Centrifugal Floatation Dry Separator

A centrifugal sorting and sorting machine technology, which is applied in centrifuges, centrifuges with rotating drums, etc., can solve the problems of complex processing technology, high cost of dust removal and high production costs, and achieves simple sorting process and high production cost. Low production cost and satisfactory sorting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

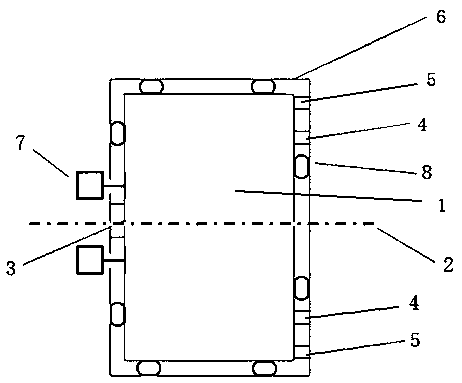

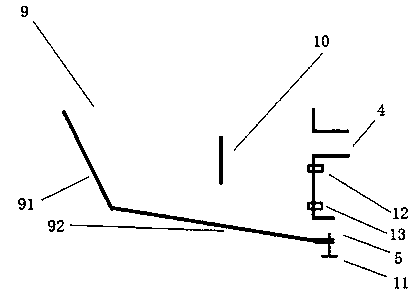

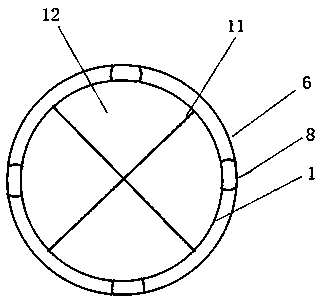

[0031] In this example, see figure 2 , The centrifugal separation chamber 1 is provided with a mineral guide plate 9 between the feed port 3 and the heavy product discharge port 5 . In the present embodiment, the mineral material guide plate 9 includes a feed plate 91 extending obliquely along the edge of the feed port 3 to the inner wall of the centrifugal separation chamber 1 in the circumferential direction, and one end is connected to the feed plate 91, and the other end extends obliquely to the heavy product. The feeding plate 92 on the outside of the discharge opening 5. The purpose is that, adopting this kind of structural design, the ore material entering from the feed port 3 can be vibrated and stratified, while comprehensively transitioning towards the light product discharge port 4 and the heavy product discharge port 5, so that the stratified ore The material can be discharged quickly and evenly, effectively preventing accumulation. It can be foreseen that adjus...

Embodiment 2

[0033] In this example, see figure 2 , The centrifugal separation chamber 1 is provided with a material dividing partition 10 between the light product discharge port 4 and the heavy product discharge port 5 . In this embodiment, the material dividing partition 10 is placed vertically, and is located at the axial center of the centrifugal separation chamber 1 slightly close to the light product discharge port 4 and the heavy product discharge port 5 . The purpose is that after the mineral material is stratified, the high-density granular material is hindered by the material distribution partition 10, falls to the mineral material guide plate 9, and is discharged from the heavy product discharge port 5. Under the action of the material, it crosses the material dividing partition 10, and discharges from the light product discharge port 4, and finally also plays the function of improving the separation speed and accuracy. It can be foreseen that adjusting the structure and hori...

Embodiment 3

[0035] In this example, see figure 2 , The light product discharge port 4 and the heavy product discharge port 5 are provided with a discharge volume controller 11 for adjusting the size of the discharge port. The discharge volume controller 11 can adopt manual or automatic control mode, and adjust the corresponding opening size according to the quantity of high-density and low-density granular materials to be discharged, so as to ensure the sorting efficiency of the whole equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com