Crossed belt type sorting system and sorting system

A sorting system and cross-belt technology, applied in the field of logistics sorting equipment, can solve the problems of low turnover rate of turnover boxes, uninterrupted use of grid openings, time-consuming and labor-intensive replacement of turnover boxes, etc. The effect of picking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

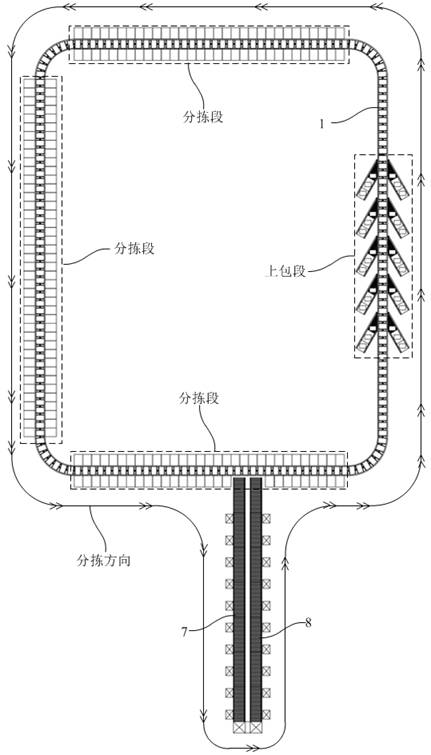

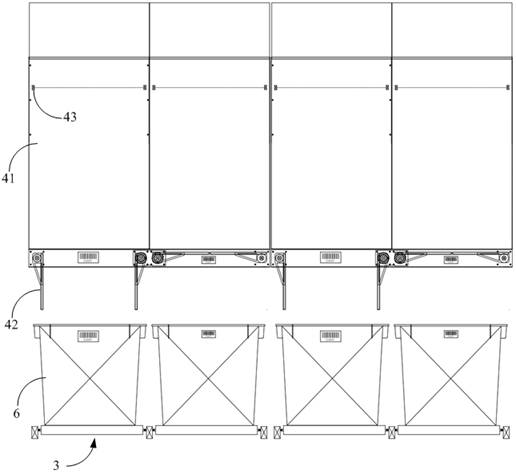

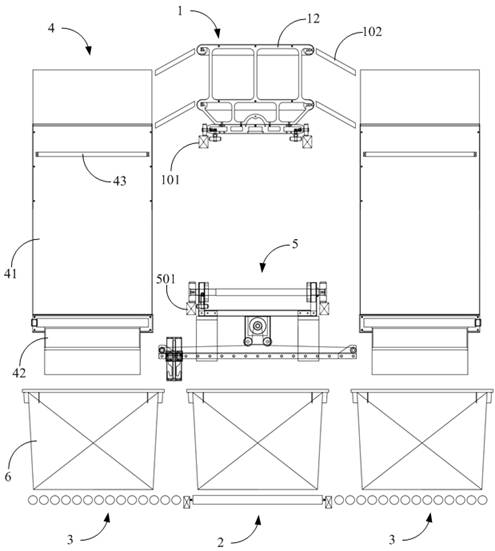

[0032] Please refer to the attached Figure 1-3 , in the embodiment of the present invention, a cross-belt sorting system is proposed, which includes a sorting conveyor line 1, and the sorting conveyor line 1 is sequentially divided into an upper bag section and three sorting sections along the sorting direction. , sorting personnel can place the parcels to be sorted on the sorting conveyor line 1 in the upper package section, and sort them when they move from the sorting conveyor line 1 to the sorting section. Specifically, the sorting conveying line 1 includes an annular track support 101, on which a plurality of end-to-end connected trolleys 11 and a drive system for driving the trolleys 11 to move between the tracks are arranged on the track support 101. The drive systems commonly used in the existing cross-belt sorting systems are the same, and will not be repeated here.

[0033] The sorting conveying line 1 is provided with a plurality of grid positions arranged side by...

Embodiment 2

[0064] On the basis of above-mentioned embodiment 1, as Figure 7 As shown, in this embodiment, the hooking and pushing mechanism 5 also includes a lifting and intercepting component 55 . In this way, when the turnover box 6 reaches the bottom of the hook and push mechanism 5, the lifting and intercepting assembly 55 can be driven down to stop the turnover box 6 from continuing to move, and the circulating roller line 2 can also maintain normal operation without the need to transfer the turnover box 6. Pause to further improve sorting efficiency.

[0065] In this embodiment, the second tag reading device 502 is arranged on the lifting and intercepting assembly 55 . When the lifting and intercepting assembly 55 descends, the second label reading device 502 can scan the first label on the turnover box 6 to determine whether there is a package in the turnover box 6, so that the turnover box 6 carrying the package can be released , so as not to affect the conveyance of the turno...

Embodiment 3

[0071] On the basis of above-mentioned embodiment 1 or embodiment 2, as Figure 10 As shown, in this embodiment, the trolley 11 adopts a double-layer sorting structure, which specifically includes the moving assembly 112 arranged on the track support 101 and the double-layer sorting assembly arranged on the walking assembly 112 .

[0072]Wherein, the traveling assembly 112 is similar to the traveling mechanism of the existing sorting trolley, and will not be described in detail here. The double-layer sorting assembly includes two hollow skeletons 111 arranged opposite to each other. The two hollow skeletons 111 are vertically arranged on the walking assembly 112. Between the two hollow skeletons 111, a conveyor belt 1111 arranged up and down in parallel is arranged.

[0073] Specifically, in this embodiment, the conveyor belt 1111 includes two rollers (not shown), one of which is a non-powered roller, and the other roller is a powered roller. The roller shaft of the unpowered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com