Mixed stacking production line by robot

A robot and mixed stacking technology, applied in the field of palletizing production line, can solve the problems of increasing labor costs, reducing palletizing efficiency, etc., and achieve the effect of compact structure and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

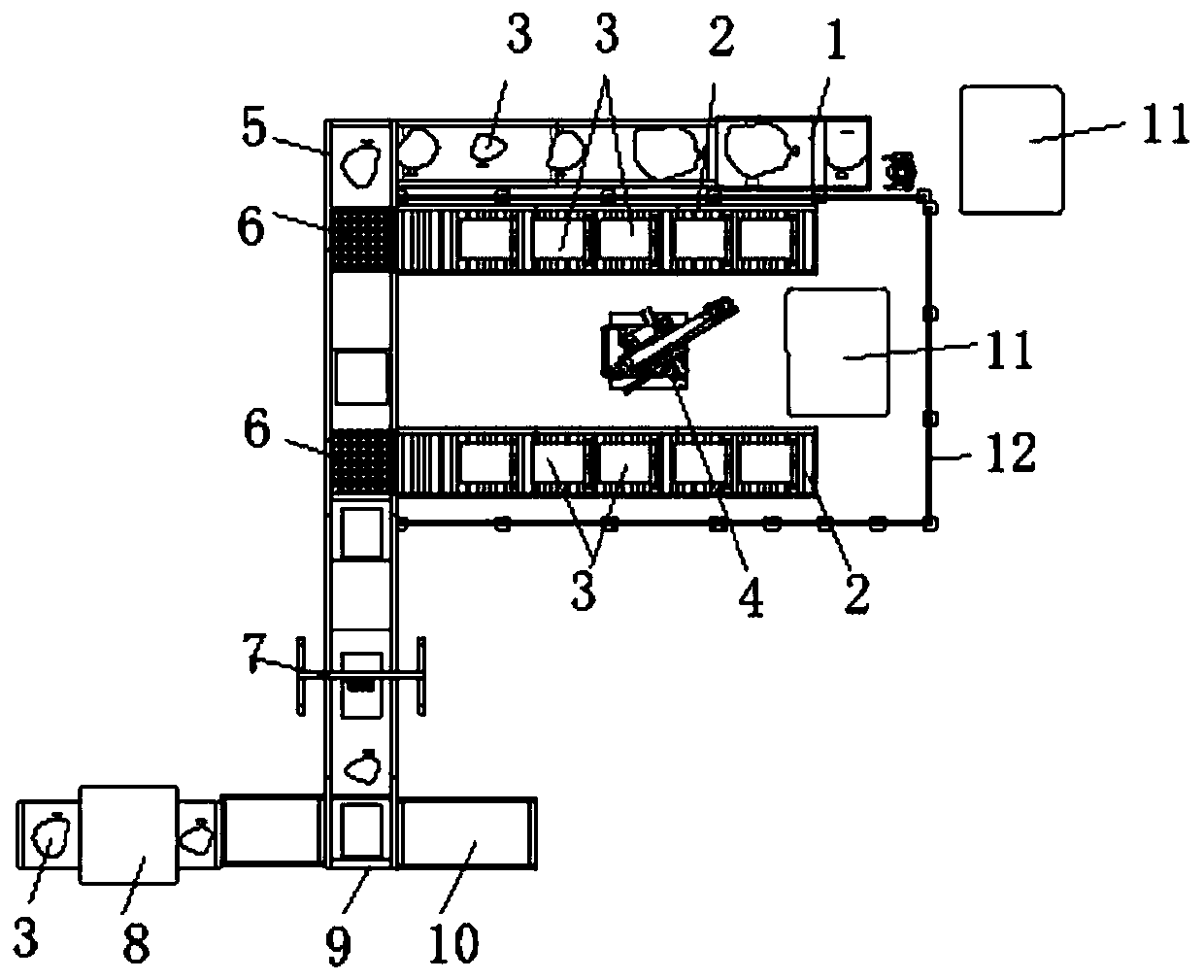

[0033] On the basis of the above structure, in this embodiment, the sorting conveyor line includes a first conveyor track 5 and a detection device, the detection device is installed at the feeding end of the first conveyor track 5, and the recovery conveyor line 1 is installed on the first conveyor track The discharge end of 5; the first distribution device 6 is respectively installed at the position where the first conveying track 5 is connected with the feed end of a plurality of stacking conveying lines 2, and the plurality of first distribution devices 6 are connected with the detection device respectively. Communication connection, the detection device detects, judges and analyzes the material 3, and controls multiple first distribution devices 6 to distribute the material 3 to multiple palletizing conveying lines 2 and recycling conveying lines 1 according to the analysis results. During the sorting process of the material 3, the material 3 is conveyed through the first c...

Embodiment 2

[0035] On the basis of Embodiment 1, in this embodiment, the detection device includes a camera 7 and a control unit, and the camera 7 is preferably a 3D camera, which is installed on the first conveying track 5 through a bracket, and is used to collect pictures of the material 3 and send them To the control unit, the control unit judges and analyzes after receiving the picture of the material 3, and then controls the operation of a plurality of first distribution devices 6 according to the analysis results; The way those skilled in the art can think of is installed on the top of the bracket, such as by bolts. At this time, the housing of the camera 7 and the top of the bracket are respectively provided with screw holes that cooperate with the bolts, which is convenient for disassembly. During the detection process, the camera 7 collects pictures of the materials 3 and sends the pictures to the control unit, and the control unit analyzes the size of each material 3 .

[0036] ...

Embodiment 3

[0039] On the basis of Embodiment 1, in this embodiment, the sorting conveyor line also includes a security inspection device 8 for security inspection of the material 3. The security inspection device 8 is installed on the feeding end of the first conveying track 5, and the material 3 Carry out security inspection to judge whether the material 3 is qualified, and then send the qualified material 3 to the first conveying track 5, and take out the unqualified material 3 manually. Security inspection is performed on the material 3 through the security inspection device 8 to ensure the safety of sorting, which is safe and reliable.

[0040] The above-mentioned security inspection device 8 adopts the existing technology, and the security inspection machine is preferred. The security inspection machine is a kind of commonly used security inspection equipment, which is often seen in life, such as the security inspection machine at a subway station or a high-speed rail station.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com