Patents

Literature

65results about How to "Guaranteed sorting efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

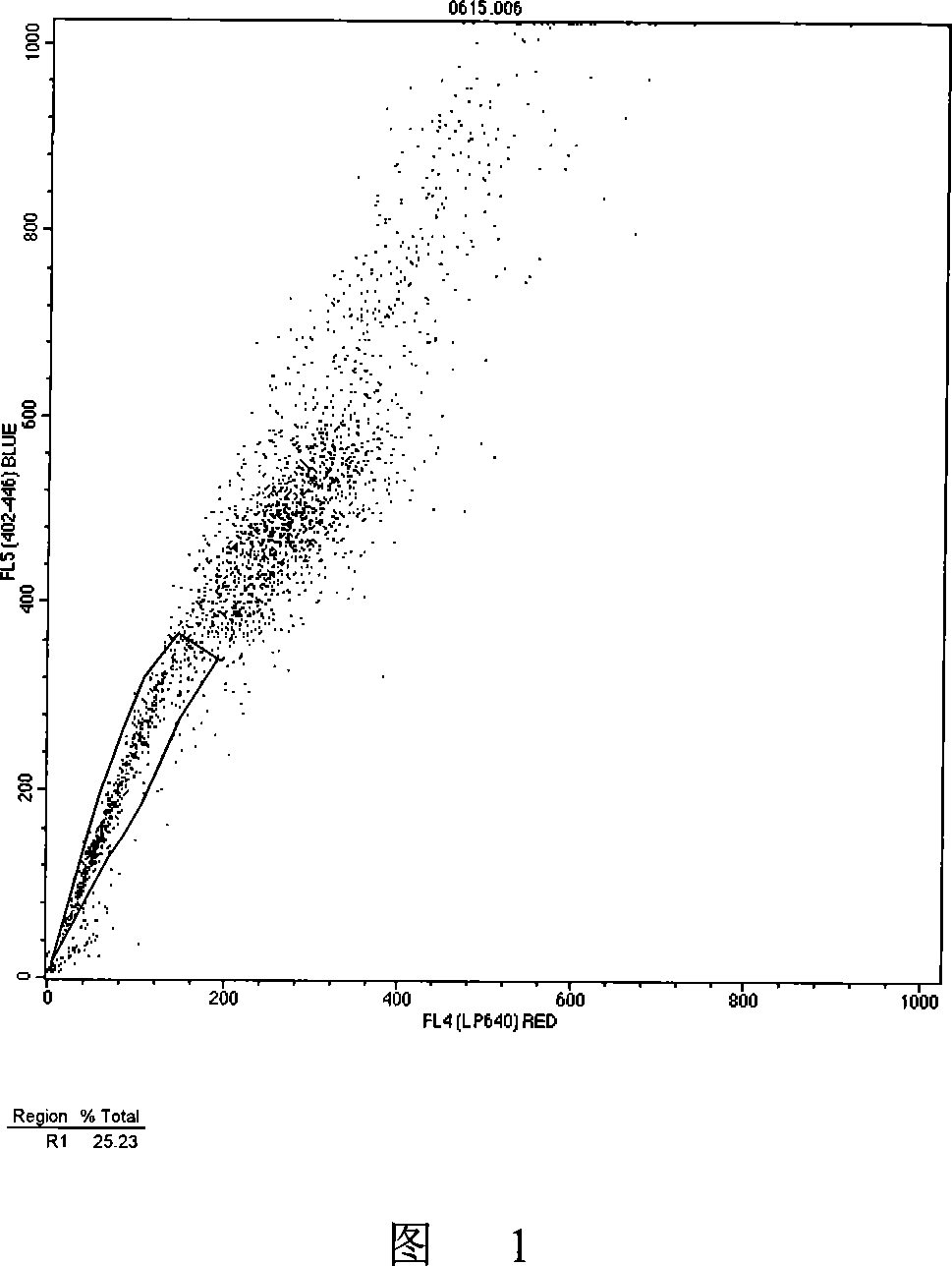

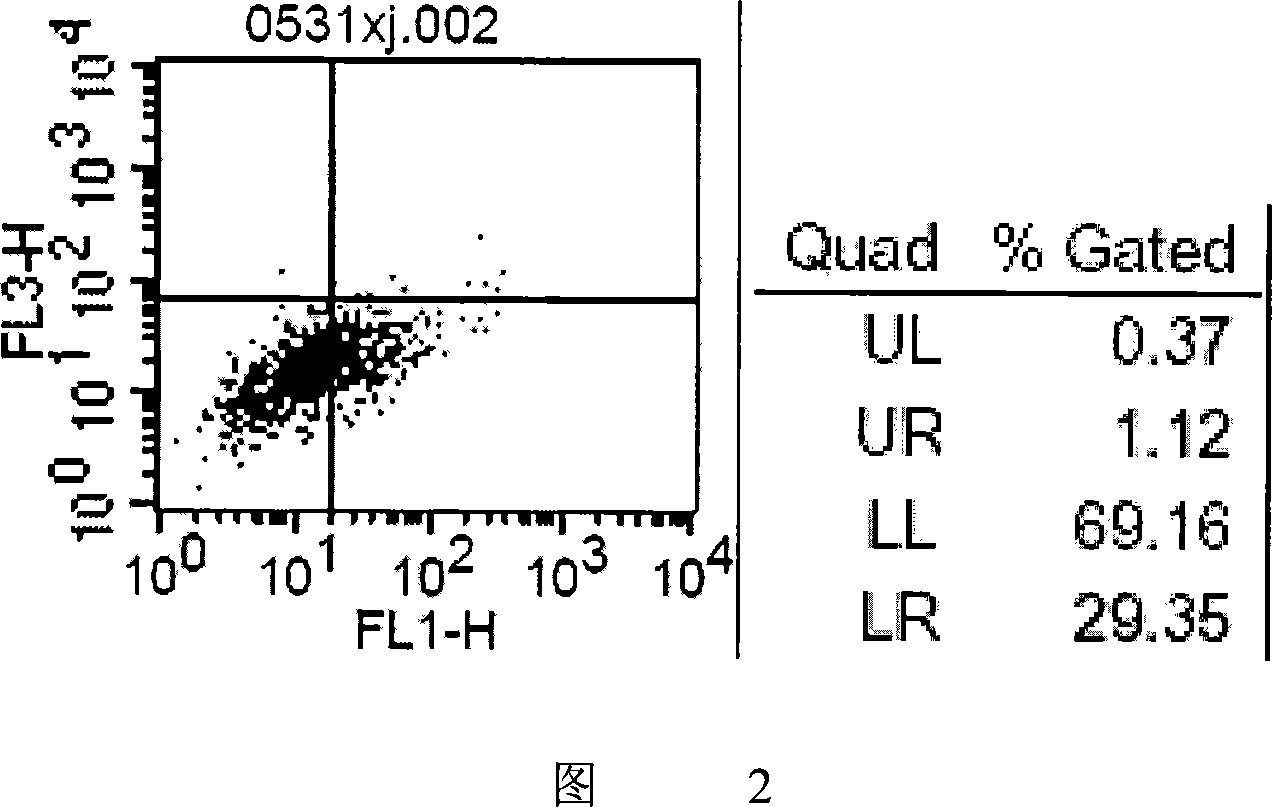

Method for separating stem cell of breast cancer

This invention relates to a method for separating breast cancer stem cells. The method comprises: digesting breast cancer cells into single cell suspension, preparing Percoll discontinuous density gradient separating medium, mixing with single cell suspension, centrifuging to separate cell subsets, detecting by comparing the experimental tube and the control tube, adjusting the density of Percoll discontinuous density gradient separating medium until the content of the cell subsets related to the breast cancer stem cells reaches predetermined enrichment degree, and screening with a flow cytometry. The method utilizes Percoll screening or serum-free culture to enrich breast cancer stem cells, and then screens with a flow cytometry to ensure the screening efficiency. The ratio of the breast cancer stem cells after primary enrichment is higher than 25%, while that after low cytometry screening is higher than 99%.

Owner:JIANGSU PROVINCE HOSPITAL

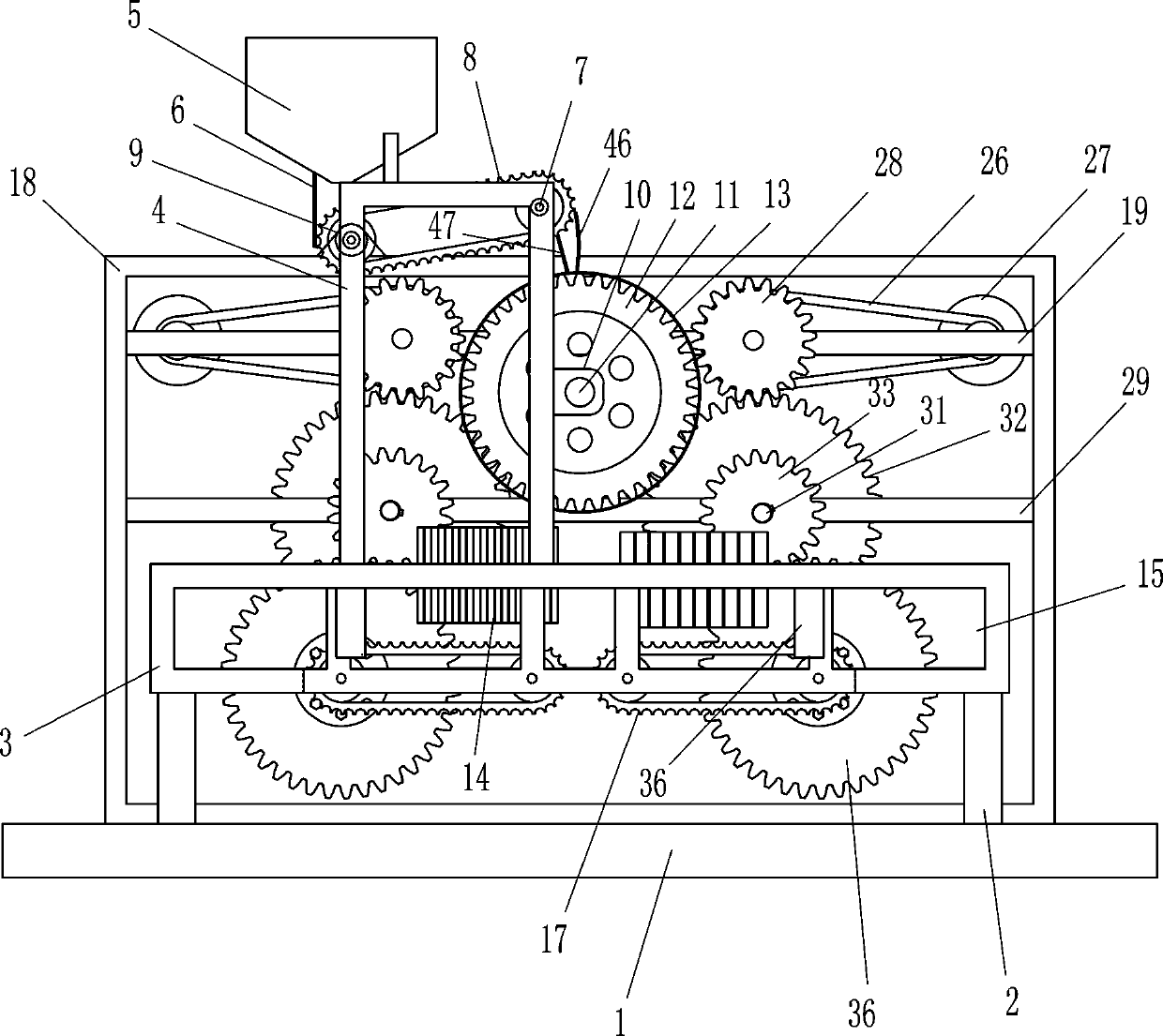

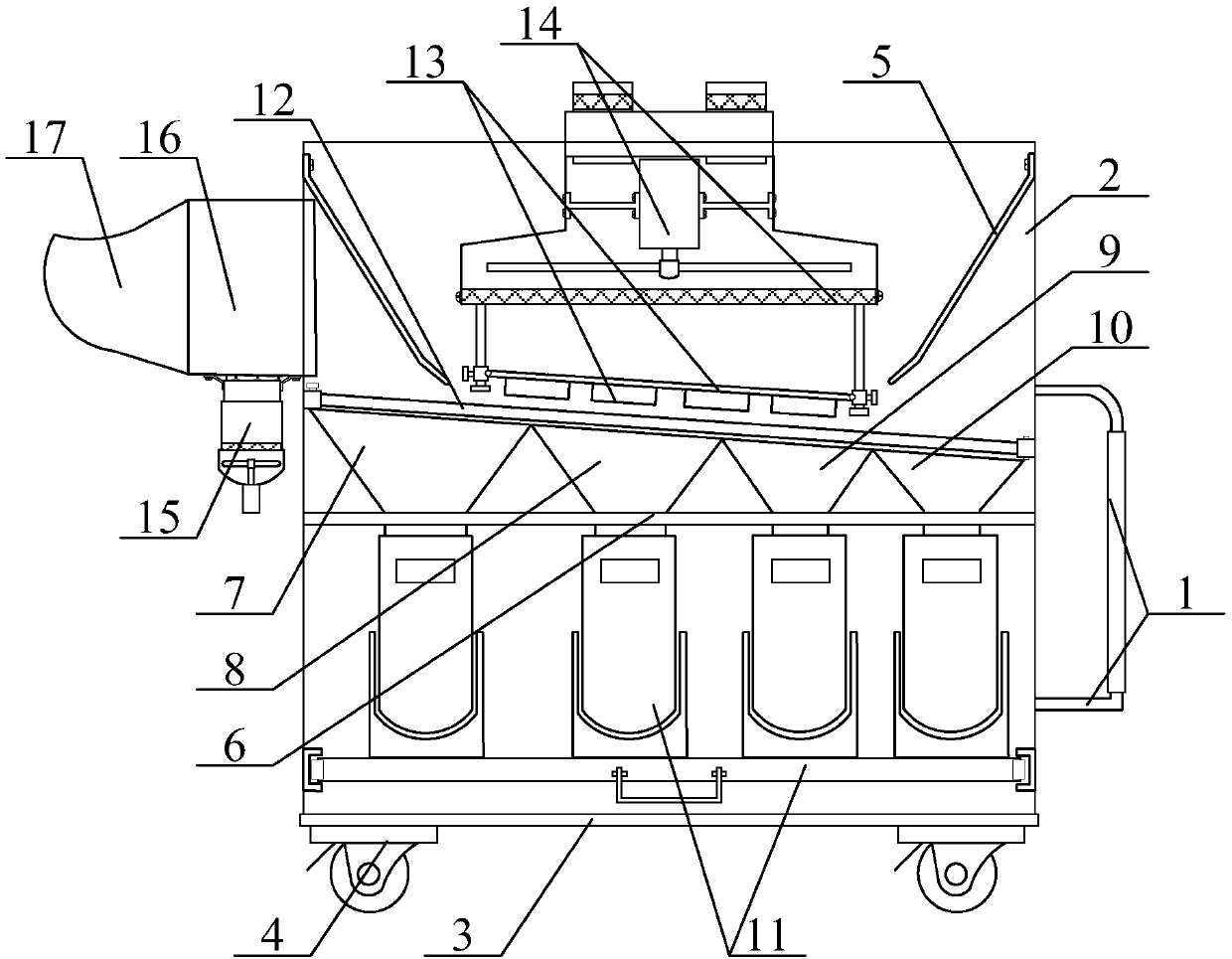

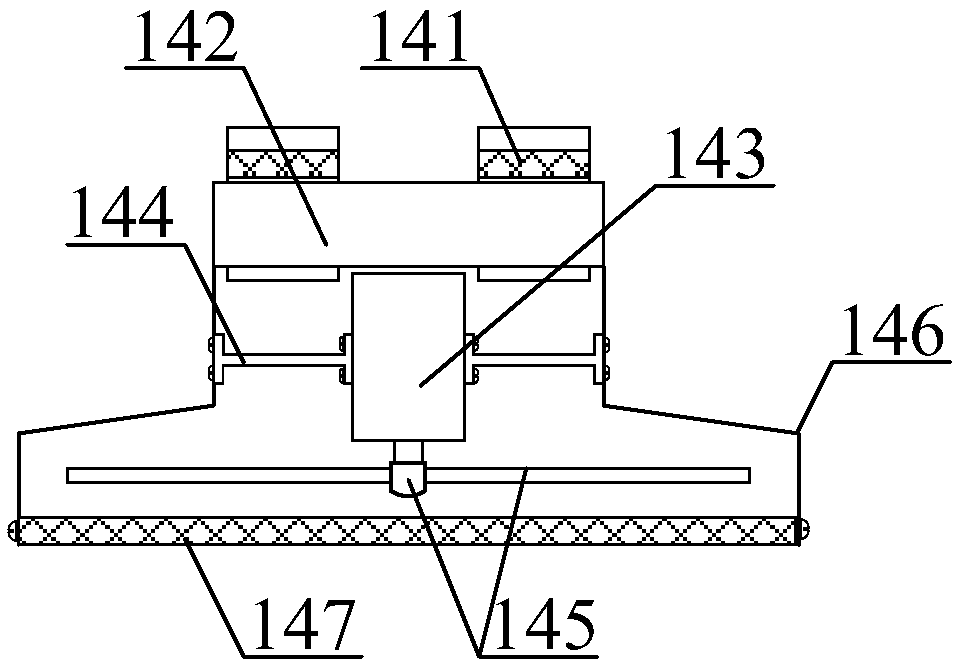

Intelligent coin sorting device

InactiveCN106097562ARealize automatic sortingReduce labor costsCoin/currency accepting devicesPulp and paper industryPaper sheet

The invention relates to an intelligent coin sorting device which comprises the components of a mixed coin separating mechanism, a paper money sorting mechanism, a coin sorting mechanism and a coin packaging mechanism. The mixed coin separating mechanism comprises a screening roller and a roller driving assembly. The mixed coins are dumped from the top opening of the screening roller. The roller driving assembly drives the screening roller to rotate. The coins fall through screening holes. The paper money slides out through the bottom opening of the screening roller. The paper money sorting mechanism comprises a paper twisting trough assembly, a single-paper-piece conveying assembly, an image identification assembly and a paper money classifying and collecting assembly. The paper twisting trough assembly performs twisting on a single piece of paper money. The single-paper-piece conveying assembly conveys the single piece of paper money to the inlet of the image identification assembly. After the image identification assembly identifies the type of the paper money through image acquisition, the paper money is classified and put into the paper money classifying and collecting assembly. Compared with the prior art, the intelligent coin sorting device realizes automatic coil sorting and furthermore has advantages of saving labor cost, improving sorting efficiency and sorting precision, etc.

Owner:EAST CHINA UNIV OF SCI & TECH

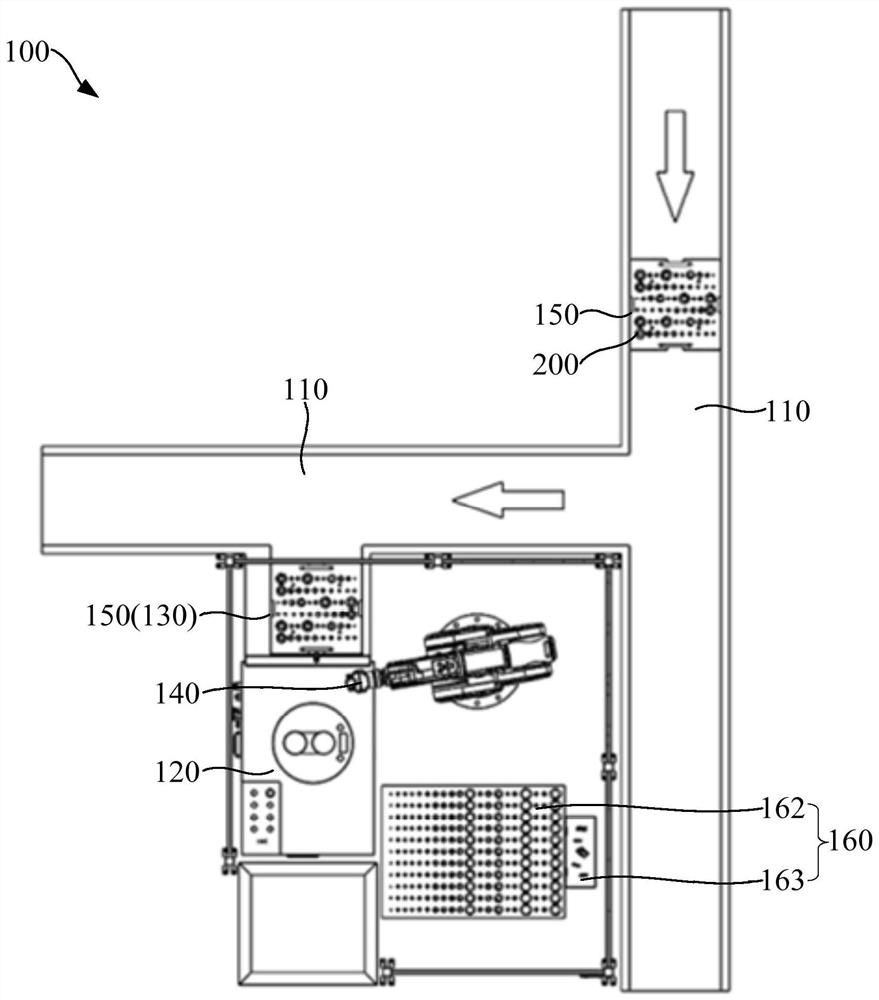

Cargo sorting system and sorting method

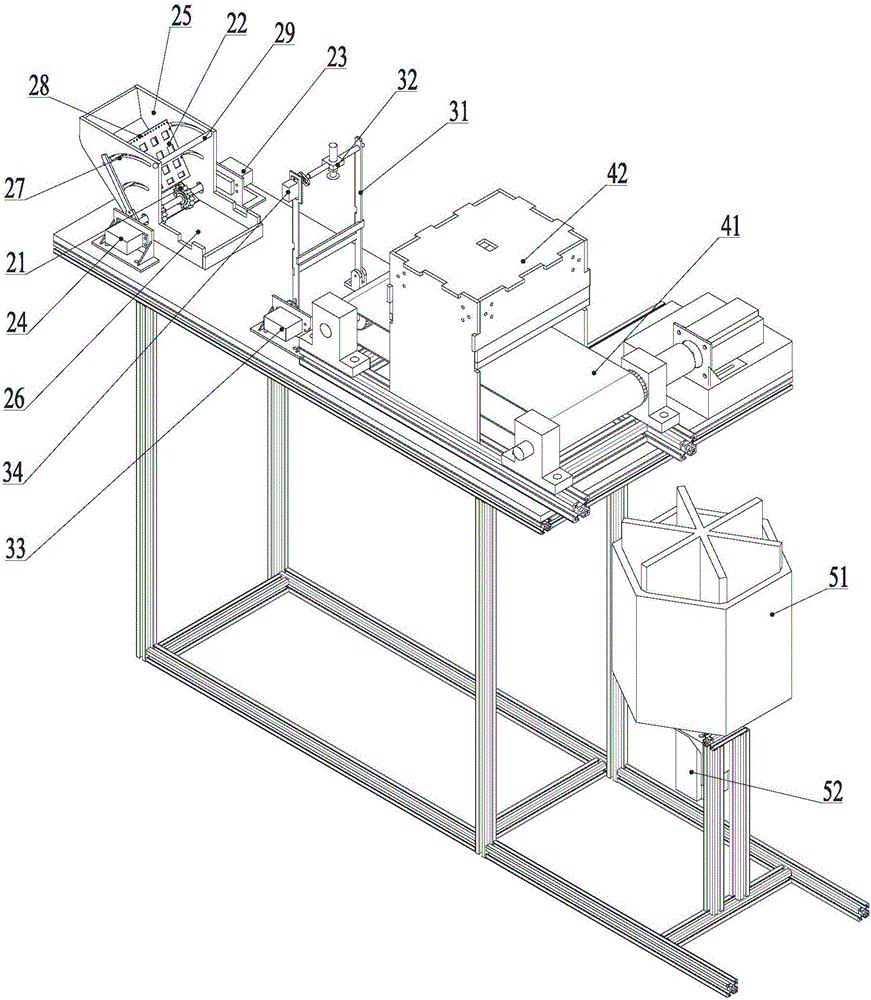

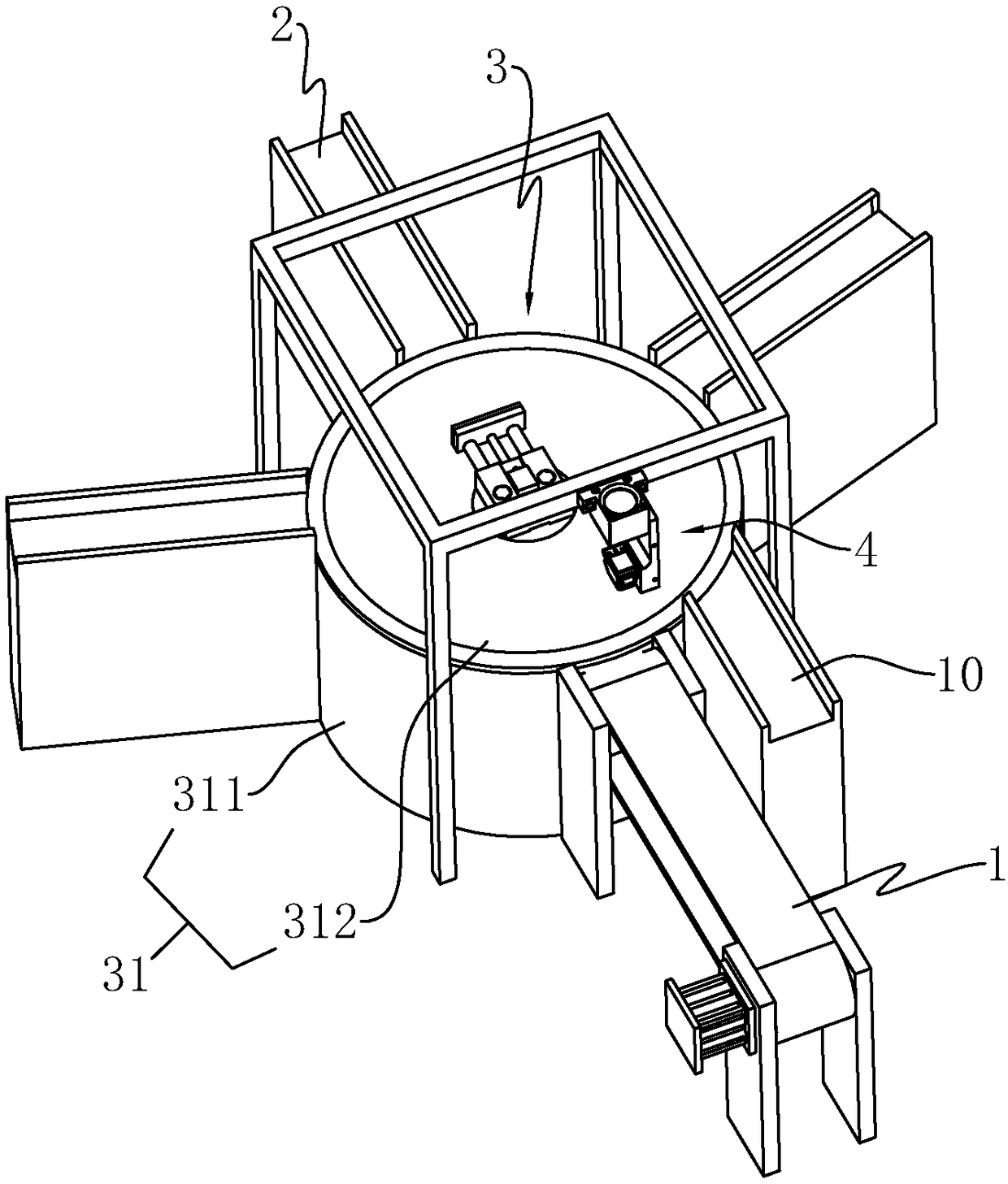

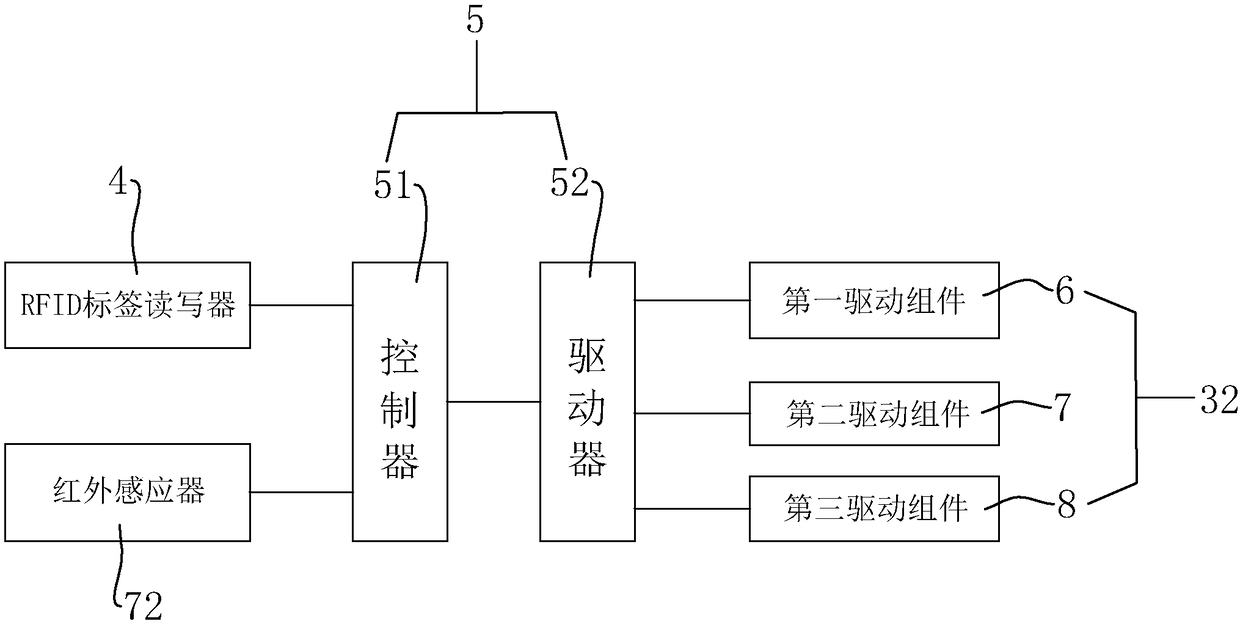

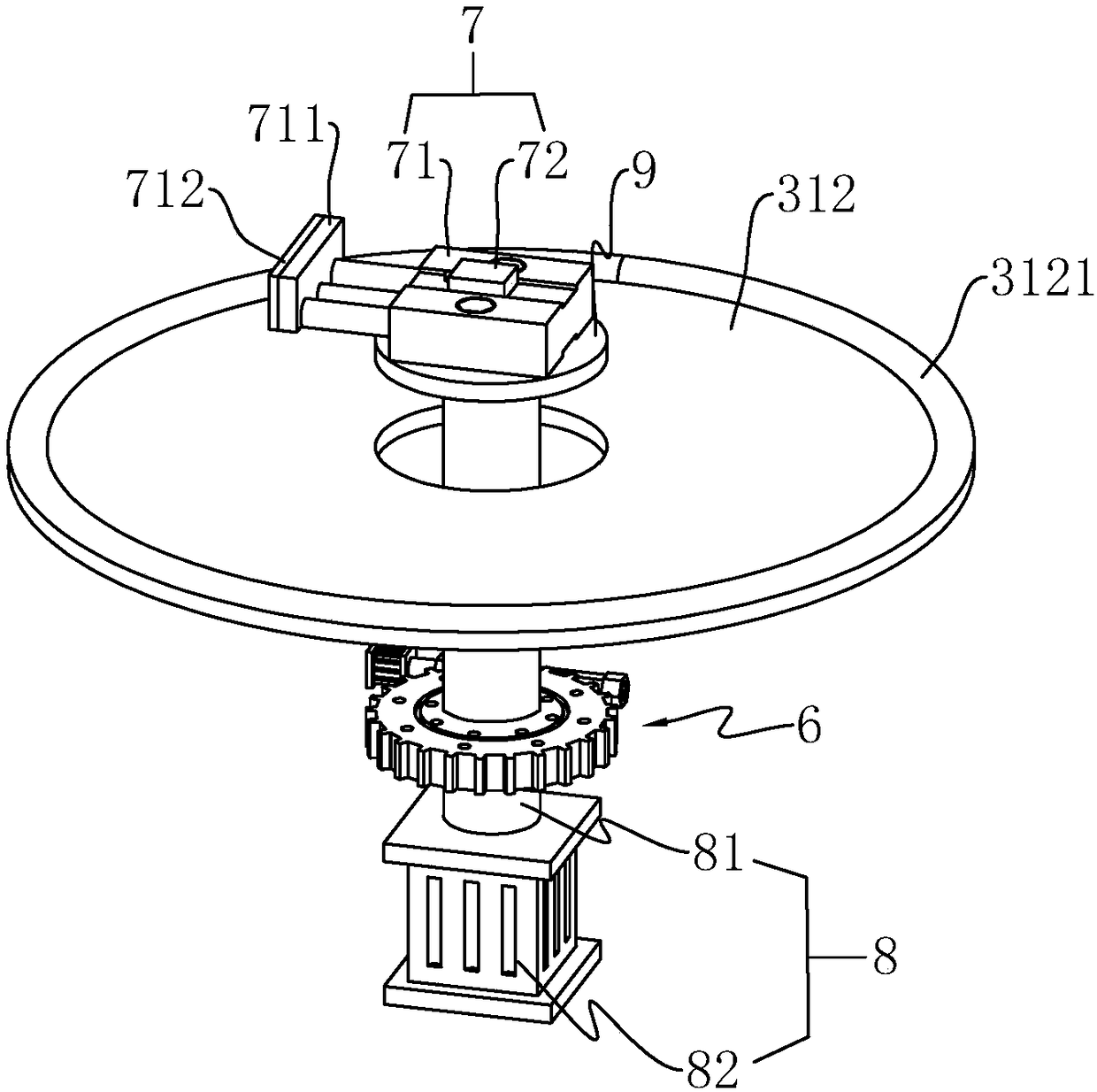

InactiveCN108438694ARealize fully automatic sortingImprove sorting efficiencyStorage devicesEngineeringReader writer

The invention discloses a cargo sorting system and sorting method, and relates to the technical field of logistics storage. The cargo sorting system comprises a put-into-storage line body, a pluralityof sets of sorting lines, a bearing device, a cargo identification module and a control module; the bearing device comprises a conveying carrier and driving assemblies, the cargo identification module is an RFID label reader-writer, and the control module comprises a controller and a driver; and the conveying carrier comprises a base and a rotary disc, and the driving assemblies comprise the first driving assembly and the second driving assembly. According to the cargo sorting method, the above cargo sorting system is adopted, and full-automatic cargo sorting is achieved. The cargo sorting system is extremely high in automation and intelligent degree, the labor intensity of workers can be greatly reduced, the cargo sorting efficiency and the sorting accuracy are greatly improved, responseto the trend of modern logistics development is achieved, and the market competitiveness of logistics enterprises is better improved.

Owner:上海诺尔国际物流有限公司

Magnetic control type full-angle-feeding three-product heavy medium cyclone

ActiveCN103909024AEffective dispersionLow densityReversed direction vortexMagnetic tension forceCyclone

The invention relates to a magnetic control type full-angle-feeding three-product heavy medium cyclone, belonging to the technical field of coal separation equipment. The heavy medium cyclone comprises a cyclone cylinder and a magnetic control device, wherein the magnetic control device is arranged on the cyclone cylinder and is used for changing weight medium distribution of to-be-separated materials in the cyclone cylinder by virtue of magnetic force traction; the magnetic control device comprises an internal magnetic system and an external magnetic system which are respectively arranged on the inner side and outer side of the cyclone cylinder, and the internal magnetic system and the external magnetic system are respectively electrified to control the magnetic force. The heavy medium cyclone has the beneficial effects that after materials are fed into the cyclone cylinder, traction forces are generated to heavy mediums by virtue of the magnetic forces of the internal and external magnetic systems of the magnetic control device, so that the distribution of the heavy mediums is regulated, the materials are effectively dispersed, and elimination of blockage is facilitated; the stability of suspension liquid is controlled, and the separation time is regulated and controlled; the distribution of separation layers of the heavy mediums is changed, the loss of clean coal is reduced, the yield of the clean coal is improved, a coarse size phenomenon is reduced, and the quality of the clean coal is improved; by arranging a flow guide device, the materials and the medium suspension liquid can be fed in batch along a 360-degree annular direction, so as to realize batch washing selection.

Owner:ANHUI UNIV OF SCI & TECH

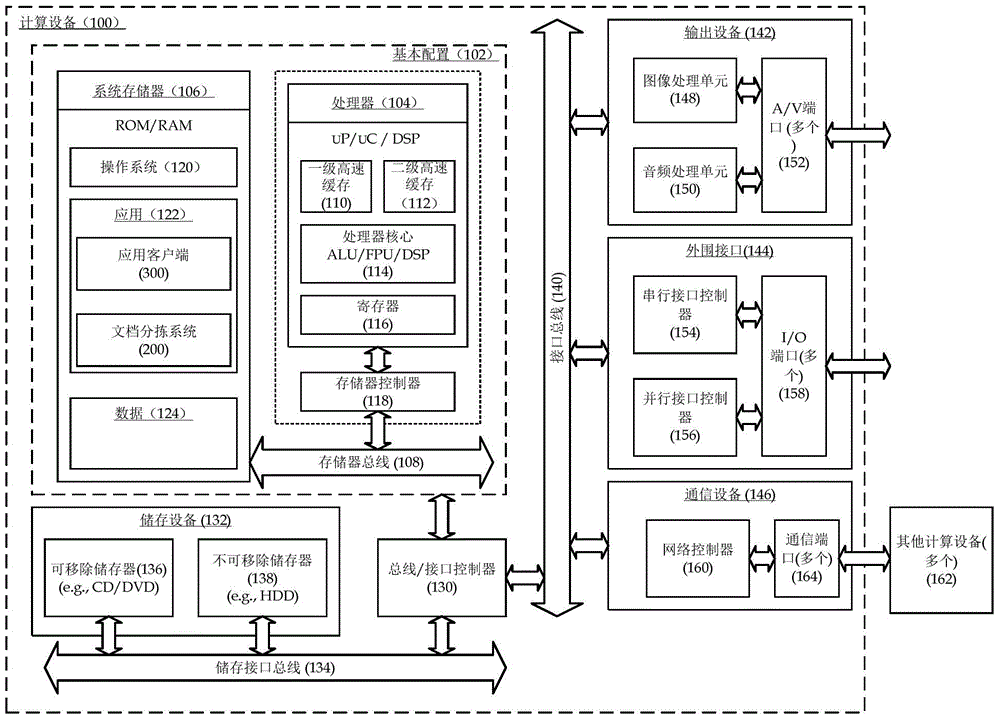

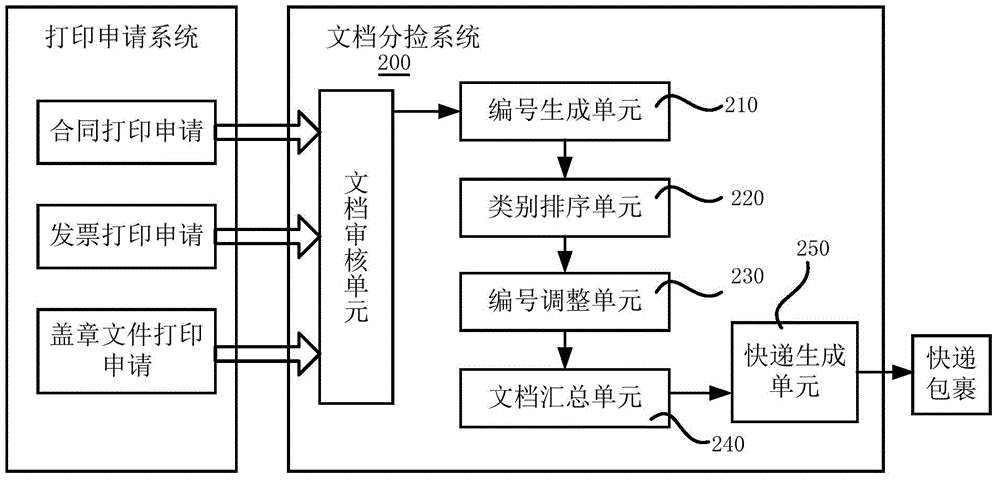

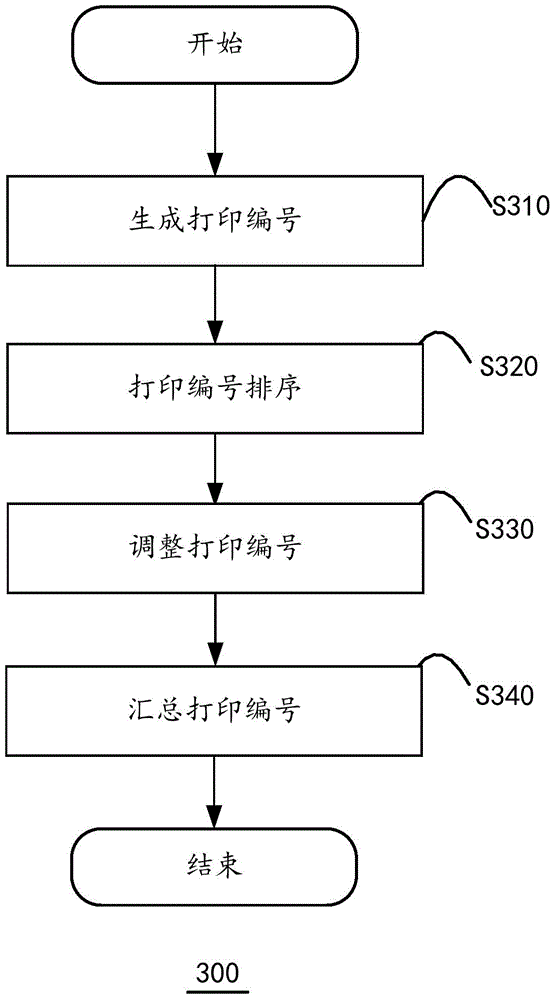

Document sorting system and method and computing equipment

ActiveCN105094716AGuaranteed sorting efficiencyImprove work efficiencySortingDigital output to print unitsInformation retrievalDocumentation

The invention discloses a document sorting system, which resides in computing equipment. The equipment comprises a number generation unit which is suitable for determining the printing sequences of documents in each document type of a plurality of document types respectively according to the printing time of the documents, and generating a printing number of each document according to the printing sequences; a type sequencing unit which is suitable for sequencing the plurality of document types according to the quantities of the documents included in each document type from large to small in order to generate a first printing list; a number adjusting unit which is suitable for adjusting the printing numbers of lowest-ranked documents having the same mailing addresses in the first printing list to the printing numbers of highest-ranked documents; and a document summarizing unit which is suitable for summarizing the plurality of documents having the same printing numbers in the first printing list to highest-ranked document locations in the plurality of documents according to the printing numbers adjusted by the number adjusting unit in order to generate a second printing list.

Owner:BEIJING CHESHANGHUI SOFTWARE

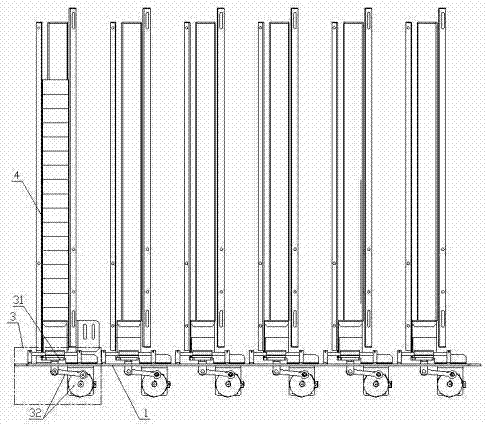

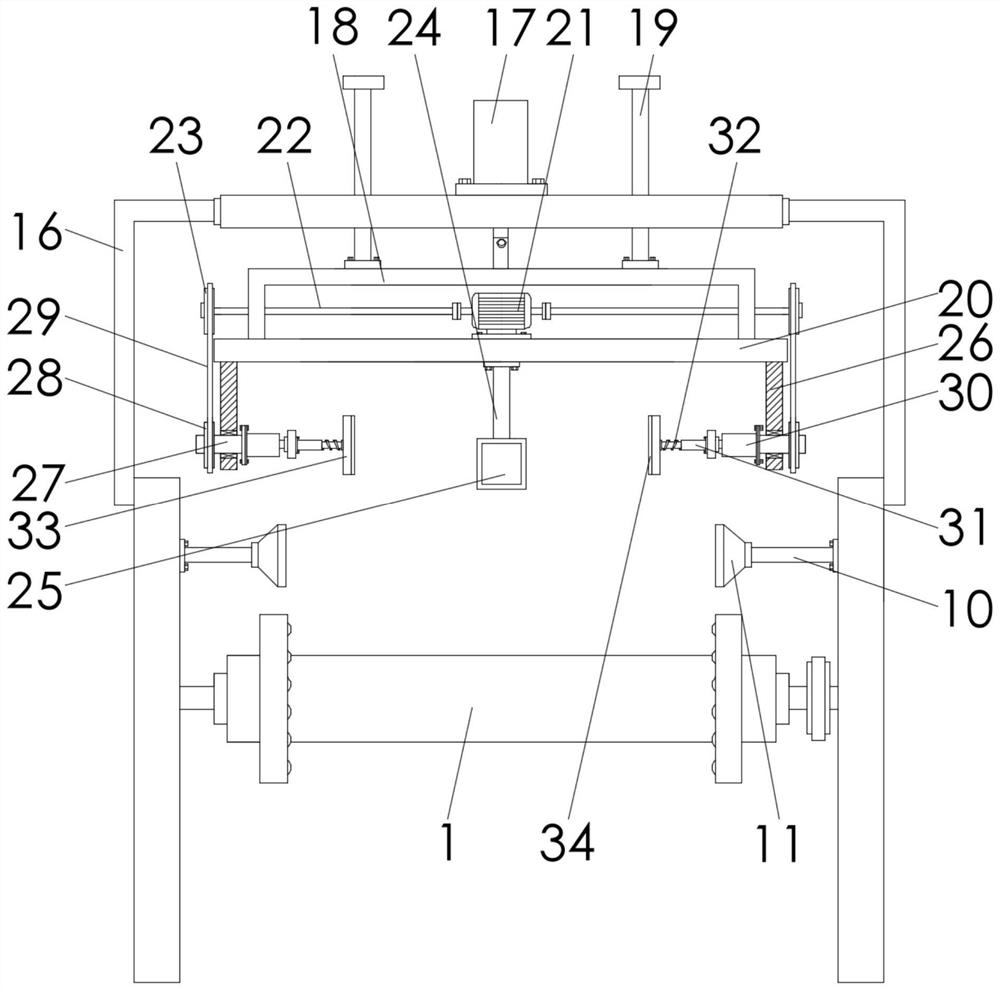

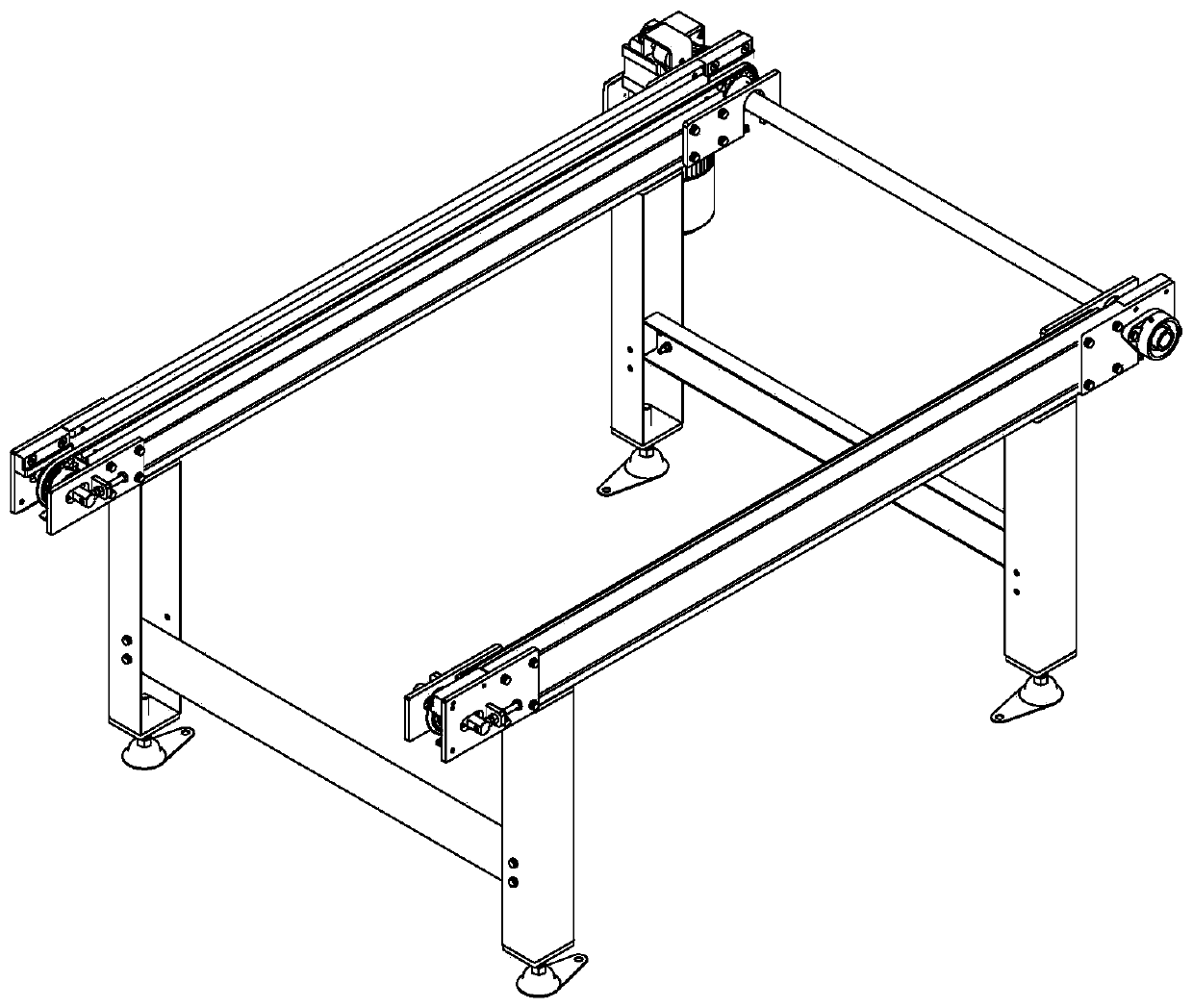

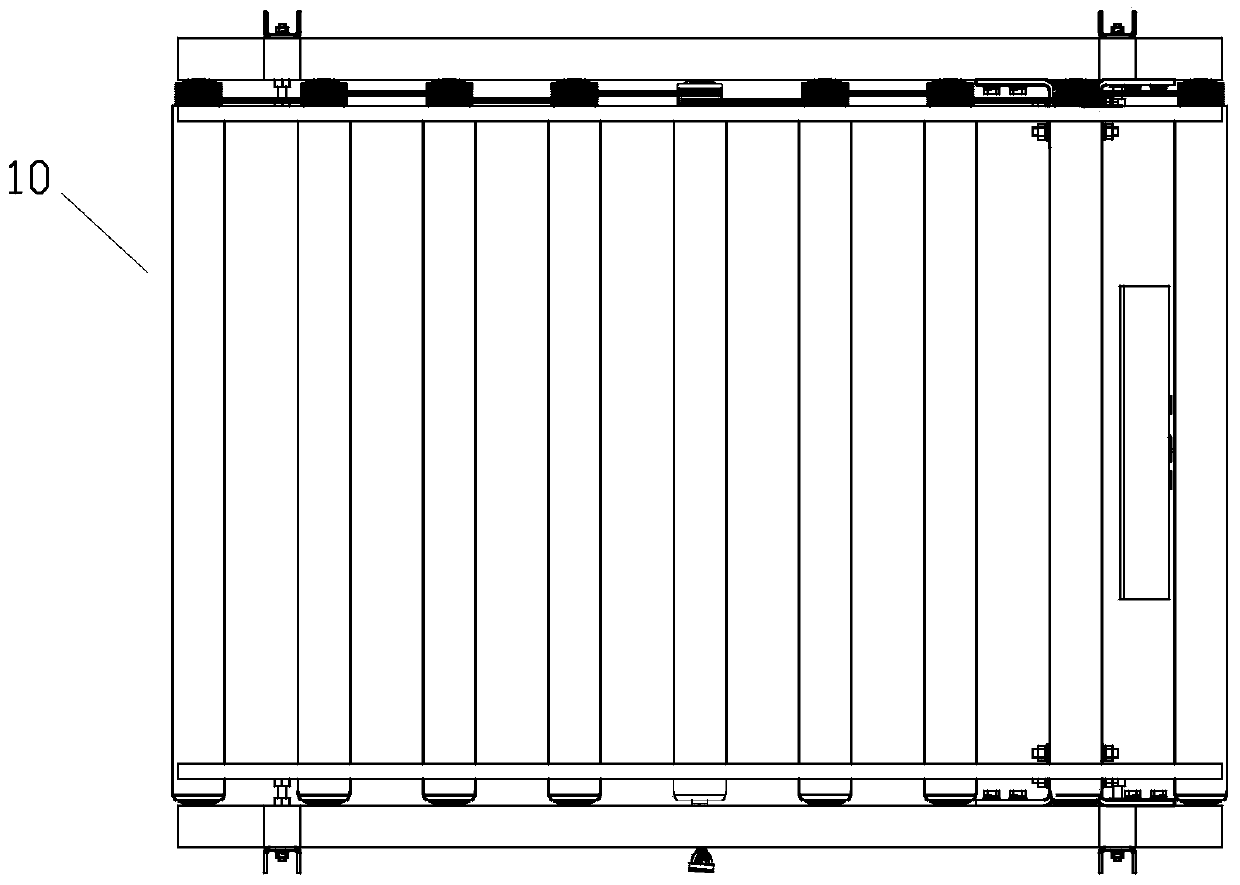

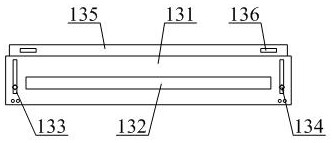

Lateral discharge type tobacco carton sorting device and method

PendingCN107335621ARealize continuous sortingSimplify the sorting processSortingConveyor partsCartonStructural engineering

The invention discloses a lateral discharge type tobacco carton sorting device and method. The lateral discharge type tobacco carton sorting device comprises a sorting substrate (1), wherein more than one tobacco outlet (2) is distributed in the sorting substrate (1); a sorting assembly (3) is arranged at each tobacco outlet (2); a tobacco storage bin (4) is arranged above each sorting assembly (3); each sorting assembly (3) comprises a push plate (31); one end of each push plate (31) is connected with a driving assembly (32); and sliding guide track assemblies (34) are further arranged at two ends of each push plate (31). The invention aims to provide the lateral discharge type tobacco carton sorting device. The lateral discharge type tobacco carton sorting device has the characteristics of simple structure, low cost, simple process and high reliability.

Owner:GUIZHOU HUILIAN TECH LIMITED

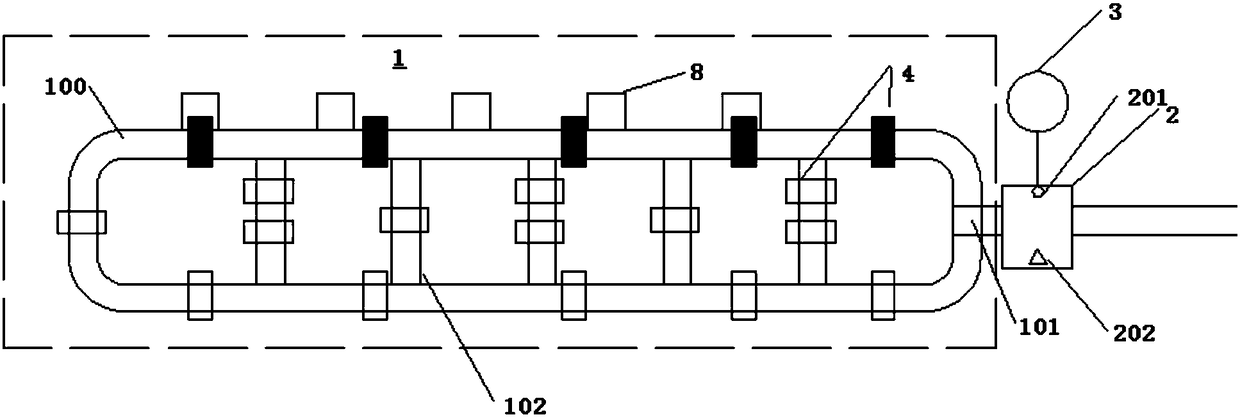

Mail sorting machine for identifying and processing fragile products

InactiveCN108160504AAvoid breakingSmooth sortingSortingProgrammable logic controllerIdentification device

The invention discloses a mail sorting machine for identifying and processing fragile products. The mail sorting machine for identifying and processing the fragile products comprises a mail sorting platform, wherein conveying tracks are arranged on the mail sorting platform, and are two annular tracks arranged in parallel; a plurality of conveying flat-bed trailers operate on the tracks; a mail identifying device and a PLC (Programmable Logic Controller) chip are arranged on an inlet end of the mail sorting platform; and an X-ray detector is arranged in a mail identifying device, and is used for detecting chemical substance information of objects and transmitting the detected information onto the PLC chip. According to the mail sorting machine for identifying and processing the fragile products provided by the invention, through distinguishing whether the fragile products are contained in mails or not, a handle-with-care handling manner is adopted for the fragile products, so that themails are prevented from being broken; and for the mails sorted to a safe product delivery port, a large number of mails are handled quickly and high-efficiently so as to be delivered.

Owner:SUZHOU TABINUO ELECTROMECHANICAL

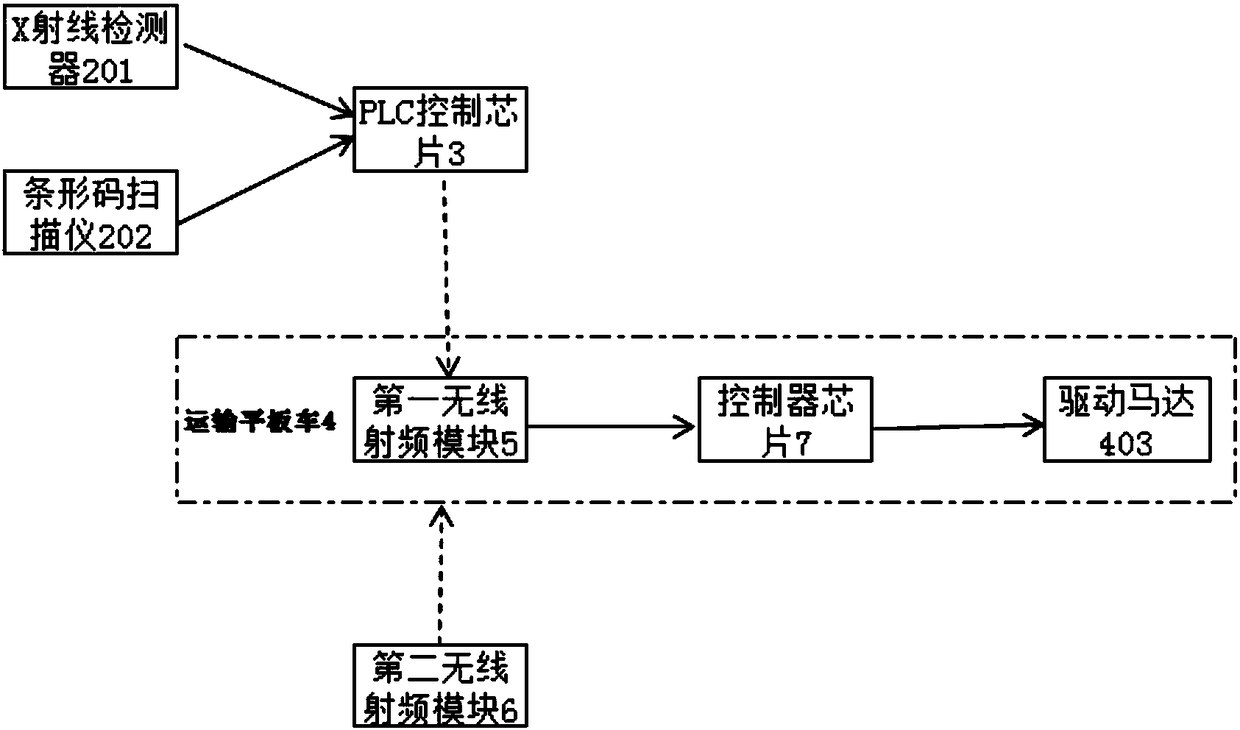

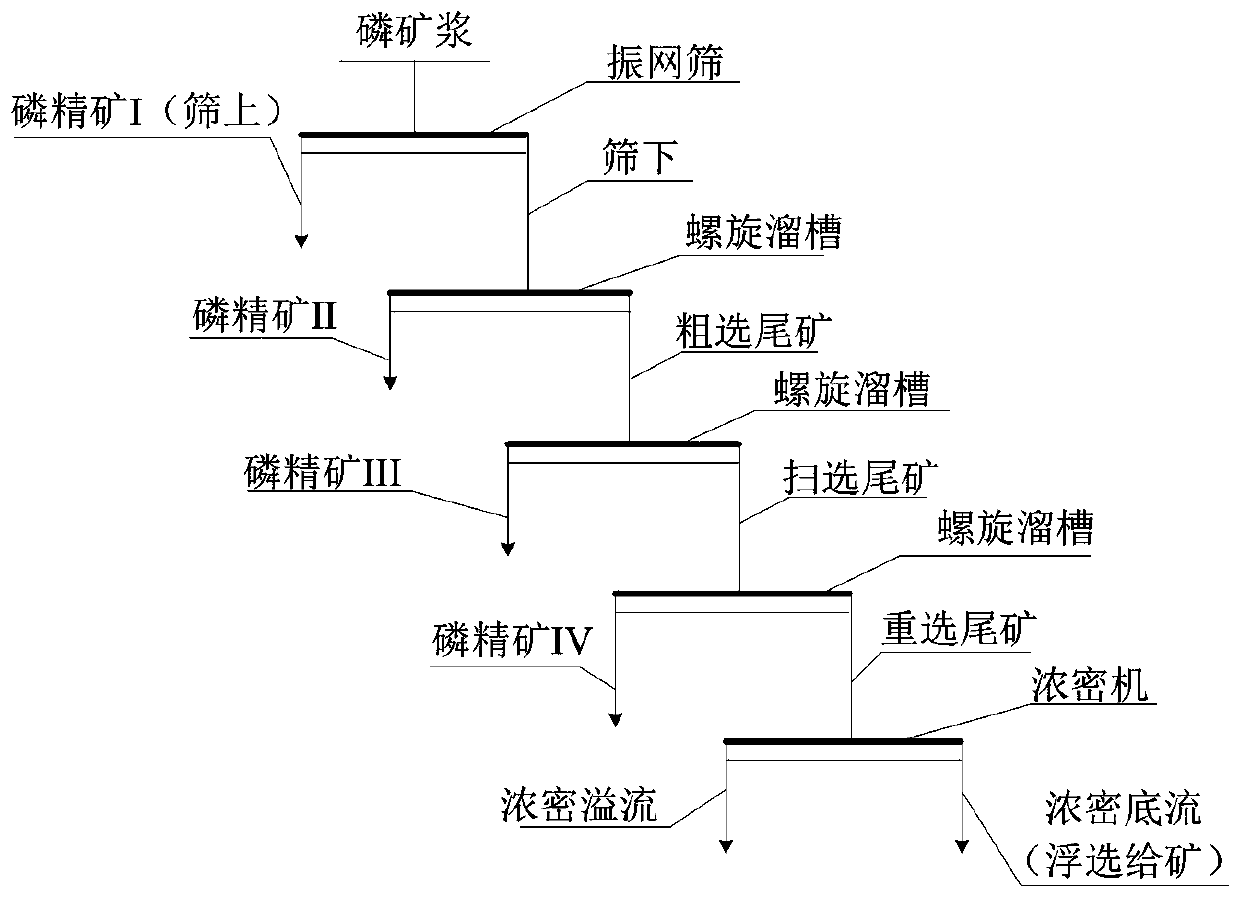

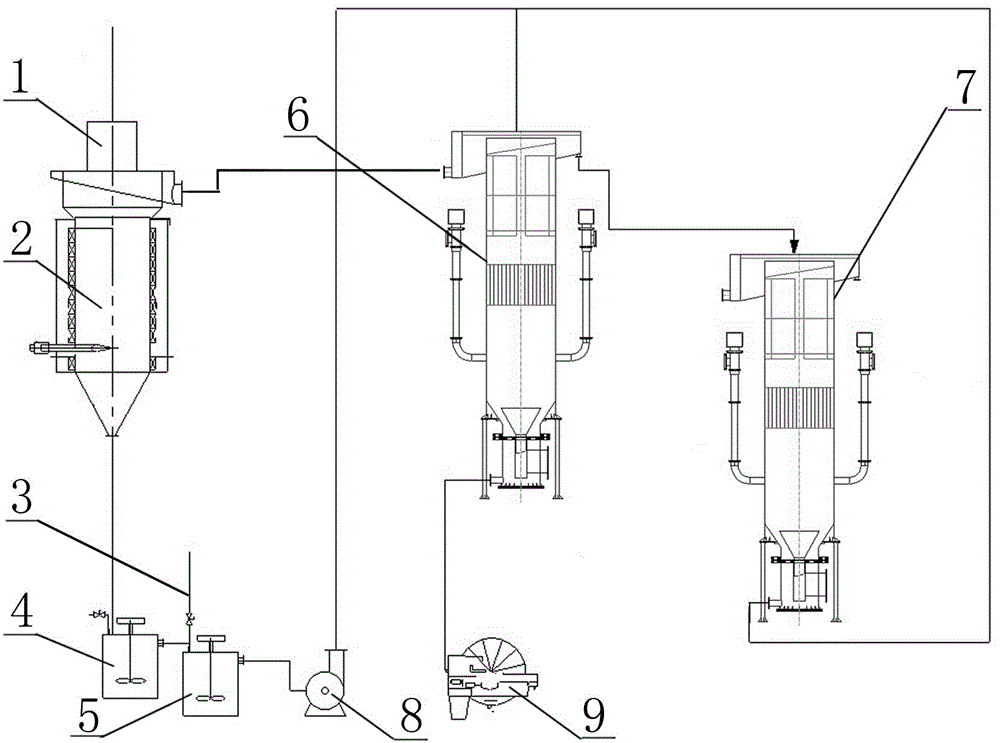

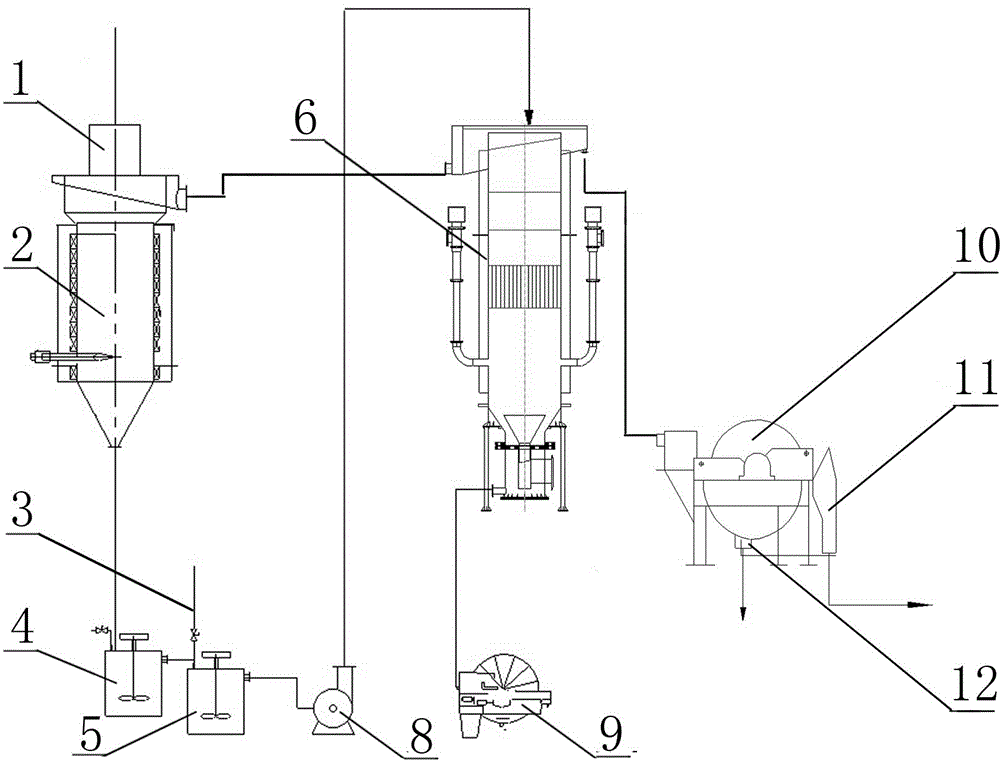

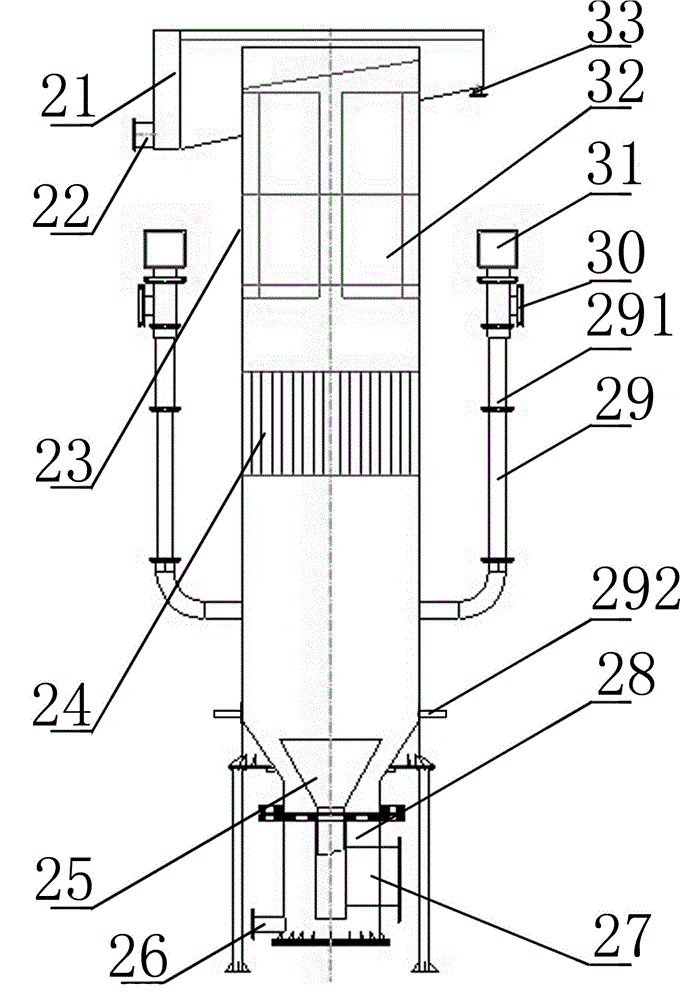

Screening-gravity separation technology added before obverse flotation operation of phosphorite

ActiveCN110369121ADecrease the u/D valueGuaranteed u/D valueFlotationWet separationThree stagePhosphorite

The invention relates to a method for pre-recovering phosphorus through a screening-gravity separation technology added before the obverse flotation operation of phosphorite. According to the technical scheme of the method, phosphorite pulp is fed into a vibrating mesh screen for grading before the obverse flotation operation, an oversize product serves as phosphate concentrate I, an undersize product is fed into a three-stage spiral chute gravity separation technology, first-stage rough separation is carried out so as to obtain phosphate concentrate II and rougher tailings, the rougher tailings are fed into second-stage scavenging so as to obtain phosphate concentrate III and scavenged tailings, the scavenged tailings are fed into third-stage scavenging so as to obtain phosphate concentrate IV and gravity-separated tailings, the gravity-separated tailings are fed into a thickener and are concentrated through the thickener so as to obtain a thick overflow and a thick underflow, the thick underflow is fed into the obverse flotation operation for obverse flotation, the thick overflow serves as circulating water, and the phosphate concentrate I, the phosphate concentrate II, the phosphate concentrate III and the phosphate concentrate IV are combined so as to obtain gravity-separated concentrate. The technology has the advantages that most of phosphorus in the phosphorite is recovered in advance before the obverse flotation operation, and therefore the treatment amount of the obverse flotation operation is effectively decreased, and the production cost of obverse flotation canbe remarkably lowered.

Owner:YIDU XINGFA CHEM COMPANY

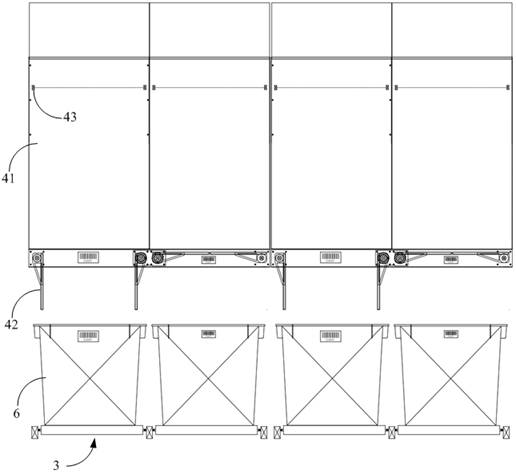

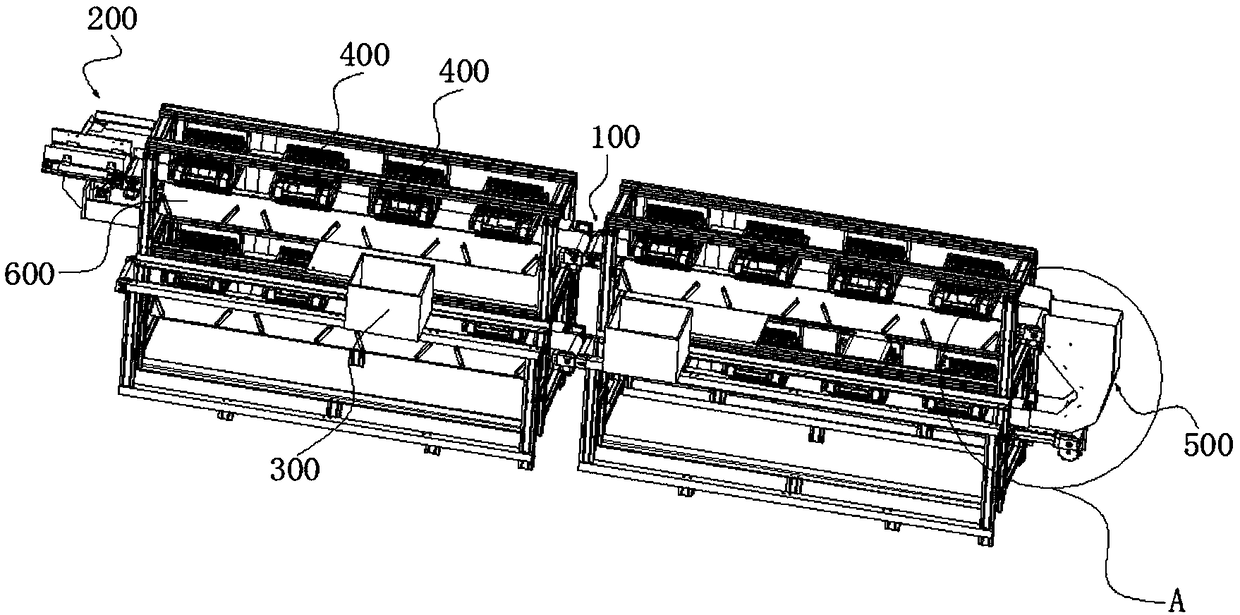

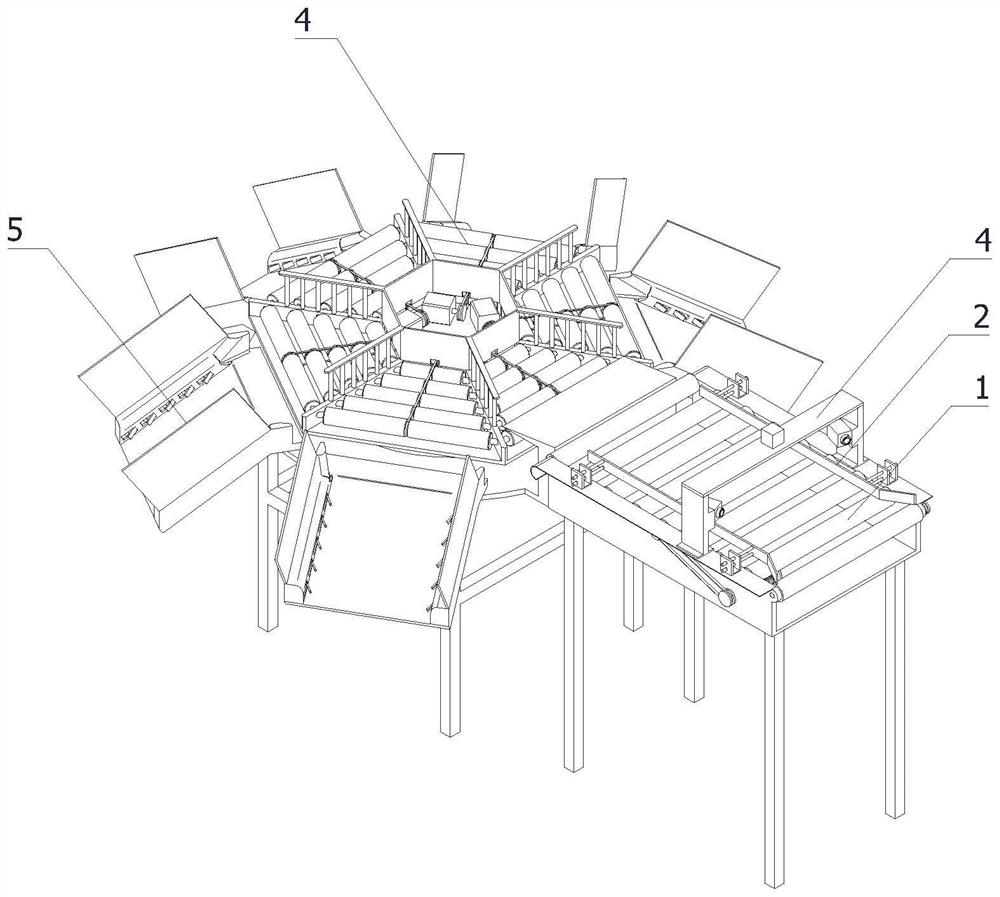

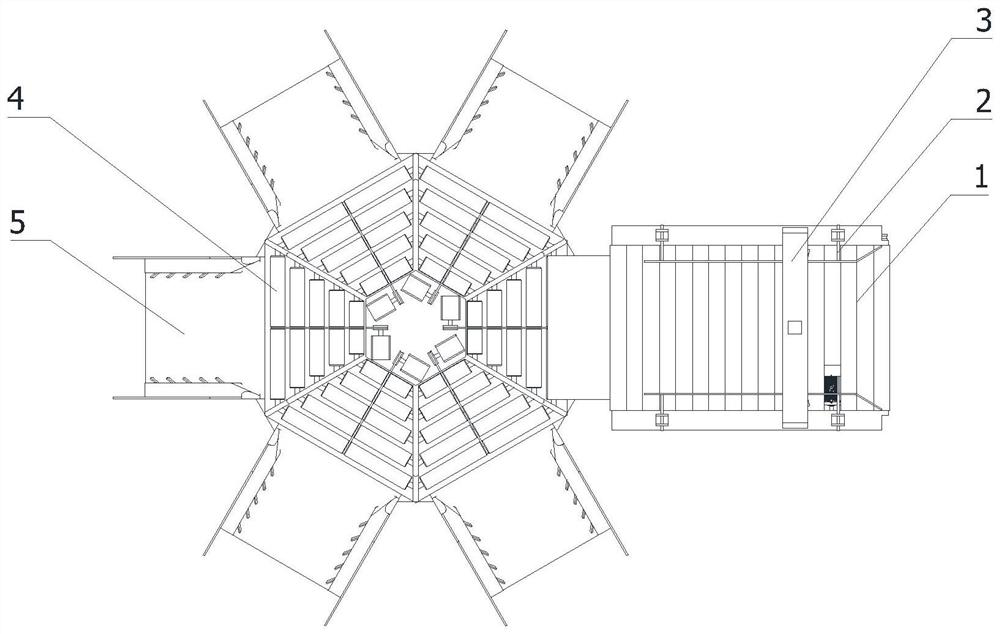

Crossed belt type sorting system and sorting system

ActiveCN112024419ARealize uninterrupted sortingQuick changeSortingStructural engineeringTransfer line

The invention discloses a crossed belt type sorting system which comprises a sorting conveying line. A circulating roller line is arranged below the sorting conveying line, multiple bearing roller lines arranged side by side along the circulating roller line are arranged on the inner side and / or the outer side of the circulating roller line, and a grid storage device is arranged above each bearingroller line. Inlets of the grid storage devices are located on the outer side of the sorting conveying line, and outlets of the grid storage devices are opposite to the corresponding bearing roller lines. Hooking and pushing mechanisms are arranged between the sorting conveying line and the circulating roller line, and when circulation boxes replaced, the circulation boxes are pushed into the bearing roller lines from the circulating roller line through the hooking and pushing mechanisms, or the circulation boxes are hooked and pulled to the circulating roller line from the bearing roller lines. By means of the crossed belt type sorting system, the circulating roller line and the hooking and pushing mechanisms are arranged below the sorting conveying line, so that quick replacement of thecirculation boxes at the positions of grids of the crossed belt type sorting machine can be achieved, uninterrupted use of the grids is further achieved, and the sorting efficiency of the crossed belt type sorting machine is effectively improved.

Owner:深圳市海达威工业自动化设备有限公司

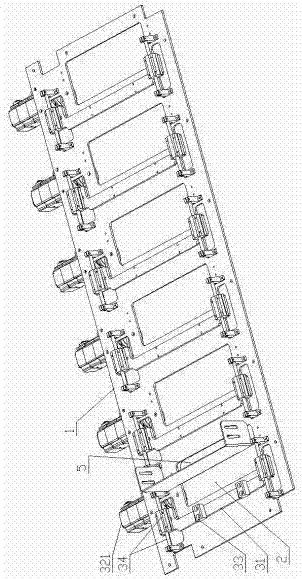

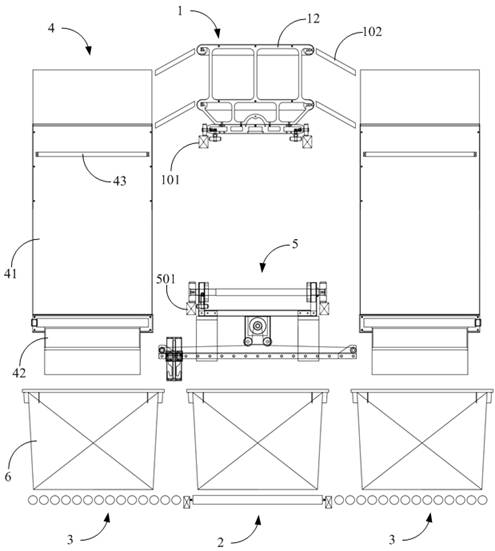

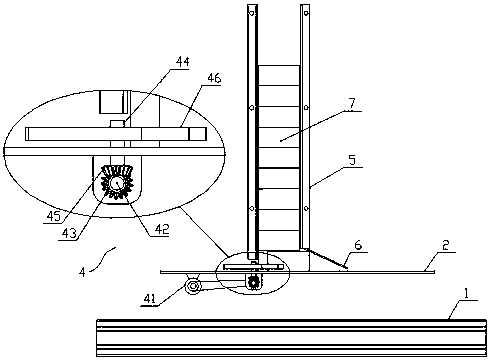

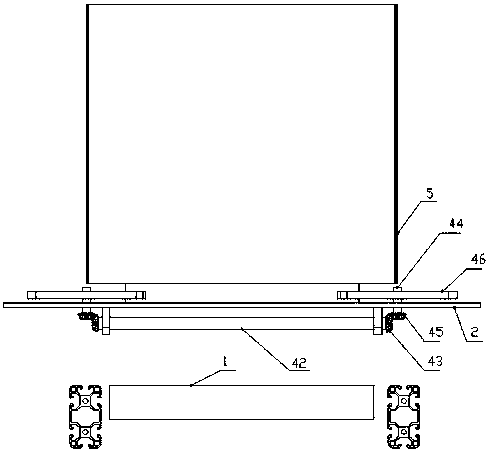

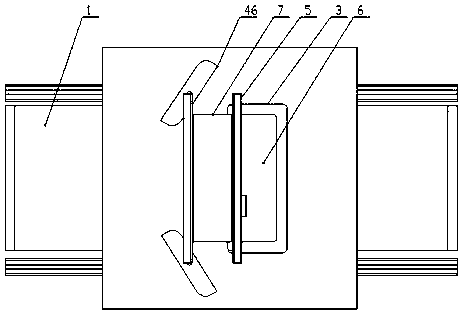

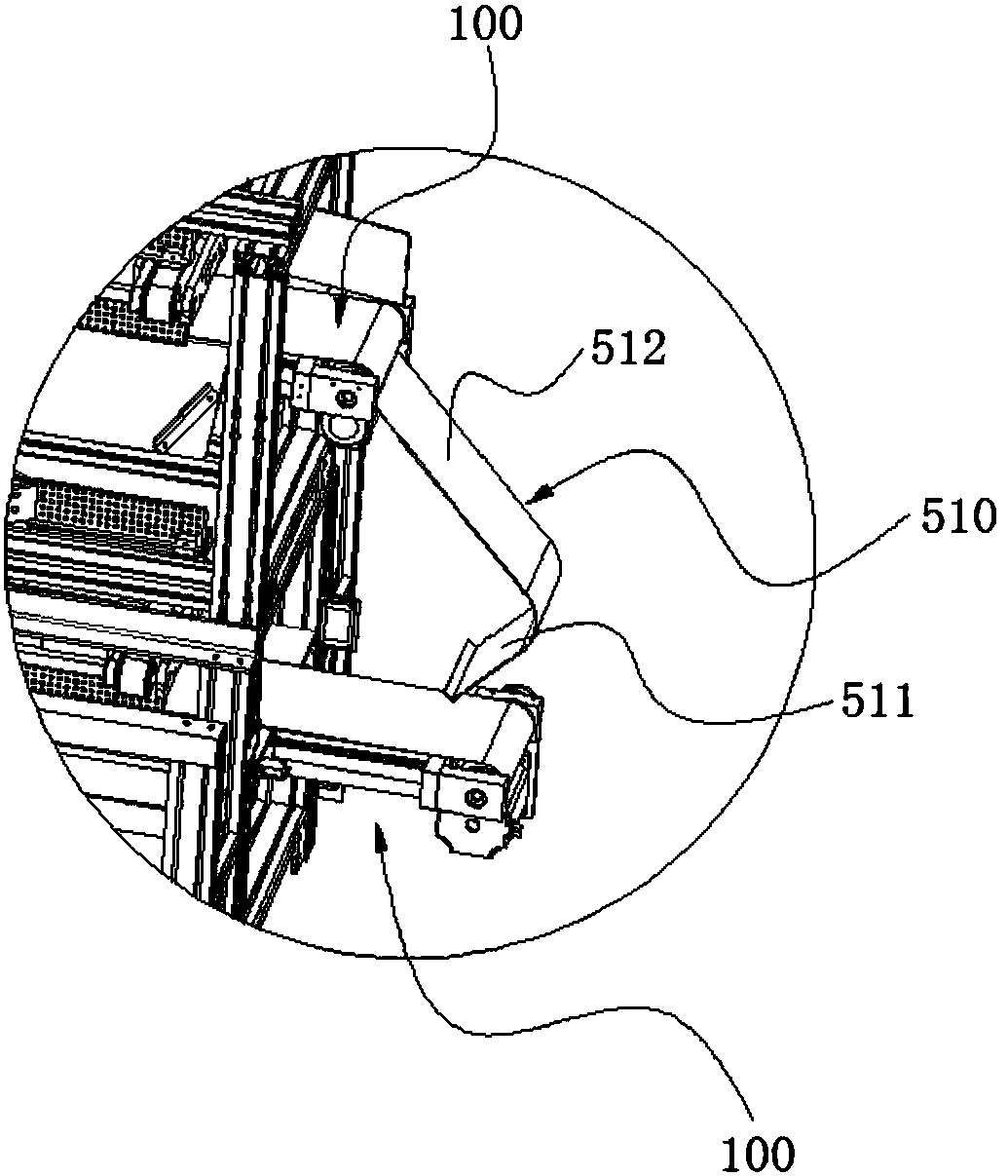

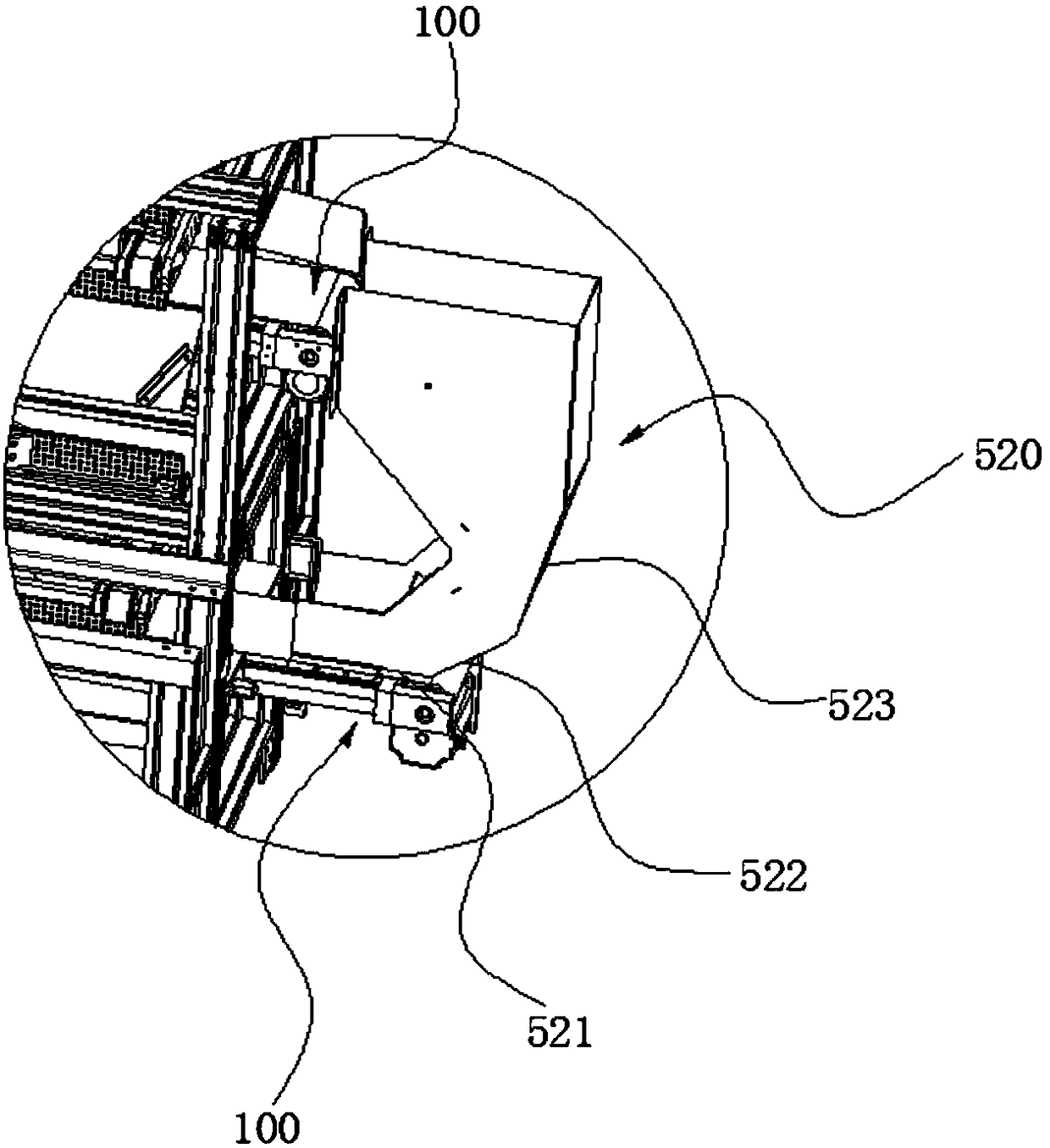

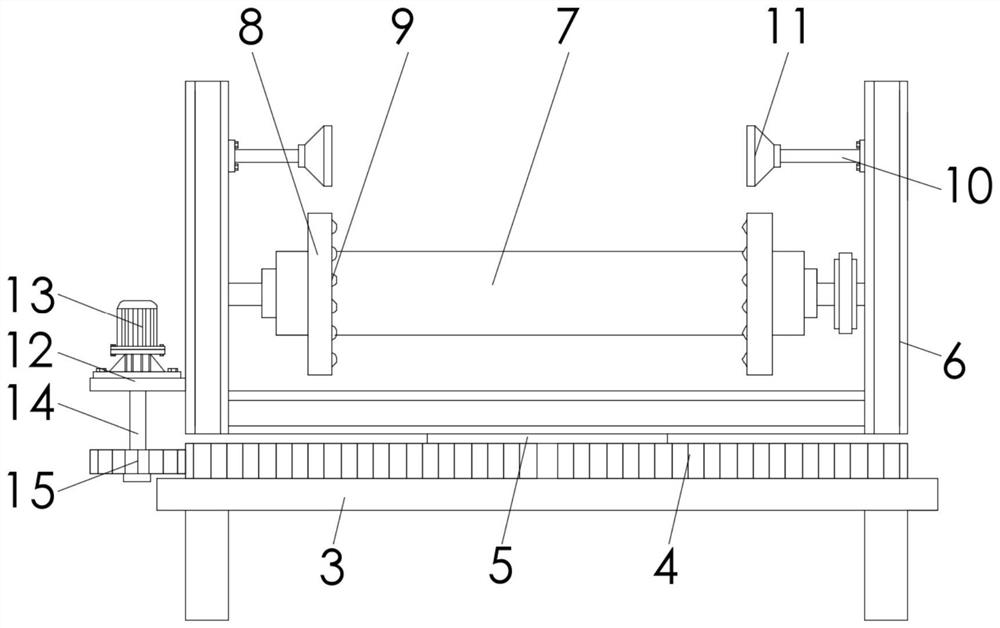

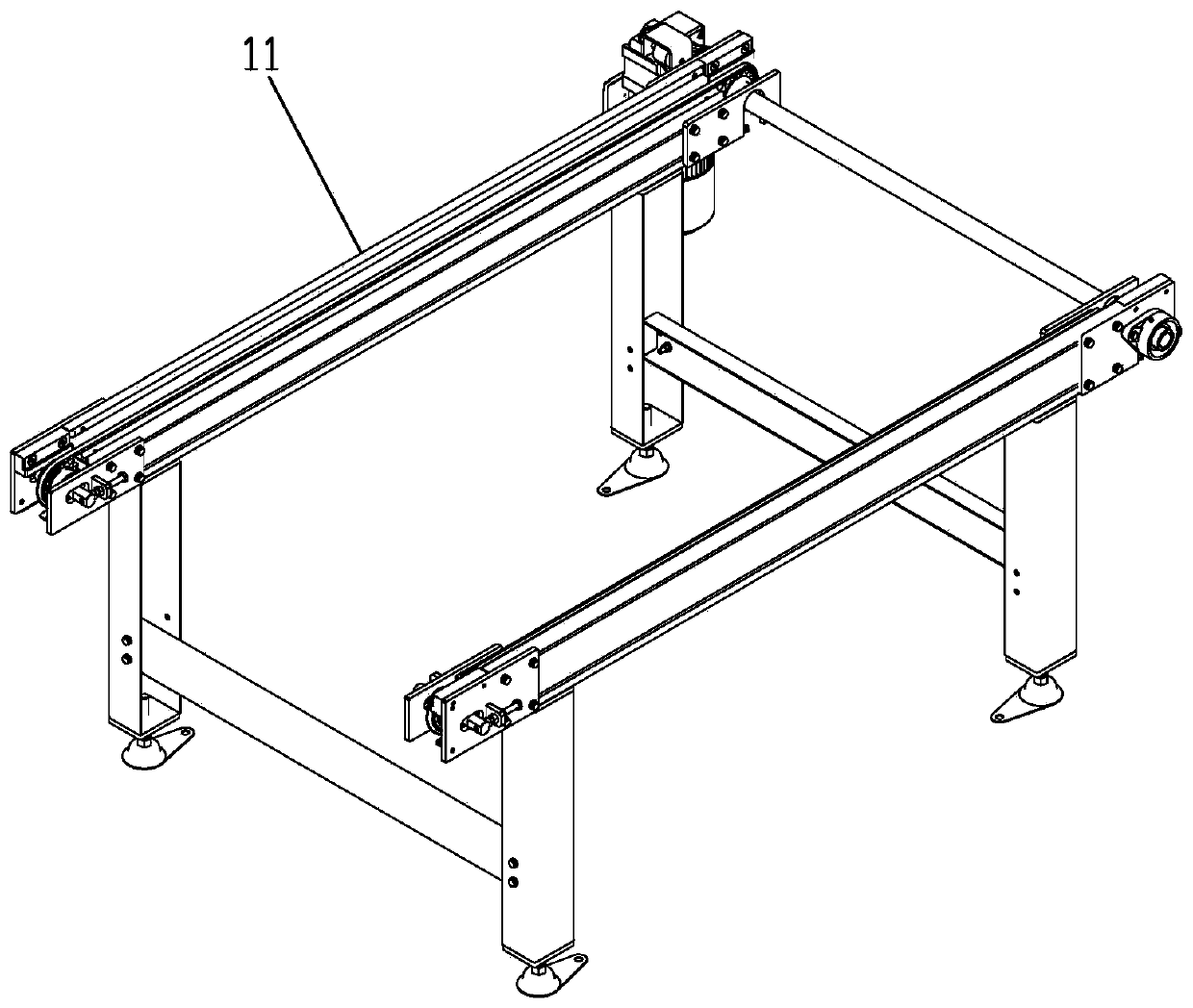

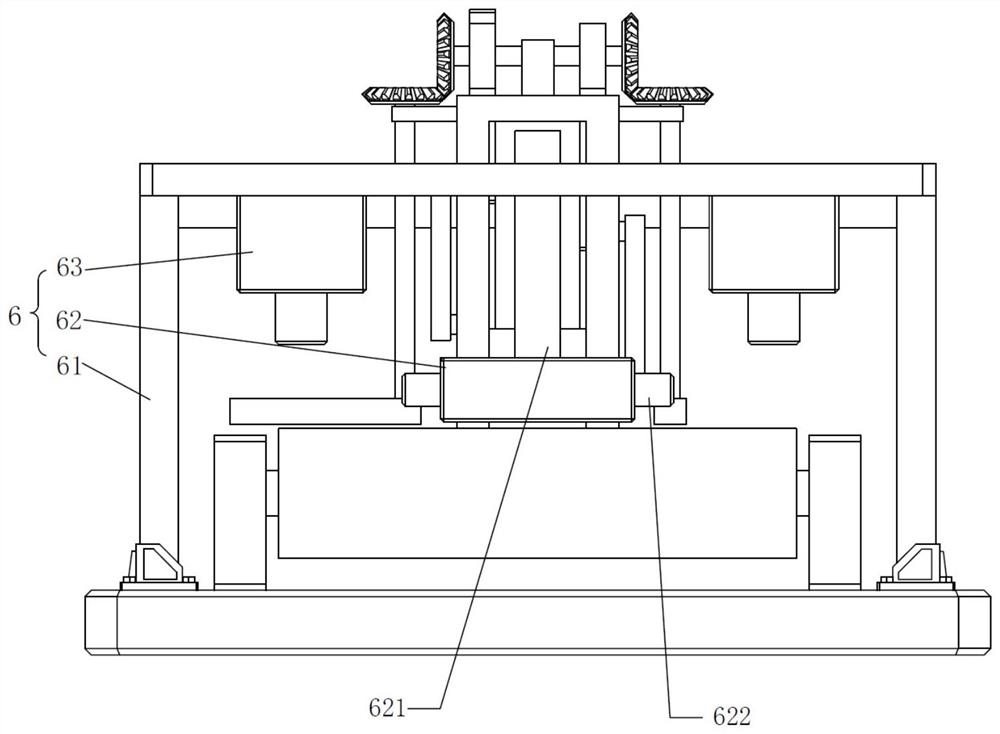

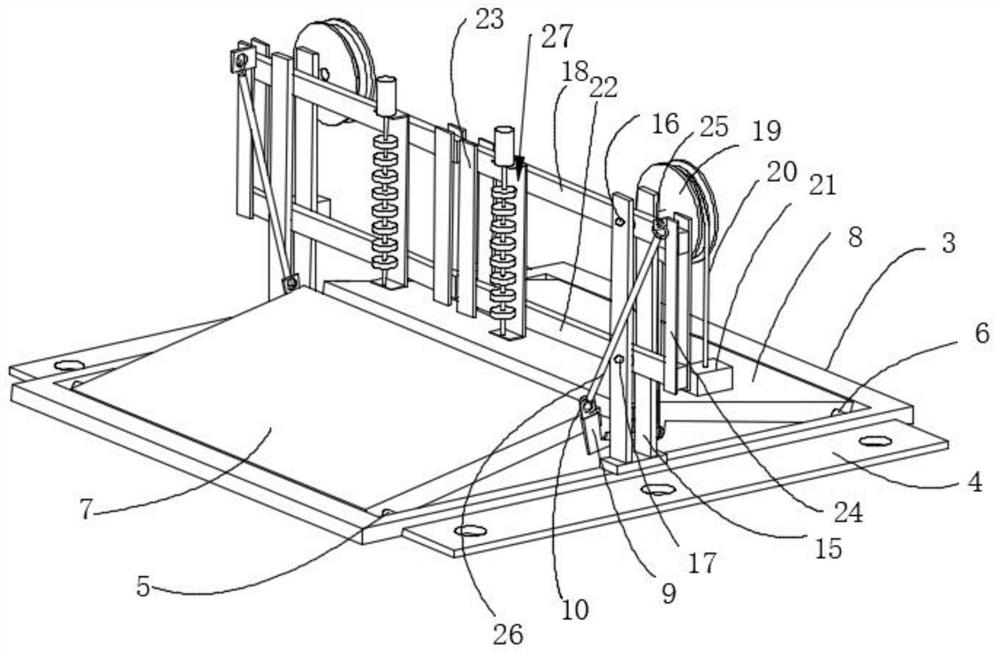

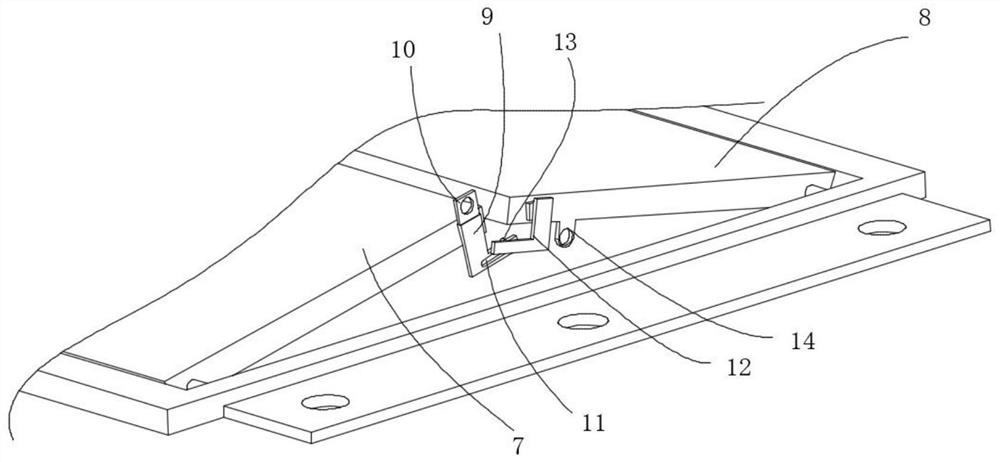

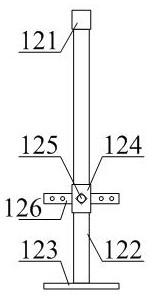

Rotating and pushing type cigarette sorting machine and sorting method

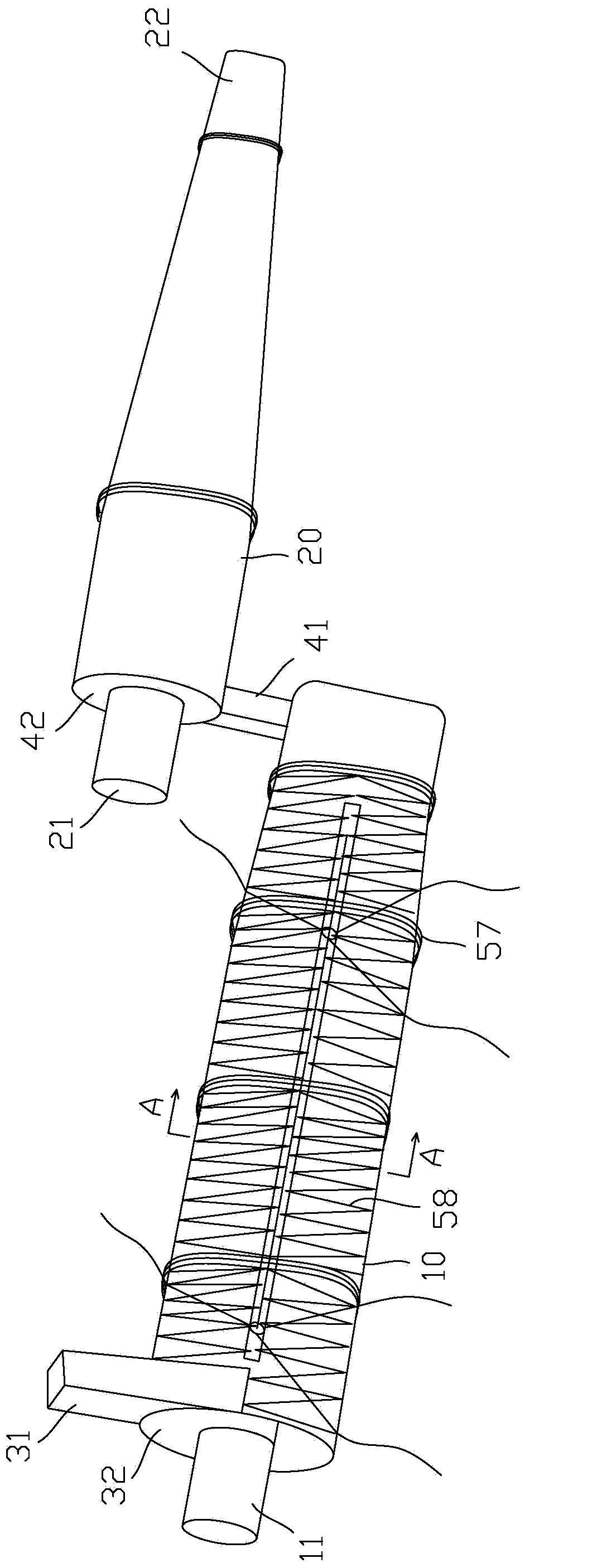

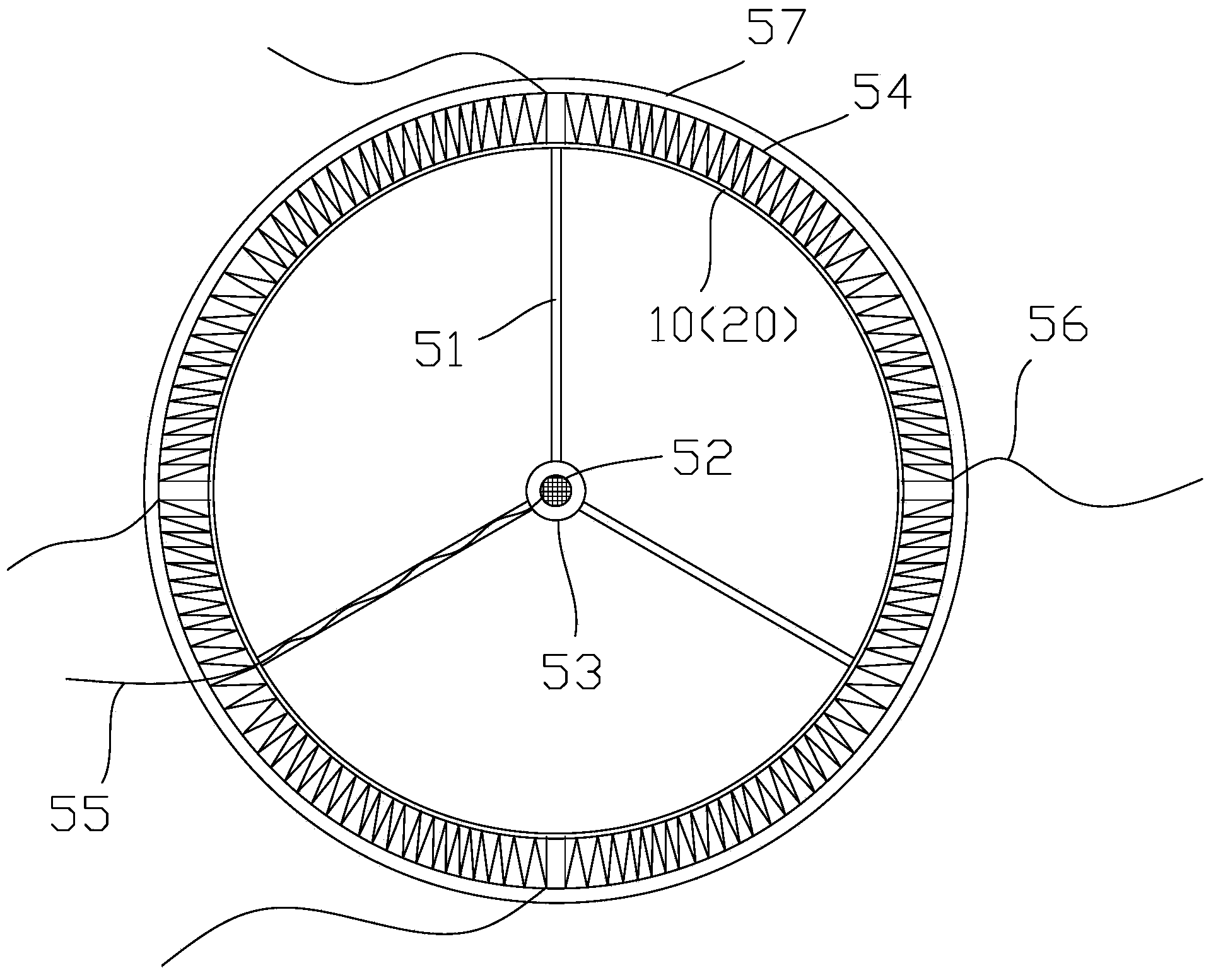

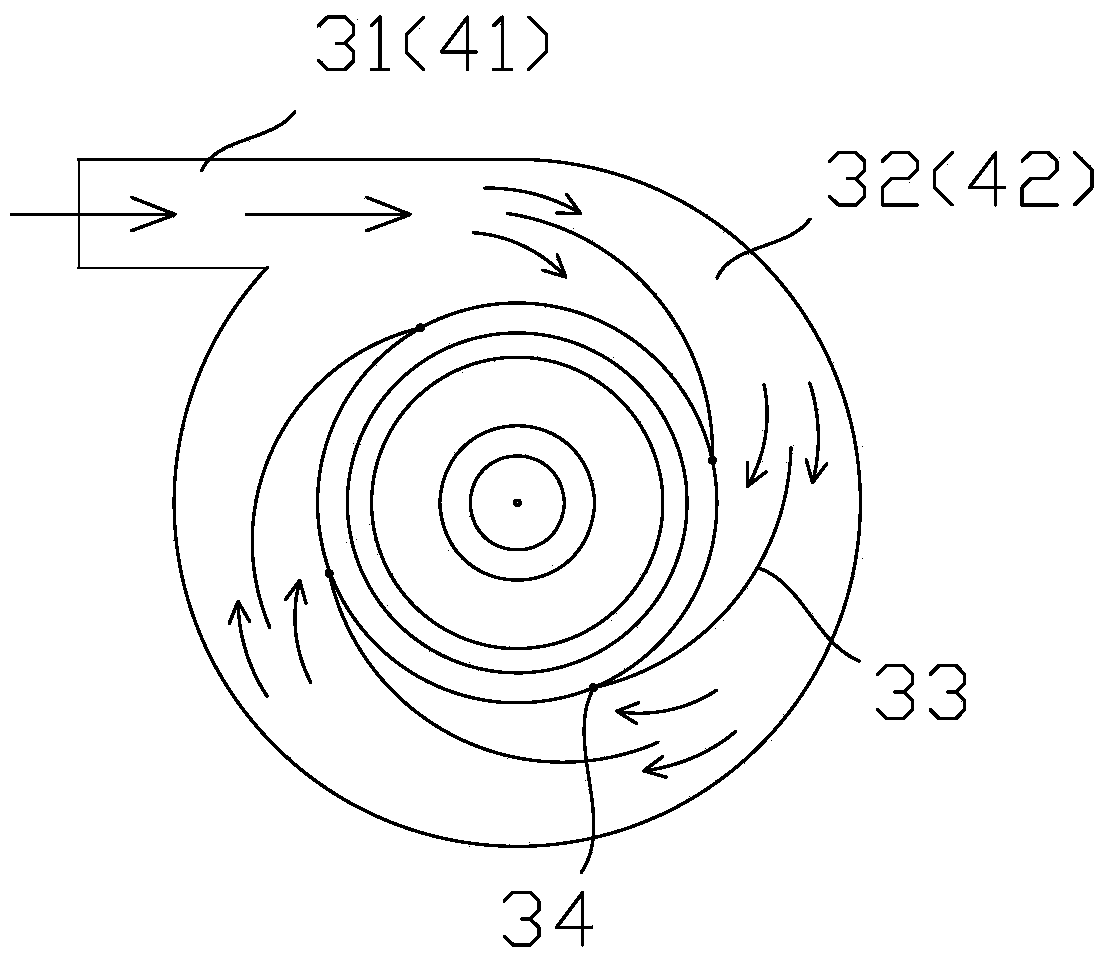

PendingCN107618859ARealize continuous sortingSimplify the sorting processConveyor partsDrive shaftEngineering

The invention discloses a rotating and pushing type cigarette sorting machine and a sorting method. The cigarette sorting machine includes a conveying belt (1). A sorting base plate (2) is installed above the conveying belt (1). A smoke outlet (3) is formed in the sorting base plate (2). A sorting assembly (4) is installed on one side of the smoke outlet (3). A smoke storage warehouse (5) is installed above the sorting assembly (4). The sorting assembly (4) comprises a driving device (41) and the driving device (41) is connected with a driving shaft (42). The driving shaft (42) is movably connected with the sorting base plate (2). Both ends of the driving shaft (42) are provided with driving bevel gears (43). The driving bevel gears (43) are connected with a transmission bevel gear (45). The transmission bevel gear (45) is connected with one end of a rotation shaft (44). The rotation shaft (44) is movably connected with the sorting base plate (2) and the other end of the rotation shaft(44) is connected with a rotation pushing block (46). The rotating and pushing type cigarette sorting machine has the characteristics of being simple in structure, low in cost, simple in working procedure and high in reliability.

Owner:GUIZHOU HUILIAN TECH LIMITED

Drug sorting facility and control method thereof

PendingCN108058973AAccurate sortingQuick sortingControl devices for conveyorsLoading/unloadingMedical equipmentEngineering

The invention provides a drug sorting facility and a control method of the drug sorting facility, relates to the technical field of medical equipment, and aims to solve the technical problem that an existing drug storing facility is low in efficiency and high in error ratio. The drug sorting facility comprises a conveying mechanism, a first driving device, a feeding device, a plurality of materialpush devices and a control module. The conveying mechanism comprises a plurality of conveying belt assemblies. The conveying belt assemblies are set to be at least two layers in the perpendicular direction, and a slideway is arranged between the conveying belt assemblies on every two adjacent layers and used for conveying drugs on the upper layer to the lower layer. Each slideway comprises a smooth cavity, wherein the smooth cavity is used for enabling the drugs to slide down and is matched with the drugs. Each smooth cavity comprises at least one bend. The feeding end of each smooth cavity receives the drugs conveyed by the corresponding conveying belt assemblies on the upper layer, and the discharging end of each smooth cavity is horizontally arranged. The drug sorting facility and thecontrol method of the drug sorting facility can achieve rapid and accurate sorting of the drugs.

Owner:苏州市厚宏智能科技有限公司

Automatic logistics cargo sorting line

InactiveCN111661612ARealize scanningAvoid unrecognized situationsConveyor partsPictoral communicationLogistics managementElectric machinery

Owner:江苏通四海物流有限公司

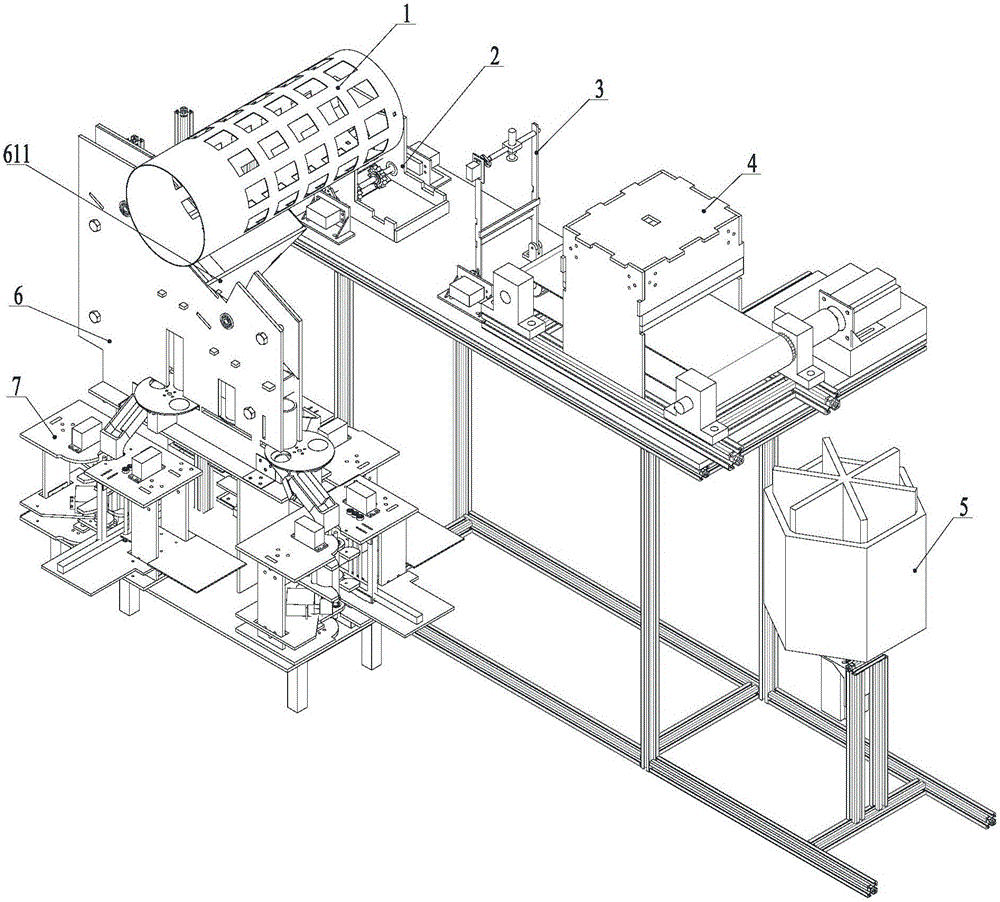

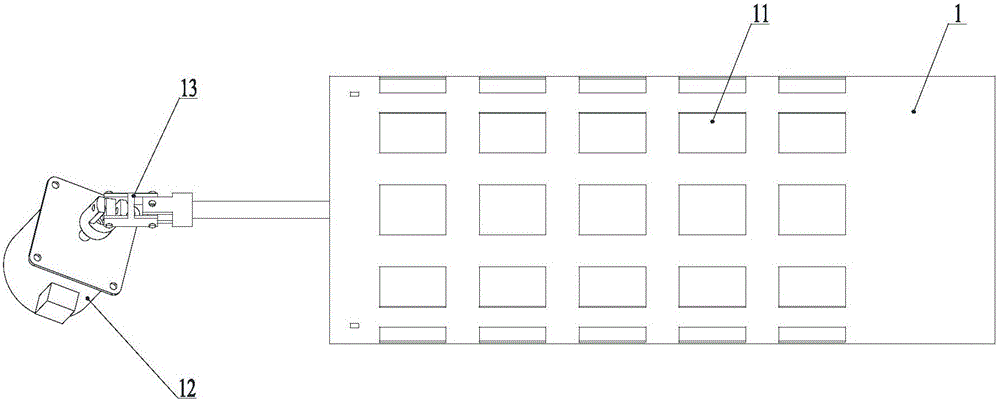

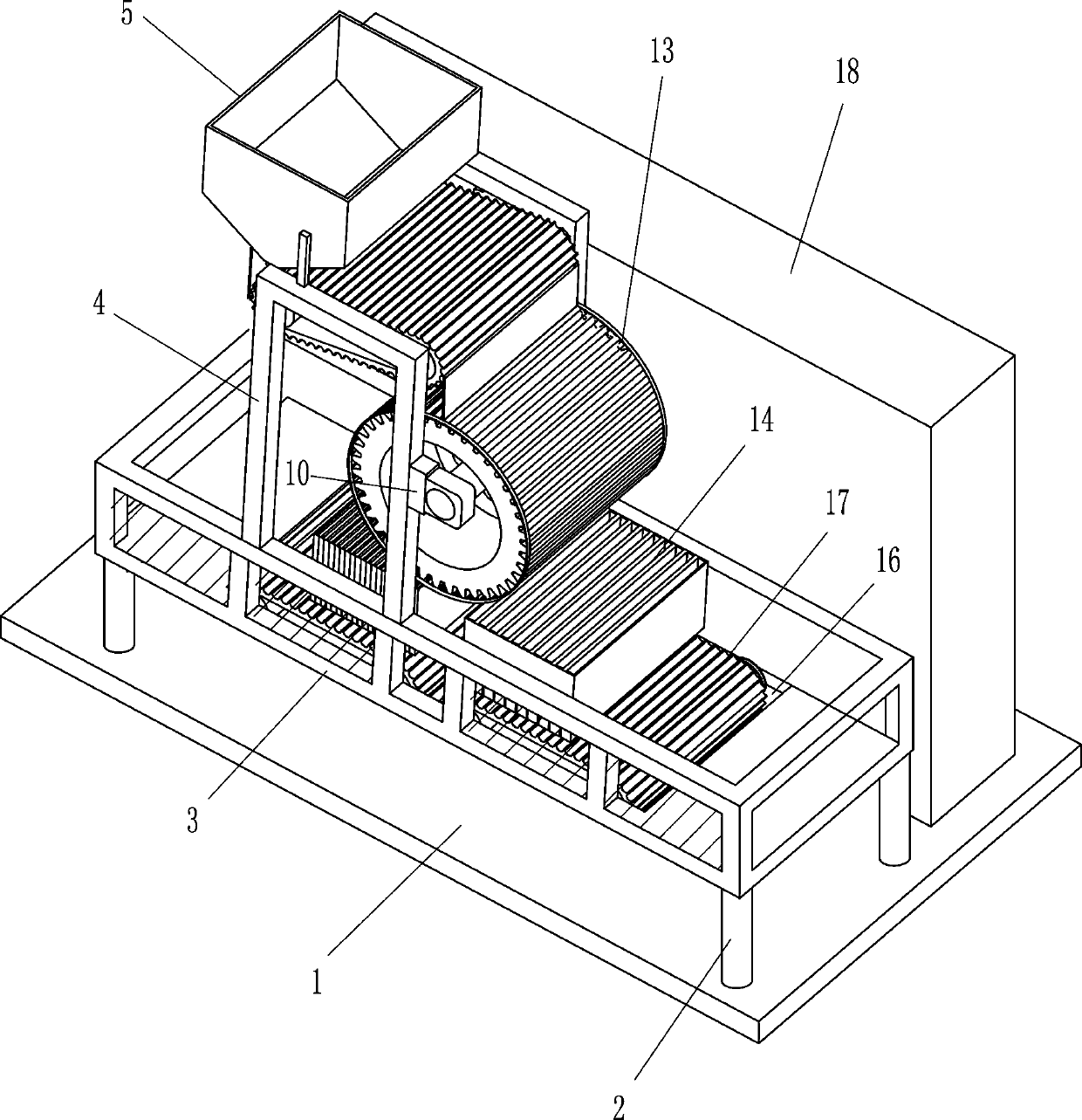

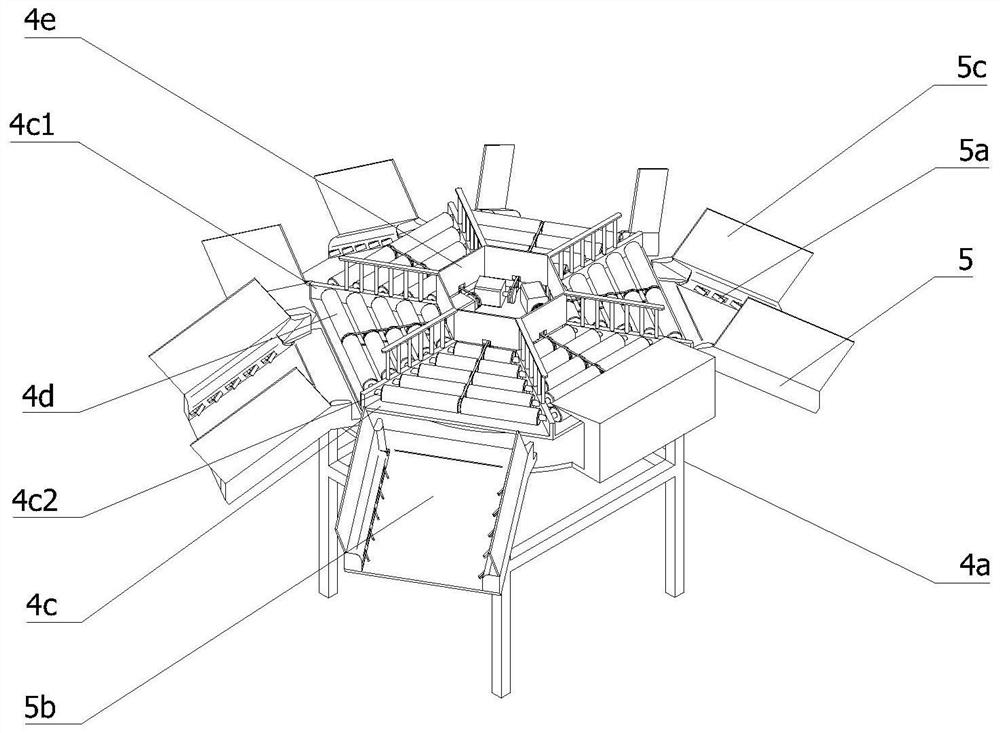

Automatic cocoon harvesting assembly line used in industrial silkworm breeding operation

PendingCN111109209AIn line with the development conceptImprove cocoon harvesting efficiencyAnimal husbandryAgricultural scienceAgricultural engineering

The invention discloses an automatic cocoon harvesting assembly line used in industrial silkworm breeding operation. The automatic cocoon harvesting assembly line comprises a breeding frame tray disassembling machine, a frame-bottom cocoon harvesting machine and a cocoon harvesting machine, wherein the breeding frame tray disassembling machine splits a breeding frame assembly into breeding frames;the breeding frame tray disassembling machine is connected with the frame-bottom cocoon harvesting machine; the frame-bottom cocoon harvesting machine sweeps the bottoms of the breeding frames; the frame-bottom cocoon harvesting machine is connected with the cocoon harvesting machine; and the cocoon harvesting machine sweeps cocoon cages. Aiming at the defects in the existing cocoon harvesting technology, the invention designs a set of automatic cocoon harvesting assembly line, and an assembly line type cocoon harvesting process is realized through the breeding frame tray disassembling machine, the frame-bottom cocoon harvesting machine and the cocoon harvesting machine in sequence, so cocoon harvesting efficiency is greatly improved, and a cocoon harvesting amount in unit time is improved in a doubling manner; the machines for cocoon harvesting all work in an automatic mode, so input labor cost is reduced, expenditure is saved, the development concept of innovative enterprises is met, and human errors caused by manual cocoon harvesting are avoided.

Owner:SHENGZHOU MOSANG HI TECH CO LTD

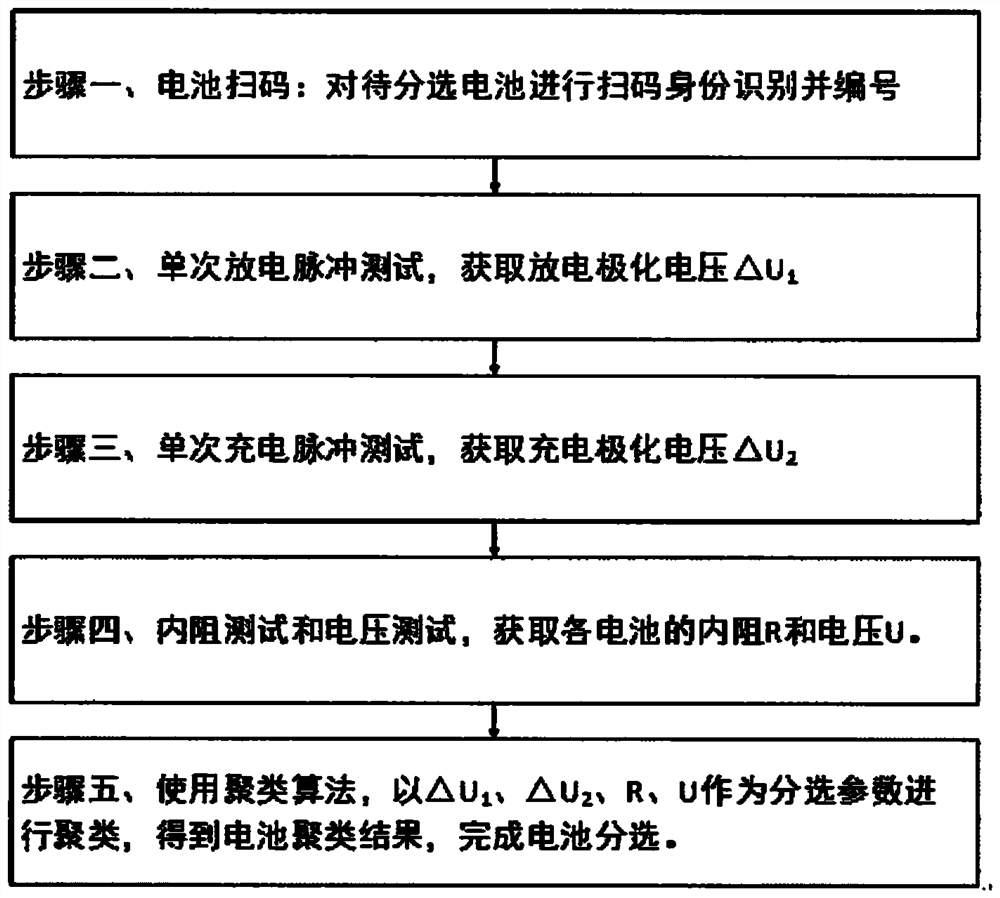

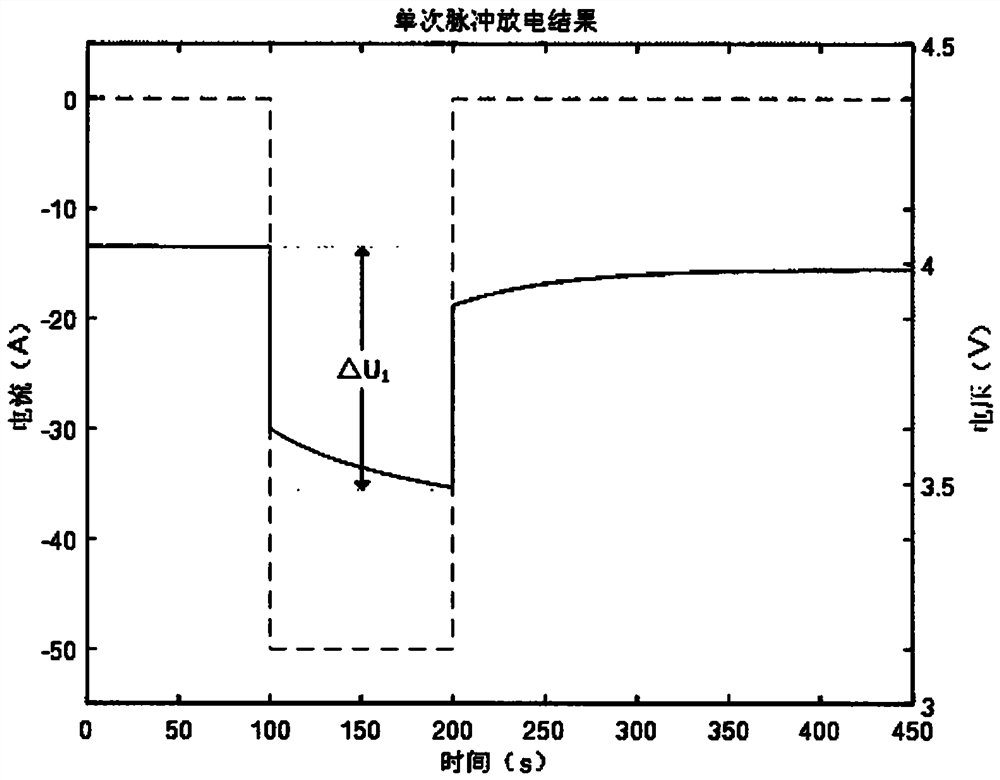

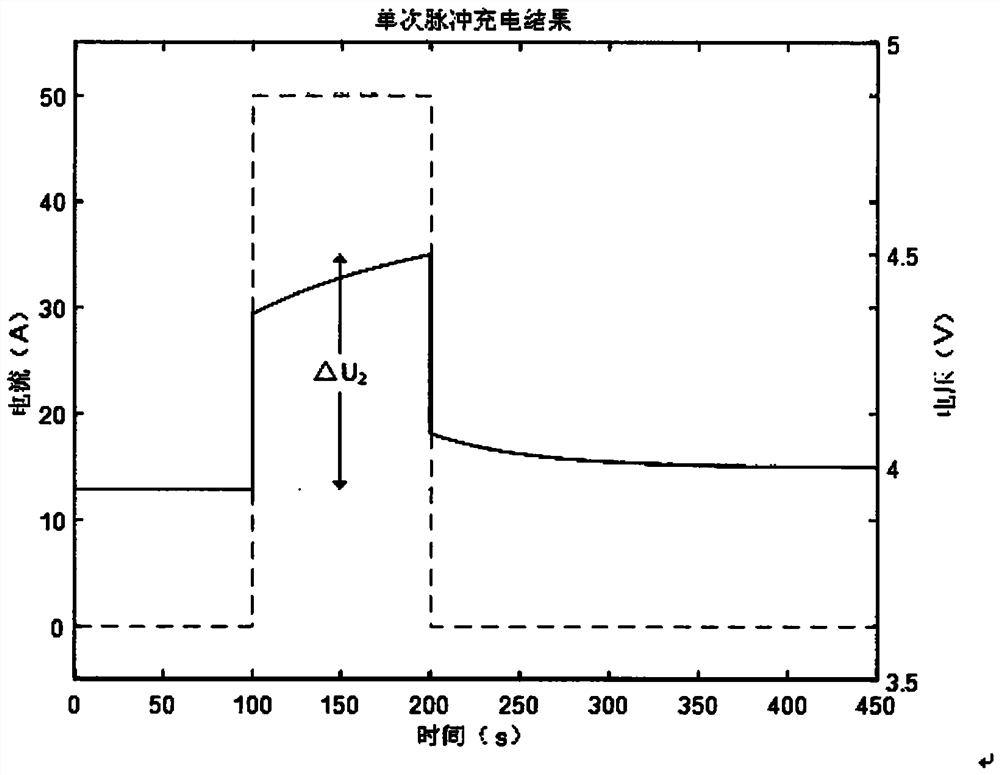

Multi-parameter sorting method for lithium ion power batteries

The invention relates to a multi-parameter sorting method for lithium ion power batteries. The method comprises the following steps that firstly, battery code scanning is carried out, then single discharge pulses and single charge pulses are tested respectively, battery end voltage-time curves are drawn, and difference values delta U1 and delta U2 between initial voltage values and minimum voltagevalues on the curves are extracted to serve as discharge polarization voltages and charge polarization voltages correspondingly, then an internal resistance tester is used for carrying out internal resistance test and voltage test on the tested batteries to obtain an internal resistance R and a voltage U of each battery, and finally delta U1, delta U2, R and U are taken as sorting parameters to carry out clustering to obtain a clustering result of each battery so as to finish battery sorting. According to the multi-parameter sorting method for the lithium ion power batteries, the polarizationvoltages are taken as one of the bases of battery sorting, static parameters such as the battery internal resistances and the battery voltages are combined, lithium battery multi-parameter sorting combining the dynamic characteristics and the static parameters is achieved, high comprehensive consistency is achieved, and meanwhile, the time can be saved, and the sorting efficiency of the batteriesis improved.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV +1

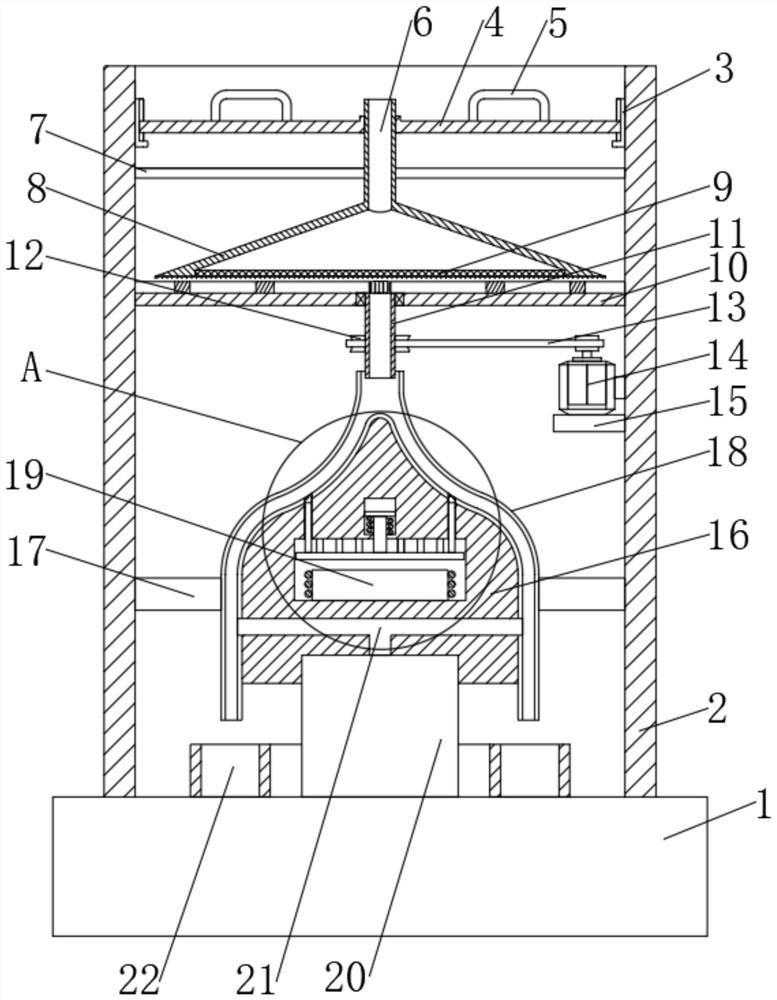

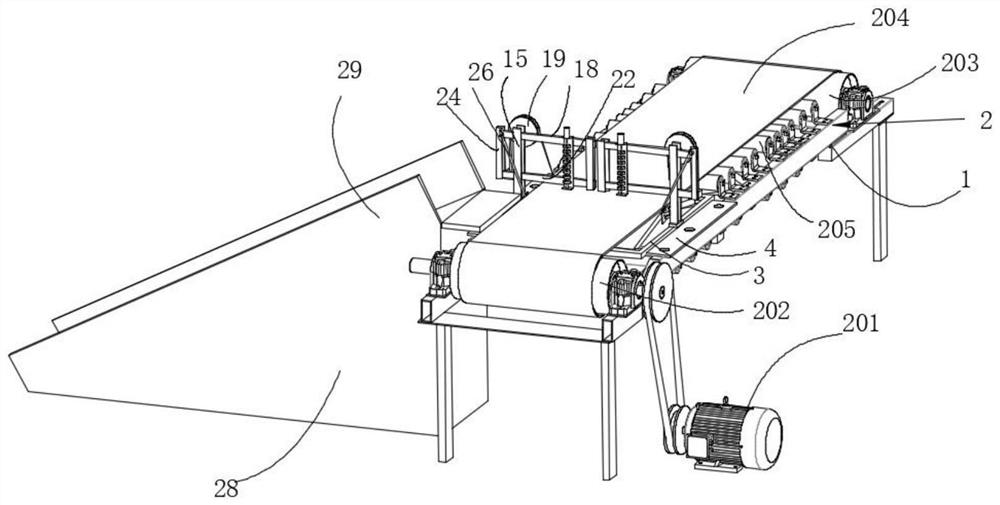

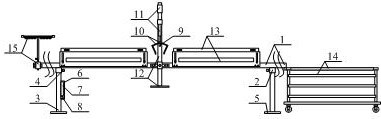

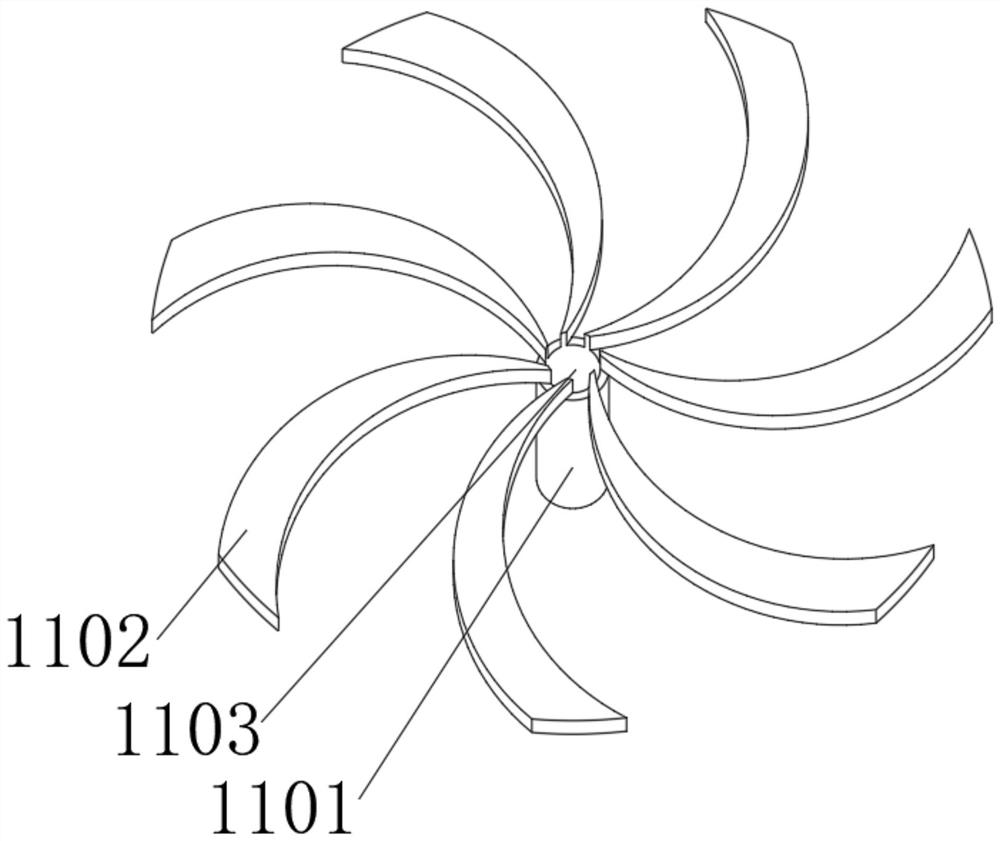

Codonopsis pilosula sorting threading machine

ActiveCN109985812AReduced root stretchGuaranteed sorting efficiencySievingScreeningCodonopsisBall bearing

The invention relates to a threading machine, in particular to a codonopsis pilosula sorting threading machine. The technical scheme aims to provide a codonopsis pilosula sorting threading machine capable of automatically stringing and rapidly screening, according to the technical scheme, the codonopsis pilosula sorting threading machine comprises a bottom plate, a support, a mounting frame, an N-shaped frame. a discharging frame, a baffle, a first roller, a first conveying belt, a driving motor, a deep groove ball bearing and a rotating shaft, wherein the mounting frame is fixedly arranged onthe bottom plate through the bracket, the N-shaped frame is arranged on the left side of the upper portion of the mounting frame, a discharging frame is arranged at the top of the mounting frame, twofirst rollers are rotationally mounted on the upper portion of the mounting frame, and the first roller on the right side is higher than the first roller on the left side. Rapid screening is achievedaccording to the machine, the rolling rod in the discharging frame is assisted to slide down, the extruding roller extrudes the material, the stretching range of the root hairs at the tail part of the codonopsis pilosula is reduced, according to the matching work of the cylindrical gear and the screening frame, the size of the codonopsis pilosula can be sorted, and the double-row threading machine can play a more stable role on threading codonopsis pilosula.

Owner:JIANGXI UNIV OF SCI & TECH

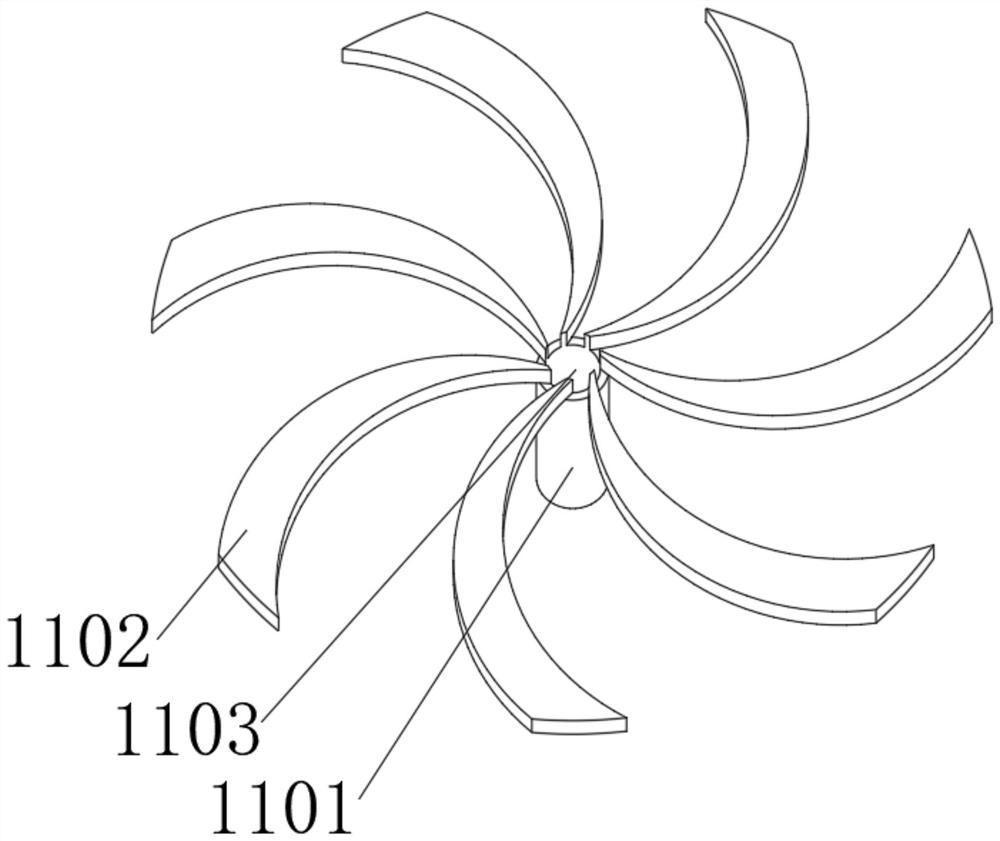

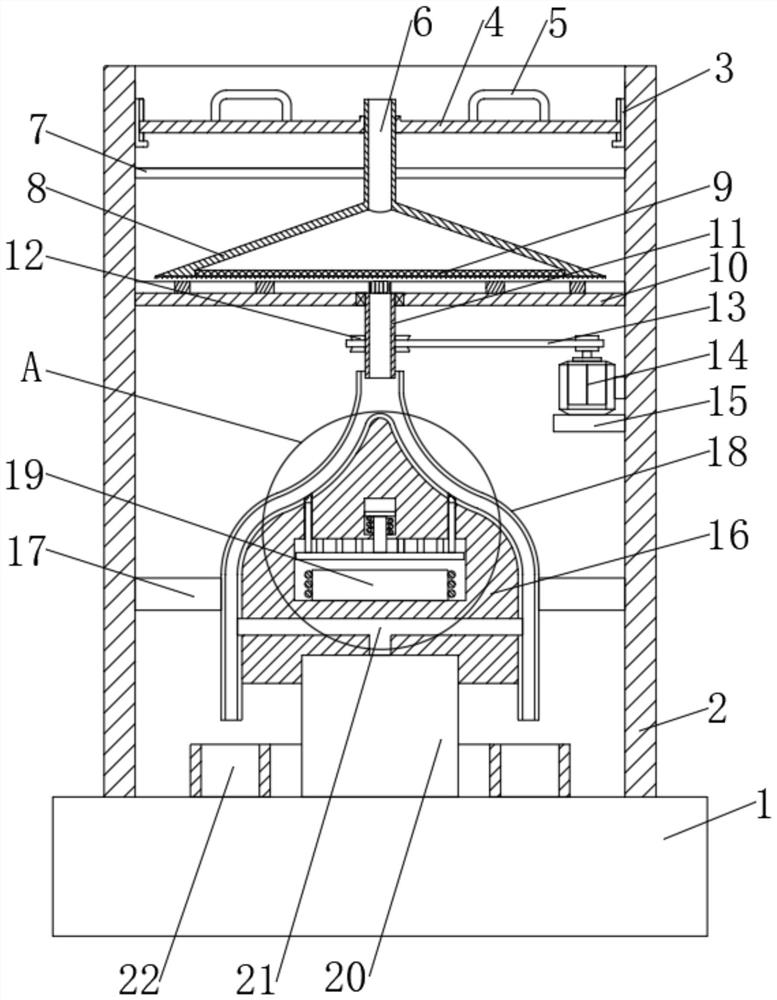

Capsule polishing machine capable of improving sorting precision

ActiveCN111660196AGuarantee the effect of waste removal and sortingGuaranteed sorting efficiencyEdge grinding machinesPolishing machinesEngineeringMechanical engineering

The invention relates to the technical field of pharmaceutical equipment and discloses a capsule polishing machine capable of improving sorting precision. The capsule polishing machine comprises a base, a barrel fixedly connected to the outer side of the upper end of the base, a sliding groove fixedly connected to the upper end of the inner wall of the barrel, an end cover movably sleeved with thesliding groove, handles fixedly connected to two sides of the upper end of the end cover, and supporting rods fixedly connected with the two sides of the inner wall of the barrel are arranged below the sliding groove. When a negative air pressure device in a waste remover of existing capsule polishing equipment absorbs unqualified capsules, due to the fact that a large number of capsules fall down, part of the unqualified capsules located in the middle are prone to being blocked by external qualified capsules and are difficult to be attracted by negative pressure, and the unqualified capsuleson the outer side are easily influenced by the capsules falling from the upper part when being attracted, so that the unqualified capsules are easily not absorbed under the interference of other capsules, a large number of unqualified capsules are mixed into qualified capsules, the screening precision is difficult to guarantee, and great influence is brought to the use of subsequent capsules in the medical treatment process.

Owner:山东赫尔希胶囊有限公司

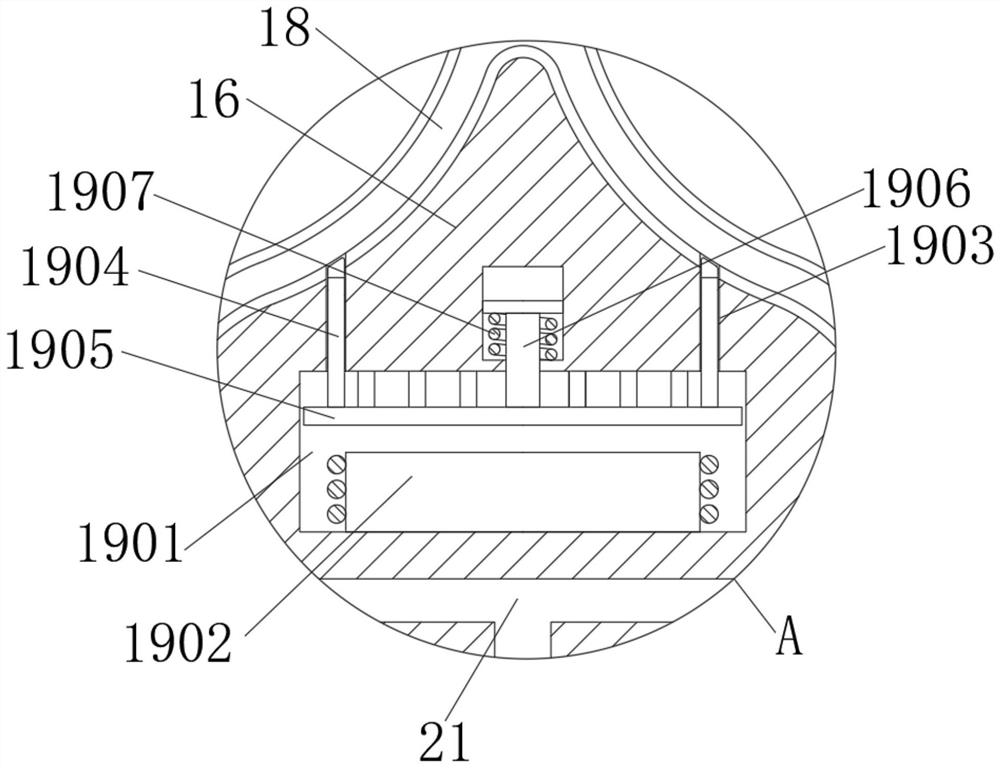

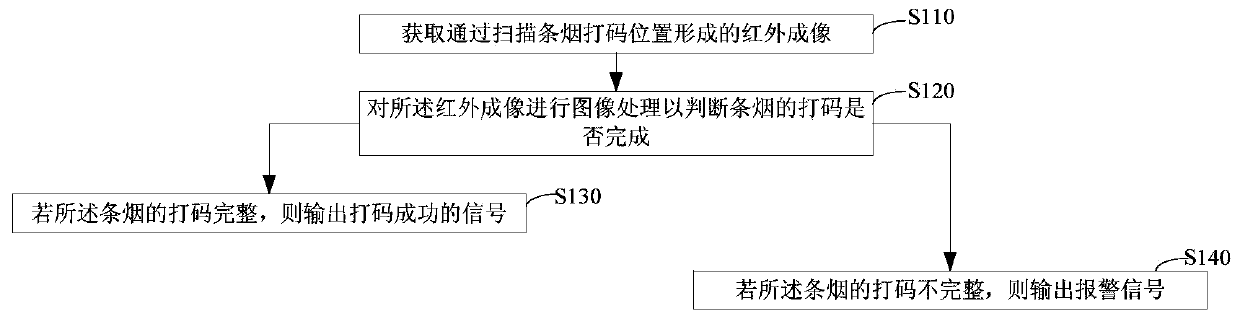

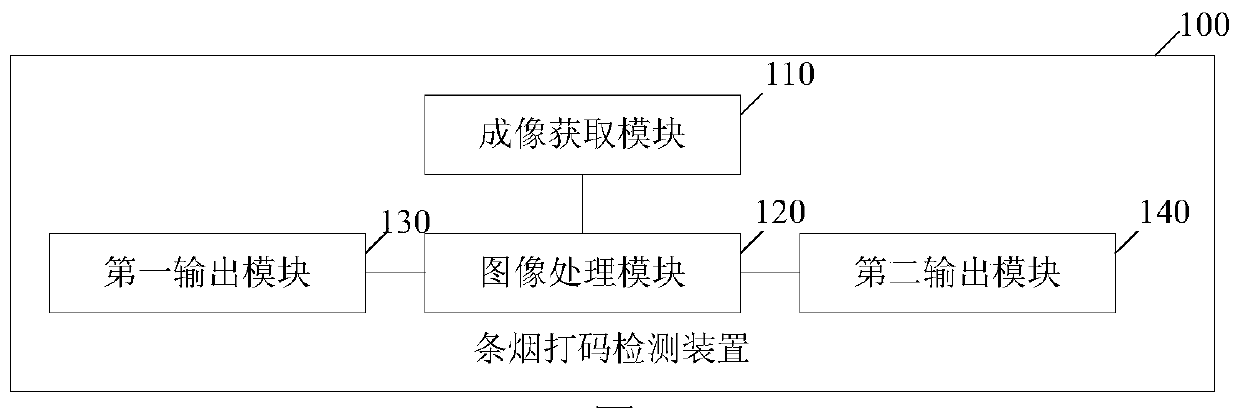

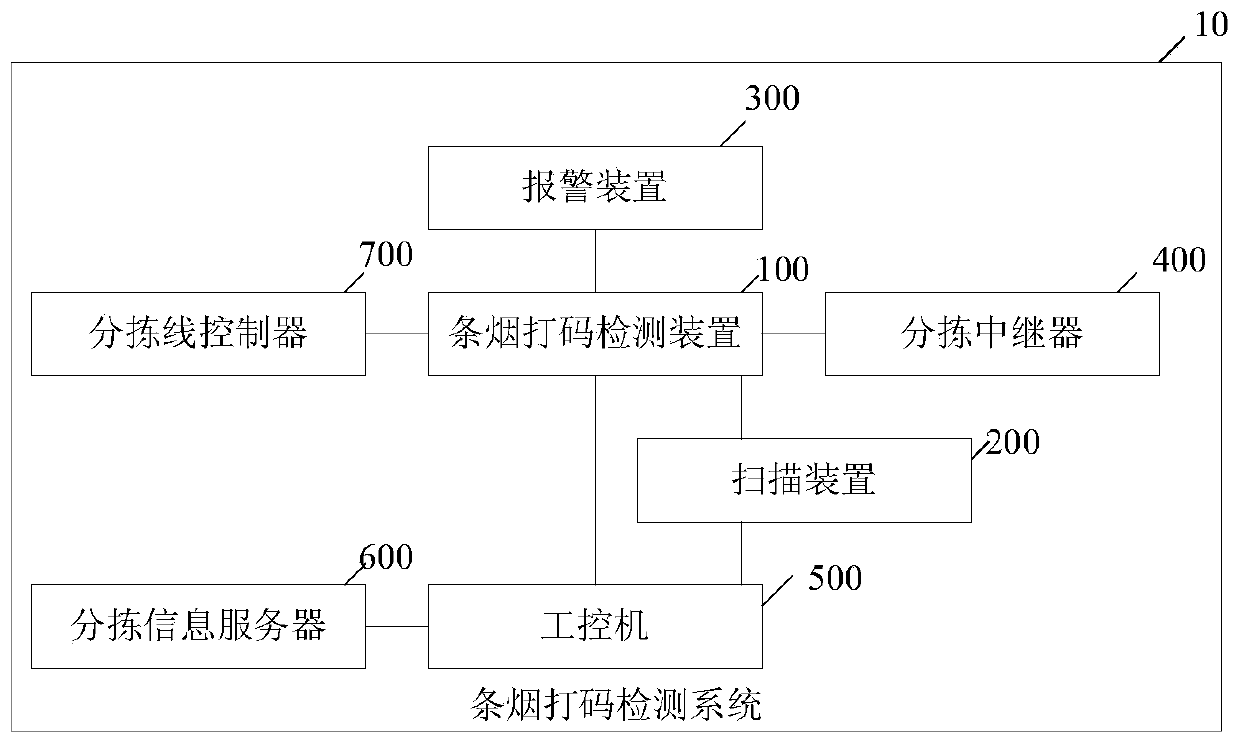

Bagged cigarette coding detecting method, device and system

InactiveCN109894387AReduce reviewReduce logistics costsPackaging cigarettePackaging cigarsSoftwareSmoke

The invention relates to the technical field of bagged cigarette coding detection, and specifically discloses a bagged cigarette coding detection method. The method comprises the steps of acquiring aninfrared image formed by scanning the bagged cigarette coding position; handling the infrared image to determine whether a bagged cigarette is coded; if codes of the bagged cigarette are complete, outputting a signal that the coding is successful; and if the codes of the bagged cigarette are not complete, outputting an alarming signal. The invention also discloses a bagged cigarette coding detecting device and system. With the adoption of the method, the bagged cigarettes with missed codes and incomplete codes can be timely accurately found out, so that the sorting efficiency is ensured, andrelated software and hardware problems can be timely found out, the problems of re-checking and returning caused by the problem of missing of the codes can be decreased on the condition that the sorting efficiency is not influenced, and as a result, the logistics cost is greatly decreased, and the overall efficiency of the logistics work is increased.

Owner:WUXI CO OF JIANGSU TOBACCO CO

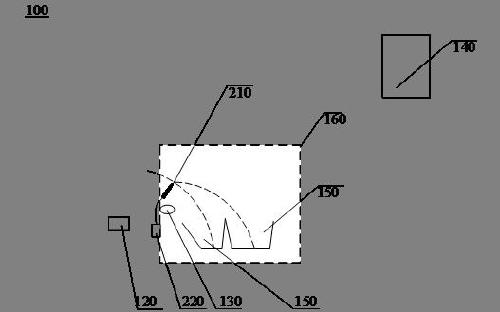

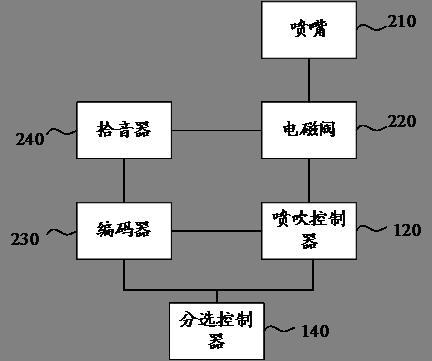

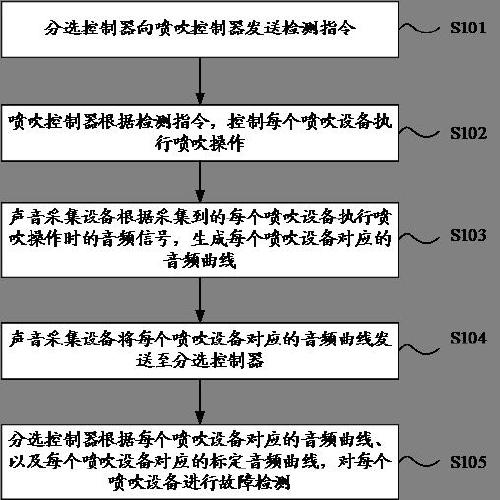

Blowing equipment detection method and material sorting system

ActiveCN111337242AEfficient detectionEfficient automationSubsonic/sonic/ultrasonic wave measurementMachine valve testingComputer hardwareIndustrial equipment

The invention provides a blowing equipment detection method and a material sorting system, and relates to the technical field of industrial equipment detection. The method comprises the steps that a sorting controller sends a detection instruction to a blowing controller; the blowing controller controls each blowing device to execute blowing operation according to the detection instruction; a sound collection device generates an audio curve corresponding to each blowing device according to the collected audio signal when each blowing device executes the blowing operation; the sound collectiondevice sends the audio curve corresponding to each blowing device to the sorting controller; and the sorting controller performs fault detection on each blowing device according to the audio curve corresponding to each blowing device and the calibration audio curve corresponding to each blowing device. Through arrangement of the sound collection device in the material sorting system, acquisition of sound signals of the blowing devices can be realized, so that device fault detection based on the sound signals is realized, efficient and automatic fault detection is realized, and the detection efficiency and the accuracy of a detection result are improved.

Owner:TIANJIN MEITENG TECH CO LTD

Pipelined cocoon harvesting process for industrialized silkworm rearing work

ActiveCN111066746AIn line with the development conceptImprove cocoon harvesting efficiencyAnimal husbandryAnimal scienceZoology

The invention discloses a pipelined cocoon harvesting process for industrialized silkworm rearing work. The process comprises the following steps of (1) splitting a rearing frame group one by one; (2)harvesting cocoons at bottoms of frames; and (3) harvesting cocoons on cocoon cages. A set of pipelined cocoon harvesting process is designed, and is realized by the steps of splitting the rearing frame group one by one, harvesting the cocoons at the bottoms of the frames and harvesting the cocoons on the cocoon cages successively, so that the cocoon harvesting efficiency is greatly increased, and the cocoon harvesting rate in unit time is doubled; and moreover, the cocoon harvesting steps are all automatically realized, and thus, on one hand, the input labor cost is reduced, the expenditureis reduced, and the development idea of an innovative enterprise is met, and on the other hand, human error generated by manual cocoon harvesting is avoided.

Owner:SHENGZHOU MOSANG HI TECH CO LTD

Combined type soybean impurity removal and air-drying device

InactiveCN109092682AEasy to cleanIncreased quick drying efficiencyGas current separationDrying gas arrangementsEngineeringGuide tube

The invention provides a combined type soybean impurity removal and air-drying device. The combined type soybean impurity removal and air-drying device comprises a push rod with a rubber sleeve, a concentric-square-shaped impurity removal and air-drying box, a base, universal wheels with brake pads, soybean anti-jump boards, a center seat, a small grain funnel, a medium grain funnel, a large grainfunnel, a super large grain funnel, a draggable mobile collection barrel structure, a soybean adjustable selection type picking rod structure, a soybean iron impurity inclination adjustable adsorption rod structure, a rapid air intake air-drying tube structure, a detachable dust and fine impurity collection tube structure, a soybean flow guiding tube and a soybean feed hopper. The push rod with the rubber sleeve is installed on the lower right side of the concentric-square-shaped impurity removal and air-drying box in a bolt mode. The concentric-square-shaped impurity removal and air-drying box is mounted on the upper surface of the base in a bolt mode. The combined type soybean impurity removal and air-drying device increases a soybean selection function, realizes the combination function of integrating the removal of iron impurities in soybeans with air drying, and can collect the impurities removed and increases a storage classification function after the soybean sorting.

Owner:郑制强 +4

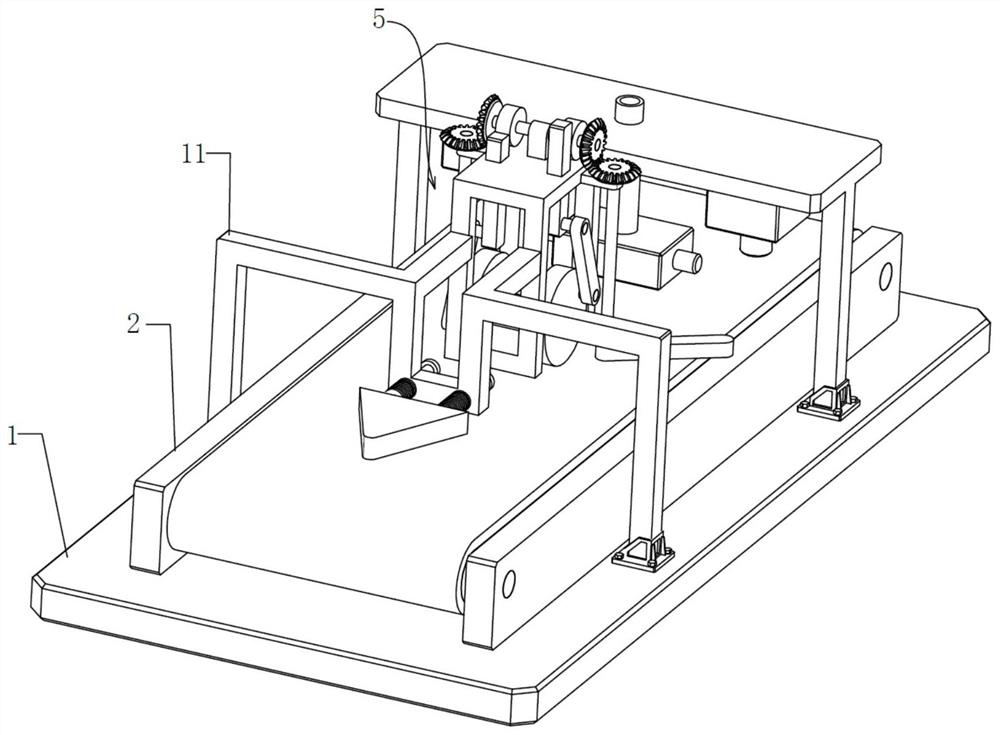

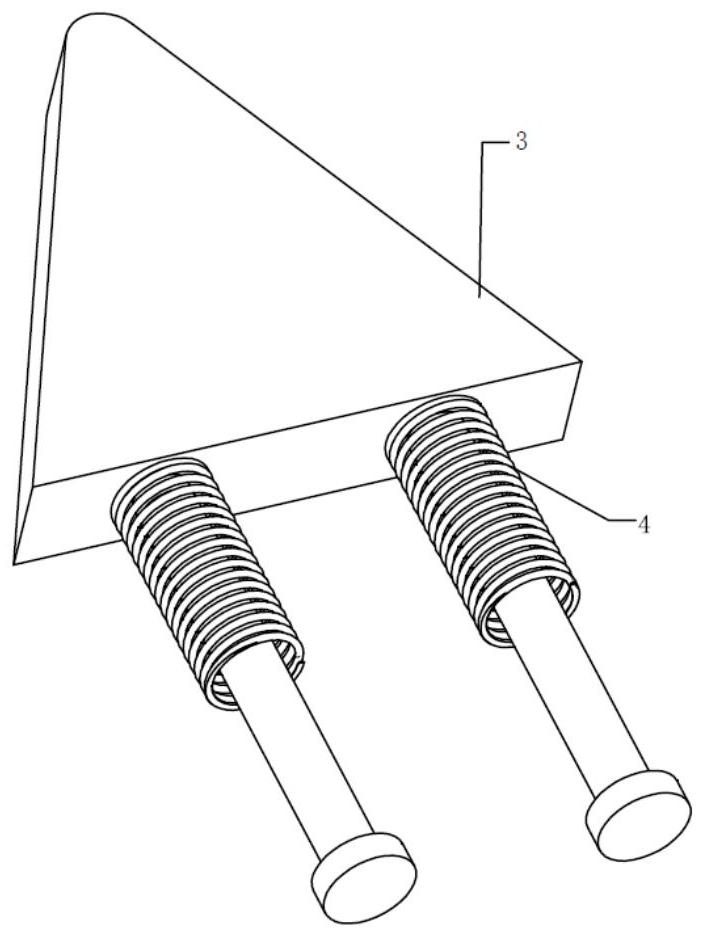

Sorting equipment for coal gangue

The invention provides a sorting device for coal gangue, which includes a bottom plate, a conveyor belt, a triangular stopper, a spring, an equidistant material distribution mechanism and an identification and sorting mechanism. The triangular stopper is movably installed on a support frame, and the triangular stopper The block is located directly above the conveyor belt and has a gap with the conveyor belt, the equidistant material distribution mechanism is arranged on the rear side of the triangular block, and the identification and sorting mechanism is located on the rear side of the equidistant material distribution mechanism. The material conveyed by the conveyor belt is blocked by the triangular stopper, then the material will be conveyed along the two sides of the triangular stopper, then the material is conveyed in two ways, and then the rollers in the equidistant material distribution mechanism are conveyed The belt is driven to rotate, and then the rotation of the roller is converted into the reciprocating swing of the baffle through friction transmission, crank rocker and gear pair, and then the baffle blocks and releases the conveyed materials, and then the materials will be arranged equidistantly Transporting on the conveyor belt ensures the subsequent sorting effect.

Owner:安徽创能环保材料有限公司

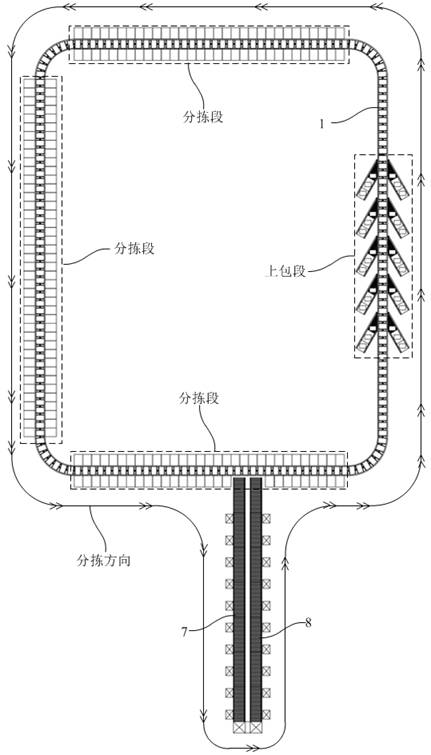

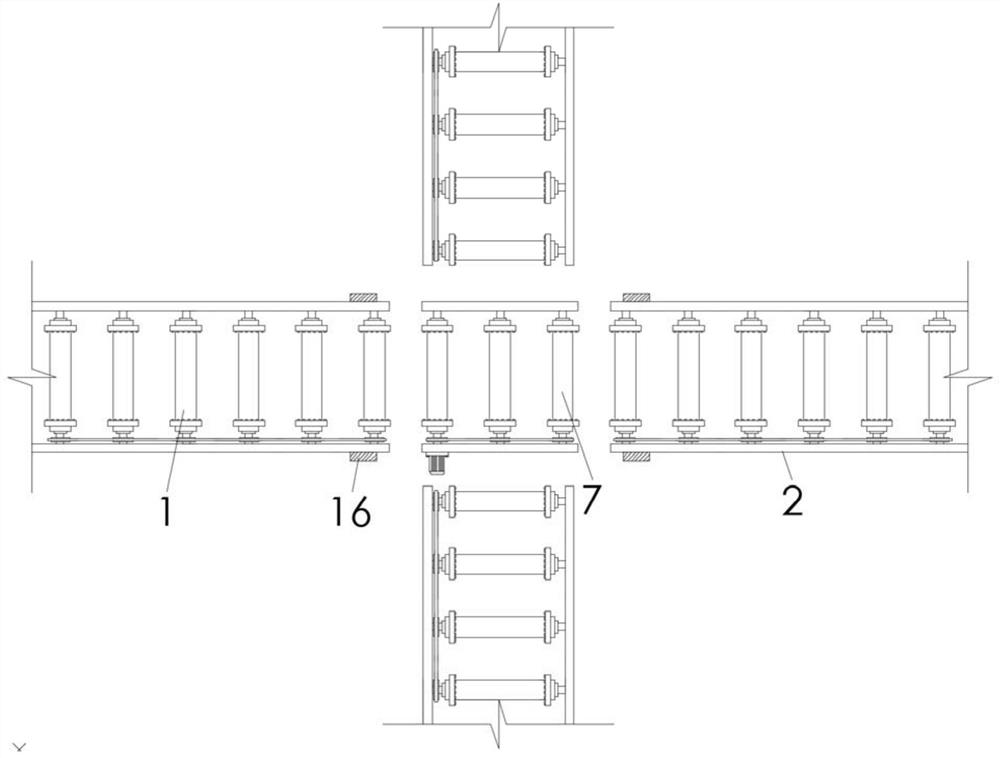

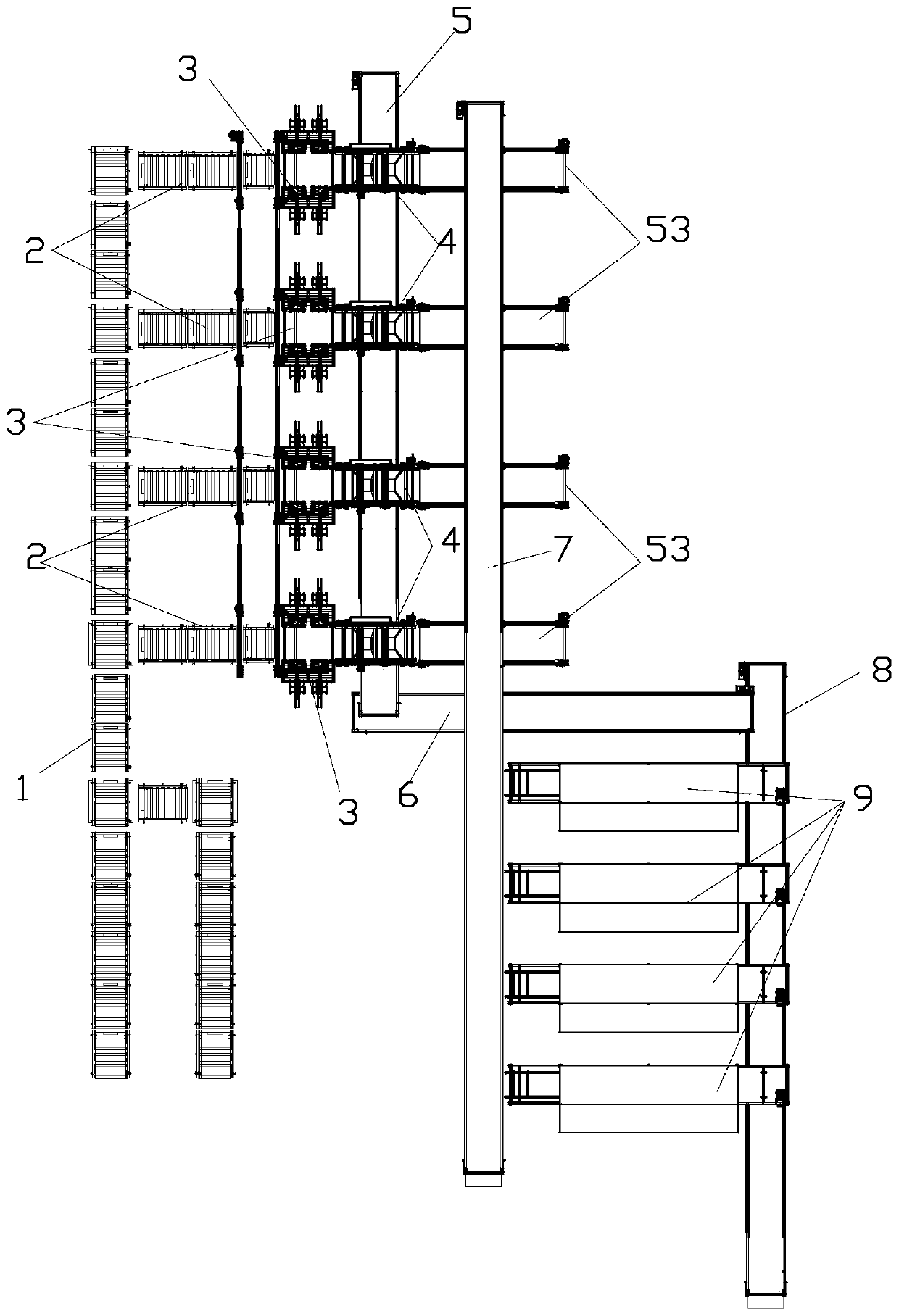

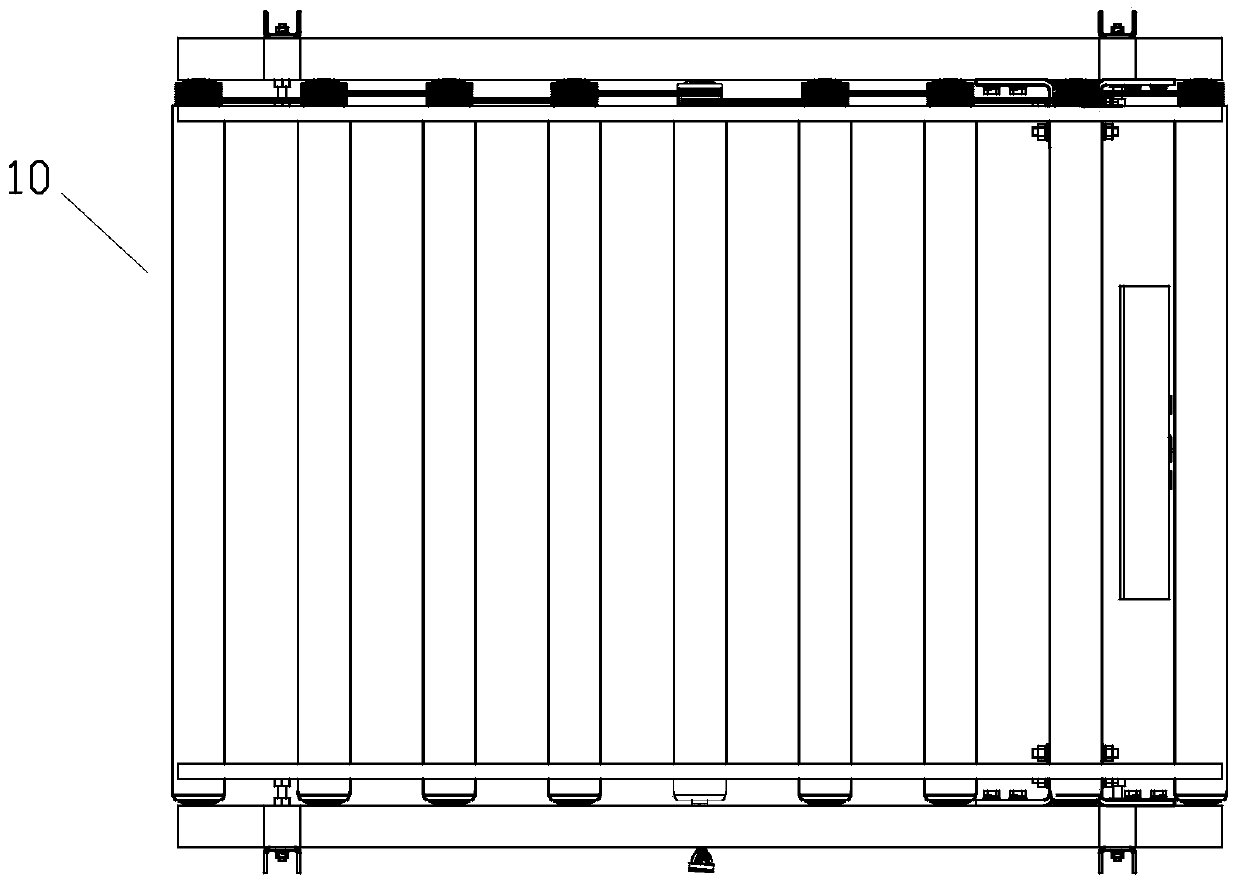

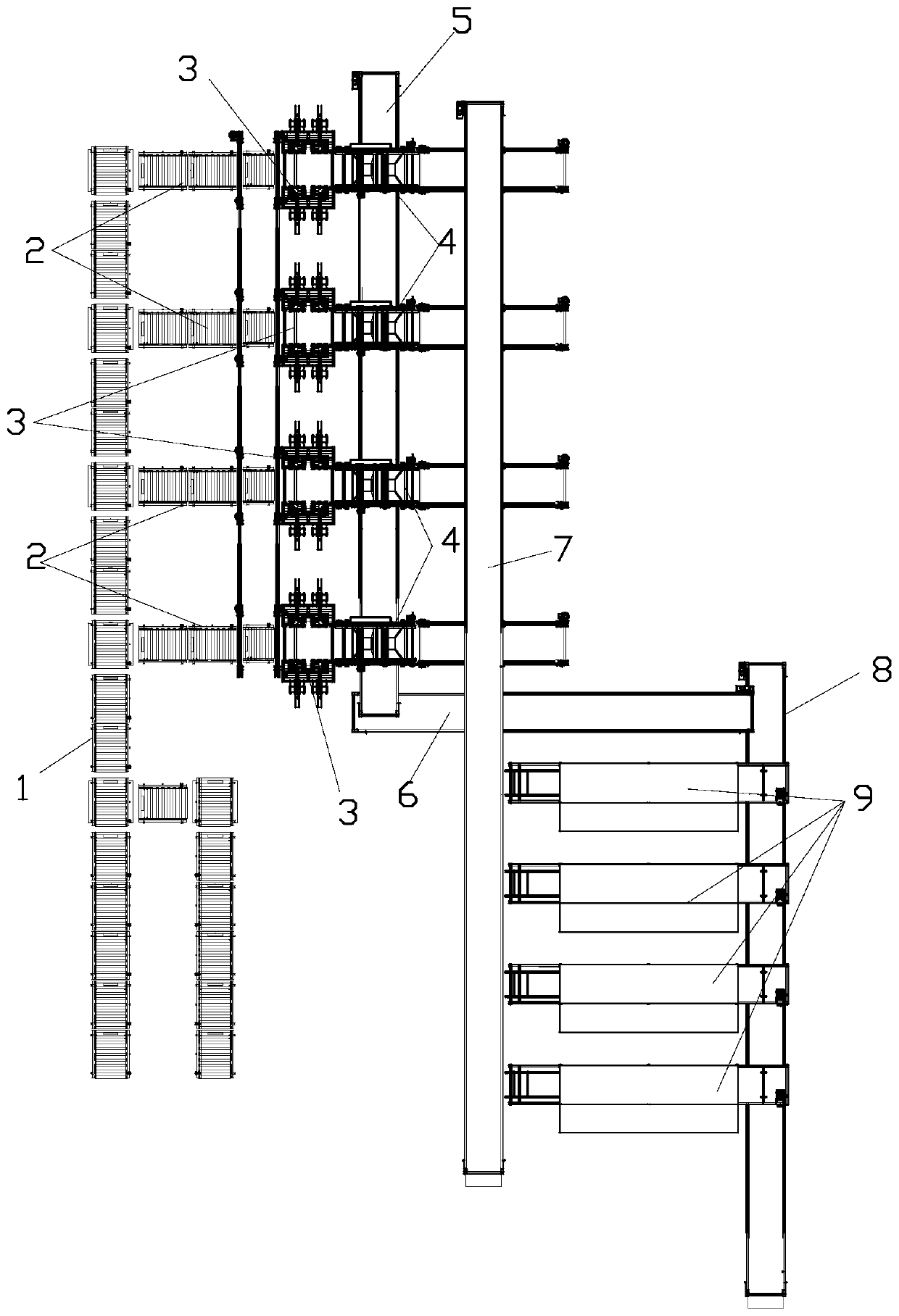

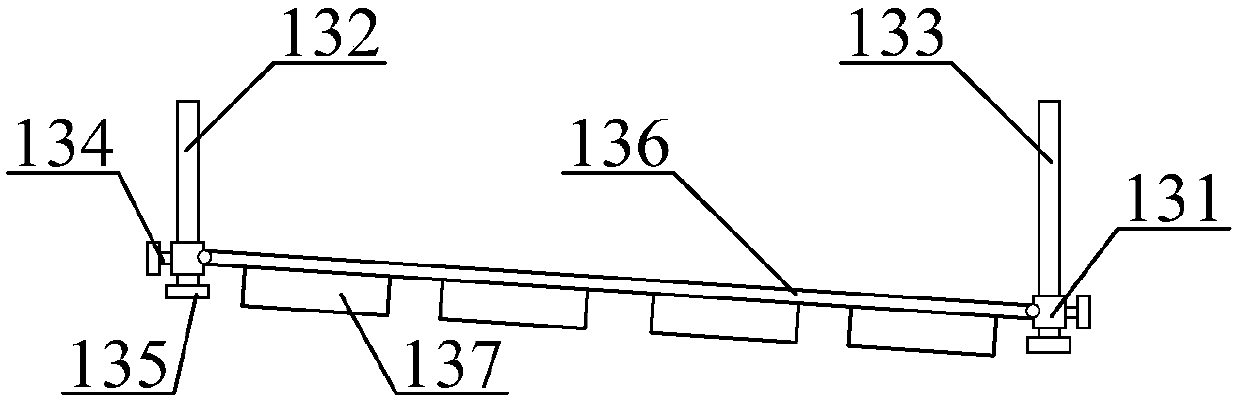

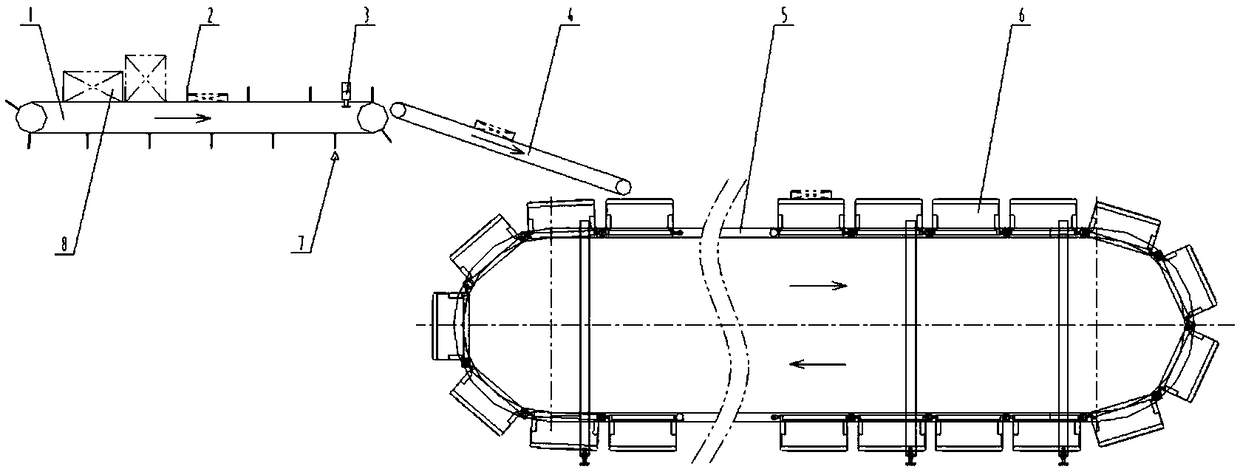

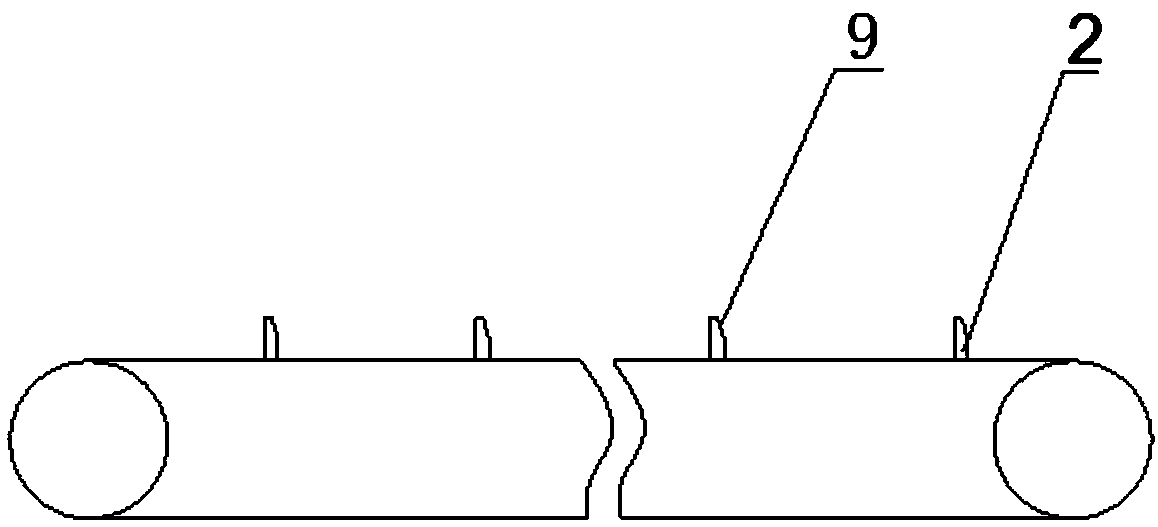

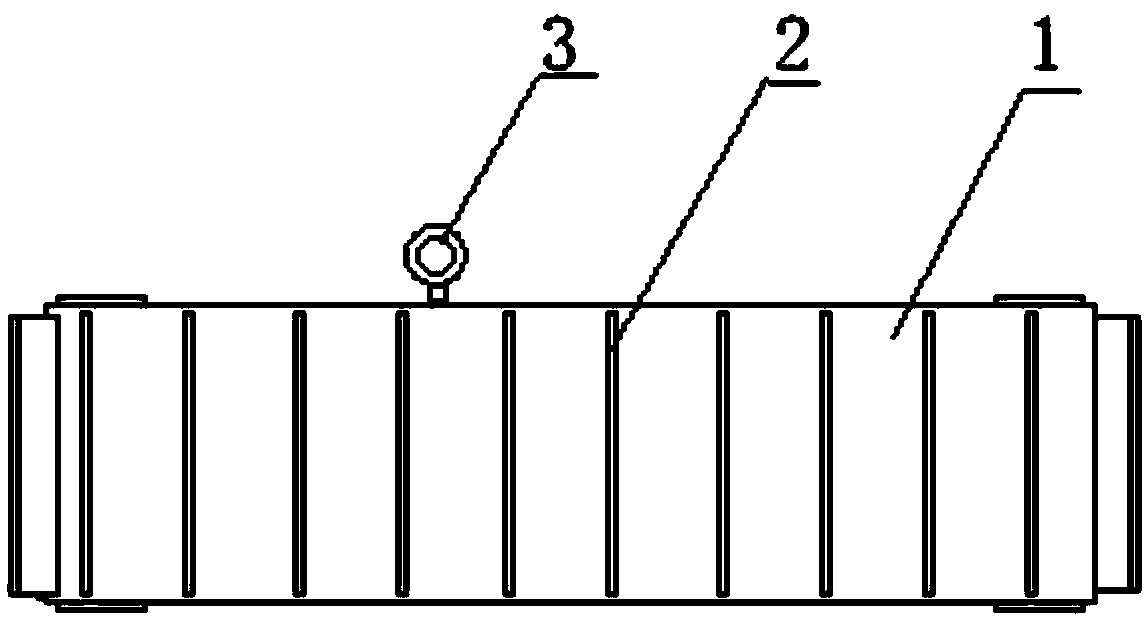

Package feeding system and method for linear crossing belt sorting machine

PendingCN109174657ARealize visual operationRegularization of the uploading processSortingLow speedControl system

The invention provides a package feeding system and method for a linear crossing belt sorting machine. The package feeding system comprises a package feeding belt conveyor (1) and a control system. The package feeding system is characterized in that a plurality of limiting ridges (2) which are arranged in the mode of being perpendicular to the conveying direction are arranged on the package feeding belt conveyor (1) and conduct belt type circulating movement along with the package feeding belt conveyor (1). The linear crossing belt sorting machine (5) and the package feeding belt conveyor (1)are connected to the control system, and the control system is used for regulating and controlling the running speed of the linear crossing belt sorting machine (5) and the running speed of the package feeding belt conveyor (1). According to the technology, few facilities and easy control are utilized, and therefore low-speed feeding and reliable injection are achieved on the premise that the sorting efficiency of a crossing belt is not affected, and the problems that in the existing linear crossing belt sorting process, the package feeding efficiency is low, the error rate is high, and the empty load exists are solved.

Owner:KUNMING KSEC LOGISTIC INFORMATION IND

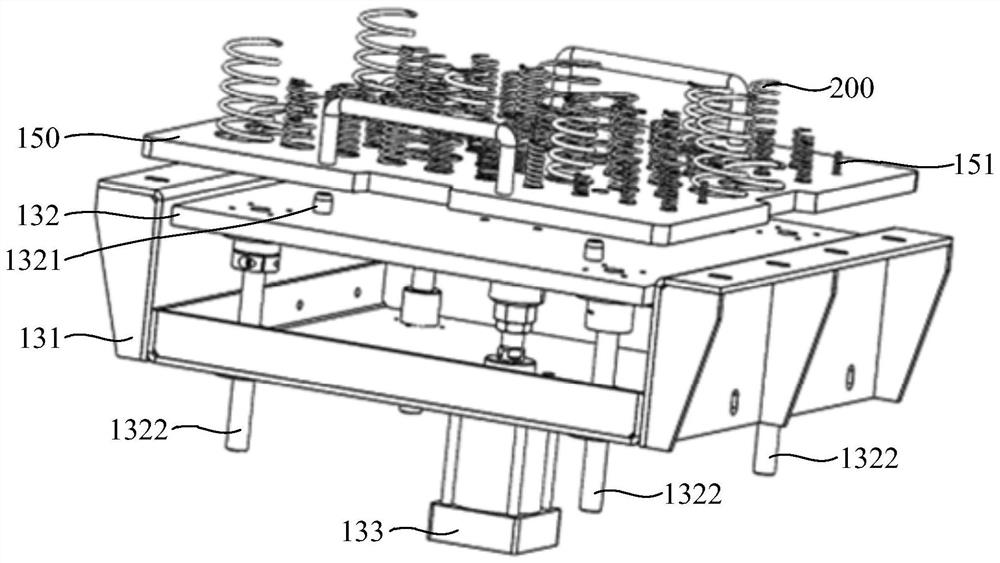

Brake valve spring detecting and sorting system and sorting method

The invention relates to a brake valve spring detecting and sorting system and method. The brake valve spring detecting and sorting system comprises a conveying piece, a detection piece, a first placing component and a sorting piece, wherein the conveying piece is used for conveying springs; the detection piece is used for detecting the spring and acquiring and processing detection data of the spring; the first placing component is arranged on a conveying path of the conveying piece, and the first placing component is used for placing the spring; and the sorting piece is electrically connected with the detection component, and the sorting piece is used for picking up and releasing the spring. According to the brake valve spring detecting and sorting system, through automatic operation of the sorting piece, brake valve springs can be effectively detected and sorted, and waste springs can be automatically replaced, so that the automation degree is high, the labor intensity of workers can be reduced, and meanwhile, the sorting and detecting efficiency is guaranteed, and the situation of misjudgment is reduced.

Owner:SHENHUA RAIL & FREIGHT WAGONS TRANSPORT

Goods sorting off-line device

PendingCN114733772ARealize rational utilizationReduce turnoverSortingLogistics managementStructural engineering

The invention relates to the technical field of logistics express equipment, in particular to a goods sorting and offline device which comprises a conveying belt, a centering mechanism is installed on the moving path of the conveying belt, a code scanning mechanism is fixedly installed on the conveying belt, and a circular truncated cone is arranged at one end of the conveying belt and provided with a first rotation driving device. A polygonal rotating disc is fixedly installed at the working end of the first rotation driving device, the first baffles are arranged in the direction of the connecting line of the vertex angle and the center of the polygonal rotating disc, a plurality of rotating shafts distributed at equal intervals are arranged between every two adjacent first baffles, and the rotating shafts are sleeved with conveying rollers independently driven to rotate. A plurality of sets of discharging tables are arranged on the peripheral side of the polygonal rotating disc in a surrounding mode, a plurality of sets of retarding mechanisms are arranged on the discharging tables, and the retarding mechanisms are used for retarding the discharging speed of the goods. And meanwhile, the turnover distance of the goods on the conveying belt is shortened, and efficiency is improved.

Owner:许东辉

A sorting device for fruit packaging

ActiveCN113441416BEfficient sortingReduce intensitySortingAgricultural engineeringStructural engineering

Owner:INST OF LASER & OPTOELECTRONICS INTELLIGENT MFG WENZHOU UNIV

Magnetic ore separation equipment and method

InactiveCN103056028BReduce the number of units usedSmall footprintFlotationMagnetic separationMining engineeringMagnetic separator

The invention discloses magnetic ore separation equipment. According to the technical point, an underflow ore discharge pipe of a magnetic separation column is connected with a feed port of a first agitating vessel, and an overflow groove ore discharge pipe of the magnetic separation column is connected with an overflow groove of a two-section magnetism flotation column; the ore discharge pipe of the first agitating vessel is connected with the feed port of a second agitating vessel, the ore discharge pipe of the second agitating vessel is connected with a feed hopper with a one-section magnetism flotation column, the one-section magnetism flotation column is connected with a scavenging device, and the overflow groove ore discharge pipe of the one-section magnetism flotation column is connected with the feeding end of the scavenging device; the two-section magnetism flotation column or a magnetic separator is used as the scavenging device, and the underflow ore discharge pipe of the two-section magnetism flotation column is connected with the feed hopper of the one-section magnetism flotation column; and the overflow groove ore discharge pipe of the two-section magnetism flotation column or a tailings discharge pipe of the magnetic separator is connected with a tailings recovery system. The invention simultaneously provides a separation method for using the equipment. Problems in the prior art that magnetic inclusion generates in the core separation of magnetite, the separation method is complicated, the floor area is large, the separation flow path is low and the separation cost is high and the like are solved.

Owner:沈阳华大科技有限公司

Multifunctional robot visual sorting device

The invention provides multifunctional robot visual sorting device. The multifunctional robot visual sorting device comprises an assembly line work sorting table, mounting pipes, supporting columns, fastening bolts, a base, an intelligent control cabinet, a main machine, a master control switch, a visual recognition camera and a sorting gripper, wherein the mounting pipes are in threaded connection to the four corners of the bottom of the assembly line work sorting table; and the supporting columns are inserted in the mounting pipes and are in fastened connection through the fastening bolts. According to the multifunctional robot visual sorting device, through the arrangement of a top frame, a movable column, an adjusting handle, a connecting pipe, an adjusting bolt and a mounting plate, the adjusting bolt is loosened, the adjusting handle is held by hand to move and adjust the position of the movable column in the connecting pipe, after the height position of the top frame is determined, the adjusting bolt is locked, objects moving on the assembly line work sorting table can be continuously recognized through the visual recognition camera, grabbing and sorting operation is conducted through the sorting gripper, the sorting work efficiency is guaranteed, and the sorting requirement for objects different in size is met.

Owner:WEIHAI OCEAN VOCATIONAL COLLEGE

A capsule polishing machine with improved sorting accuracy

ActiveCN111660196BGuarantee the effect of waste removal and sortingGuaranteed sorting efficiencyEdge grinding machinesPolishing machinesSurgeryMechanical engineering

The invention relates to the technical field of pharmaceutical equipment, and discloses a capsule polishing machine for improving sorting accuracy, which includes a base, a cylinder is fixedly connected to the outer side of the upper end of the base, a chute is fixedly connected to the upper end of the inner wall of the cylinder, and the movable sleeve of the chute Connected to the end cover, the two sides of the upper end of the end cover are fixedly connected with handles, and the support rods fixedly connected with both sides of the inner wall of the cylinder are arranged under the chute. When the negative wind pressure device in the waste removal device of the existing capsule polishing equipment absorbs unqualified capsules, due to the falling of a large number of capsules, some unqualified capsules located in the middle are easily blocked by the qualified capsules outside, and are difficult to be attracted by the negative pressure. The unqualified capsules located on the outside are easily affected by the capsules falling above them when they are attracted, resulting in the unqualified capsules being easily not absorbed under the interference of other capsules, resulting in a large number of unqualified capsules mixed into the qualified capsules, which is difficult to guarantee Screening accuracy has a huge impact on the use of subsequent capsules in medical procedures.

Owner:SHANDONG HEALSEE CAPSULE CO LTD

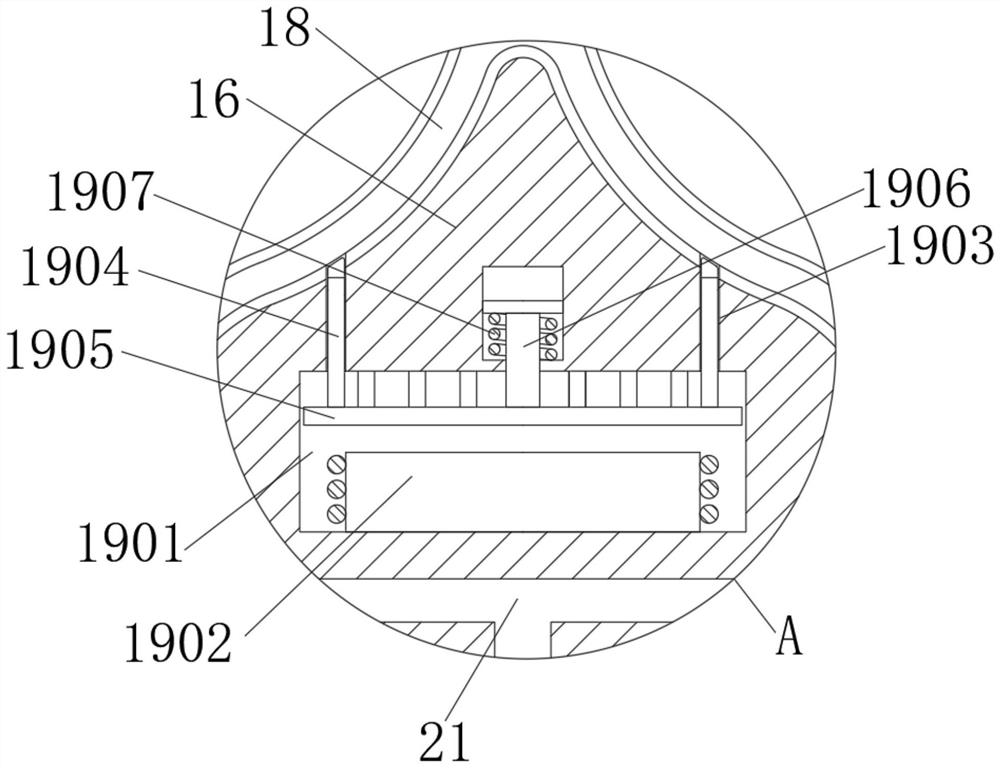

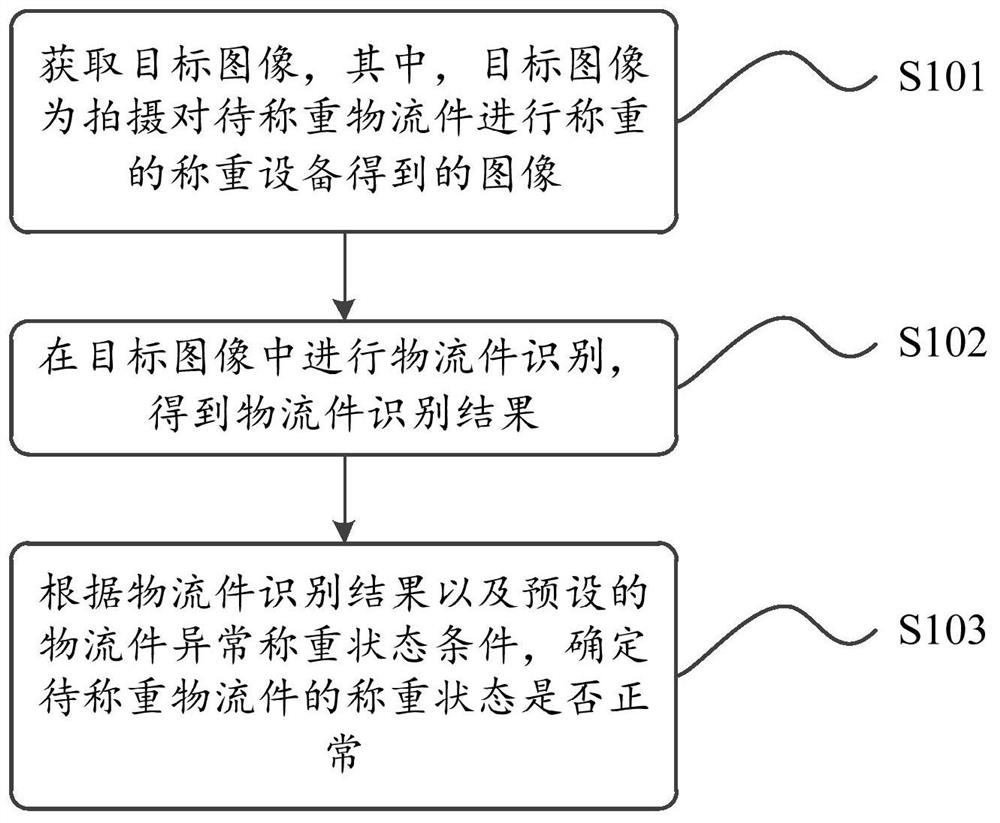

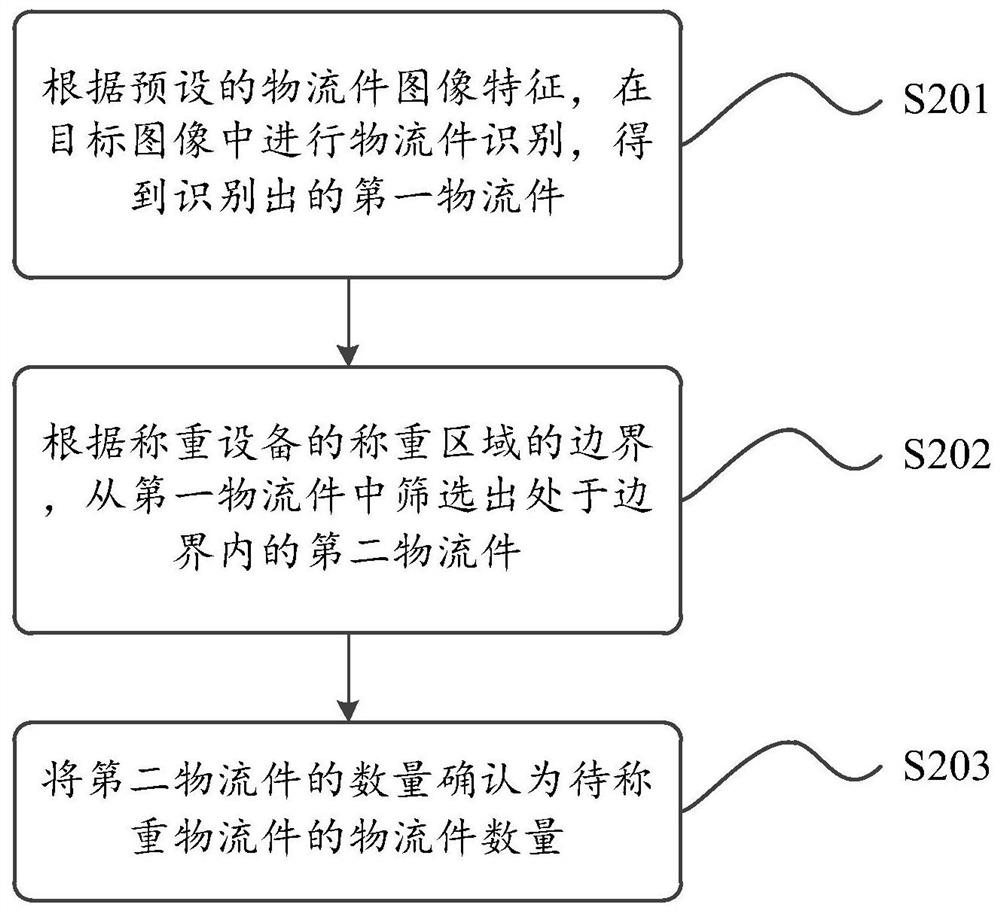

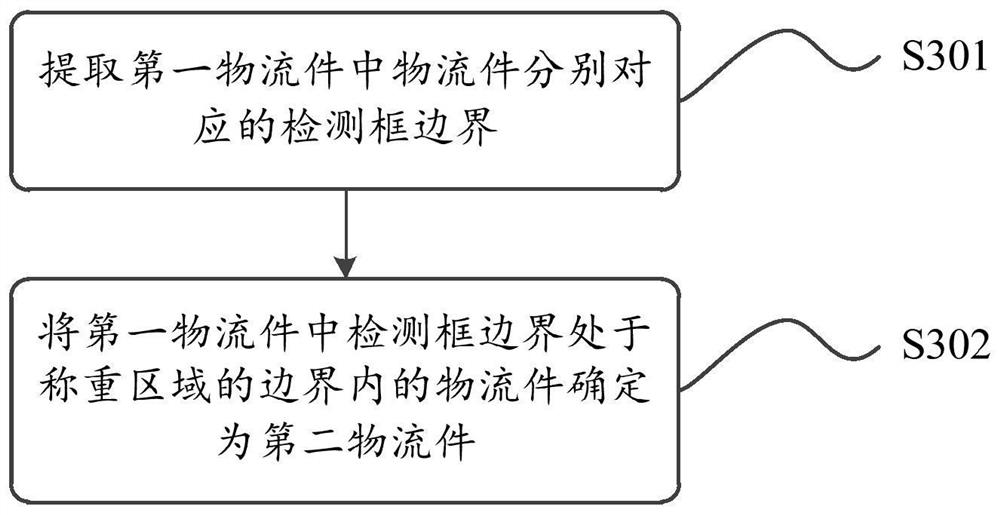

Weighing state determination method, device and equipment

PendingCN114359759AGuaranteed stabilityGuaranteed sorting efficiencyCharacter and pattern recognitionLogisticsLogistics managementArtificial intelligence

The invention provides a method, a device and equipment for determining a weighing state, which are used for more intuitively and accurately judging whether the weighing state of a to-be-weighed logistics piece is normal or not from an image level, can perform accurate response processing according to a weighing state judgment result, and ensures the stability and the sorting efficiency of automatic sorting operation. The weighing state determination method provided by the invention comprises the steps that a target image is acquired, and the target image is an image obtained by shooting and weighing equipment for weighing a to-be-weighed logistics item; carrying out logistics item identification in the target image to obtain a logistics item identification result; and determining whether the weighing state of the to-be-weighed logistics item is normal or not according to the logistics item identification result and a preset abnormal weighing state condition of the logistics item.

Owner:SF TECH

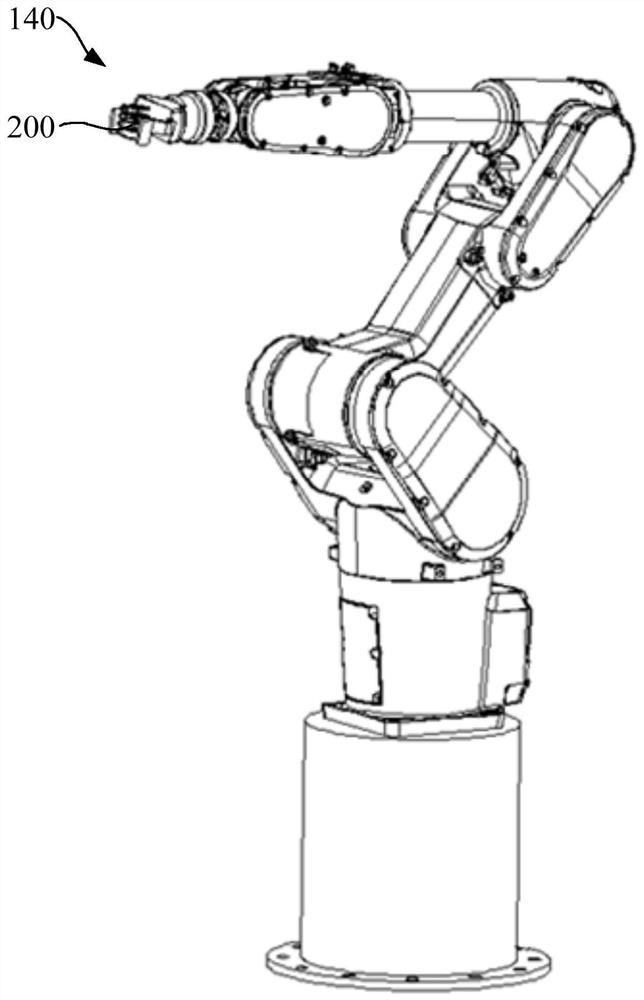

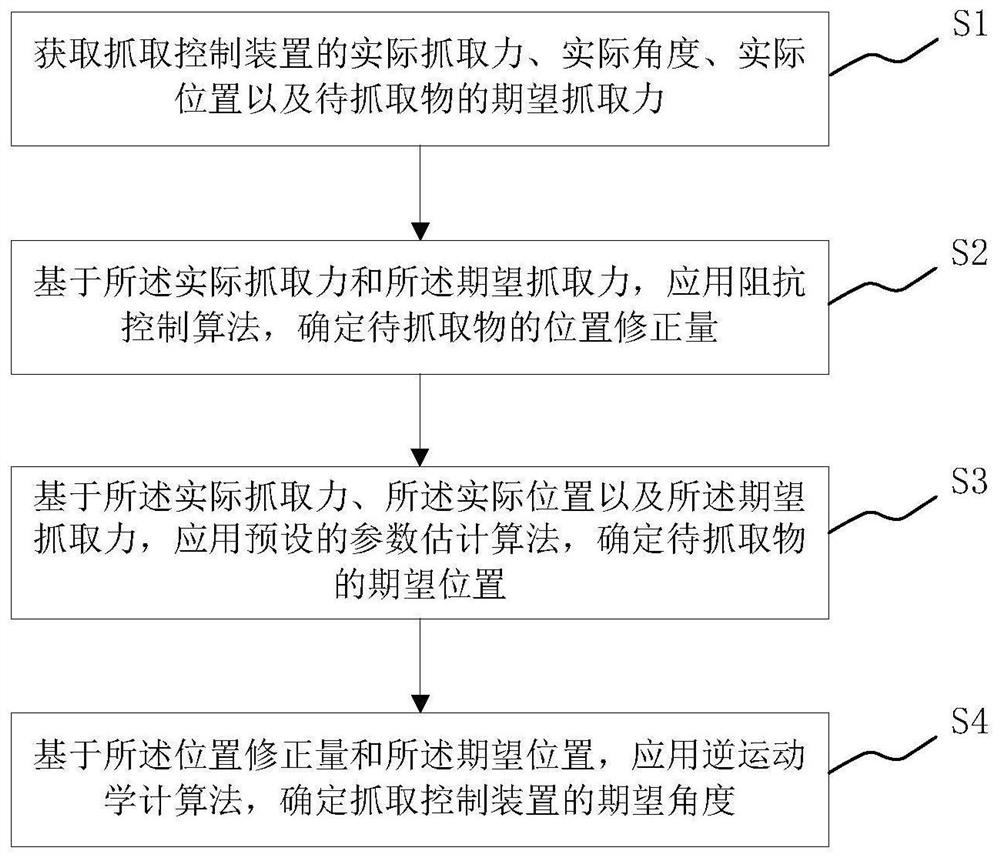

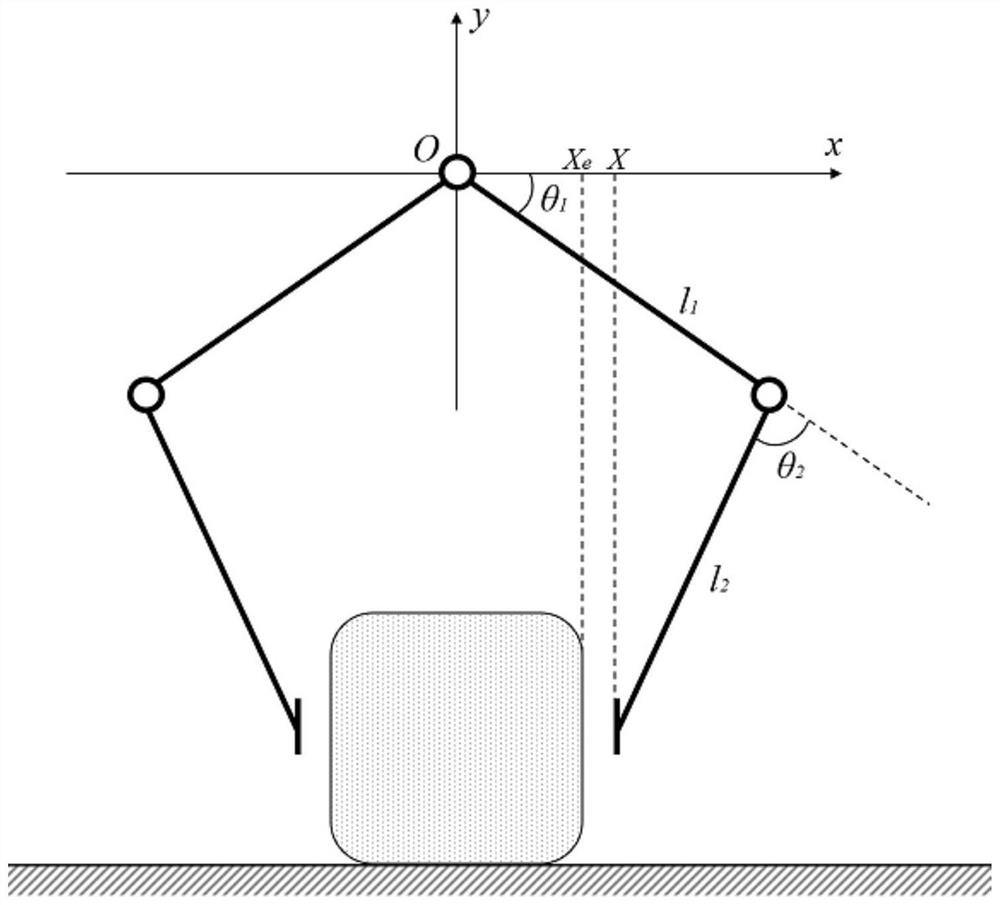

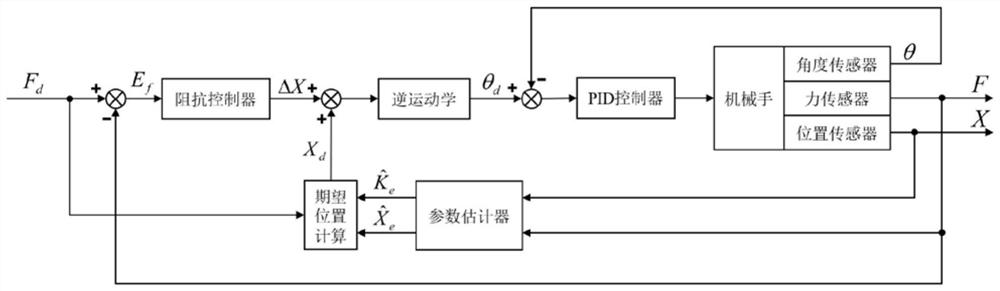

Grabbing control method and device of construction waste sorting manipulator

ActiveCN113400316AImprove gripImprove robustnessProgramme-controlled manipulatorRobot handSelf adaptive

The invention provides a grabbing control method and device for a construction waste sorting manipulator. The grabbing control method comprises the following steps that the actual grabbing force, the actual angle and the actual position of the grabbing control device and the expected grabbing force of a to-be-grabbed object are obtained; based on the actual grabbing force and the expected grabbing force, an impedance control algorithm is applied, and the position correction amount of the to-be-grabbed object is determined; based on the actual grabbing force, the actual position and the expected grabbing force, a preset parameter estimation algorithm is applied, and the expected position of the to-be-grabbed object is determined; and based on the position correction amount and the expected position, an inverse kinematics calculation method is applied, and the expected angle of the grabbing control device is determined. According to the grabbing control method and device of the construction waste sorting manipulator, it is ensured that the grabbing control device can still conduct self-adaptive adjustment to achieve stable grabbing when the position and the surface rigidity of the to-be-grabbed object are estimated to be deviated or the surface rigidity of the to-be-grabbed object is changed in the grabbing process; and the sorting efficiency of the to-be-grabbed object is ensured.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com