Dissociation and recleaning process for coking middlings

A dissociation and process technology, applied in the direction of solid separation, grain processing, etc., can solve the problem that the low ash part cannot be released and recycled, and achieve the effects of reducing energy consumption, large crushing ratio, and small amount of over-grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

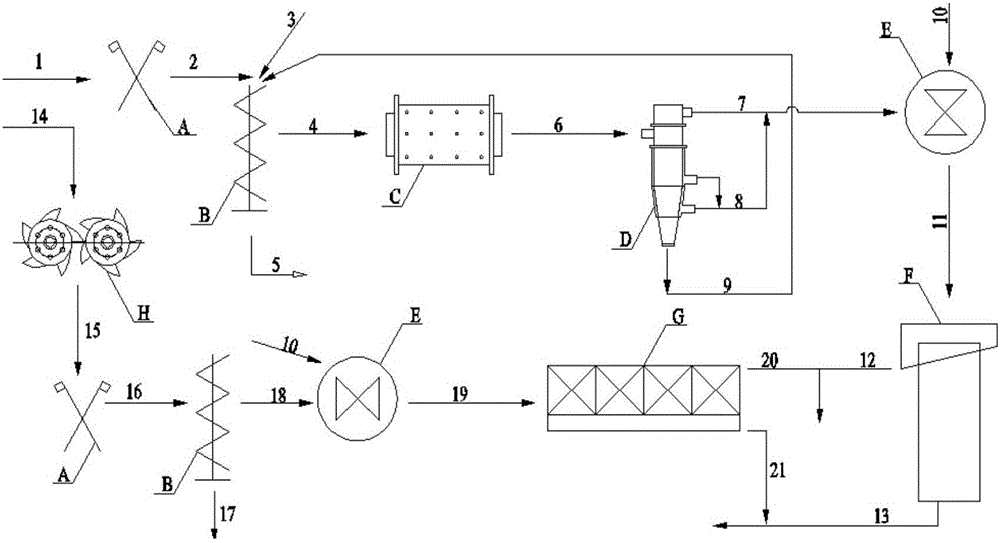

[0014] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

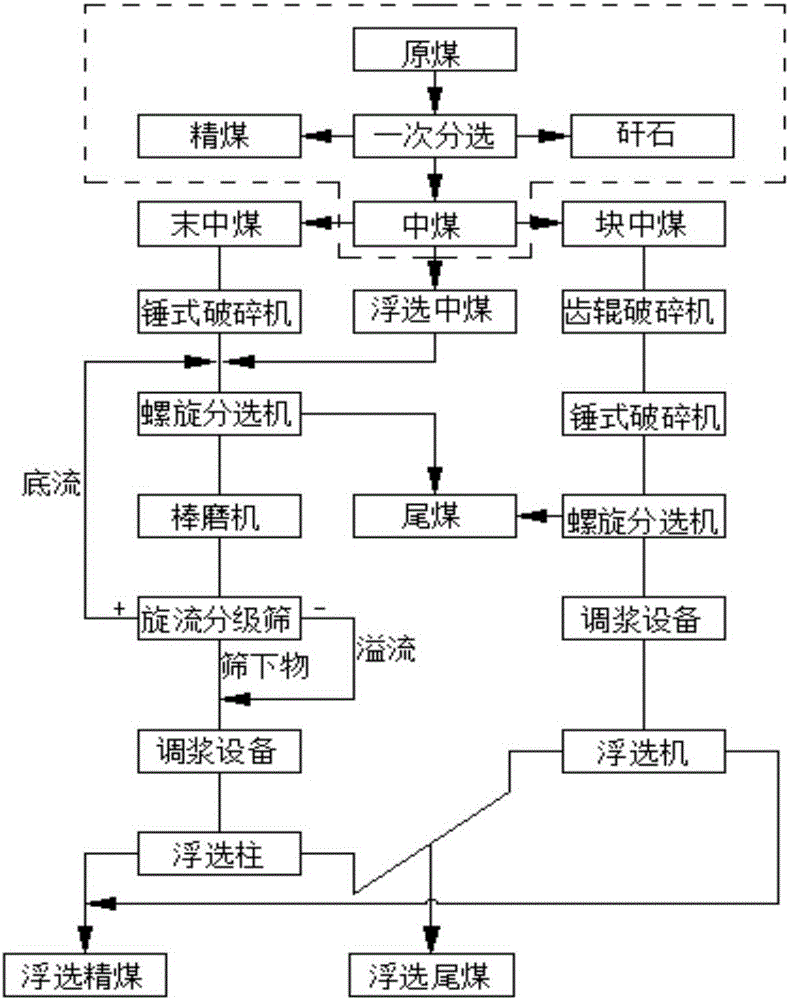

[0015] Such as figure 1 As shown, the dissociation and re-selection process of medium coal in coking comprises the use of a flotation machine to separate raw coal into clean coal, medium coal and gangue, which is characterized in that the steps are as follows:

[0016] a. Classify the medium coal with a diameter of 13mm, and separate the raw coal into lump medium coal with a diameter greater than 13mm and fine medium coal with a diameter less than 13mm;

[0017] b. The coal in the block is fed into the crushing system as a raw material for crushing to obtain finely crushed materials, and the finely crushed materials are fed into the spiral separator for sorting, and the part of the high ash tailing coal in the finely crushed materials is separated by the spiral separator; The hardness of medium coal is lower than that of gangue. Whether in the process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com