Package feeding system and method for linear crossing belt sorting machine

A cross-belt sorting and straight-line technology, applied in the field of packaging system, can solve the problems of no-load, high error rate, low packaging efficiency, etc., and achieve the effect of precise supply operation, simple control and small number of equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

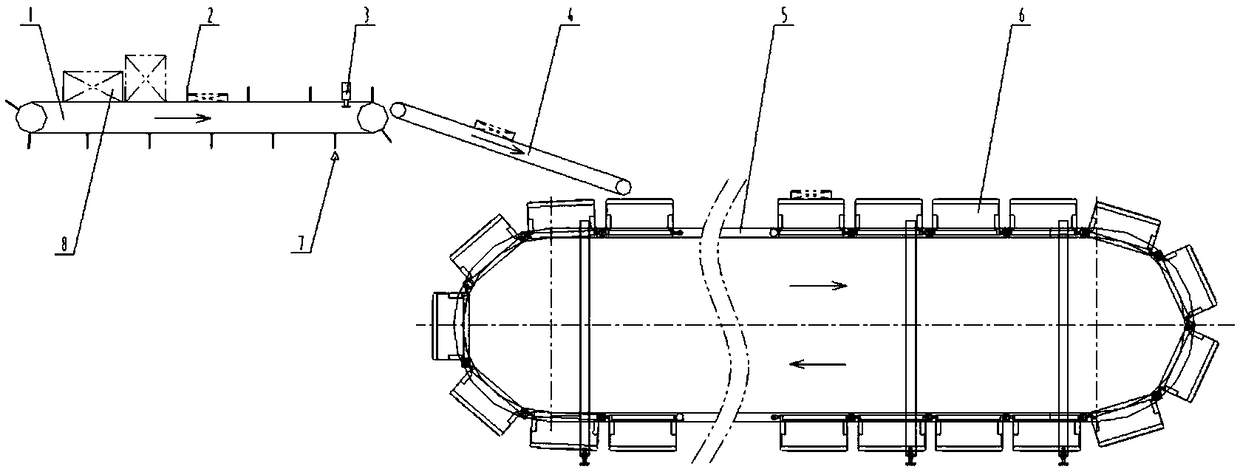

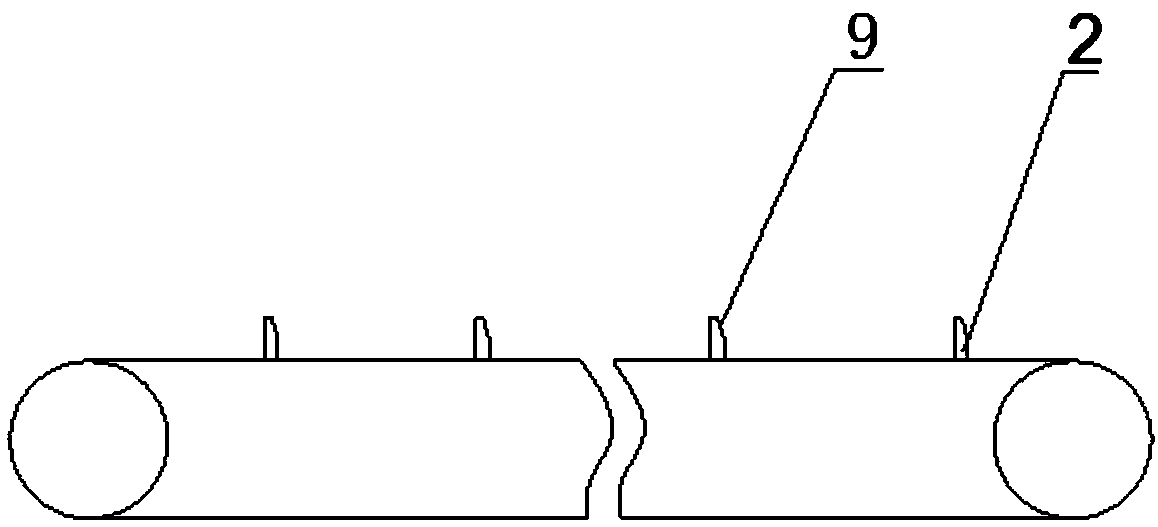

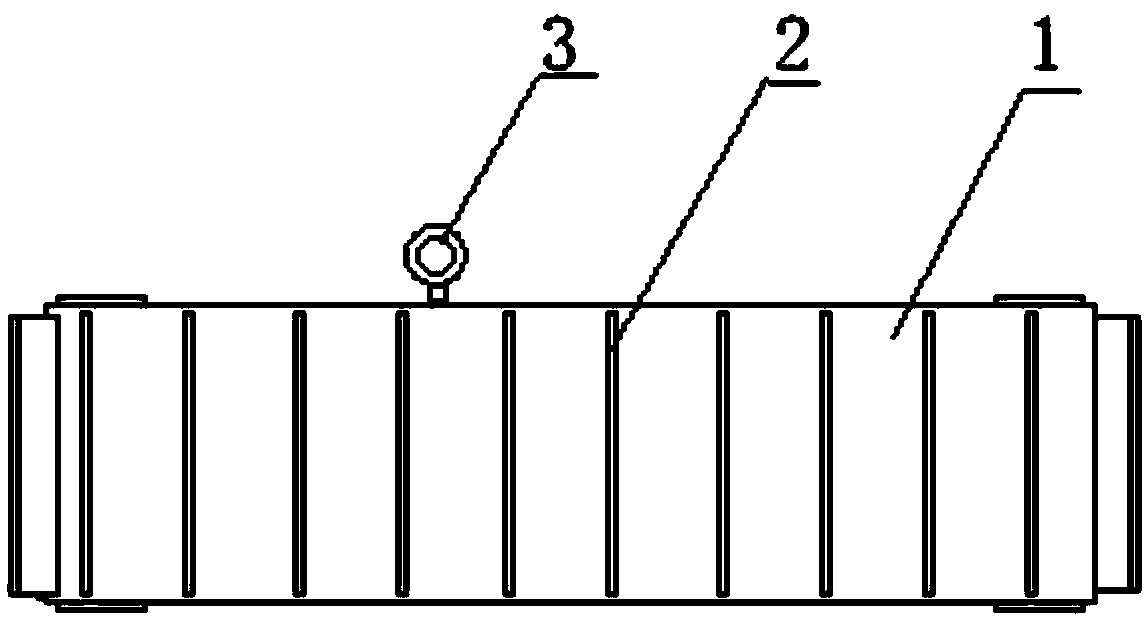

[0034] Embodiment 1: as figure 1As shown, a packing system for a linear cross-belt sorter includes a packing belt conveyor 1 and a control system. The packing belt conveyor 1 is provided with several limit ribs 2 arranged perpendicular to The limit edge 2 moves in a belt-shaped cycle with the upper belt conveyor 1; the linear cross-belt sorter 5 and the upper belt conveyor 1 are connected to the control system, and the control system is used to regulate the linear cross-belt sorter 5 And the running speed of the upper belt conveyor 1. In actual use, the system is turned on, and the loading belt conveyor 1 rotates. When the operation is stable, the loading work can be started, and the packages 8 are placed one by one between each limit edge 2 through equipment or manually. The package 8 corresponds to a station of the limit edge 2, the limit edge 2 pushes the package 8 to run forward under the rotation of the belt, and after reaching the end, it is loaded into the linear cross...

Embodiment 2

[0037] Embodiment 2: On the basis of Embodiment 1, the upper bag system also includes a detection device 7 connected to the control system, and the detection device 7 is installed below the upper bag belt conveyor 1 for detecting the The limit edge 2, and the detection information is transmitted to the control system. The control system is used to receive and process the detection information sent by the detection device 7, and determine the predetermined delivery speed of the upper belt conveyor 1 according to the processed result of the detection information and adjust the speed of the upper belt conveyor 1 to reach the predetermined speed, so that The timing at which each package 8 of the upper belt conveyor 1 is transported to the linear cross-belt sorter 5 is consistent with the timing at which each of the 6 sorting cars on the linear cross-belt sorter 5 moves into place. The control system is used to collect and process the detection information of the detection device 7...

Embodiment 3

[0040] Embodiment 3: A method for uploading packets based on the packet-uploading system described in the above-mentioned embodiments, comprising the following steps:

[0041] S1. Start the bag-up system, the linear cross-belt sorter, the bag-up belt conveyor, the transition belt conveyor and the control system are all started until the equipment operates stably;

[0042] S2. Put the package into the grid formed between two adjacent limit ribs on the upper belt conveyor, and place a package in each grid;

[0043] S3, the detection device is started, and the detected limit edge information is transmitted to the control system;

[0044] S4. The control system performs processing after receiving the limit edge information, and determines the predetermined delivery speed S of the upper belt conveyor according to the processing results, and adjusts the speed of the upper belt conveyor to reach the predetermined speed S, so that the upper belt conveyor The timing of delivering each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com