Automatic shoe cutting machine

A cutting machine and shoe upper technology, which is applied to shoemaking machinery, footwear, heel pads, etc., can solve the problems of high labor intensity, low sorting efficiency, and low efficiency, so as to reduce labor intensity and facilitate operation , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below with reference to the accompanying drawings.

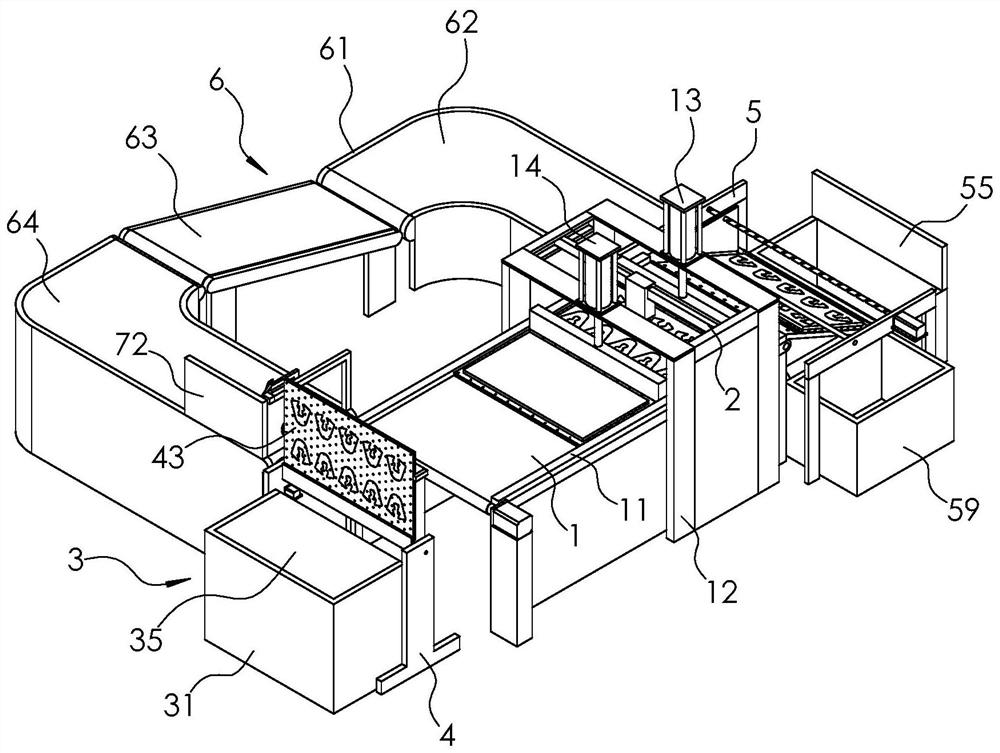

[0040] like figure 1 As shown, an automatic shoe upper cutting machine includes a first conveyor belt 1, a cutting device 2 located just above the first conveyor belt 1, and a placement rack 3 located at the input end of the first conveyor belt 1. The cutting device 2 is a numerically controlled vibration Knife cutting machine, because the numerical control vibration knife cutting machine is the prior art, so it will not be repeated here.

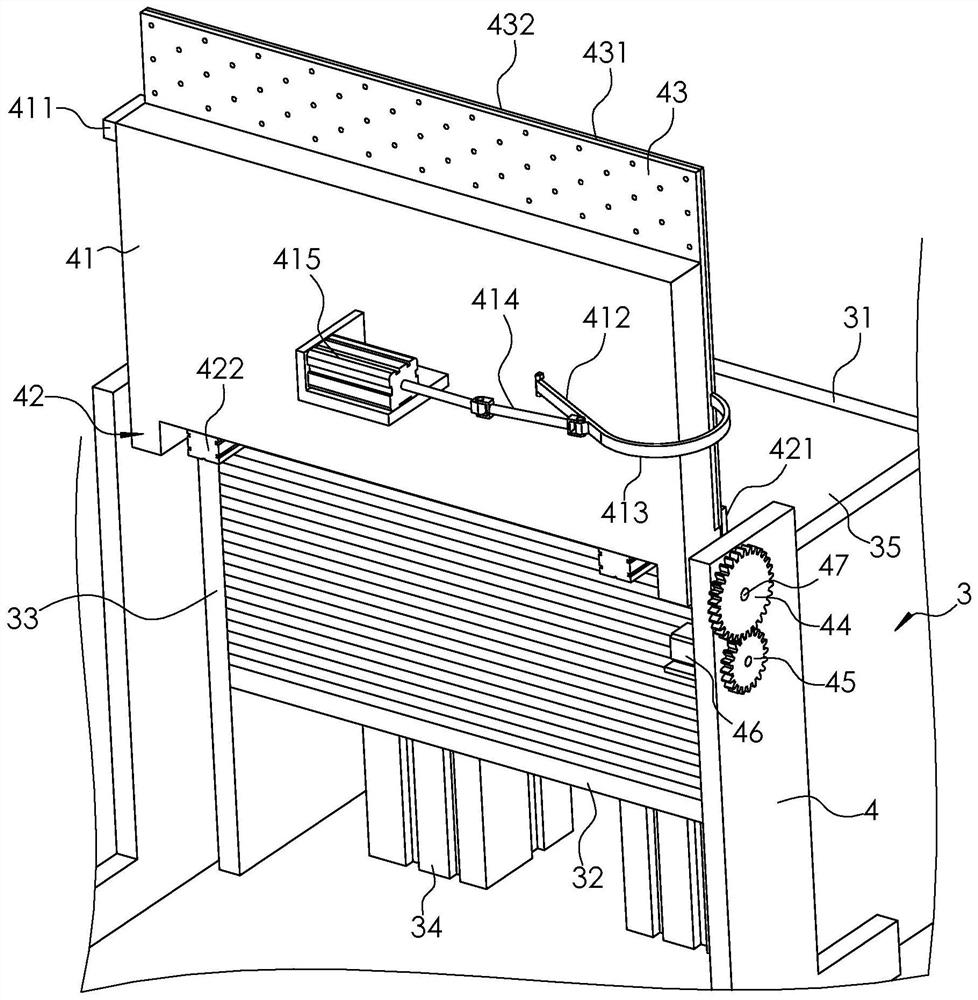

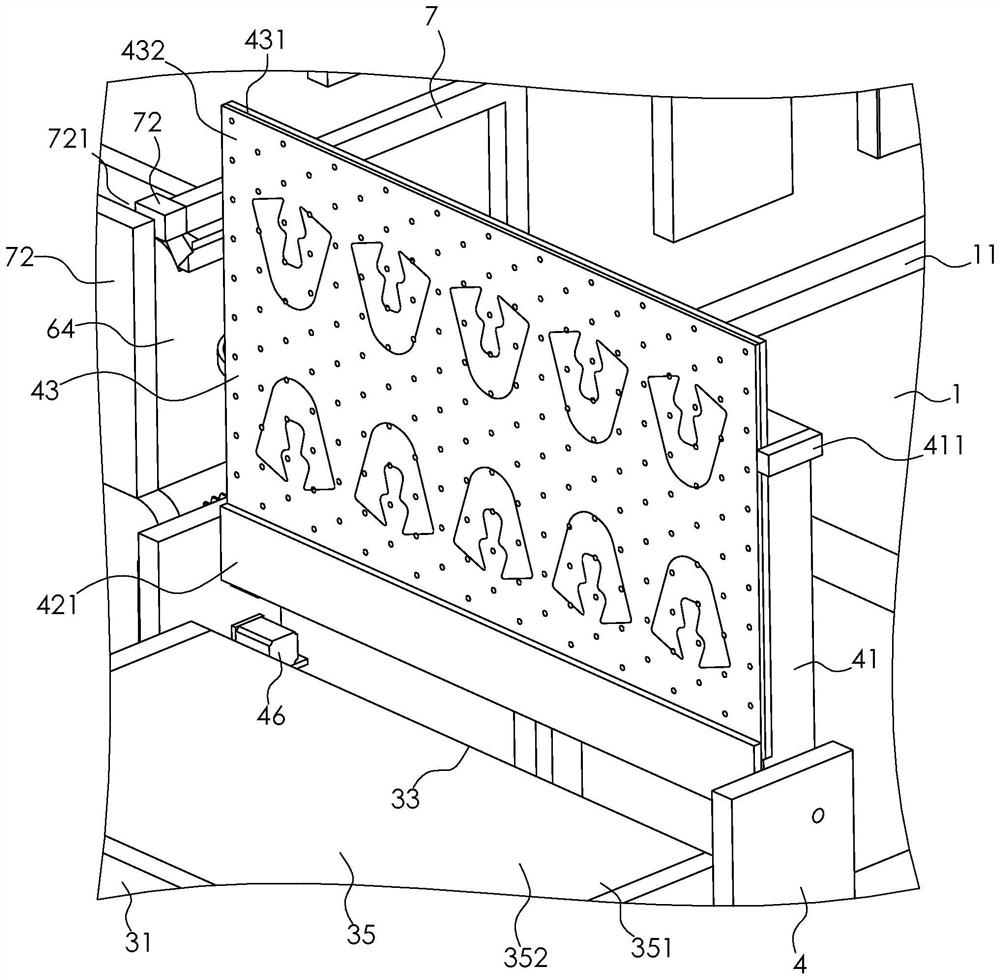

[0041] like figure 2 and image 3 As shown, the placing rack 3 includes a vertical plate 31 fixed on the ground and arranged in a "U" shape, and a support plate 32 slidably embedded in the vertical plate 31. The vertical plate 31 is provided with an opening facing the first conveyor belt 1 33. The fabric 35 is stacked on the pallet 32. The lower side of the placing frame 3 is provided with two sets of lifting parts, bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com