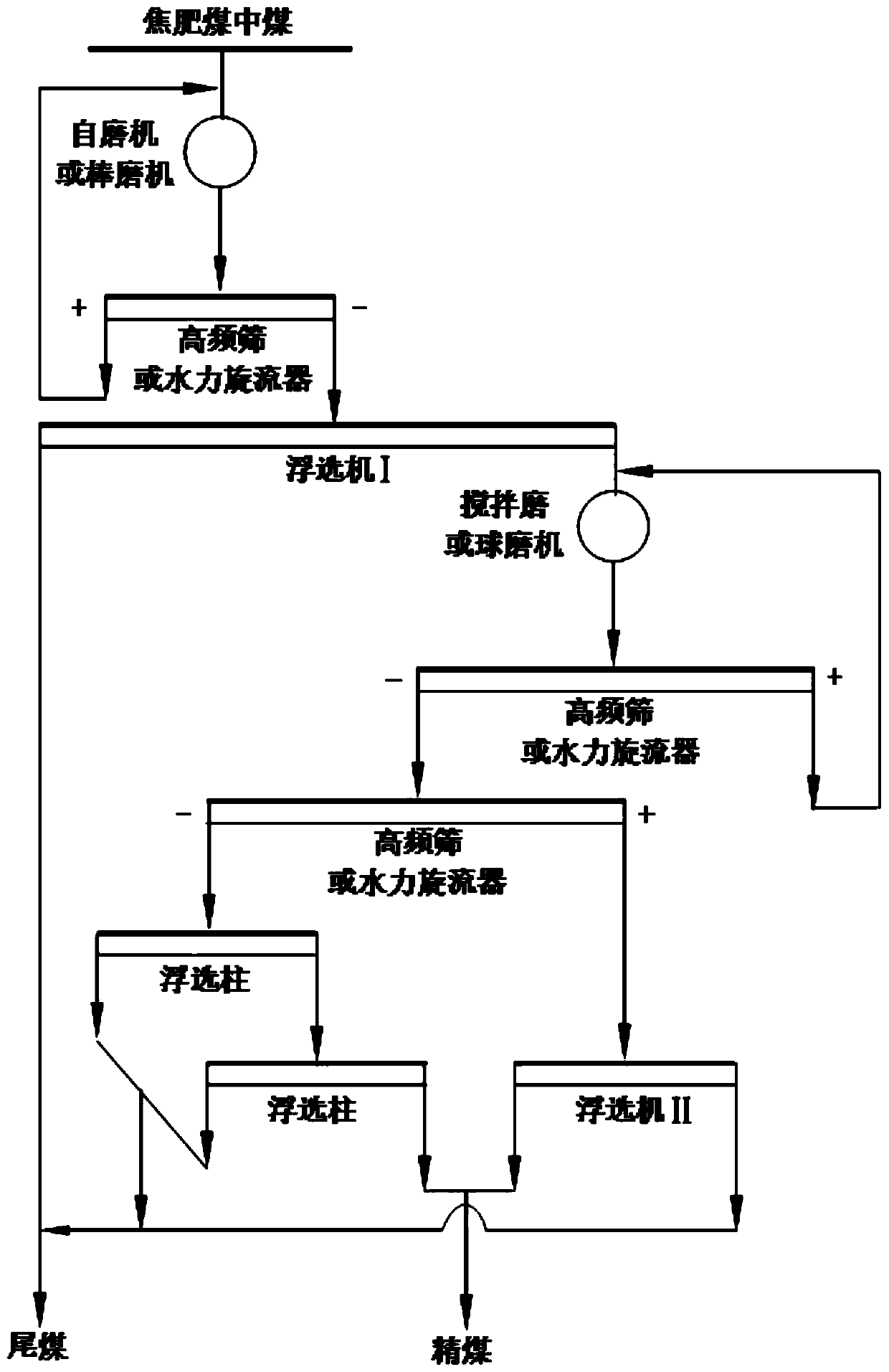

Dissociation and recleaning process for coking middlings

ActiveCN105728155ALarge crushing ratioSmall amount of crushingSolid separationGrain treatmentsRefractoryEngineering

The invention discloses a dissociation and recleaning process for coking middlings which are high in ash content and refractory, and belongs to coal washing methods. The coking middlings are divided into lump middlings (+13 mm) and slack middlings (with the granularity of -13 mm, and including coarse granules in floatation tailings) according to the granularity. The dissociation and recleaning process for the lump middlings involves a crushing system, a spiral tailing discarding system and a floatation system according to the characteristics of the lump middlings. The dissociation and recleaning process for the slack middlings involves a crushing system, a coarse slime dissociation and recleaning system, a grading system and a floatation system. Full coverage is realized for recycling of the coking middling resources at different granularity grades, clean coal in the middlings is recycled to the maximum extent, and the process is simple, reliable, small in investment and remarkable in economical benefit.

Owner:CHINA UNIV OF MINING & TECH

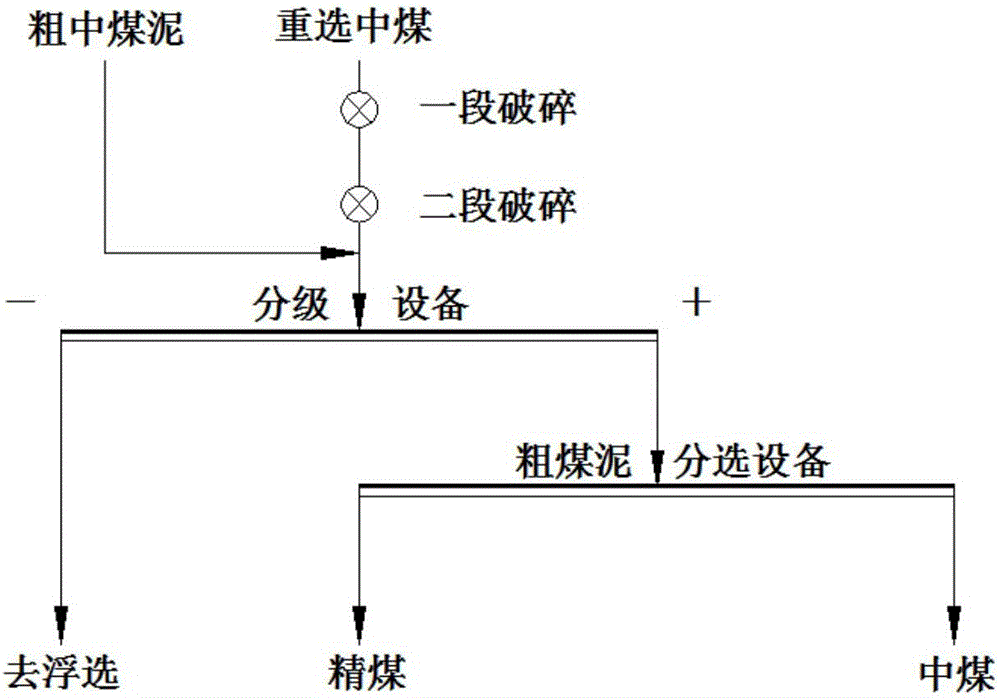

Process for recycling fine coal from middlings

The invention relates to a process for recycling fine coal from middlings. The process comprises the following steps: feeding the middlings into crushing equipment and crushing the middlings until the sizes of the middlings are below 6 mm; mixing the crushed middlings with coarse middlings slurry, then feeding the mixture into classifying equipment and carrying out 0.25 mm classification to generate overflow formed by -0.25 mm materials and bottom flow formed by +0.25 mm materials, wherein -0.25mm shows that the particle size is smaller than 0.25 mm, and +0.25 mm shows that the particle size is greater than 0.25 mm; mixing the overflow and a flotation reagent, then feeding the mixture into pulp mixing equipment and carrying out pulp mixing to form ore pulp, carrying out flotation on the ore pulp by using flotation equipment to generate flotation fine coal and flotation tailings, and recycling the flotation fine coal; and feeding the bottom flow into coal slime gravity concentrating equipment, carrying out separation to generate fine coal and tailings, and recycling the fine coal. The technological process is simple, the cost is low, the benefic is good, and the process has significance on full utilization and protection of scarce coking coal resources and ensuring of safety of national energy.

Owner:CHINA UNIV OF MINING & TECH

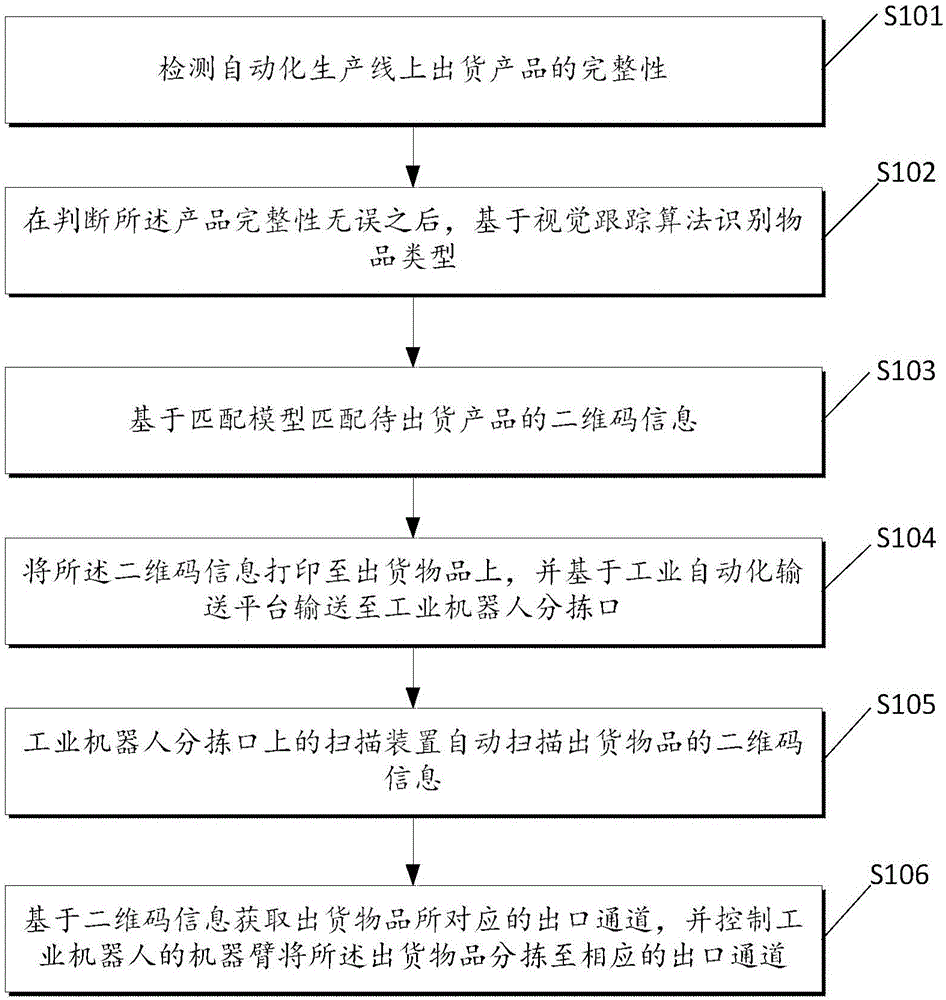

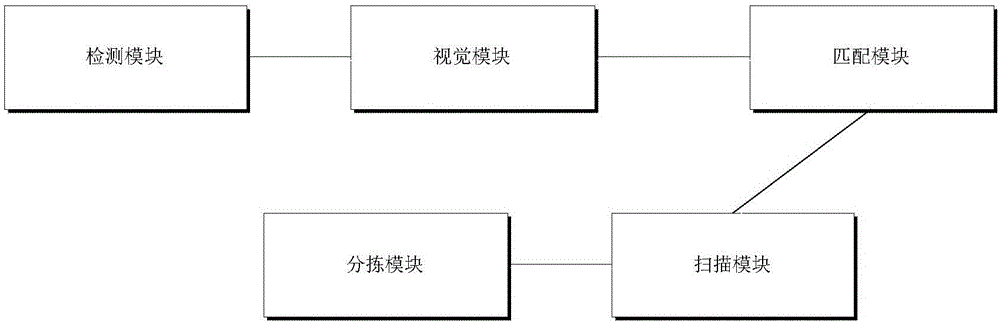

Automatic sorting method and system of industrial robot

ActiveCN106672345AEasy to identify processingSimplify the sorting processPackaging automatic controlSensing by electromagnetic radiationProduct typeProduction line

The invention discloses an automatic sorting method and system of an industrial robot. The automatic sorting method of the industrial robot comprises the steps that the integrity of an output product on an automatic production line is detected; the product type is recognized based on the visual tracking algorithm after it is judged that the product integrity is good; two-dimensional code information of a to-be-output product is matched based on an industrial matching model; the two-dimensional code information is printed on the output product, and conveyed to an industrial robot sorting port based on an automatic industrial conveying platform; a scanning device at the industrial robot sorting port automatically scans the two-dimensional code information of the product; and an outlet channel corresponding to the output product is obtained based on the two-dimensional code information, and a machine arm of the industrial robot is controlled to sort the output product into the corresponding outlet channel. Through the automatic sorting method and system of the industrial robot, the integrity of the to-be-packaged product is detected based on the visual tracking algorithm, the corresponding product type is matched, the product is coded, recognition is easy, accordingly automatic sorting is completed, and the efficient and automatic sorting automation process is achieved.

Owner:华南智能机器人创新研究院 +1

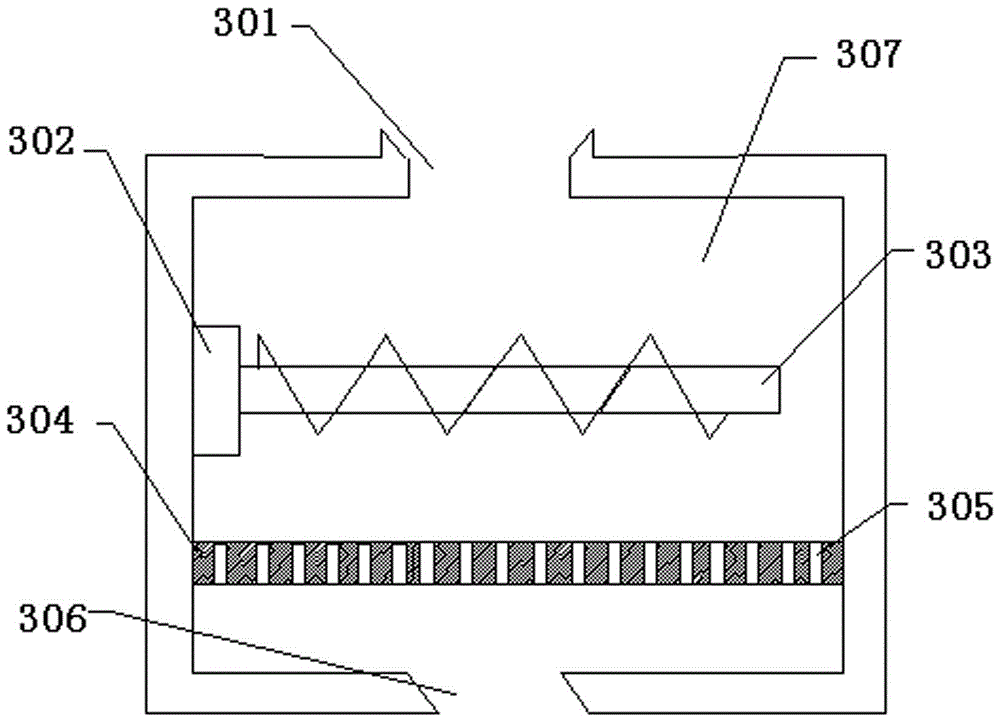

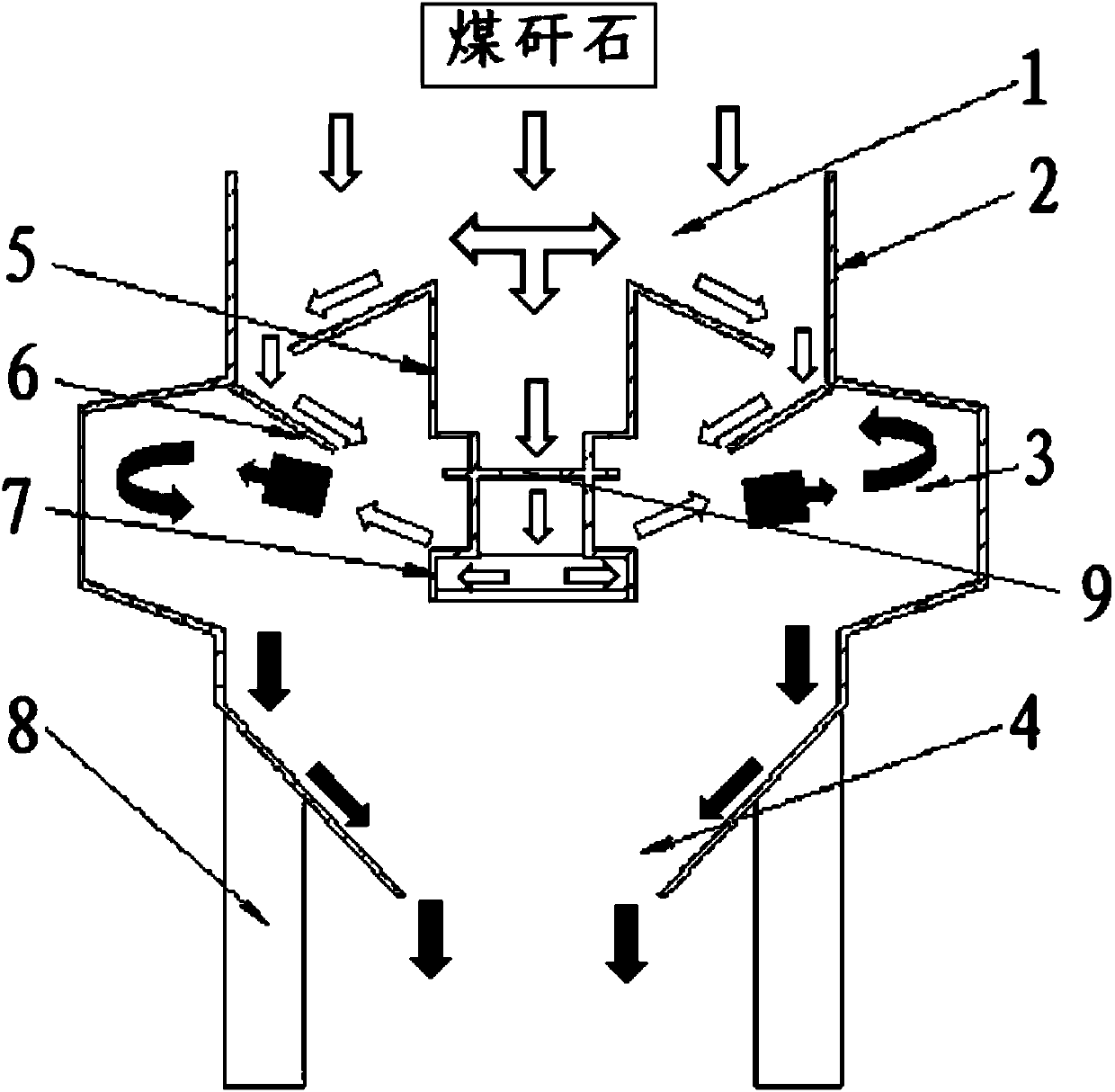

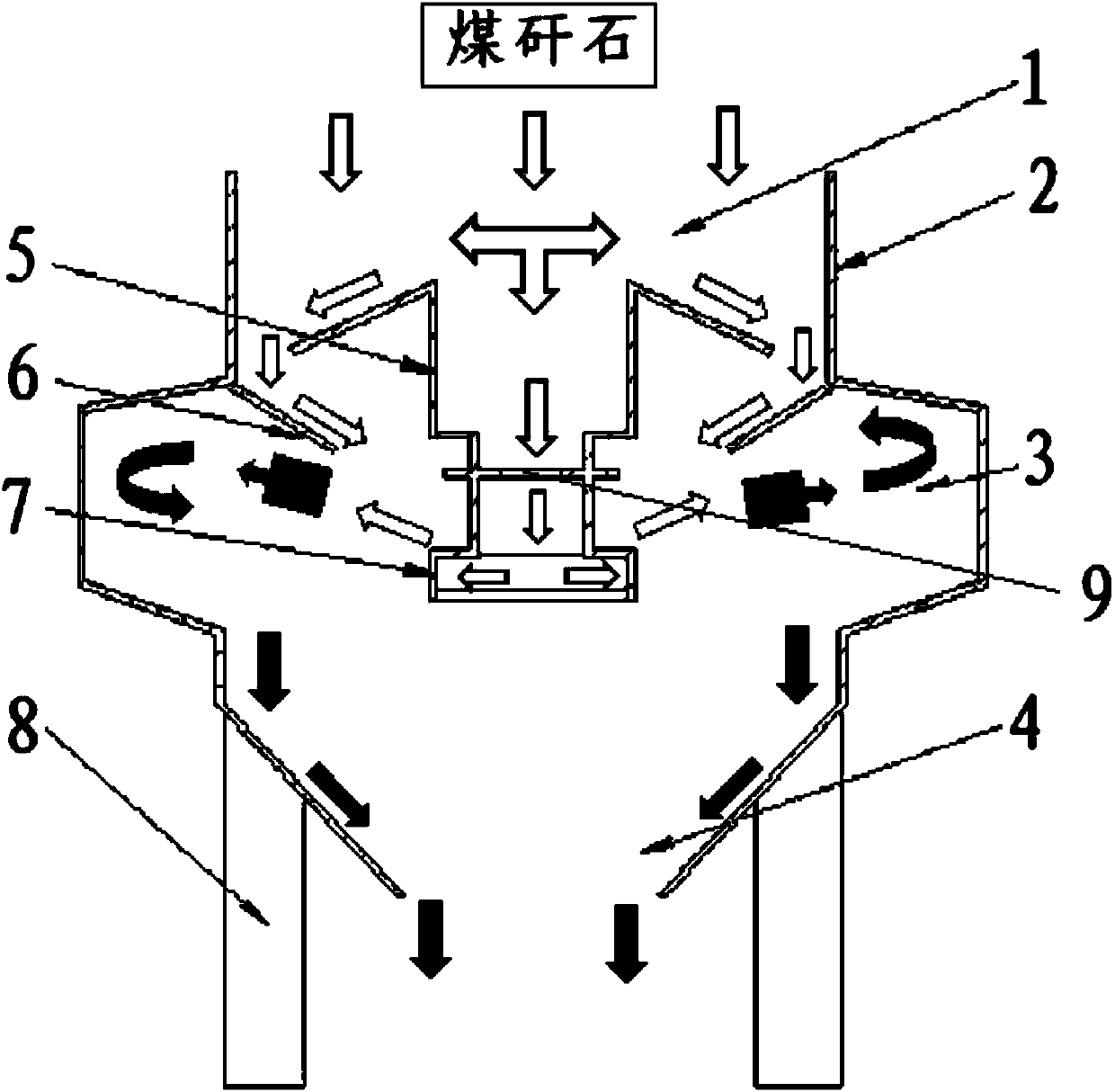

Crushing device for coal gangue separation

ActiveCN103433106AImprove impact efficiencySimple crushing workGrain treatmentsEngineeringCoal gangue

The invention relates to a crushing device for coal gangue separation. The crushing device comprises an outer cover, a material separating device, a plurality of guide plates, a material throwing tray and a bracket, wherein the outer cover is fixed on the bracket; a feeding hole is formed in the top of the outer cover; the bottom of the outer cover is provided with a discharge hole; a vortex bin is arranged in the middle of the outer cover; the material separating device is arranged in the feeding hole and the vortex bin; the upper part of the material separating device has an umbrella-shaped structure; a feed opening is formed in the top of the material separating device; a coal gangue storage bin is arranged in the middle of the material separating device; the material throwing tray is arranged under the material separating device; the plurality of guide plates are respectively arranged under the umbrella-shaped structure of the material separating device and fixed on the outer cover. The crushing device can be used for selectively crushing coal components in the coal gangue while maintaining the integrity of the gangue component, thus meeting the requirement of separation.

Owner:长治市武理工工程技术研究院

Crushing device for sorting gangues and sorting method

The invention relates to a crushing device for sorting gangues and a sorting method. The crushing device is structurally characterized in that an outer cover is fixed on a support, a feed port is formed in the top of the outer cover, a discharge port is formed in the bottom of the outer cover, and the middle of the outer cover is provided with a vortexing bin; a material divider is arranged in the feed port and the vortexing bin, the upper part of the material divider is of an umbrella-shaped structure, the top of the material divider is provided with a feeding hole, the middle of the material divider is provided with a storage bin of the gangues, and a material throwing disc is arranged below the material divider; a plurality of guide plates are respectively installed below the umbrella-shaped structure of the material divider and are fixed on the outer cover. The method provided by the invention comprises the steps of throwing the gangues into the sorting crushing device, then selectively crushing the gangues in a self-collision manner, and sieving the crushed gangues. The crushing device and the sorting method provided by the invention have the characteristics that the coal components in the gangues are selectively crushed, the integrality of gangue components is kept, the sorting requirement is met, the sorting efficiency is high, the use value of the sorted gangue is high, the process is simple, the energy is saved, the emission amount is reduced, the cost of investment is low, and the production capacity is high.

Owner:武汉中理环保科技有限公司

Method for improving grade of magnetic concentrate by using reagent

InactiveCN102580844ARaise the gradeSimplify the sorting processMagnetic separationSodium metasilicatePolyvinyl alcohol

The invention discloses a method for improving the grade of a magnetic concentrate by using a reagent. Fine fraction magnetic minerals can be easily mixed with impurities in the magnetic separation process to cause a low grade of the concentrate. By the method, dispersing agents such as sodium carbonate, sodium metasilicate, sodium tripolyphosphate, sodium thiophosphate or a mixture of the sodium carbonate, the sodium metasilicate, the sodium tripolyphosphate and the sodium thiophosphate, organic dispersing agents such as starch, humic acid, polyvinylpyrrolidone, polyvinyl alcohol, a polyvinyl alcohol homolog or a mixture of the starch, the humic acid, the polyvinylpyrrolidone, the polyvinyl alcohol and the polyvinyl alcohol homolog, or organic dispersing agents and a mixed dispersing agent of the organic dispersing agents are used for preparing a 5 to 30 weight percent aqueous solution, the using amount of the aqueous solution is 1 to 50mg / L, and mineral particles are dispersed in ore pulp and then are subjected to magnetic separation, so that the grade of the magnetic concentrate is improved, and the problem of complicated processes due to a low grade of the magnetic concentrate or requirements of flotation and reconcentration after the magnetic concentration is solved. By the method, extremely good magnetic separation effects on ferromagnetic mineral resources or low-magnetic mineral resources such as various iron minerals, chromite, iron pyrite, manganese minerals, wolframite, copper sulfide ores and copper oxide cobalt ores can be achieved.

Owner:CENT SOUTH UNIV

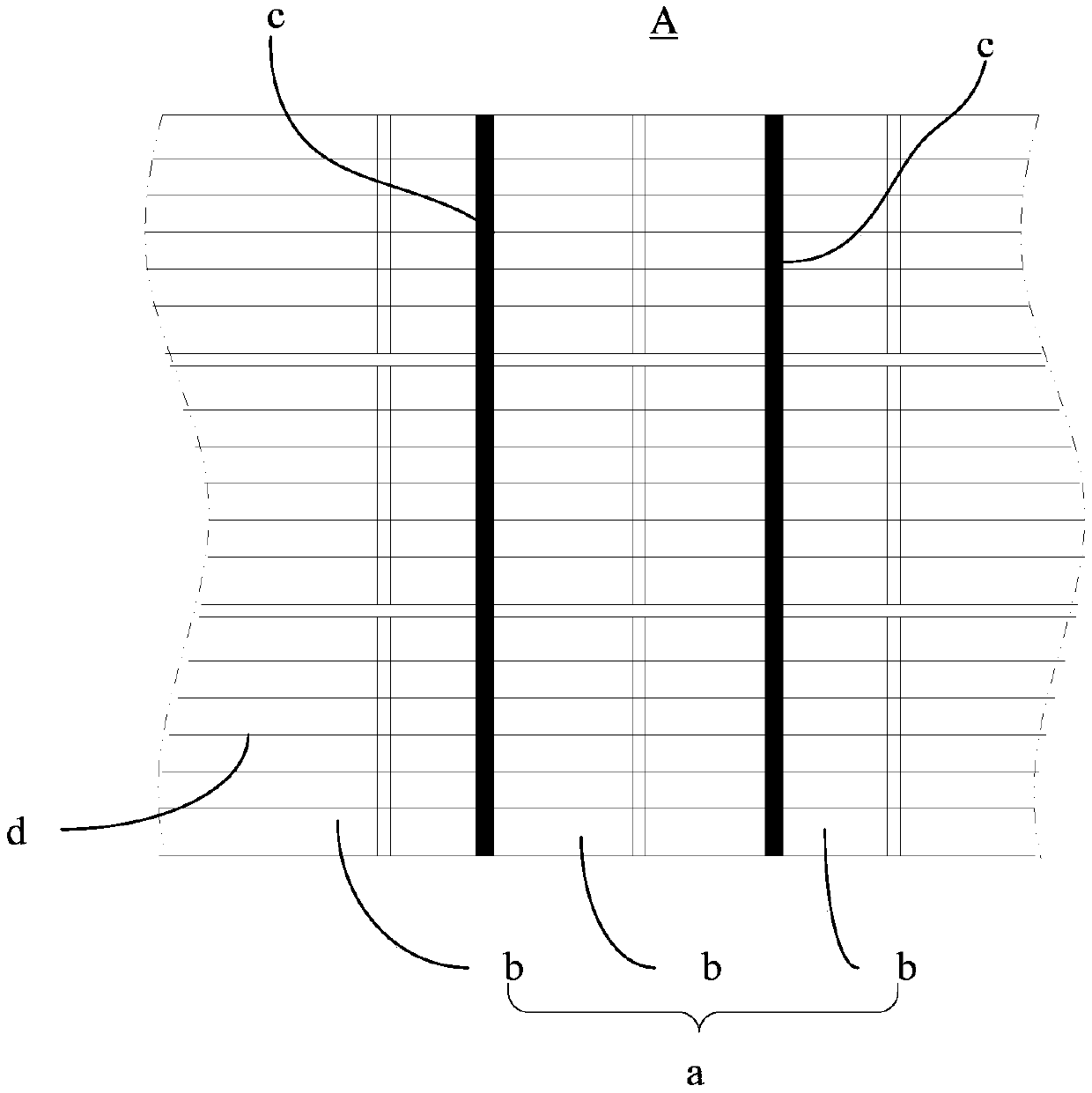

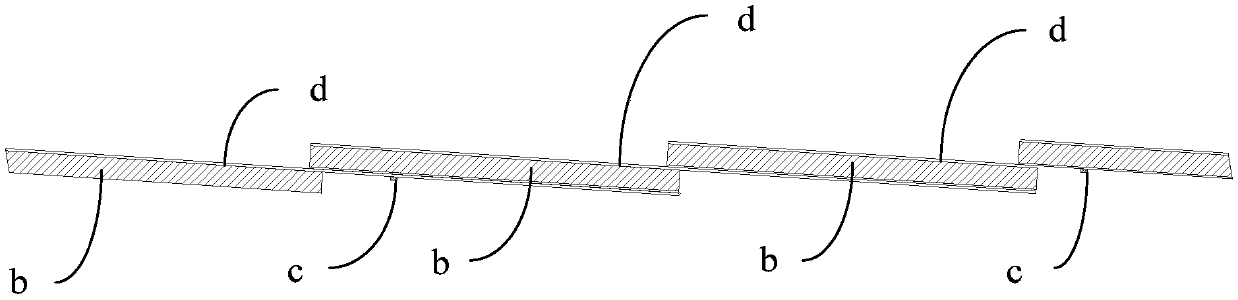

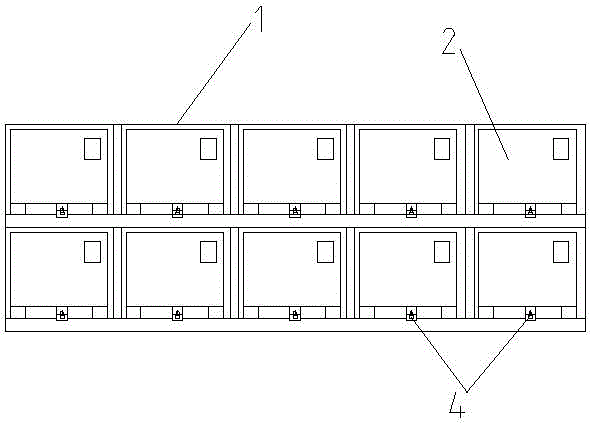

Lateral discharge type tobacco carton sorting device and method

PendingCN107335621ARealize continuous sortingSimplify the sorting processSortingConveyor partsCartonStructural engineering

The invention discloses a lateral discharge type tobacco carton sorting device and method. The lateral discharge type tobacco carton sorting device comprises a sorting substrate (1), wherein more than one tobacco outlet (2) is distributed in the sorting substrate (1); a sorting assembly (3) is arranged at each tobacco outlet (2); a tobacco storage bin (4) is arranged above each sorting assembly (3); each sorting assembly (3) comprises a push plate (31); one end of each push plate (31) is connected with a driving assembly (32); and sliding guide track assemblies (34) are further arranged at two ends of each push plate (31). The invention aims to provide the lateral discharge type tobacco carton sorting device. The lateral discharge type tobacco carton sorting device has the characteristics of simple structure, low cost, simple process and high reliability.

Owner:GUIZHOU HUILIAN TECH LIMITED

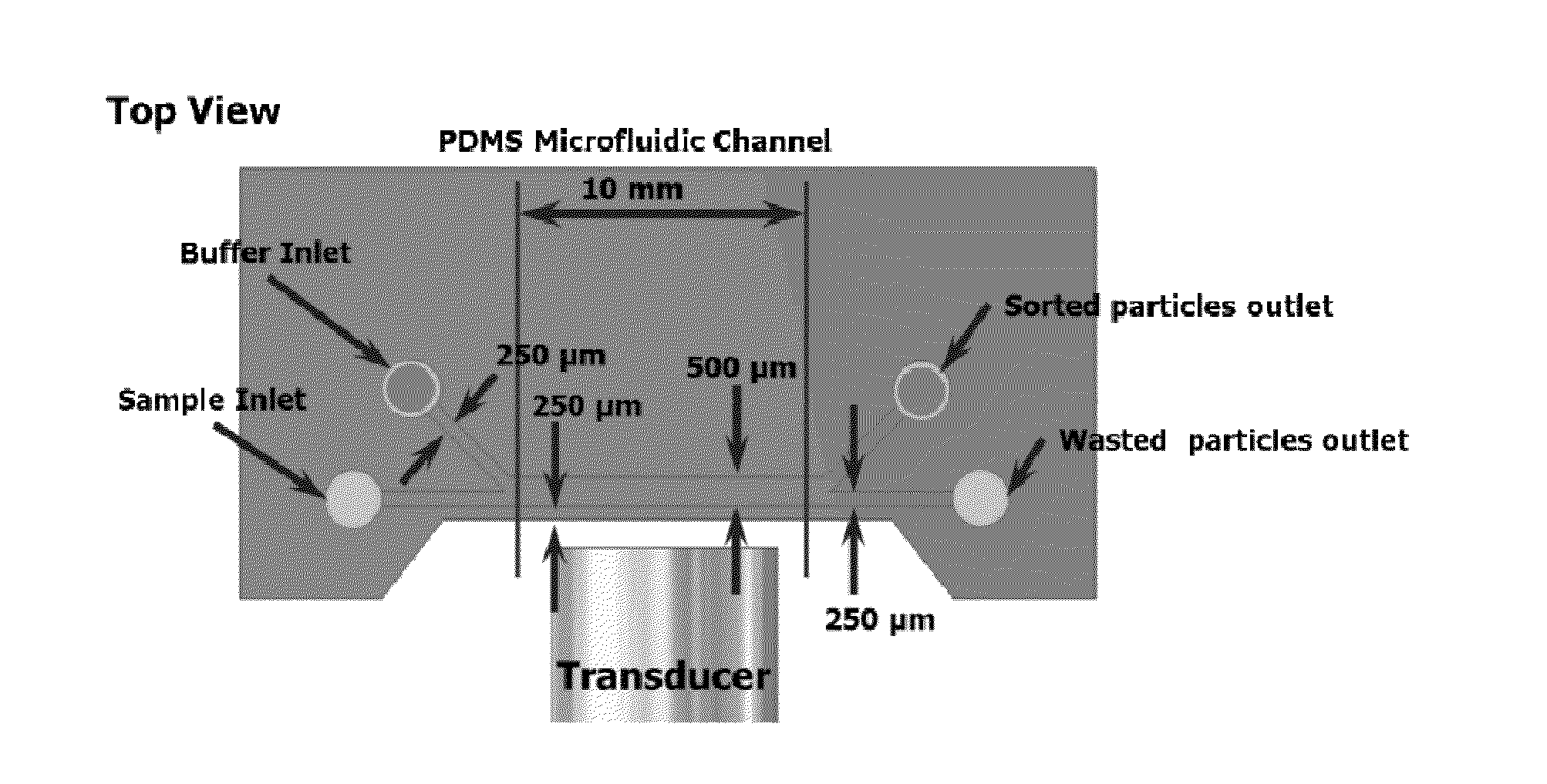

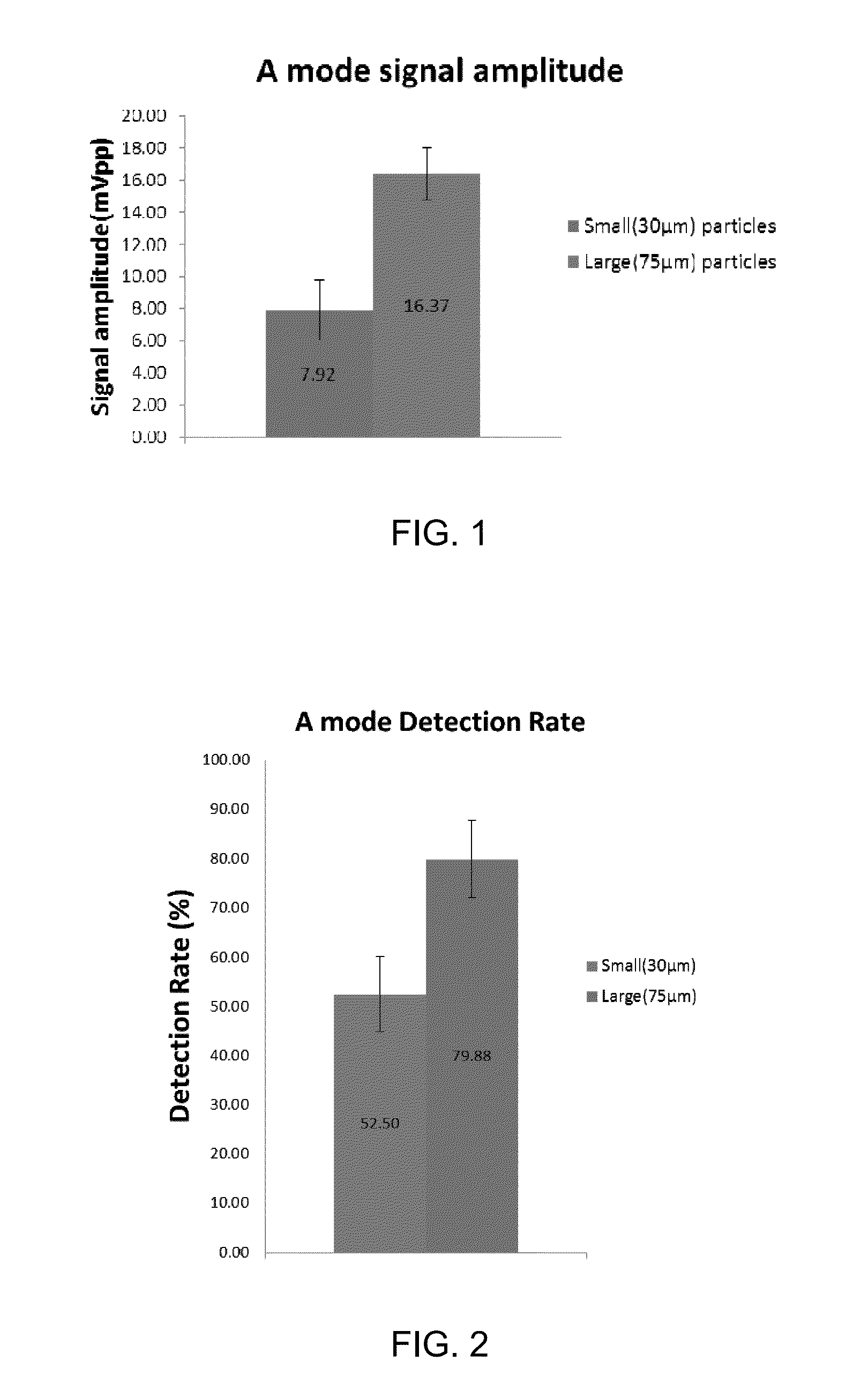

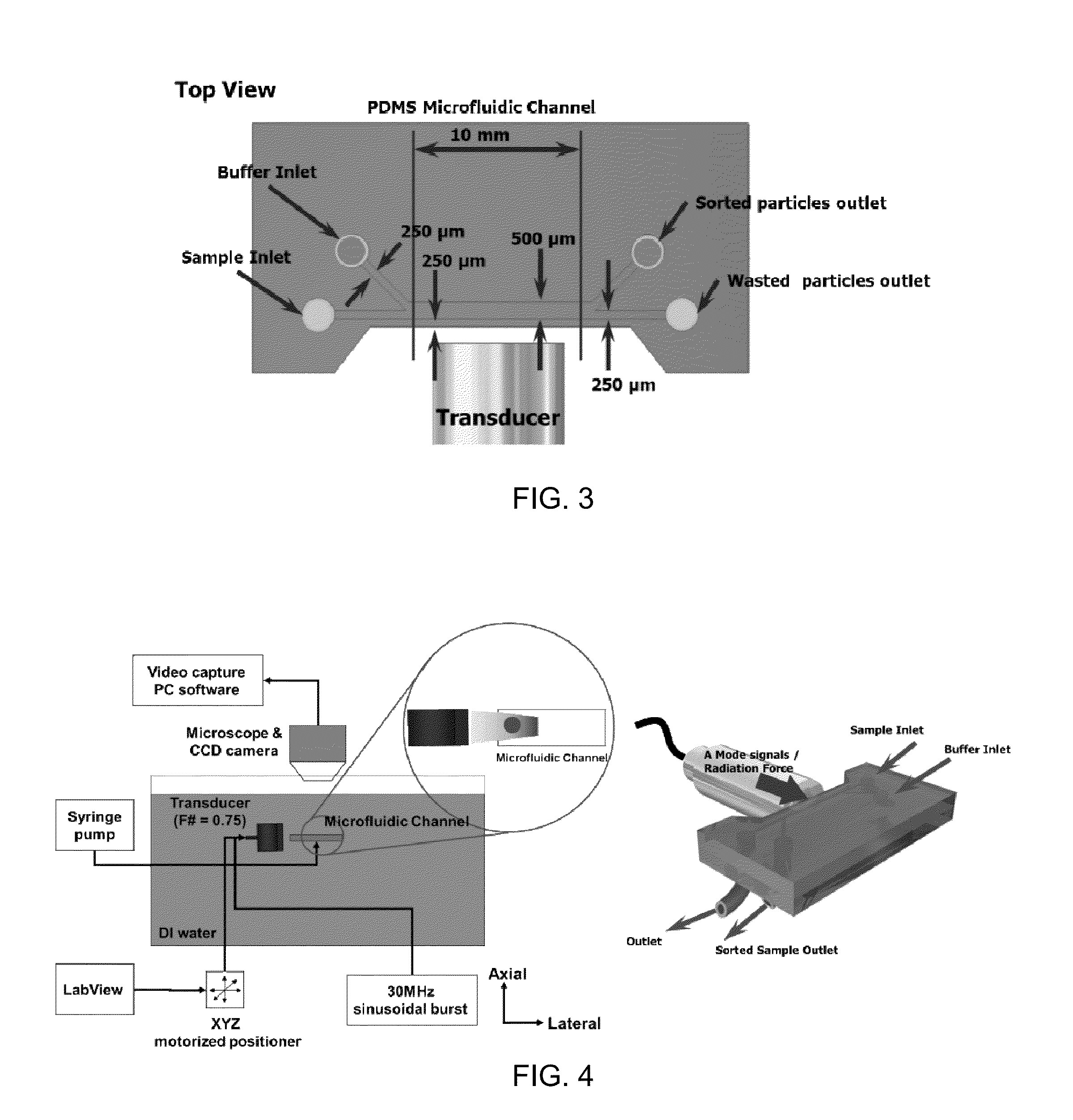

Acoustic particle sorting in microfluidic channels

InactiveUS20130139575A1Simplify the sorting processRemove restrictionsAnalysing solids using sonic/ultrasonic/infrasonic wavesParticle suspension analysisSonificationParticle sorting

A method for sensing and sorting single tiny particles in microfluidic channels may comprise subjecting the particles to ultrasound; detecting scattering of the ultrasound from these particles; and pushing or sorting these particles using ultrasound based on the scattered ultrasound that is detected.

Owner:UNIV OF SOUTHERN CALIFORNIA

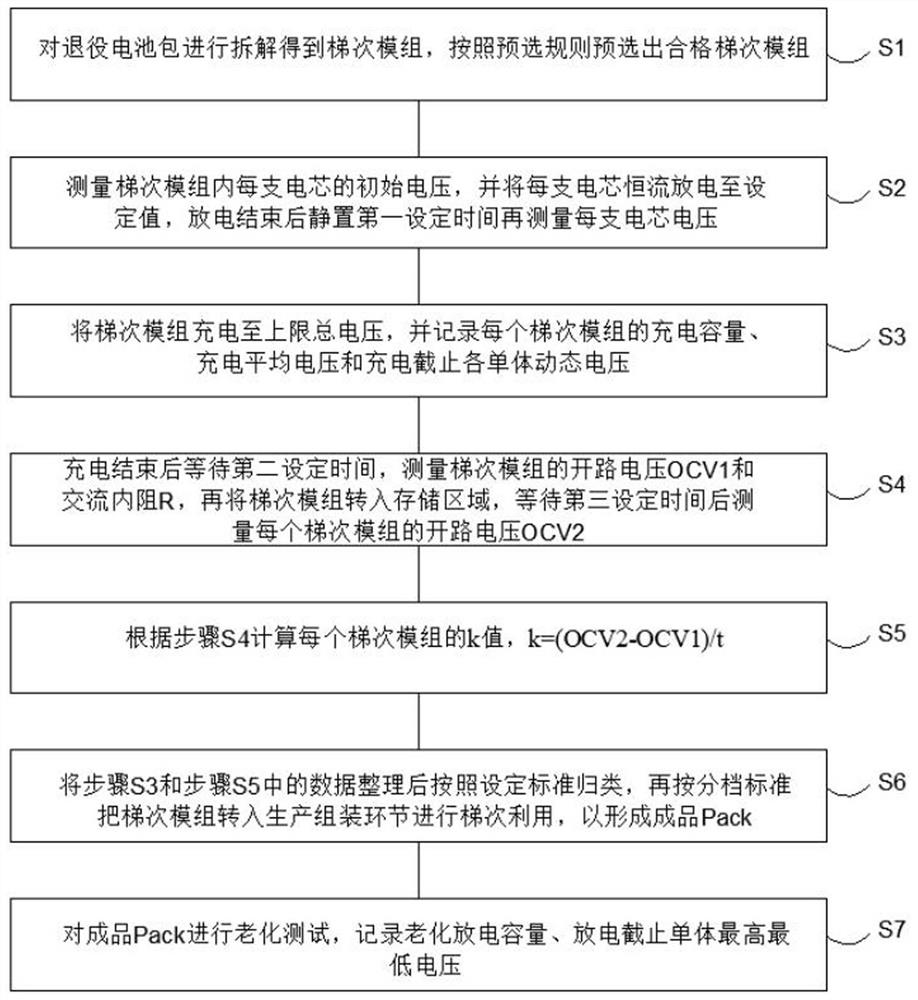

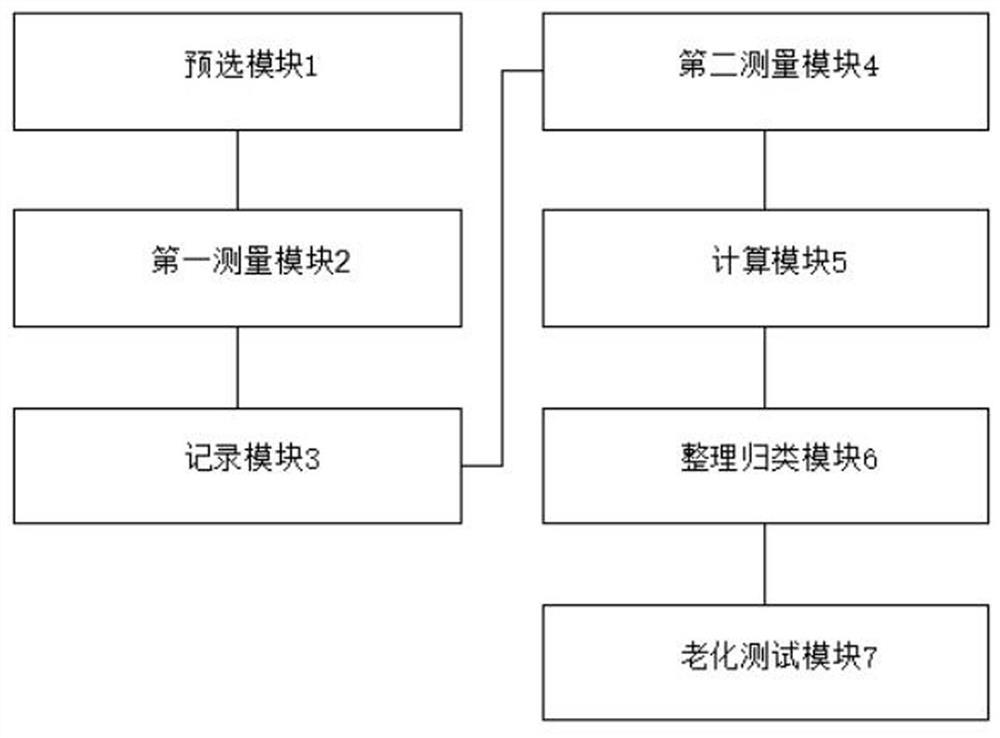

Sorting method and system for reuse of retired battery modules

ActiveCN113369287AReduce internal pressure dropIncrease capacitySolid waste disposalSecondary cells charging/dischargingElectrical batteryInternal resistance

The invention discloses a sorting method and system for reuse of retired battery modules. The method comprises the steps that S1, qualified echelon modules are pre-selected according to a pre-selection rule; S2, the initial voltage of each battery cell in the echelon modules is measured, each battery cell is subjected to constant-current discharging to a set value, and after discharging is finished, standing is conducted for a first set time, and then the voltage of each battery cell is measured; S3, the echelon modules are charged to the upper limit total voltage; S4, after charging is finished, waiting is conducted for a second set time, the open-circuit voltage OCV1 and the alternating-current internal resistance R of the echelon modules are measured, then the echelon modules are transferred into a storage area, and after waiting is conducted for a third set time, the open-circuit voltage OCV2 of each echelon module is measured; S5, the k value of each echelon module is calculated; and S6, data in the step S3 and the step S5 are sorted and then classified according to set standards, and then the echelon modules are transferred into a production and assembly link according to grading standards for echelon utilization so as to form the finished product pack. According to the sorting method and system for reuse of the retired battery modules, the sorting process is simple and reliable, the processing time is short, and the requirement for mass production is met.

Owner:GUANGZHOU FELICITY SOLAR TECH

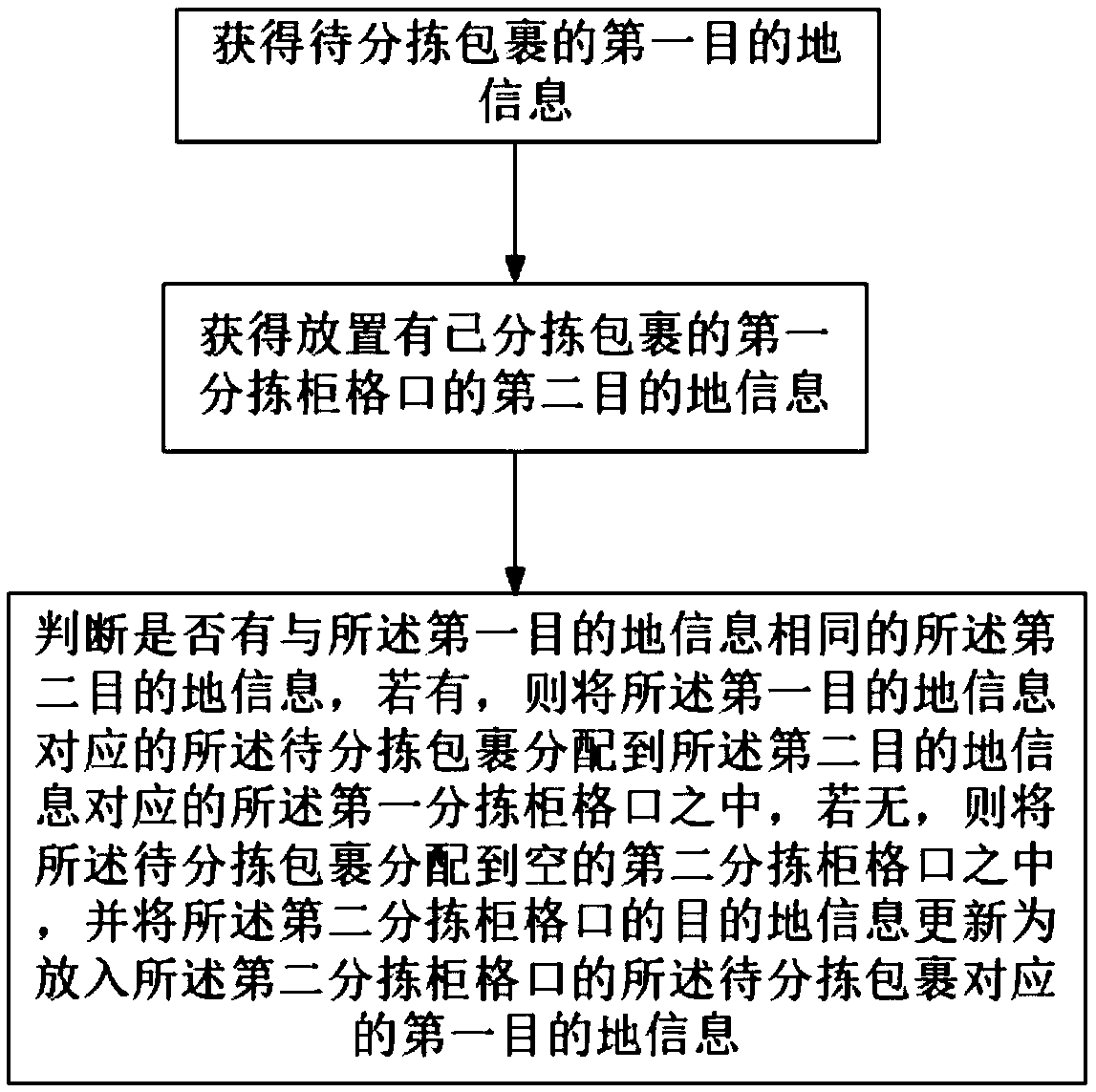

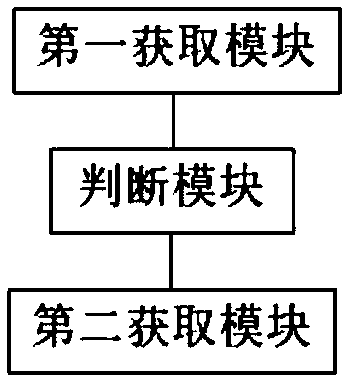

Sorting method and sorting system

The invention discloses a sorting method and a sorting system. The sorting method comprises the following steps of obtaining first destination information of a to-be-sorted parcel; obtaining second destination information of a first sorting cabinet grid containing a sorted parcel; judging whether second destination information is the same as the first destination information, and if yes, putting the to-be-sorted parcel with the corresponding first destination information into the first sorting cabinet grid with the corresponding second destination information; and if not, putting the to-be-sorted parcel into an empty second sorting cabinet grid, and updating the destination of the second sorting cabinet grid to the corresponding first destination information of the to-be-sorted parcel in the second sorting cabinet grid. According to the method, sorting efficiency and sorting speed are improved, and manpower investment of sorting and wrapping is reduced.

Owner:SF TECH

Household garbage sorting machine

The invention discloses a household garbage sorting machine. The household garbage sorting machine comprises a machine body and a transmission motor, wherein a feeding hopper is arranged at the top ofthe machine body, supporting legs are arranged at the bottom of the machine body, a sorting shaft II, a sorting shaft II and a sorting shaft III distributed in a triangular shape are arranged in themachine body, and three sorting shafts with steel bars, stop bars, steel bar plates, grid mesh plates and mesh plates are used for carrying out high-efficiency sorting on the household garbage in fivestages, so that the sorting quantity is large, and the effect is obvious; and the household garbage sorting machine is simple in structure, convenient to manufacture and maintain, strong in adjustingcapability, small in occupied area, and small in noise, and simplifies the sorting process, can meet the processing requirements of household garbage with different scales, and is beneficial to popularization and application.

Owner:陶淘

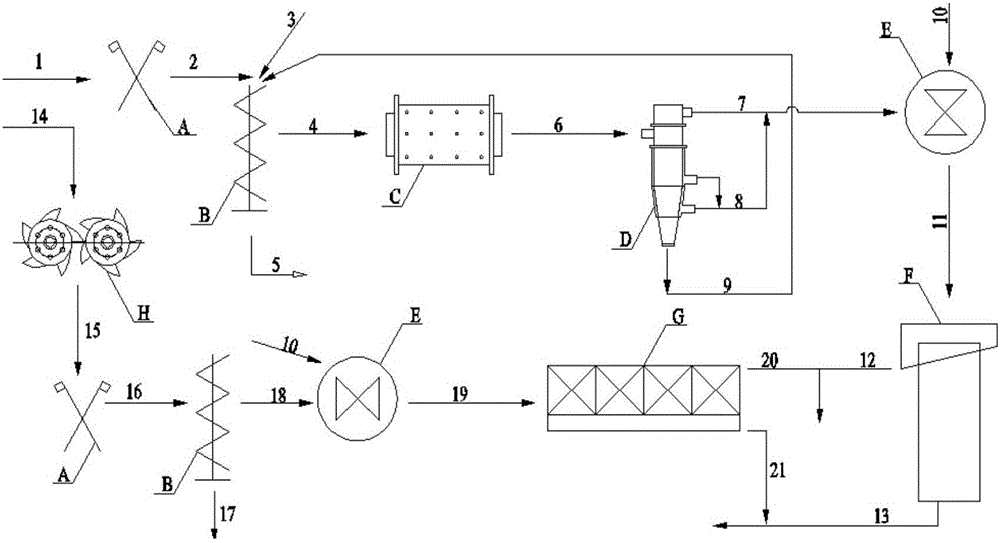

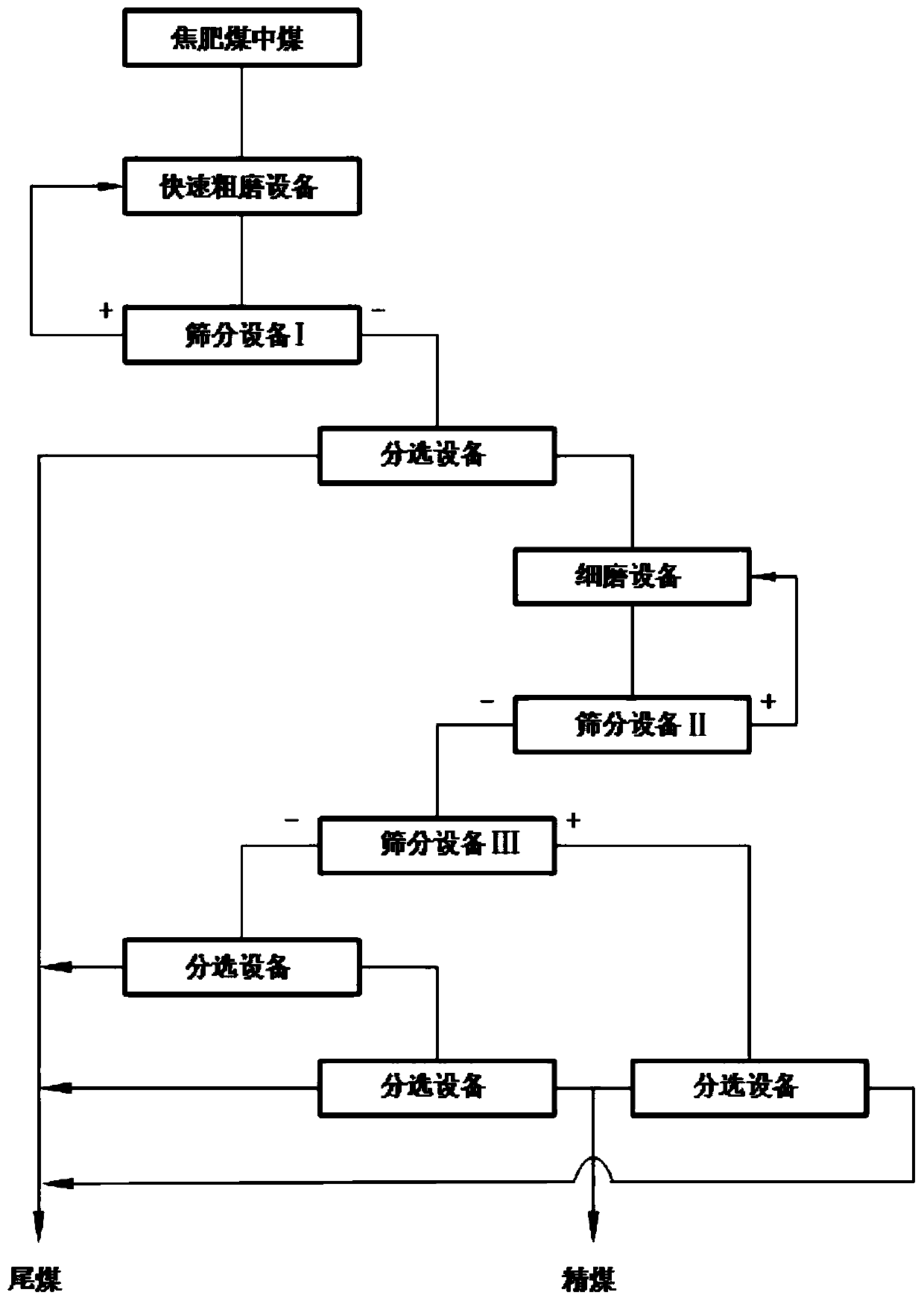

Multi-stage dissociation-machine and column combined recleaning technology for middling coal intergrowth body of coking fat coal

InactiveCN109746115AEffective dissociationEfficient recyclingSievingScreeningEngineeringCoarse particle

The invention provides a multi-stage dissociation-machine and column combined recleaning technology for a middling coal intergrowth body of coking fat coal, and belongs to a coal separation method. The multi-stage dissociation-machine and column combined recleaning technology comprises the following steps that middling coal of the coking fat coal is fed into quick rough grinding equipment; a product obtained after rough grinding is fed into sieving equipment; a first-time oversize product is returned to be fed into the quick rough grinding equipment, a first-time undersize product is fed intoseparation equipment, and first-time sorted clean coal is fed into fine grinding equipment; a product obtained after fine grinding is fed into the sieving equipment to be subjected to second-time sieving, a second-time oversize product is returned to be fed into the fine grinding equipment, and the second-time oversize product is fed into the sieving equipment to be subjected to third-time sieving; the oversize product is fed into second-time separation equipment to be subjected to separation, and an undersize product is fed into the series separation equipment to be subjected to separation. Dissociation of the middling coal intergrowth body with the fine disseminated grain size is achieved, the recovery rate of coarse particles is effectively increased through stage flotation, the selectivity of fine particles is effectively improved through stage flotation, the recovery rate of the clean coal and the ash content of the clean coal are ensured, the multi-stage dissociation-machine andcolumn combined recleaning technology is simple and reliable in procedure, and the clean coal in the middling coal of the coking fat coal is recovered to the maximum extent.

Owner:CHINA UNIV OF MINING & TECH +2

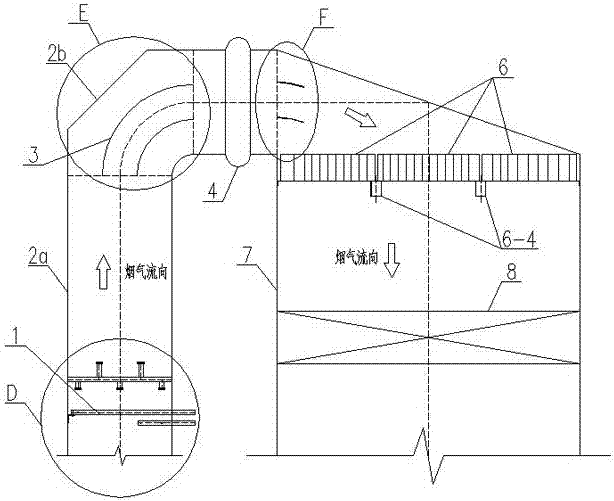

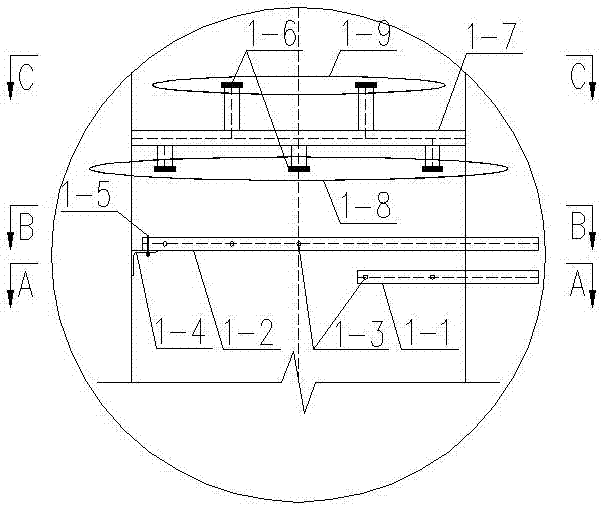

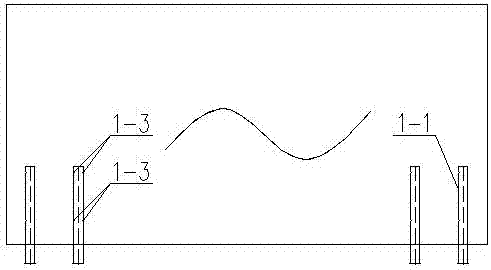

SCR denitrification ammonification and flow field homogeneous structure and operating method thereof

PendingCN107126835AEfficient mixingImprove the flow fieldGas treatmentDispersed particle separationMixed flowFlue gas

The invention provides an SCR denitrification ammonification and flow field homogeneous structure and an operating method thereof. The structure has the advantages of high mixing uniformity between ammonia gas and flue gas, reasonable flow field, low local resistance and simple configuration. Ammonification pipe series are fixed in a linear-segment flue; the ammonification pipe series are provided with ammonification holes; the outer bend of the bend flue is composed of an outer-chamfer plate; the inner bend of the bend flue is composed of an inner arc plate; a front guide plate is fixed in the bend flue; a back guide plate is fixed to the inside of an inlet of a reactor; and a rectifier unit module is fixed in the reactor. Ammonia gas is quickly ejected via the ammonification holes of the ammonification pipe series, and is subjected to opposed-flow diffusion and taken away by the flue gas; ammonia molecules are further diffused under the barrier action of mixed flow plates of mixed flow assemblies, are divided to the two sides of the mixed flow plates at higher speed, are subjected to slow guiding after sufficient mixing, and finally, are uniformly dispersed in the flue gas; and the flue gas is adjusted and distributed uniformly by the rectifier unit module and reaches the catalyst on the first layer.

Owner:CHINA UNITED ENG

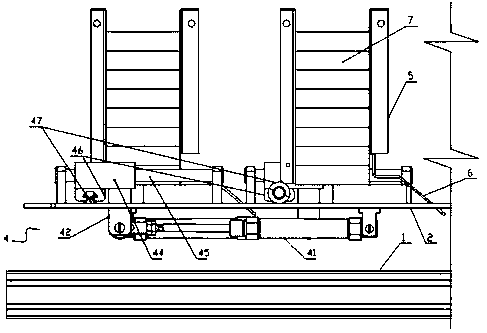

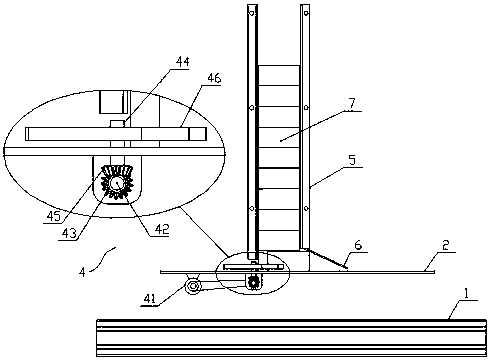

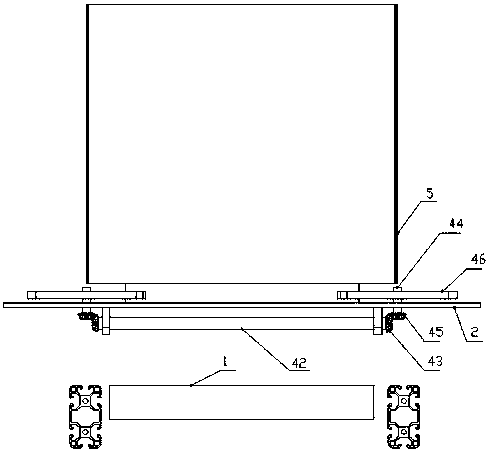

Horizontal pushing and side out type cigarette sorting machine and sorting method

PendingCN107618891ASimple sorting processSimple structureDe-stacking articlesLoading/unloadingEngineeringSmoke

The invention discloses a horizontal pushing and side out type cigarette sorting machine and sorting method. The cigarette sorting machine includes a conveying belt (1). A sorting base plate (2) is installed above the conveying belt (1). A smoke outlet (3) is formed in the sorting base plate (2). A sorting assembly (4) is installed on one side of the smoke outlet (3). A smoke storage warehouse (5)is installed above the sorting assembly (4). The sorting assembly (4) comprises a driving device (41) and the driving device (41) is connected with a connecting block (42). The connecting block (42)penetrates through a receding groove (43) formed in the sorting base plate (2) and is connected with a sliding block (44). The sliding block (44) is connected with the sorting base plate (2) through asliding rail (45). The sliding block (44) is also connected with one end of a smoke pushing rod (46). The horizontal pushing and side out type cigarette sorting machine has the characteristics of being simple in structure, low in cost, simple in working procedure and high in reliability.

Owner:GUIZHOU HUILIAN TECH LIMITED

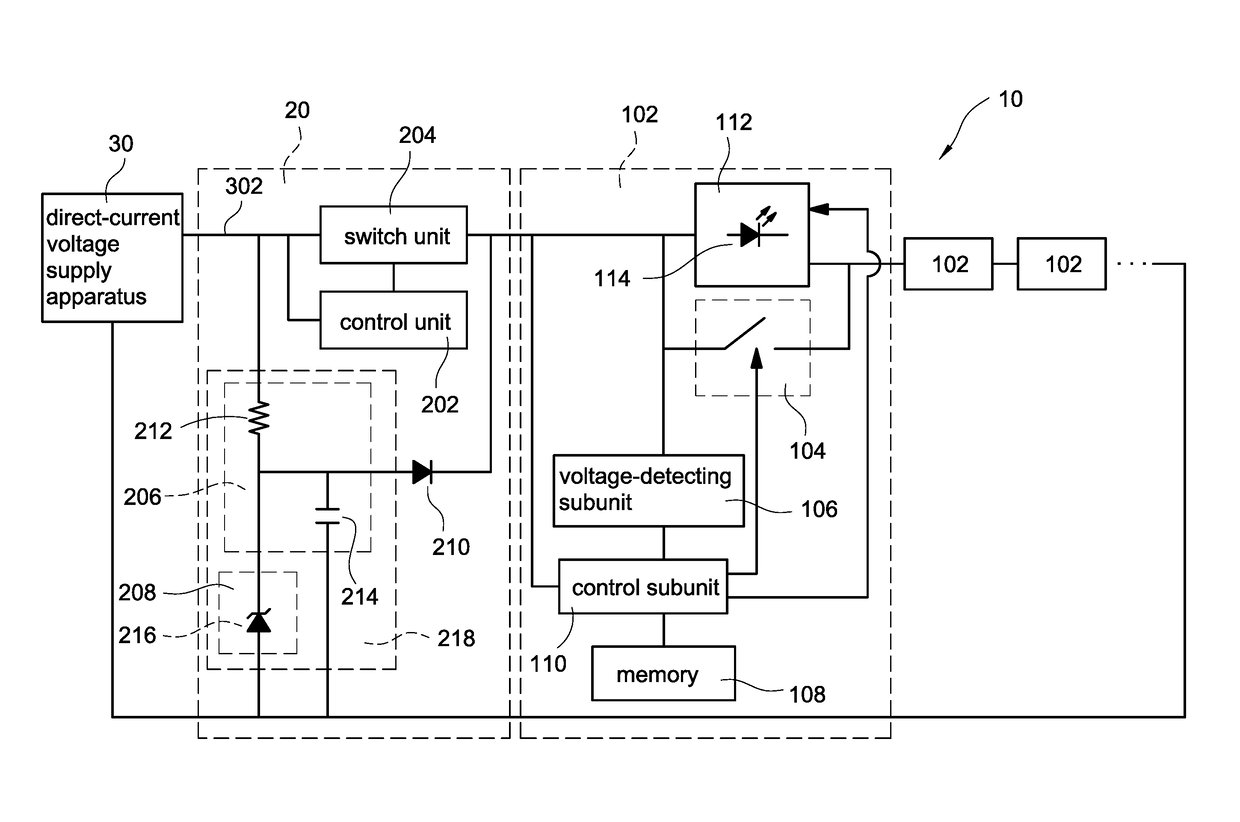

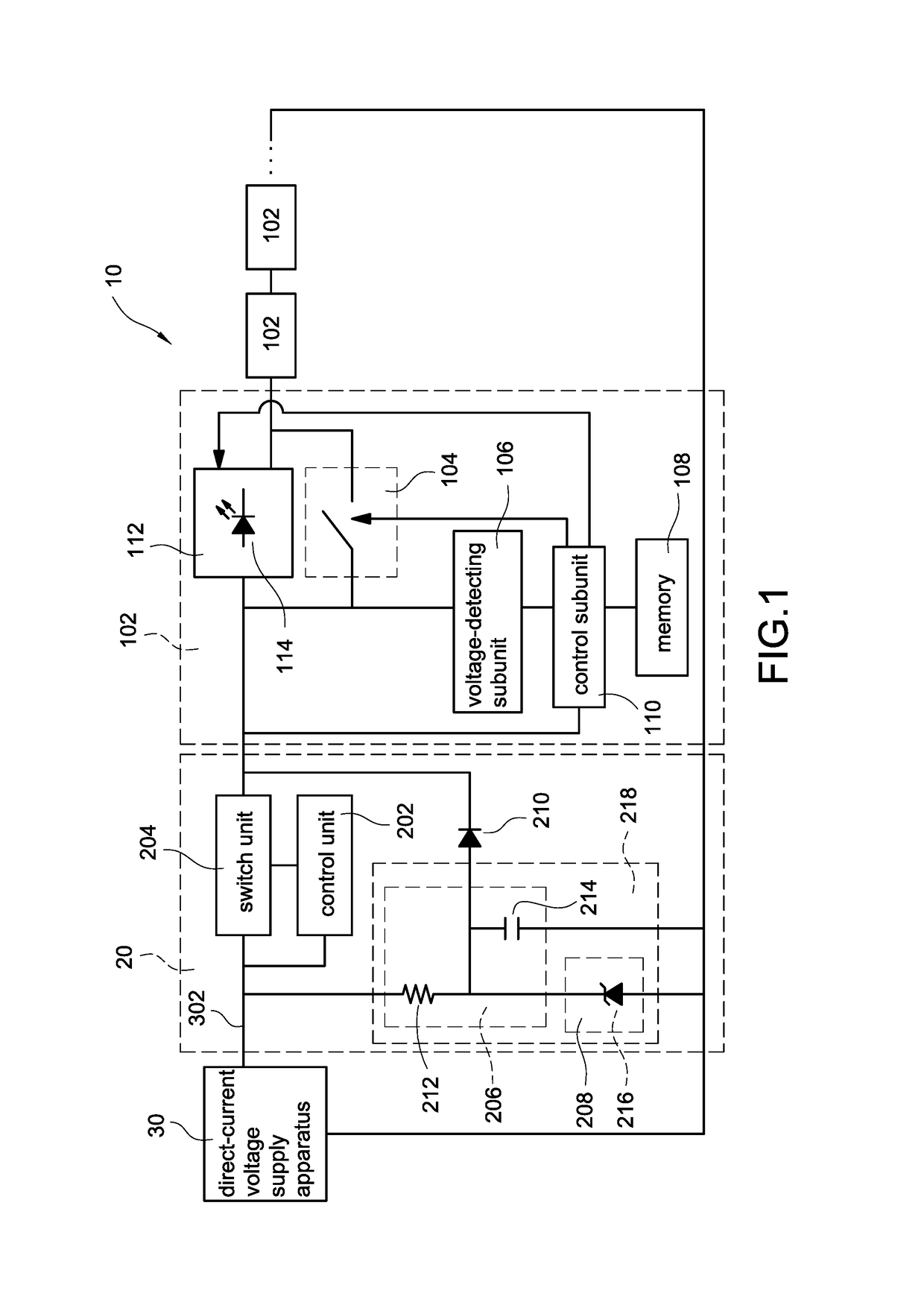

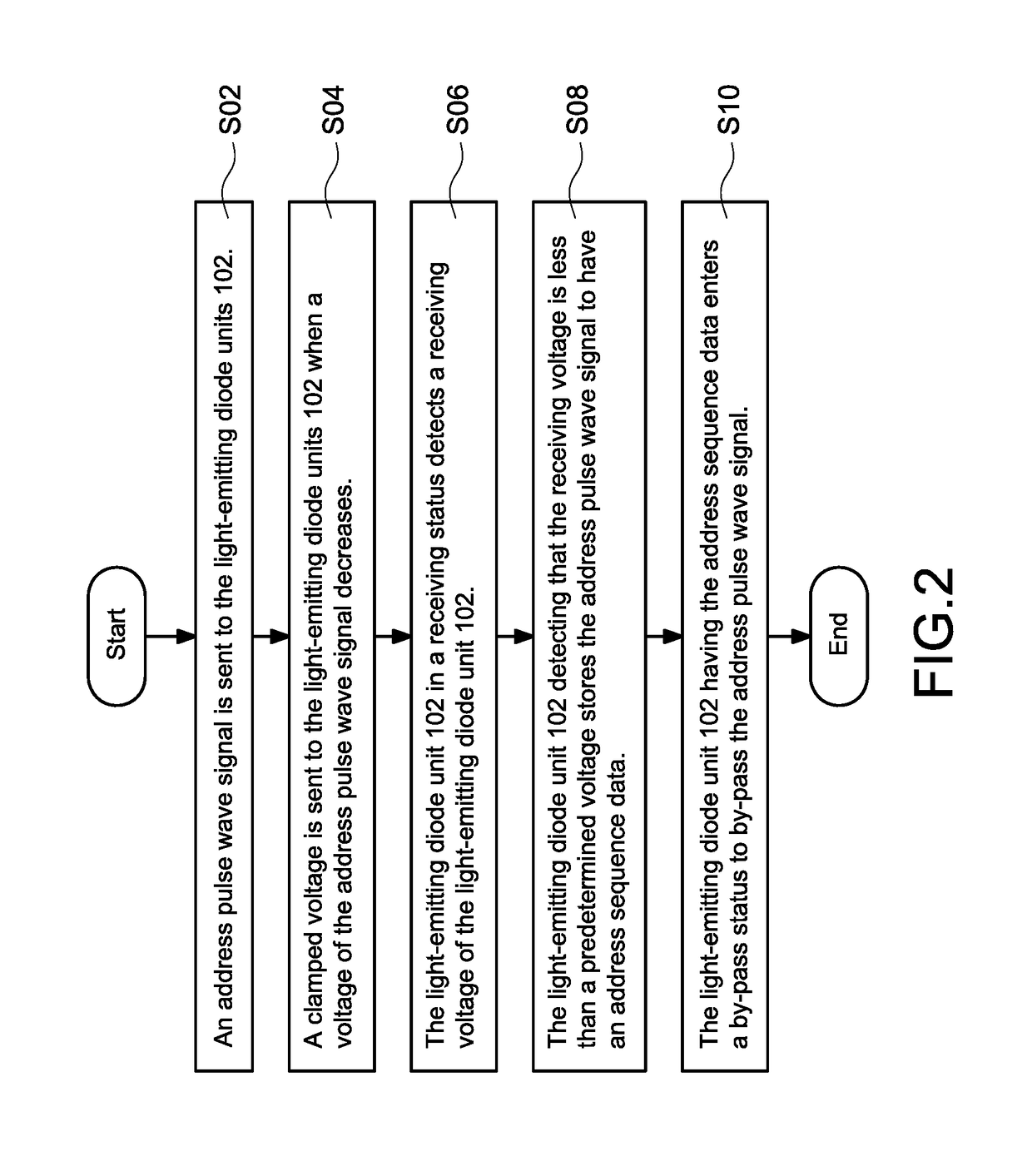

Sequencing method for light-emitting diode lamp string

ActiveUS10039164B1Simplify the sorting processElectroluminescent light sourcesSolid-state devicesResistance capacitanceParasitic capacitance

A sequencing method is applied to a light-emitting diode lamp string. The light-emitting diode lamp string includes a plurality of light-emitting diode units connected to each other in series. The light-emitting diode units have different parasitic capacitive reactance and resistance-capacitance time constant after being connected to each other in series. The sequencing method includes following steps. An address pulse wave signal is sent to the light-emitting diode units. A clamped voltage is sent to the light-emitting diode units when a voltage of the address pulse wave signal decreases. The light-emitting diode unit in a receiving status detects a receiving voltage of the light-emitting diode unit. The light-emitting diode unit detecting that the receiving voltage is less than a predetermined voltage due to an overshoot phenomenon stores the address pulse wave signal to have an address sequence data.

Owner:SEMISILICON TECH

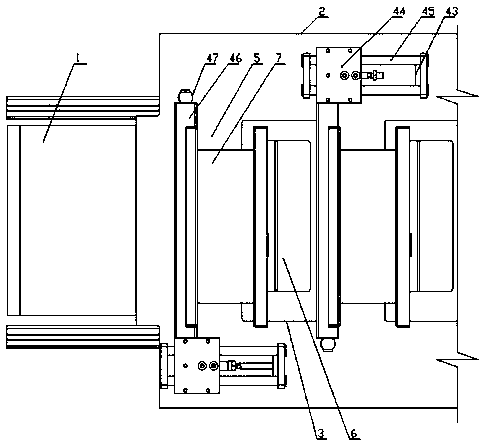

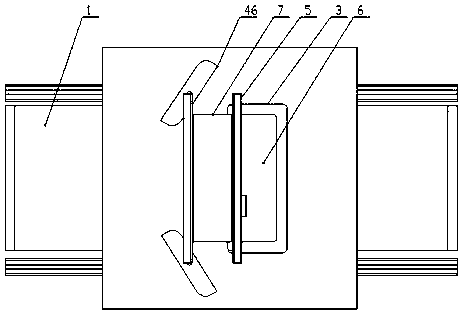

Rotating and pushing type cigarette sorting machine and sorting method

PendingCN107618859ARealize continuous sortingSimplify the sorting processConveyor partsDrive shaftEngineering

The invention discloses a rotating and pushing type cigarette sorting machine and a sorting method. The cigarette sorting machine includes a conveying belt (1). A sorting base plate (2) is installed above the conveying belt (1). A smoke outlet (3) is formed in the sorting base plate (2). A sorting assembly (4) is installed on one side of the smoke outlet (3). A smoke storage warehouse (5) is installed above the sorting assembly (4). The sorting assembly (4) comprises a driving device (41) and the driving device (41) is connected with a driving shaft (42). The driving shaft (42) is movably connected with the sorting base plate (2). Both ends of the driving shaft (42) are provided with driving bevel gears (43). The driving bevel gears (43) are connected with a transmission bevel gear (45). The transmission bevel gear (45) is connected with one end of a rotation shaft (44). The rotation shaft (44) is movably connected with the sorting base plate (2) and the other end of the rotation shaft(44) is connected with a rotation pushing block (46). The rotating and pushing type cigarette sorting machine has the characteristics of being simple in structure, low in cost, simple in working procedure and high in reliability.

Owner:GUIZHOU HUILIAN TECH LIMITED

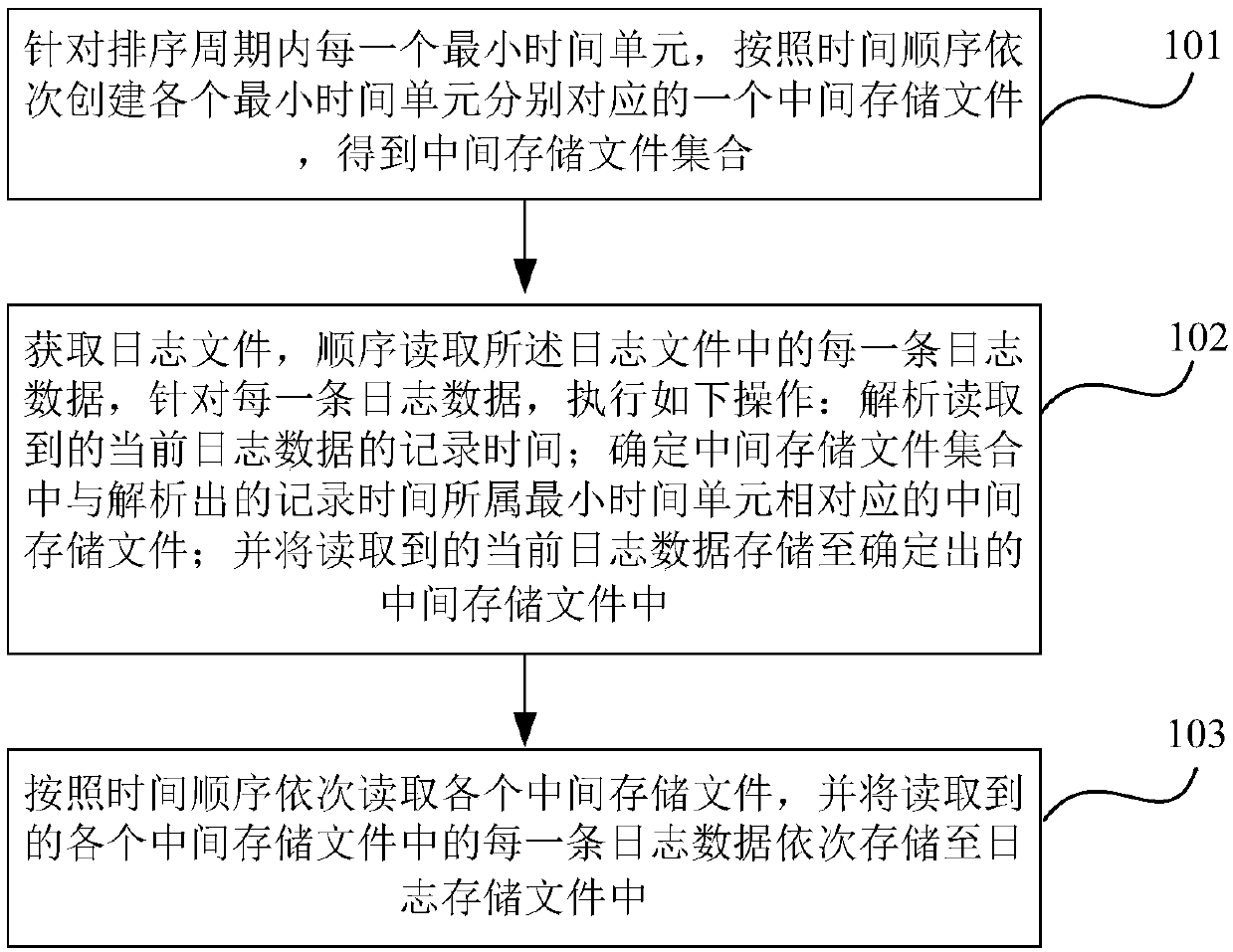

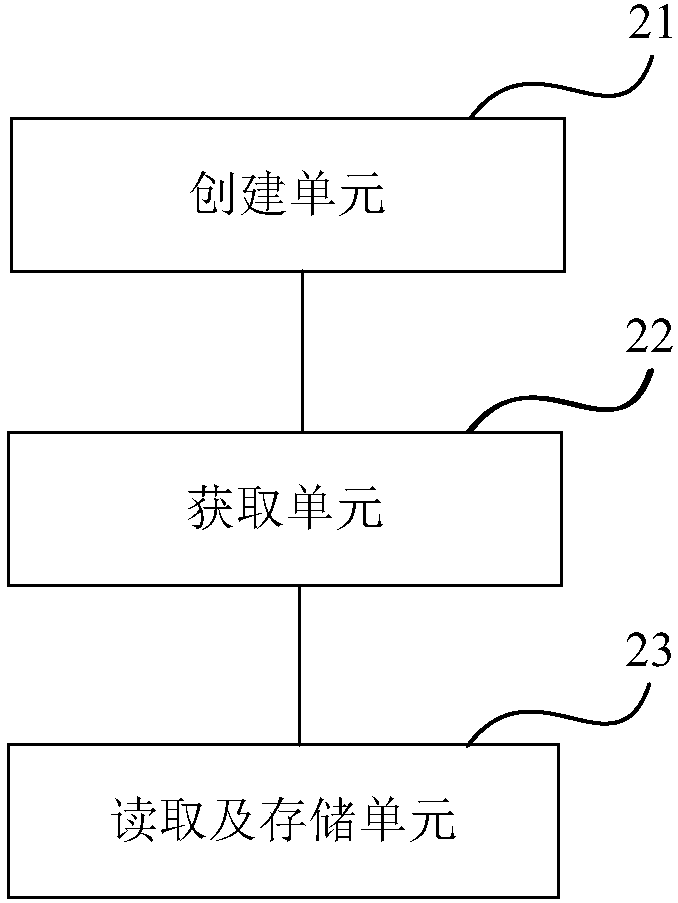

Method and device for sorting log data

ActiveCN107729375AQuick sortingSimplify the sorting processFile/folder operationsSpecial data processing applicationsMinimum timeRead through

The embodiment of the invention provides a method and device for sorting log data. The method comprises the steps that for each minimum time unit in the sorting period, intermediate storage files corresponding to the minimum time units respectively are sequentially created according to the time sequence, and an intermediate storage file set is obtained; a log file is obtained, and the log data inthe log file is read sequentially, wherein the following operations are conducted on each log data that the record time of the current log data is read through analysis, the intermediate storage filecorresponding the minimum time unit where the analyzed record time belongs is determined from the intermediate storage file set, and the read current log data is stored in the determined intermediatestorage file; the intermediate storage files are sequentially read according to the time sequence, and the log data in the read intermediate storage files is sequentially stored in a log storage file.By means of the method, a huge quantity of data can be quickly and easily sorted.

Owner:MICRO DREAM TECHTRONIC NETWORK TECH CHINACO

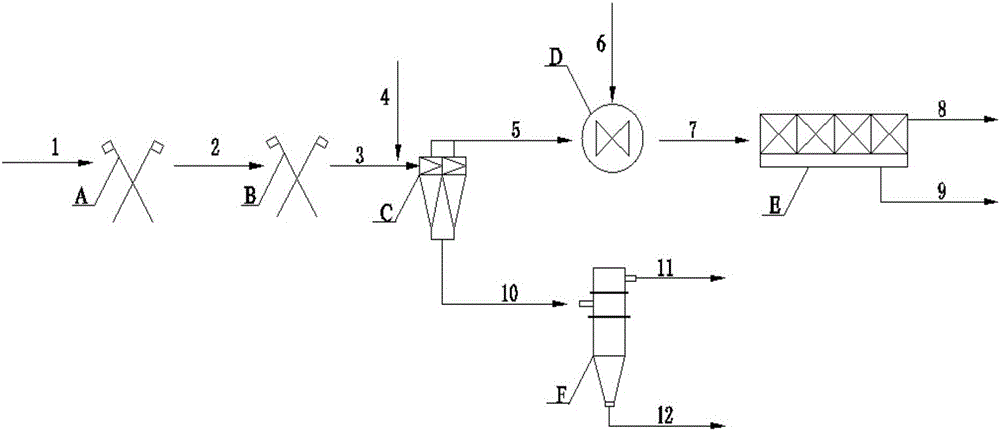

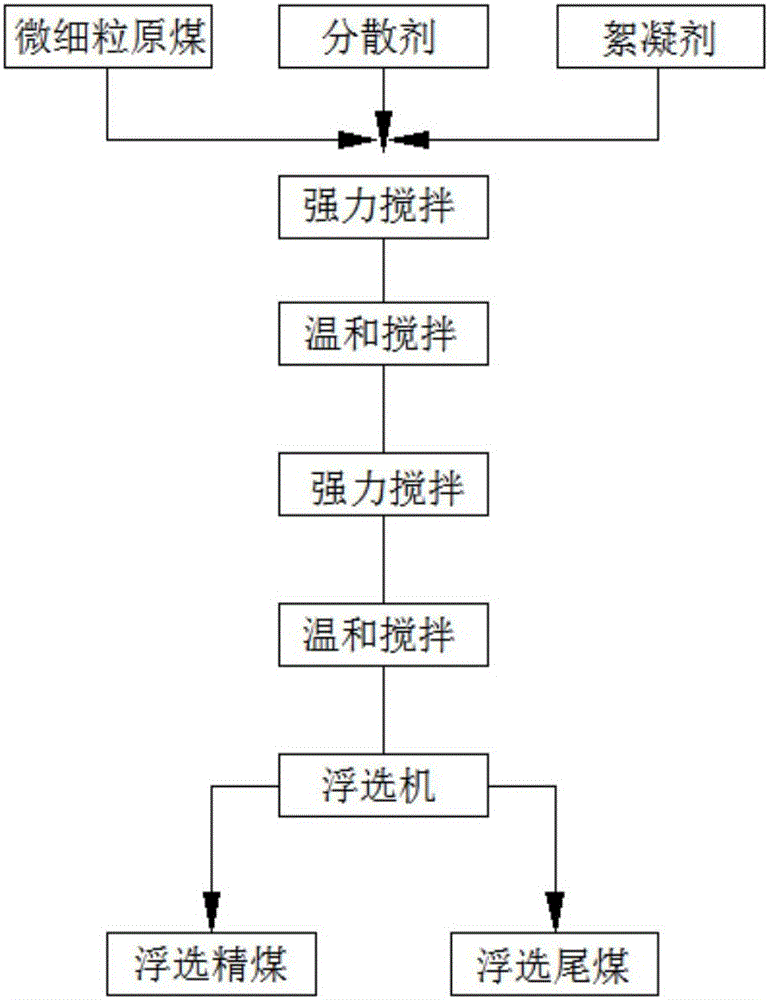

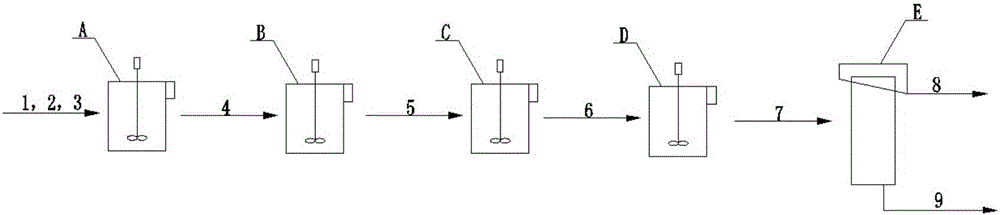

Selective flocculation separation process for micro-fine particle coking coal

ActiveCN105728204AAchieve selective flocculationAvoid destructionDifferential sedimentationFlotationFlocculationReactive site

The invention relates to a selective flocculation separation process for micro-fine particle coking coal. The selective flocculation separation process is suitable for coal washing. The process includes the steps that firstly, ore pulp, a flocculating agent and a dispersing agent are fed into a stirring device for intense stirring for 2 minutes, and the ore pulp is sufficiently dispersed; secondly, gentle stirring is carried out for 2 minutes, and target ore grains and parts of non-target particles have the flocculation phenomenon under the effect of the flocculating agent; the ore pulp is subject to intense stirring for 2 minutes again, and the parts of non-target particles are separated from active sites on flocculating agent molecules; during follow-up gentle stirring, exposed active sites are combined with the target ore grains, and the flocculating purifying process is completed; and the ore pulp obtained after flocculating is fed into a countercurrent air inflation type flotation column to be subject to separated operation in the static environment, and the micro-fine particle mineral separation is completed. The selective flocculation separation process solves the problem that the hybrid flocculent phenomenon exists, coal flocculation and gangue flocculation avoiding are achieved to the maximum degree, and damage to flocculation clusters is avoided; the process is simple in technological process, less in investment and low in running cost; and scarce coking coal resources are effectively recovered.

Owner:CHINA UNIV OF MINING & TECH

Controlling method of waypoint flow

ActiveCN103065506AImplement flow controlFlexible controlAircraft traffic controlTime rangeSorting algorithm

The invention relates to a controlling method of waypoint flow. The controlling method of the waypoint flow comprises establishing a time slice containing a plurality of time ranges according to a time sequence, initializing the time ranges, enabling each time range to be in an open and free state, setting the pass frequency of a waypoint in different time ranges according to the flow control information of the waypoint, adjusting width of different time ranges according to the passing frequency, and marking the opening-closing state of the time range corresponding to the pass frequency to be a closed state when the passing frequency is zero. The controlling method of the waypoint flow describes and controls the trafficability characteristic of an aircraft of the waypoint at a specific time through the width change, the opening-closing change, and the free-non-free change of the time slice, is suitable for different flight sort algorithms, namely, can carrying out flexible sorting according to the properties of different aircrafts, and is easy to control and high in precision, and therefore the flow control of the waypoint can be effectively achieved, and conflicts are prevented from occurring.

Owner:CICIL AVIATION HUADONG NAVIGATION MANAGEMENT EQUIP INSTALLATION DEPT

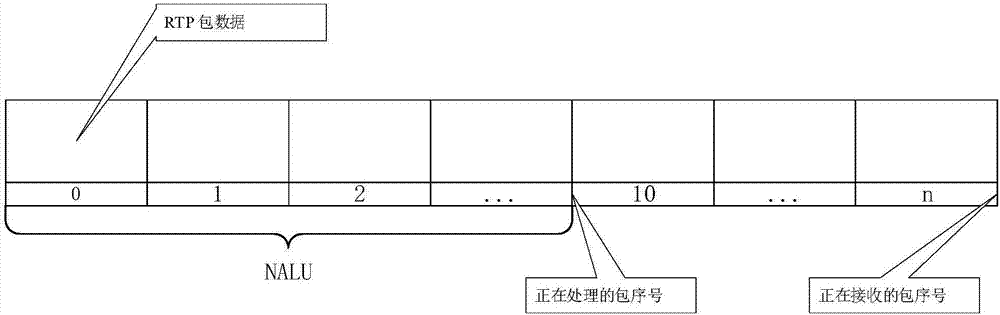

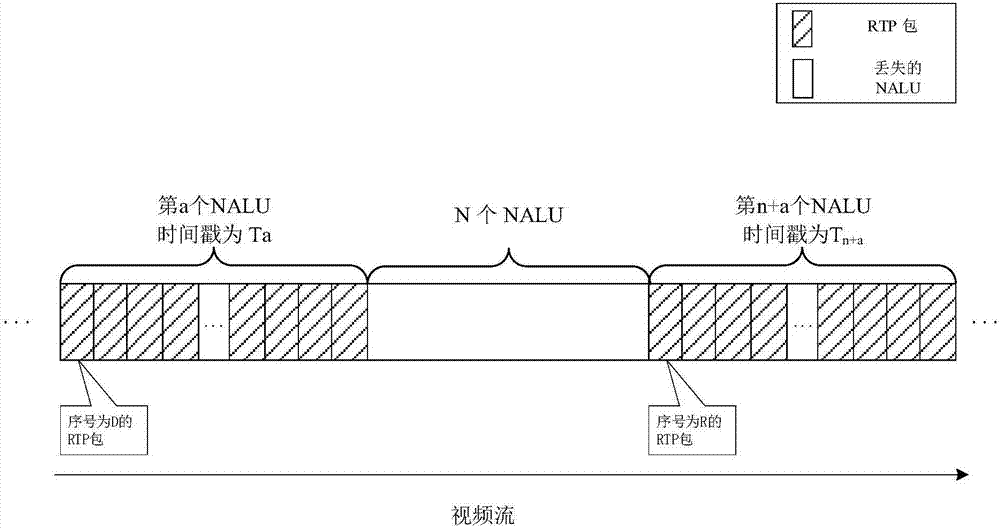

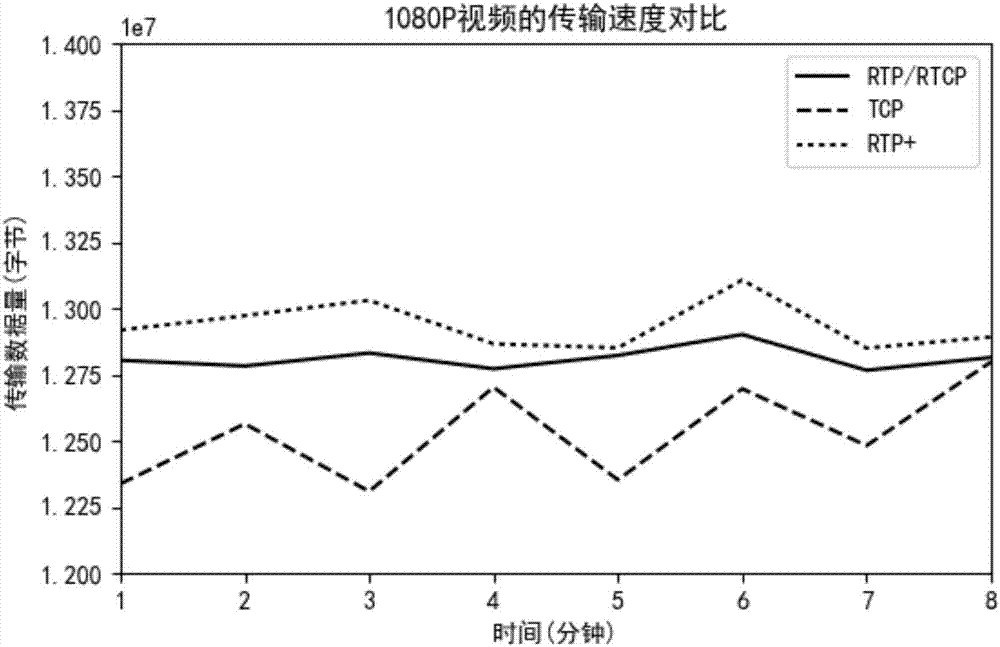

Method for improving real-time video playing quality

ActiveCN106961627AImprove transmission delayQuality improvementTransmissionSelective content distributionTime rangeSlide window

The invention discloses a method for improving real-time video playing quality. The method comprises the process of setting a sliding window, wherein the sliding window is to map the time range as a number of a RTP packet, the sliding window is to wait a packet which has small serial number and but is delayed to receive within a certain time range, and to map the time range as the span between the packets; the sliding window comprises two ranges: a left boundary Wl and a right boundary Wr; the sliding window divides the whole numerical range into three parts; when the difference between the serial number of the unreceived packet and the serial number of the currently received packet falls in different ranges, the method enters different handling processes. The real-time video playing quality is obviously improved by use of the method disclosed by the invention.

Owner:北京金风易通科技有限公司

Grid type container and grid type freight car

InactiveCN104859977ASimple structureChange the logistics freight modeLarge containersModularityEngineering

The invention discloses a grid type container and a grid type freight car and belongs to the technical field of containers. The grid container comprises a plurality of boxes and a box rack, wherein the boxes are in a cuboid shape, the volume of each box is not larger than 4 square meters, the box frame is provided with at least two box grids, and the boxes are put into the box grids. The grid type container and the grid type freight car have the advantages of being flexible, convenient to use and capable of achieving modularization. A large amount of small cargos can be separately loaded according to the destinations of the cargos, splitting and transferring of the large amount of cargos are facilitated, the sorting flow is simplified to the maximum, and the logistic cost is reduced. In addition, the number of the cargos located in each box is proper, arranging and sorting of the cargos are facilitated, and the workload of workers is reduced.

Owner:CRRC SHIJIAZHUANG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com