Cargo sorting system and sorting method

A sorting system and cargo technology, applied in the field of logistics and warehousing, can solve the problems of low sorting efficiency, non-conformity, and high work intensity, and achieve the effects of ensuring sorting efficiency, reducing the probability of errors, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

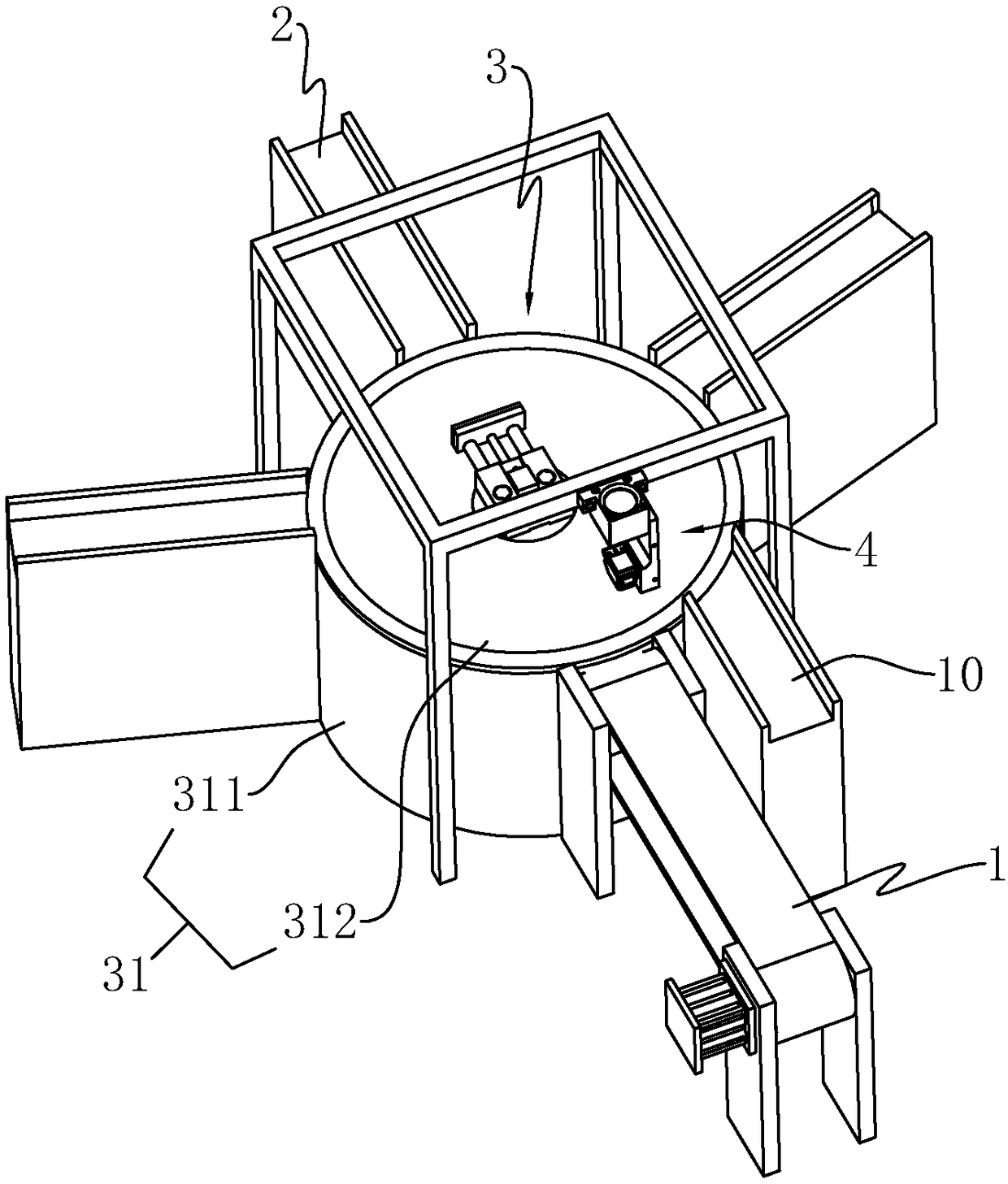

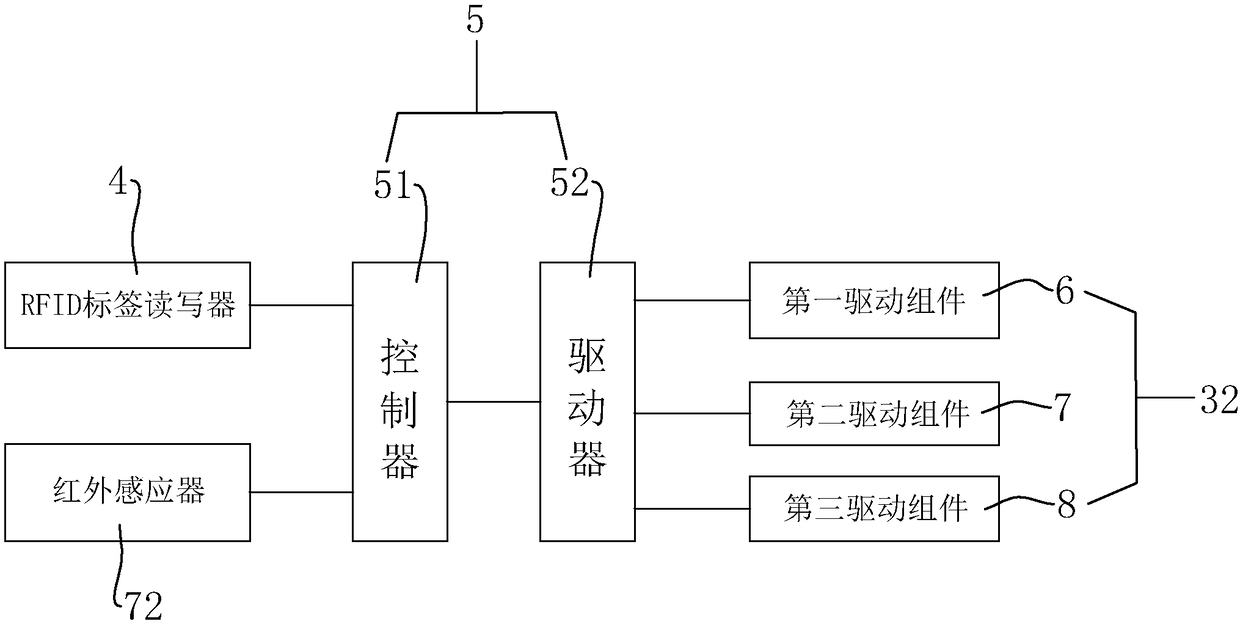

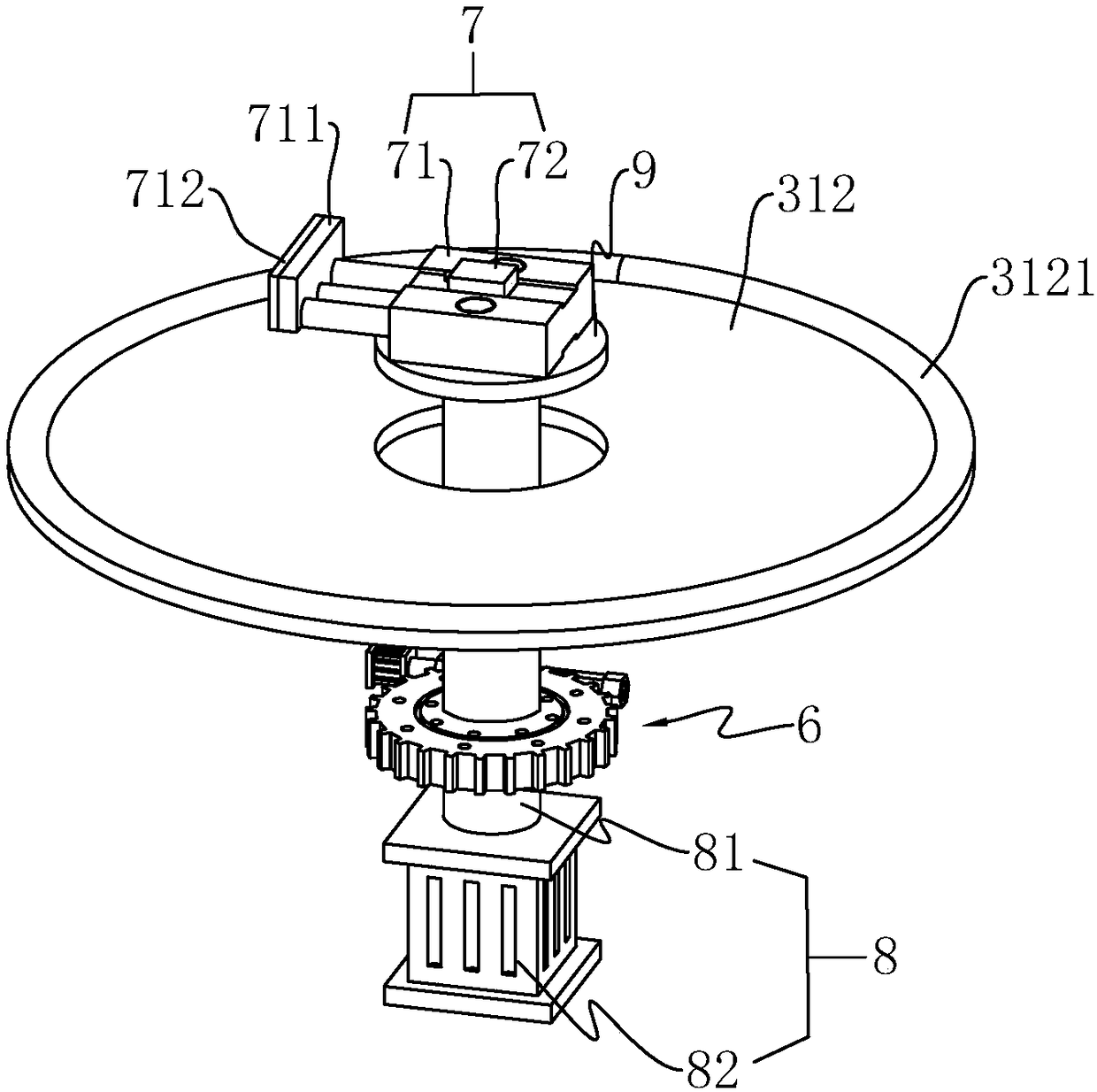

[0037] See attached Figure 1-2 , a sorting system for goods, mainly used for automatic sorting of goods, it includes a storage line body 1 and at least two sets of sorting lines 2 for receiving different goods, the storage line body 1 and sorting line 2 can be The goods are conveyed by conveyor belts and other similar means. A receiving device 3 is provided between the storage line body 1 and the sorting line 2; wherein, a cargo identification module is provided at the connection between the storage line body 1 and the receiving device 3 . Moreover, the cargo sorting system also includes a control module 5 for comprehensive control, the control module 5 includes a controller 51 and a driver 52; the cargo identification module is electrically connected to the controller 51, and the receiving device 3 is electrically connected to the driver 52 sexually connected.

[0038] In actual work, the controller 51 can control the receiving device 3 to start through the driver 52; the ...

Embodiment 2

[0051] See attached Figure 2-3 , the present invention also provides a method for sorting goods, comprising the following steps:

[0052] S1. According to the rotation direction of the turntable 312, the sorting lines 2 are sequentially numbered from 1 to n.

[0053] S2. The storage line body 1 transports the goods to the turntable 312, the RFID tag reader 4 scans the RFID electronic tags on the outer packaging of the goods, and transmits the relevant information to the controller 51 through electrical signals.

[0054] S3. After the controller 51 decodes and compares the electrical signals from the RFID tag reader 4, it specifies the corresponding sorting line 2 for the goods that are about to enter the carousel 312.

[0055] In actual work, each sorting line 2 corresponds to a type of goods; then, according to the type of goods to be sorted by each sorting line 2, arrange them on the peripheral side of the turntable 312, and use 1 to n to sort them. The serial number mean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com