Soft magnetic size automatic sorting device

An automatic sorting and driving device technology, applied in sorting and other directions, can solve the problems of consuming large human resources, low efficiency of manual sorting, and pollution of workers, so as to reduce damage to human health and improve the efficiency of soft magnetic sorting. , the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

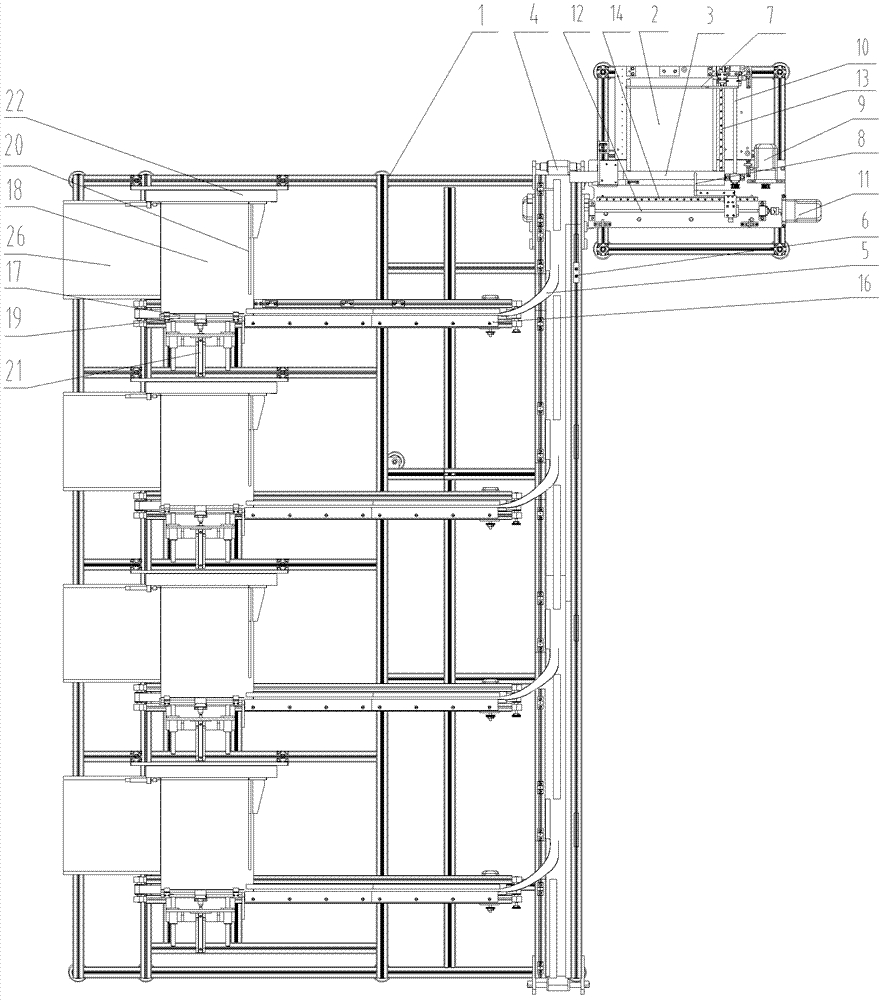

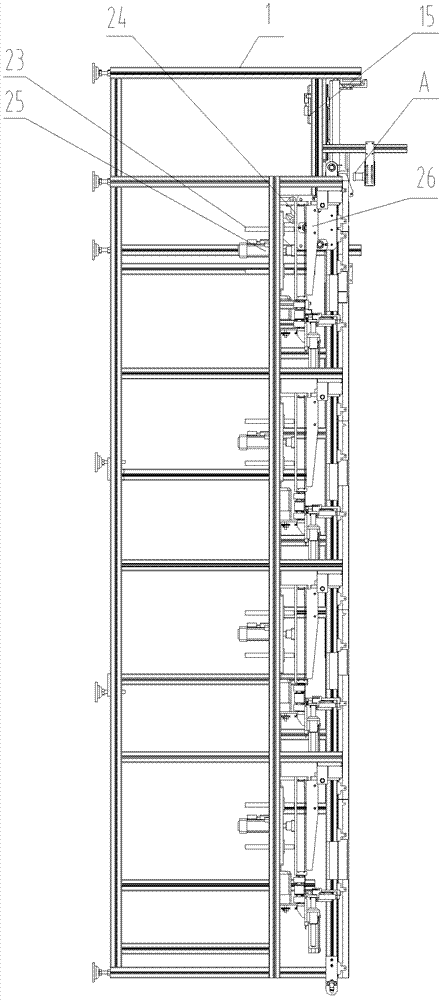

[0030] Example: Combined figure 1 , figure 2 As shown, this soft magnetic size automatic sorting device provided by the present invention has a body 1, and the body 1 is provided with:

[0031] Feeding mechanism: The feeding mechanism is composed of a storage tray 2, a feeding and pushing device for pushing materials out of the storage tray 2, and a storage tray advance and retreat drive device. The feeding and pushing device in this embodiment consists of a feeding slide rail 13, a feeding slide block (not shown in the figure) arranged on the feeding slide rail 13, and a feeding pusher fixed on the feeding slide block. Plate 7 and is connected and drives the feed push pedal driving device that feed push pedal 7 advances along feed slide rail 13 and is formed. The feeding pushing plate drive device includes a feeding reduction motor 9 and a feeding screw nut transmission pair 10, the feeding reduction motor 9 is connected via a belt and drives the screw in the feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com