High pressure steam catalysis hydrolysis process for treating domestic refuse

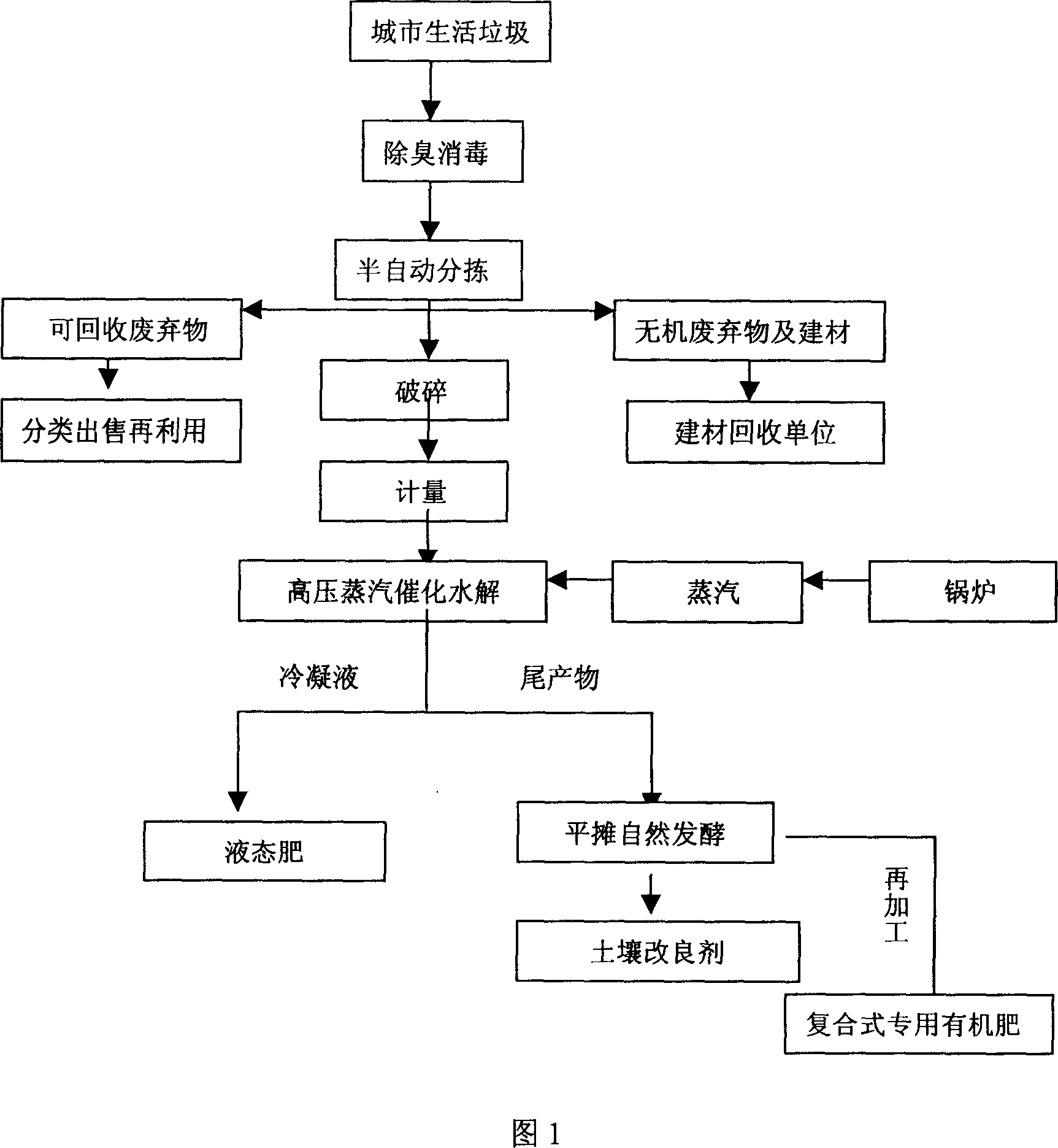

A high-pressure steam and catalytic hydrolysis technology, which is applied in climate change adaptation, organic fertilizer, recycling technology, etc., can solve the problems of high energy consumption cost, complex and cumbersome process, and low processing capacity, so as to save transportation costs and strengthen the hydrolysis effect , The effect of simple sorting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

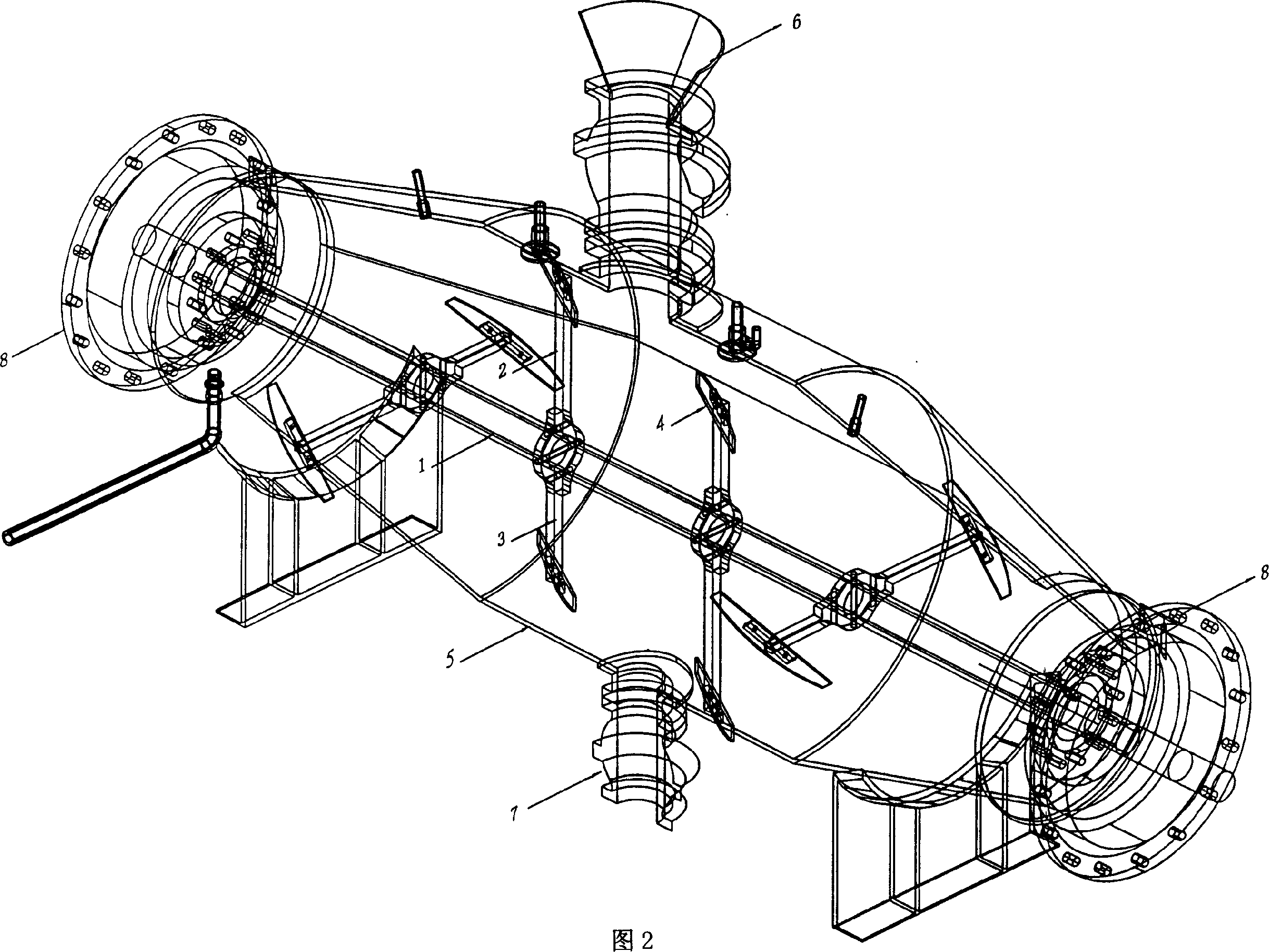

[0018] The structure of the high-pressure steam catalytic hydrolysis treatment device used in the present invention is shown in FIG. 2 . The device is composed of a cooking kettle, a stirring shaft, a stirring blade and a blade plate. Its structure is shown in Figure 1, wherein, cooking kettle 5 is marquis shape, and left and right ends is provided with sealing cover 8, and middle upper part is provided with feed inlet 6, and middle lower part is provided with discharge outlet 7, and feed inlet 7 and discharge outlet 8 are equipped with ball valves, which are used to seal and control the feeding port and the feeding port; the stirring shaft 1 is located in the center of the cooking kettle 5, and the two ends are fixed on the inner center of the sealing cover at both ends of the cooking kettle. There are 3-5 sets of stirring blades, basically Evenly installed on the stirring shaft 1, each set of stirring blades is divided into two upper and lower blades, one is the longer blade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com