Horizontal pushing and side out type cigarette sorting machine and sorting method

A sorting device and a technology of cigarette sticks, which are applied in the directions of transportation and packaging, loading/unloading, and unstacking of objects, etc., can solve the problems of complicated production control, increased shaping process, and low production efficiency, so as to ensure the sorting efficiency, Simple sorting process and reduced equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

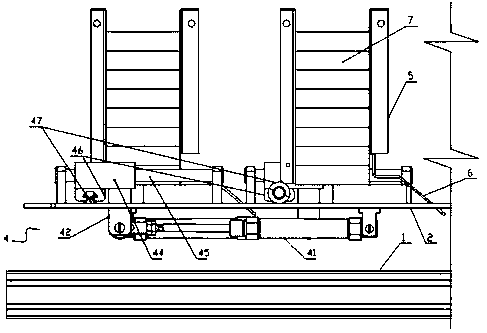

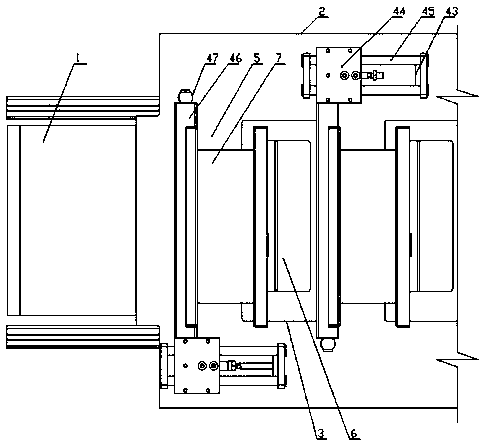

[0020] Example 1. A kind of horizontal pushing and side-out cigarette sorting device, which is constituted as follows: Figure 1-2 As shown, it includes a conveyor belt 1, a sorting substrate 2 is arranged above the conveyor belt 1, a smoke outlet 3 is arranged on the sorting substrate 2, and a sorting assembly 4 is arranged on one side of the smoke outlet 3, and the sorting assembly 4 is provided with a smoke storage bin 5 above; the sorting assembly 4 includes a driving device 41, the driving device 41 is connected with a connecting block 42, and the connecting block 42 passes through the avoidance groove 43 and the sliding block arranged on the sorting substrate 2 Block 44 is connected, and slide block 44 is connected with sorting base plate 2 through slide rail 45, and slide block 44 is also connected with one end of push rod 46.

[0021] A smoke outlet baffle 6 is also provided above the aforementioned smoke outlet 3 .

[0022] The smoke outlet direction of the cigarett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com