Lateral discharge type tobacco carton sorting device and method

A sorting device and technology for cartons, applied in the direction of sorting, transportation and packaging, conveyor objects, etc., can solve problems such as low production efficiency, complicated production control, and increased shaping procedures, so as to reduce equipment costs and sort The effect of simple process and streamlined equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

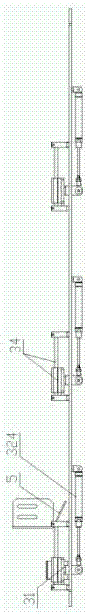

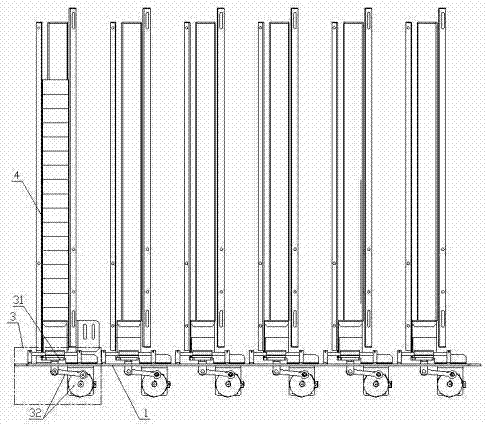

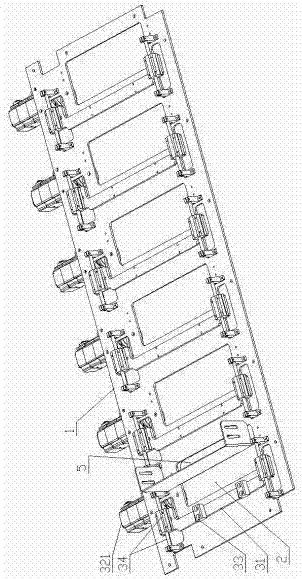

[0024] Example 1. A side-out type cigarette sorting device, which is composed of Figure 1-5 As shown, including a sorting substrate 1, there are more than one smoke outlet 2 distributed on the sorting substrate 1, a sorting assembly 3 is provided at the smoke outlet 2, and a smoke storage bin 4 is arranged above the sorting assembly 3; The sorting assembly 3 includes a push plate 31, one end of the push plate 31 is connected to the drive assembly 32, and the two ends of the push plate 31 are also provided with a sliding guide rail assembly 34; the push plate 31 is located at the smoke outlet 2 .

[0025] The aforementioned smoke outlet 2 is also provided with a smoke outlet baffle 5 . The smoke outlet baffle 5 is set, and when the cigarette is pushed to the outlet 2, the cigarette can be accurately dropped into the outlet 2, thereby increasing the stability of sorting.

[0026] The aforementioned push plate 31 is also provided with an adjustable cigarette pushing block 33 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com