Screening-gravity separation technology added before obverse flotation operation of phosphorite

A technology of positive flotation and pre-operation, which is applied in the field of adding screening-gravity separation process before the positive flotation of phosphate rock, can solve the problems of non-universality and achieve the effect of process stability guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

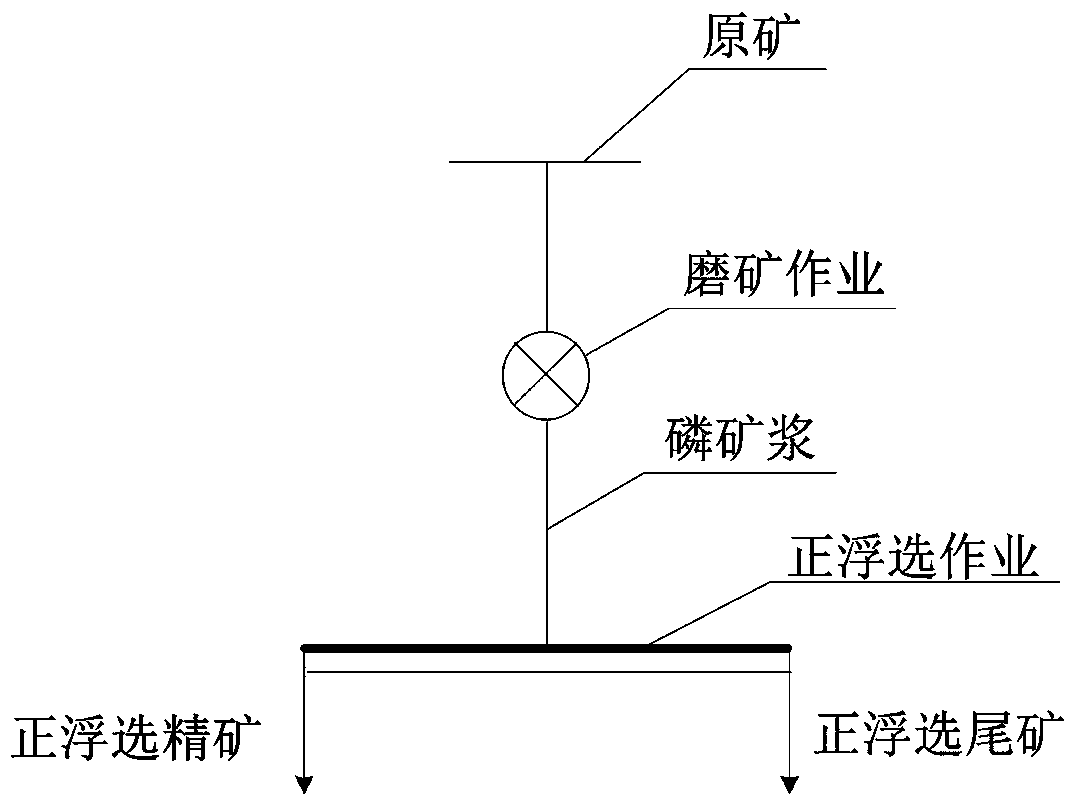

Method used

Image

Examples

Embodiment 1

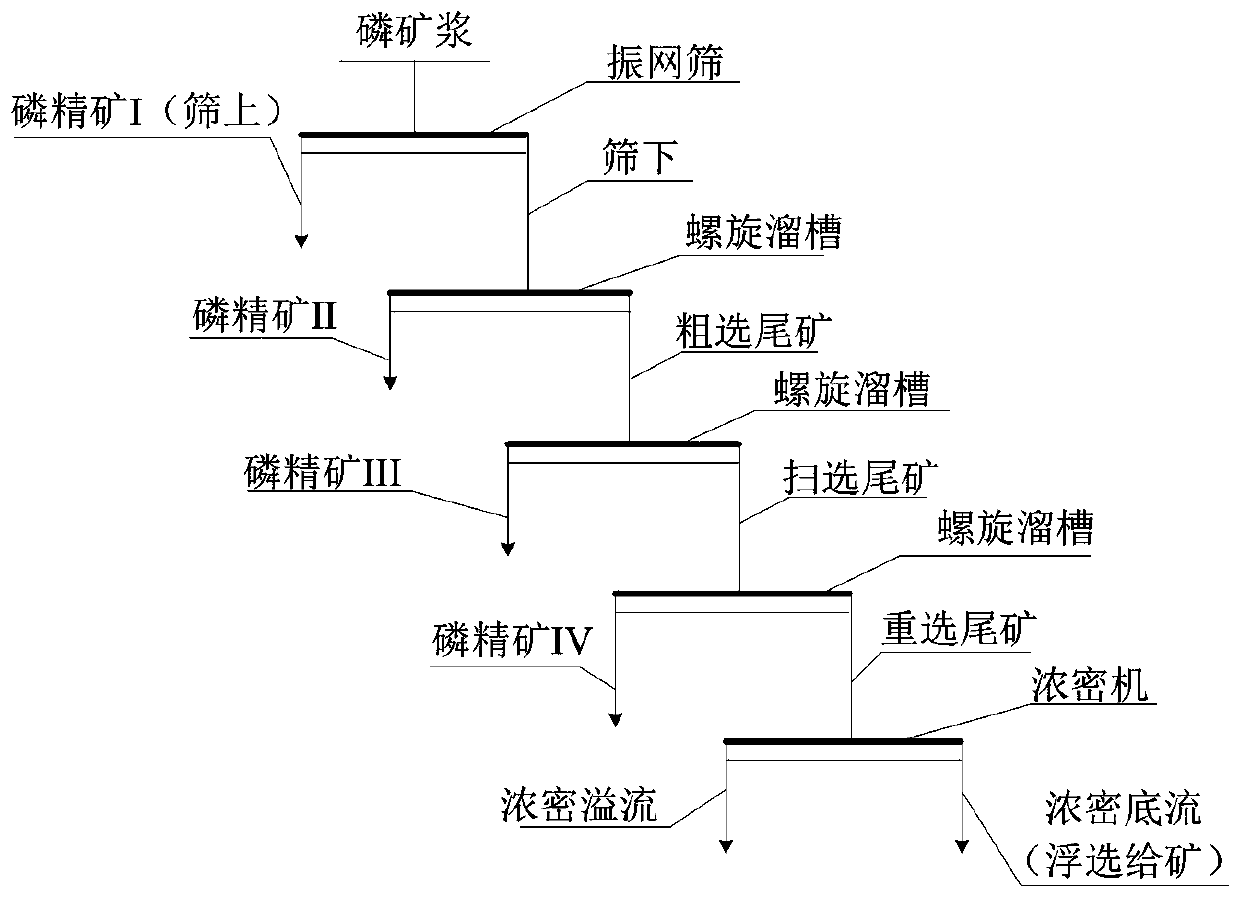

[0020] A screening-gravity separation process is added before the positive flotation of phosphate rock. The method described in this embodiment is:

[0021] Will P 2 o 5 Grade is 18.0wt%, MgO content is 3.0wt%, Al 2 o 3 The phosphate slurry with a content of 5.5wt% and a particle size of less than 0.074mm accounting for 70~85wt% is fed into the vibrating screen. The aperture of the vibrating screen is 0.15mm. The material on the screen is used as phosphorus concentrate I, and the material under the screen is fed into the third section Spiral chute re-election process, one-stage roughing to obtain phosphorus concentrate II and roughing tailings, the roughing tailings are fed into the second-stage sweeping to obtain phosphorous concentrate III and sweeping tailings, and the sweeping tailings are fed into Three stages of sweeping to obtain phosphorous concentrate IV and gravity tailings, gravity tailings fed into thickener, after the thickener thickened, concentration is 25wt...

Embodiment 2

[0025] A screening-gravity separation process is added before the positive flotation of phosphate rock. The method described in this embodiment is:

[0026] Will P 2 o 5 Grade is 24.7wt%, MgO content is 1.4wt%, Al 2 o 3 Content 4.7wt%, particle size less than 0.074mm accounted for 55 ~ 65wt% phosphate slurry is fed into the vibrating screen, the aperture of the vibrating screen is 0.10mm, the material on the screen is used as phosphorus concentrate I, and the material under the screen is fed into the spiral chute Gravity separation process, one-stage roughing to obtain phosphorous concentrate II and roughing tailings, the roughing tailings are sent to the second-stage sweeping to obtain phosphorous concentrate III and gravity tailings, and the gravity tailings are fed to the thickener After thickening by the thickener, the dense underflow with a concentration of 30wt% is fed into the positive flotation operation for flotation, and the phosphorous concentrate I, phosphorous...

Embodiment 3

[0030] A screening-gravity separation process is added before the positive flotation of phosphate rock. The method described in this embodiment is:

[0031] Will P2 o 5 Grade is 27.5wt%, MgO content is 1.2wt%, Al 2 o 3 Content 3.7wt%, particle size less than 0.074mm accounted for 45 ~ 54wt% phosphate slurry is fed into the vibrating screen, the aperture of the vibrating screen is 0.08mm, the material on the sieve is used as phosphorus concentrate I, and the material under the sieve is fed into the third section Spiral chute re-election process, one-stage roughing to obtain phosphorus concentrate II and roughing tailings, the roughing tailings are fed into the second-stage sweeping to obtain phosphorous concentrate III and sweeping tailings, and the sweeping tailings are fed into Three stages of sweeping to obtain phosphorus concentrate IV and gravity separation tailings, gravity separation tailings feed thickener, after thickener concentration, concentration is 35wt% dense ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com