Crushing device for sorting gangues and sorting method

A crushing device and coal gangue technology, applied in the direction of grain processing, etc., can solve the problems of unsatisfactory sorting particle size and precision, unable to meet the requirements of sorting density, unable to meet the requirements of coal gangue sorting, etc., and achieve the goal of improving the utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in conjunction with the accompanying drawings.

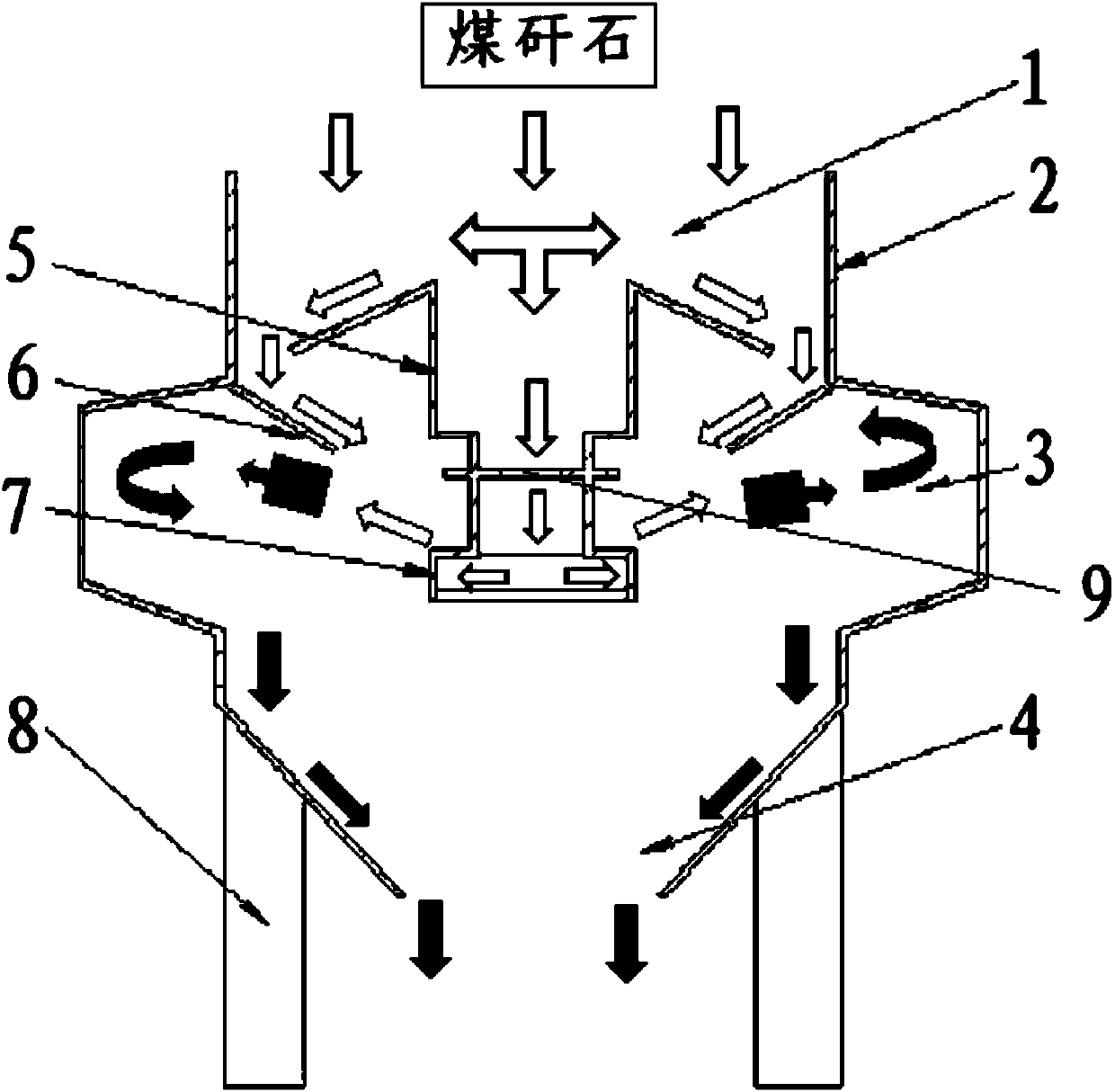

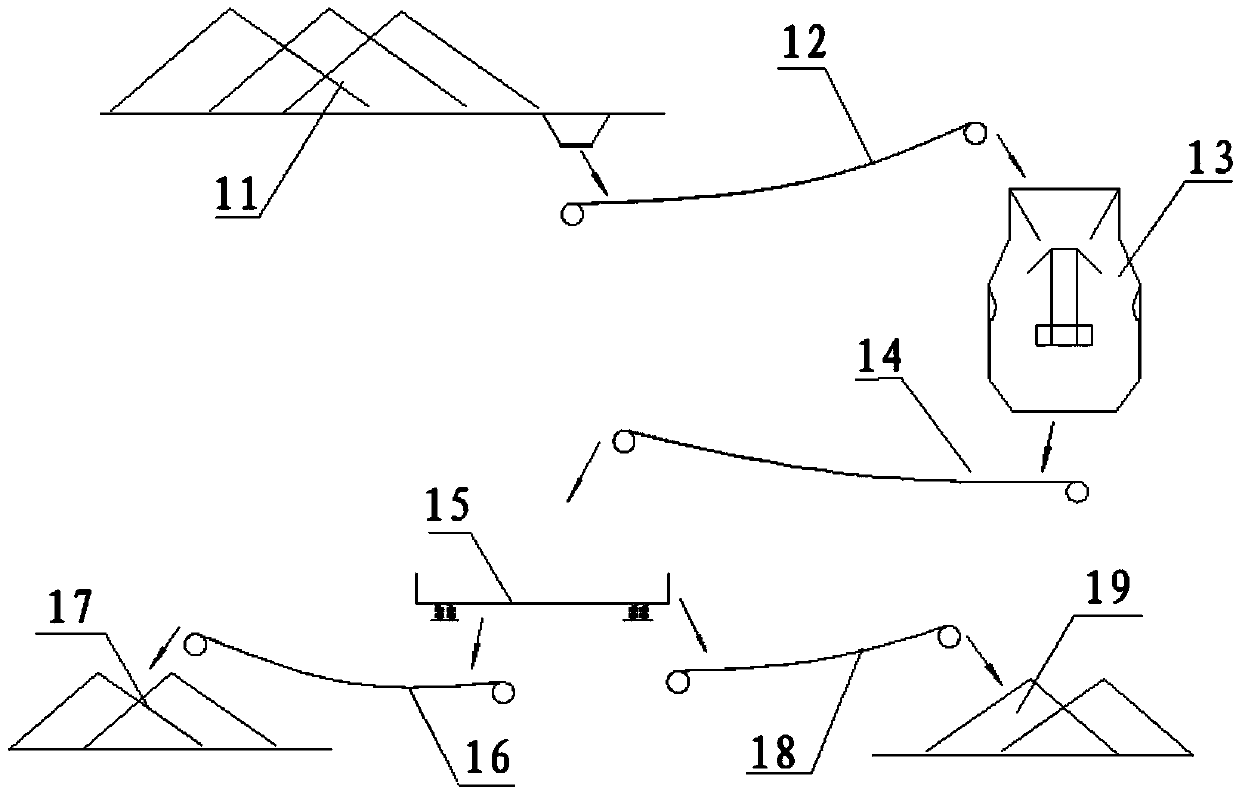

[0021] Such as figure 1 As shown, the present invention includes an outer cover 2, a material distribution device 5, some deflectors 6, a material rejection tray 7, and a support 8, and is characterized in that: the outer cover 2 is fixed on the support 8, and the top of the outer cover 2 is provided with a feed port 1, The bottom of the outer cover is provided with a discharge port 4, and the middle part of the outer cover 2 is a vortex chamber 3; the material distribution device 5 is installed in the feed port 1 and the vortex chamber 3, and the upper part of the material distribution device 5 is an umbrella structure. The top of 5 is provided with a feeding hole, which can evenly disperse the coal gangue coming in from the feeding port 1 through the upper part of the material distribution device 5 in an umbrella-shaped structure. The middle part of the material distributi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com