Production process of rectorite for nano composite material

A technology of nanocomposite materials and production methods, which is applied in the field of polymer compound compositions, can solve the problems of long production time, complex process, and various equipment, and achieve increased dispersion performance, good dispersion suspension, and good sorting effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: the rectorite coarse concentrate is crushed through a jaw crusher, get 10kg rectorite coarse concentrate and add 130kg water, then add 0.4kg sodium pyrophosphate, place in a mixing tank and carry out linear speed of 10.51m / After 1 hour of high-speed stirring, the rectorite and the dispersant fully interacted to form a uniformly dispersed suspension A in water. The suspension A was placed in a centrifuge for high-speed centrifugation. The separation factor was 1375 and the separation time was 4.0. min, the tailings and purified rectorite suspension B can be obtained from the discharge, and then the suspension B is placed in the same centrifuge. Under the same separation factor, the separation time is extended to 10min, and the suspension The rectorite in the liquid B is all settled and dehydrated, and then the obtained rectorite is put into an oven, and dried at a temperature of 100°C until the water content is less than 10%, and the nanometer with a purity...

Embodiment 2

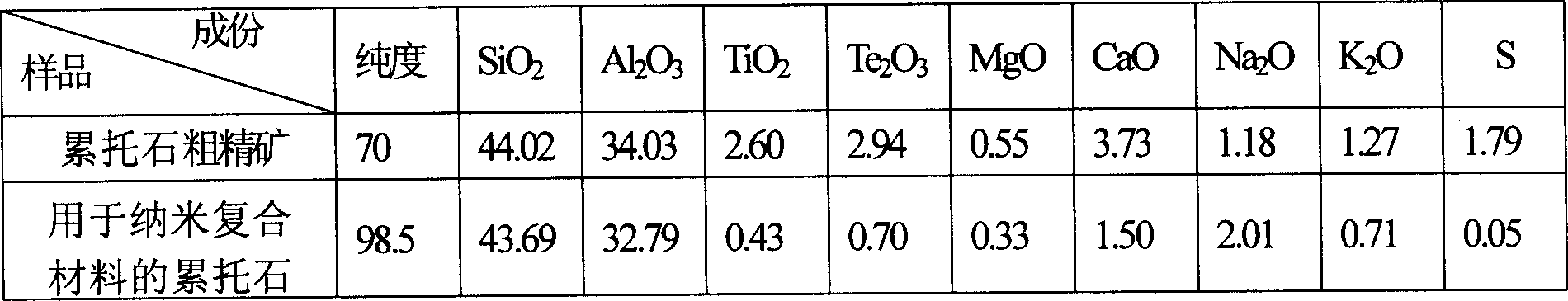

[0031]Example 2: Crushing the rectorite coarse concentrate, and then superfinely grinding to a particle size of more than 75% of the rectorite <15 μm, taking 10kg of ultrafine rectorite, adding it to 190kg of water, and then adding 0.5kg of hexametaphosphoric acid Sodium, placed in a mixing tank and stirred at a high speed of 10.51m / s for 1 hour, the rectorite and the dispersant fully interacted to form a uniformly dispersed suspension A in water, and the suspension A was placed in a centrifuge for High-speed centrifugation, the separation factor is 3244, and the separation time is 7 minutes. The tailings and the purified rectorite suspension B can be obtained from the discharge. The suspension B is placed in the same centrifuge, and then re- After separating for 10 minutes, all the rectorite in the suspension B can be settled and dehydrated, and then the obtained rectorite is placed in an oven and baked at 100°C until the water content is less than 10%. 98.5% rectorite for na...

Embodiment 3

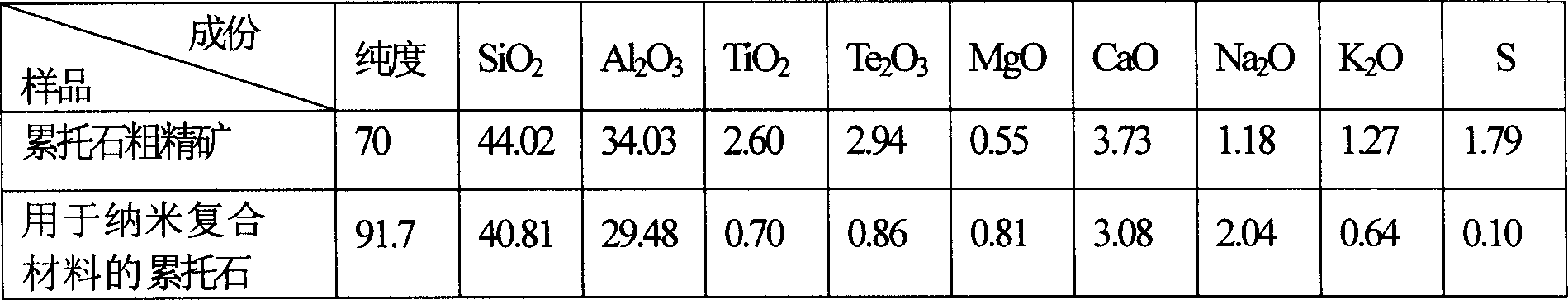

[0036] Embodiment 3: the tailings obtained in Example 2 are placed in an oven, baked to a water content<10% at a temperature of 100° C., get 10 kg and add it to 190 kg of water, then add 0.2 kg of sodium hexametaphosphate, and then Perform the same operation as in Example 2 to obtain 91.7% rectorite for nanocomposite materials.

[0037] It can be seen from the above examples that the production method of the present invention is simple, the equipment is simplified, the time is short, safe and convenient, and the rectorite series products for the preparation of organic polymer nanocomposites with a purity of 91% to 98.5% are produced.

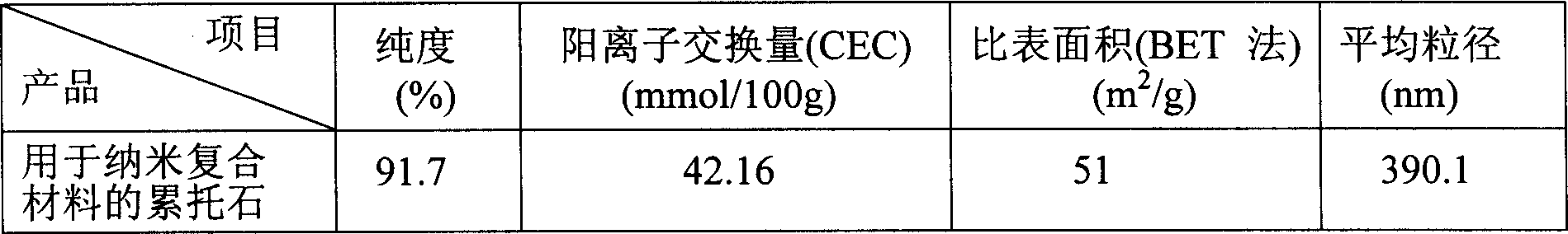

[0038] The purity of the rectorite used in the nanocomposite produced by the invention can reach 91%-98.5%, and the average particle size is 100-400nm. The specific surface area is 50~60m 2 / g, the total amount of cation exchange (CEC) is 40-50mmol / 100g, it is an excellent inorganic filler for polymer nanocomposites, suitable for the synthesis ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com