Bagged cigarette coding detecting method, device and system

A detection device and detection method technology, applied in the direction of packaging cigarettes, packaging cigars, sorting, etc., can solve the problems of retailer influence, service level, waste of manpower, etc., to reduce re-inspection, increase overall efficiency, and reduce logistics costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

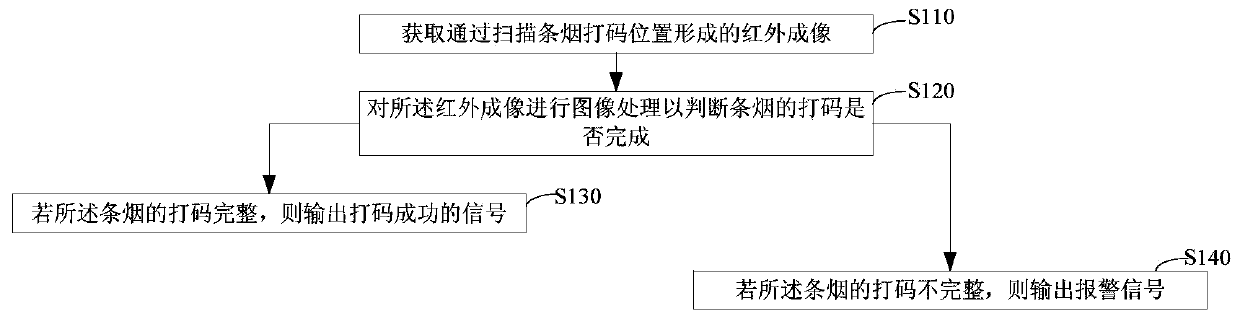

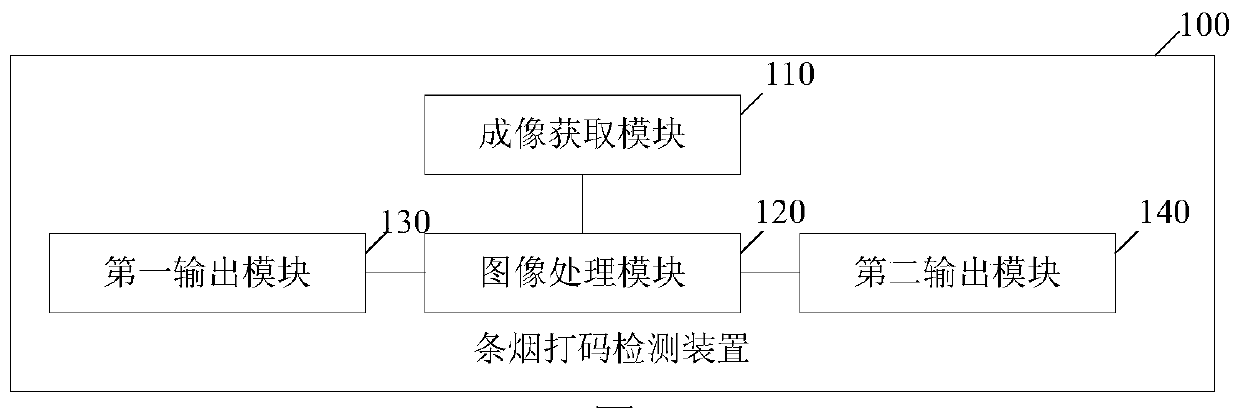

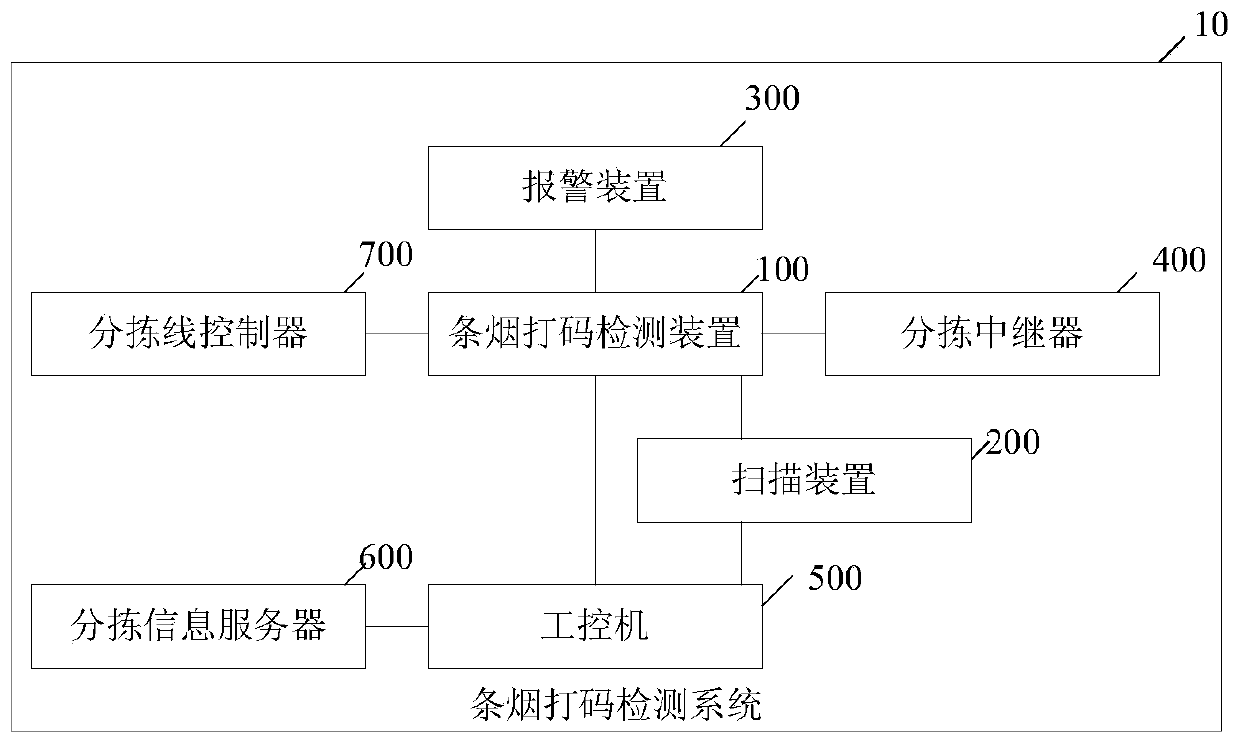

Method used

Image

Examples

Embodiment Construction

[0039] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0040] Infrared thermal imaging uses photoelectric technology to detect infrared specific band signals of thermal radiation of objects, converts the signals into images and graphics that can be distinguished by human vision, and can further calculate the temperature value. Infrared thermal imaging technology enables human beings to transcend visual barriers, so that people can see the temperature distribution on the surface of objects.

[0041] If the surface temperature of an object exceeds absolute zero, it will radiate electromagnetic waves. As the temperature changes, the radiation intensity and wavelength distribution characteristics of electromagnetic wave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com