Quartz crystal wafer thickness sorting machine and method

A technology of quartz wafers and sorting machines, applied in sorting and other directions, can solve problems such as large errors, achieve the effects of increasing production capacity and wafer pass rate, improving sorting efficiency, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

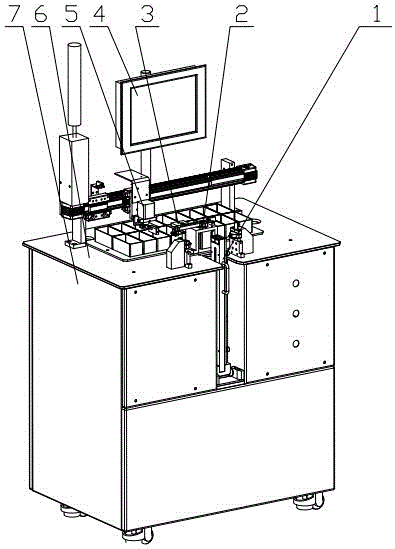

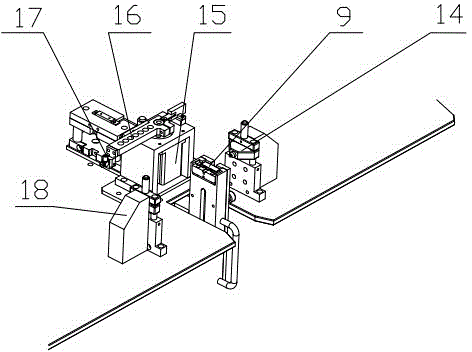

[0041] like figure 1 As shown, the quartz wafer thickness sorter of the present invention includes a feeding module 1, a retrieving module 2, a thickness measurement module 3, and a sorting module 5; the retrieving module 2 includes a retrieving motor 15, and the output end of the retrieving motor 15 Connect the fixed end of the arm 16, and the motor 15 can drive the arm 16 to rotate around its fixed end; the free end of the arm 16 is provided with an upper electrode 17;

[0042] One side of the retrieving motor 15 is provided with a feeding module 1, and the other side of the retrieving motor 15 is provided with a thickness measurement module 3; one side of the thickness measurement module 3 is provided with a sorting module 5;

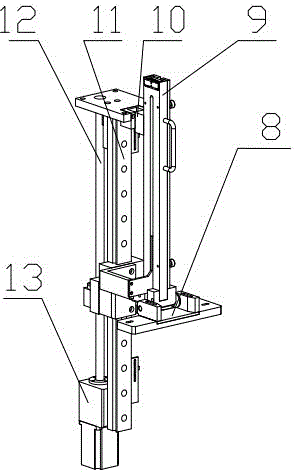

[0043] like figure 2 As shown, the feeding module 1 includes a feeding motor 13, and the output end of the feeding motor 13 is connected to a ball screw 12; the ball screw 12 is connected to a slide block arranged in the elongated film box 9 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com