Goods sorting off-line device

A technology of cargo and rotary drive device, which is applied in the direction of sorting, etc., to achieve the effects of avoiding cargo deviation, improving efficiency, and stabilizing the position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to further understand the features, technical means, and specific goals and functions of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

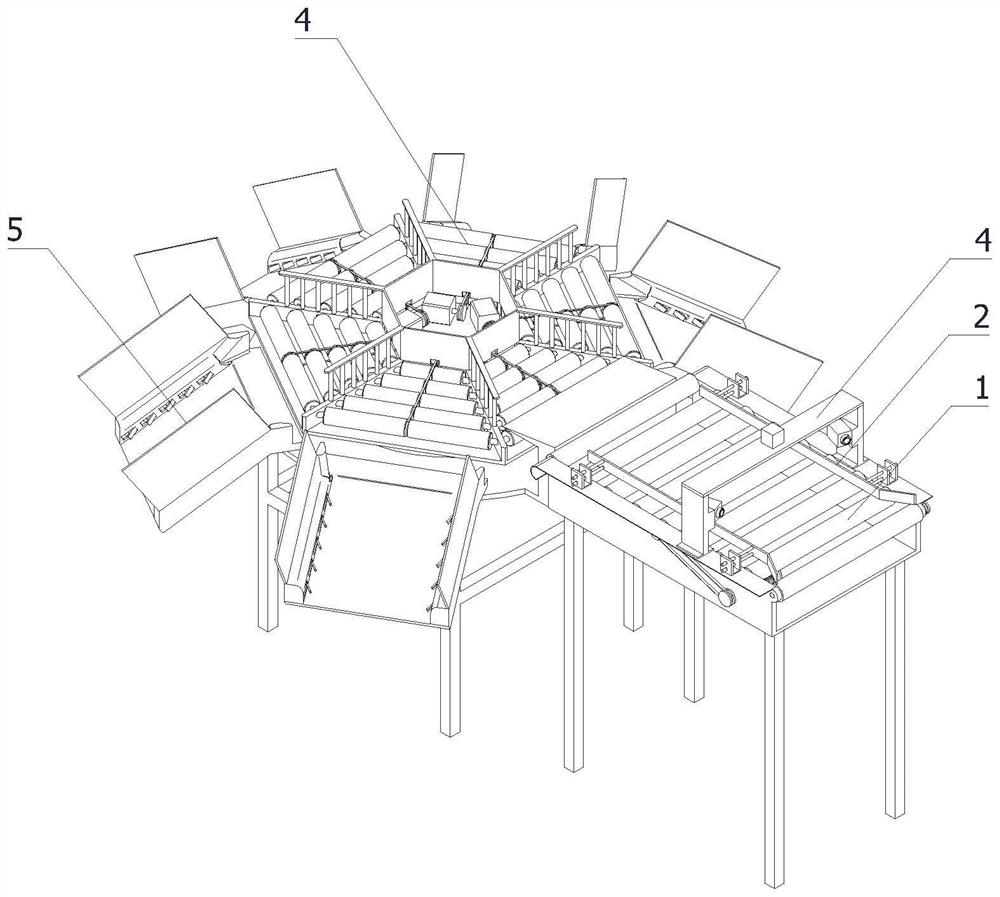

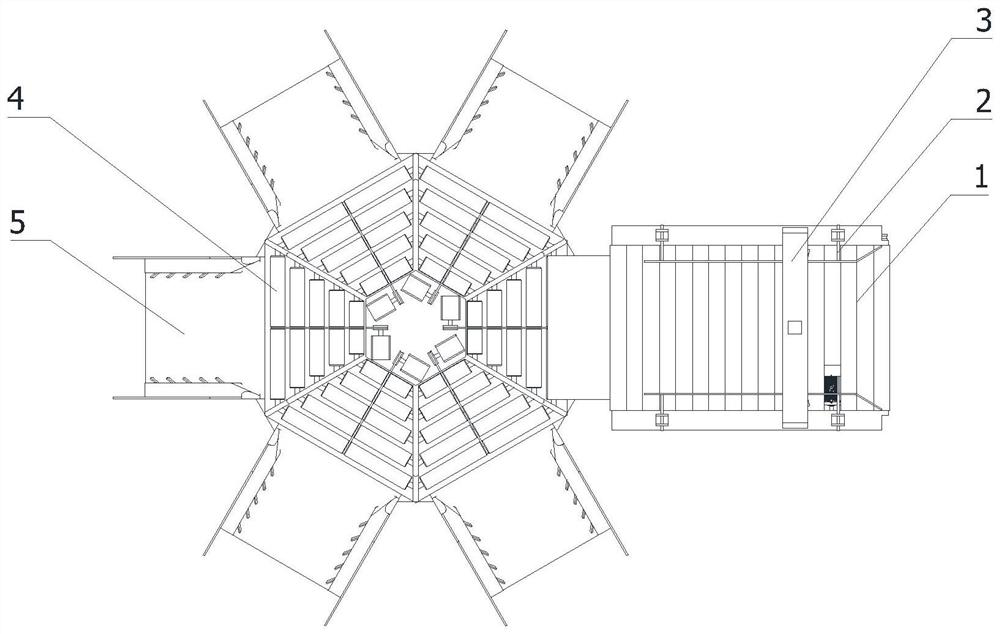

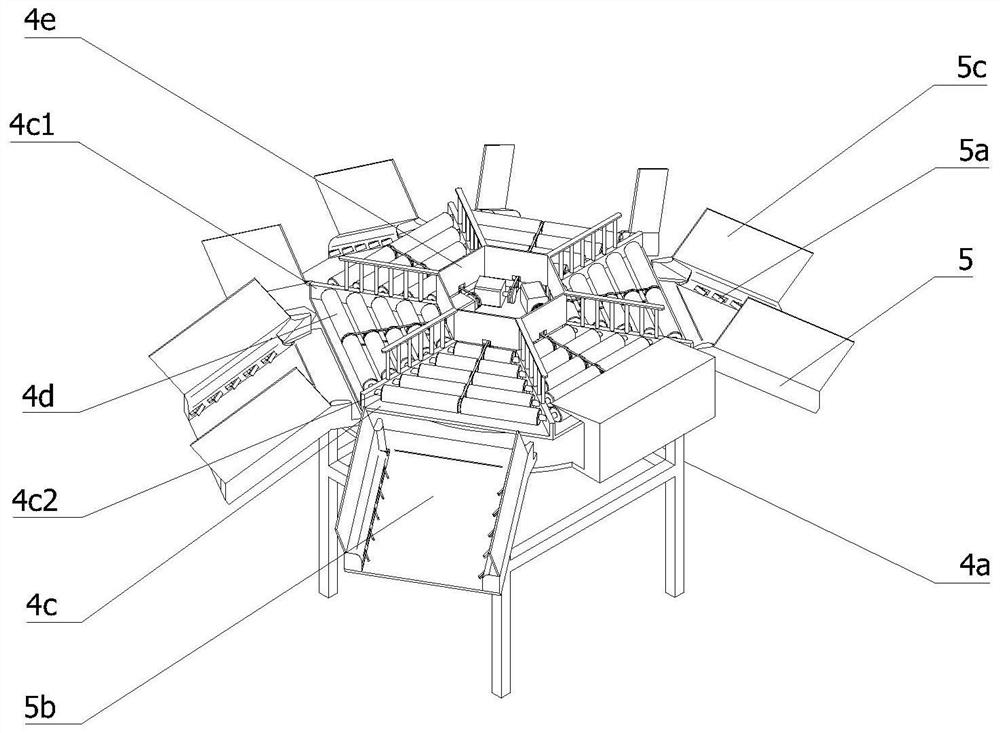

[0051] like Figure 1 to Figure 5 Shown: A cargo sorting and offline device includes a conveyor belt 1 for conveying goods, a centering mechanism 2 is installed on the moving path of the conveyor belt 1, a code scanning mechanism 3 is fixedly installed on the conveyor belt 1, and the scanning mechanism 3 It is used to scan the barcode information of the goods on the conveyor belt 1. One end of the conveyor belt 1 is provided with a sorting mechanism 4, the feeding end of the sorting mechanism 4 is set towards the output end of the conveyor belt 1, and the discharging end of the sorting mechanism 4 is provided with The unloading table 5; the sorting mechanism 4 includes a round table 4a, a first rotary drive device 4b ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com