Process for recycling fine coal from middlings

A clean coal and process technology, which is applied in the field of clean coal recovery from China Coal, can solve the problem that scarce coking coal resources cannot be recycled and reused, and achieve the effects of improving equipment utilization, significant economic benefits, and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

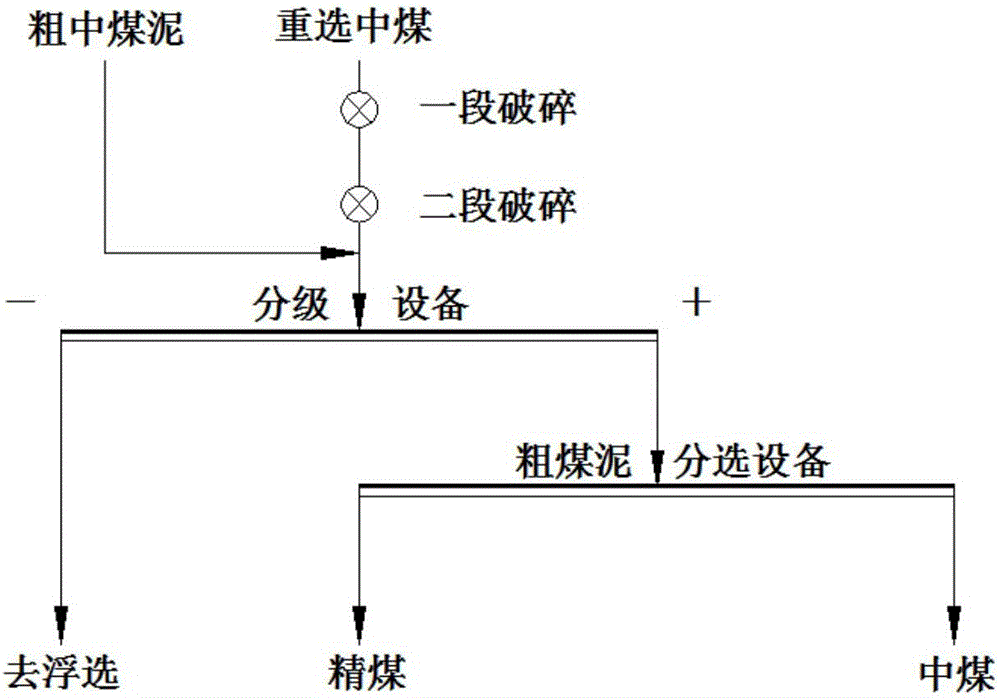

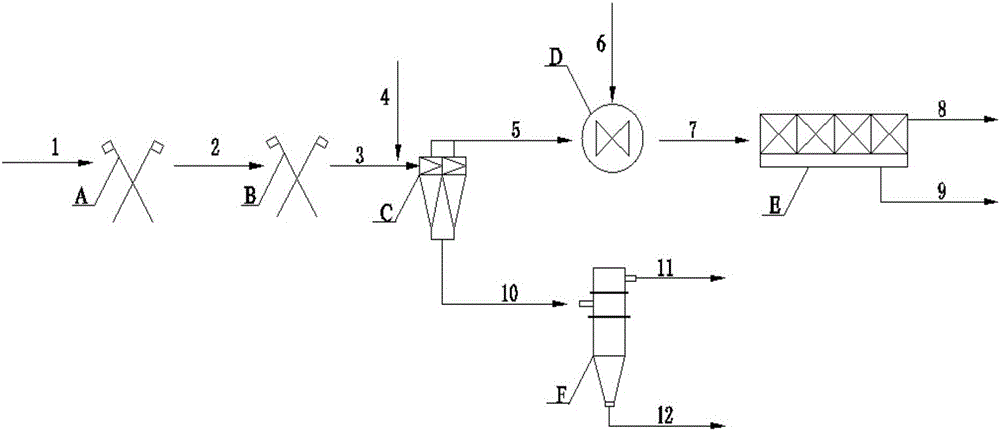

[0034] Such as figure 1 as shown, figure 2 for figure 1 The corresponding equipment contact diagram includes the following steps:

[0035] Step 1: Firstly, pass the middling coal through the media-removing sieve, and feed the mid-coal (with a particle size of 50-0.5mm) 1 on the media-removing sieve into the reversible hammer crusher A for crushing to 13 mm by belt or scraper transportation. For the following first-stage crushing product 2, feed the first-stage crushing product 2 to the reversible hammer crusher B for secondary crushing, and crush it to the second-stage crushing product 3 with a particle size below 5mm; crush the medium coal to below 5mm, which can reduce energy consumption , The crushing equipment adopts a reversible hammer crusher, which has a smaller over-crushing amount than the two-stage dissociation device, and the -0.25mm yield can be reduced by about 16%, which reduces the unreasonable impact of medium coal recovery on the existing flotation system. ...

Embodiment 2

[0040] The addition of flotation agent 6 in step 3 in Example 1 is that the addition of diesel oil in per ton of overflow is 1000g, and the addition of foaming agent is 50g.

Embodiment 3

[0042] The addition of flotation reagent 6 in step 3 in embodiment 1 is that the addition of diesel oil in per ton of overflow is 700g, and the addition of foaming agent is 80g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com