A fine-grained coal acoustic field fluidized bed separation method and device

A sorting device and fluidized bed technology, applied in chemical instruments and methods, solid separation, wind shaker, etc., can solve the problem of hindering the normal fluidization of the bed, affecting the uniformity and stability of the bed, and poor separation results of fine-grained coal and other problems, to achieve the effect of improving fluidization quality, improving sorting performance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

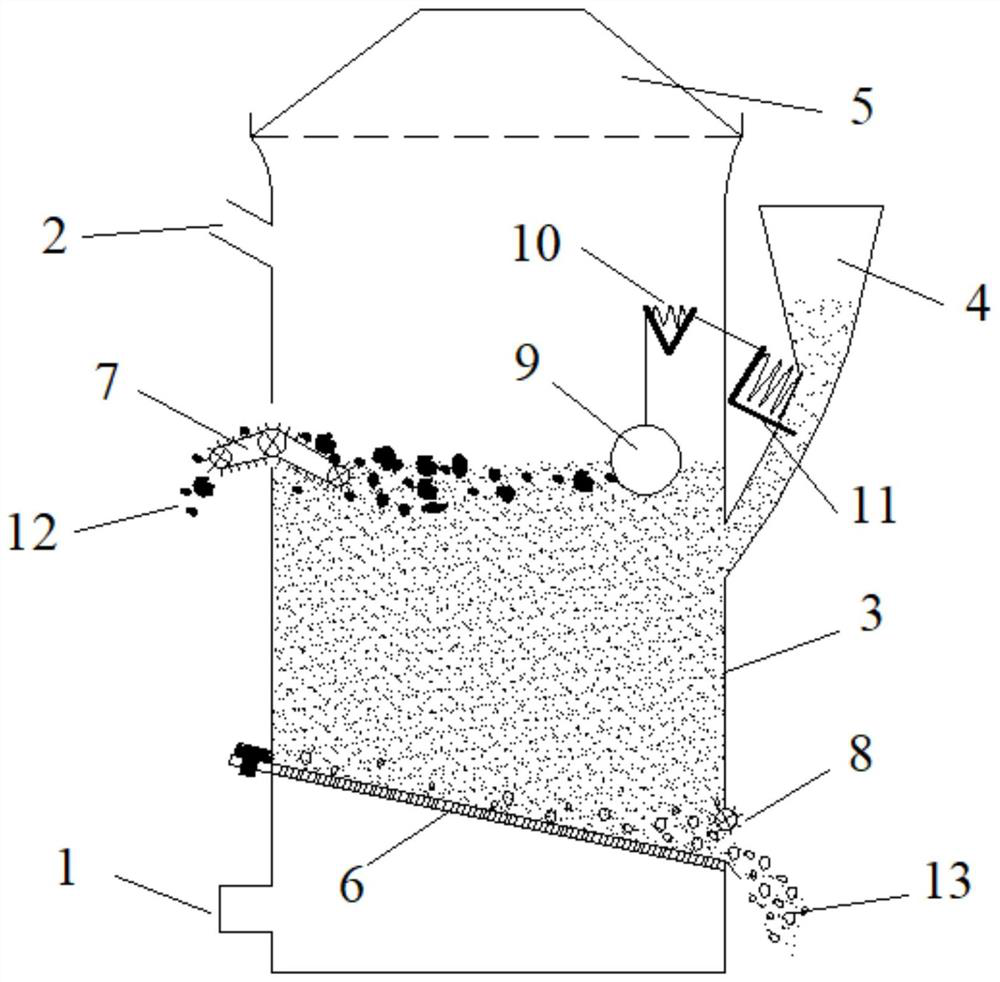

[0024] like figure 1 As shown, the fine-grained coal acoustic field fluidized bed separation device of the present invention is mainly composed of a feed and medium funnel 4, an acoustic wave generator 5, a gas distribution plate 6, a clean coal scraper 7, a dial wheel 8, and an automatic density control The fluidized bed body 3 that holds the medium and sorting materials is composed of components, the acoustic wave generator 5 is arranged on the top of the fluidized bed body 3, and the interior of the fluidized bed body 3 is provided with an automatic density control assembly, and the described The density automatic control assembly includes a density ball 9 floating on the medium and sorting materials, a V-shaped spring clip rod 10 above the density ball 9 and an elastic valve 11 connected to the V-shaped spring clip rod 10. One end connecting rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com