Mud on-site separation device and separation method

A separation device and mud technology, which is applied in waterproof and anti-seepage and construction fields, can solve the problems of high transportation costs and environmental pollution, and achieve the effects of saving water resources, convenient transportation and saving land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

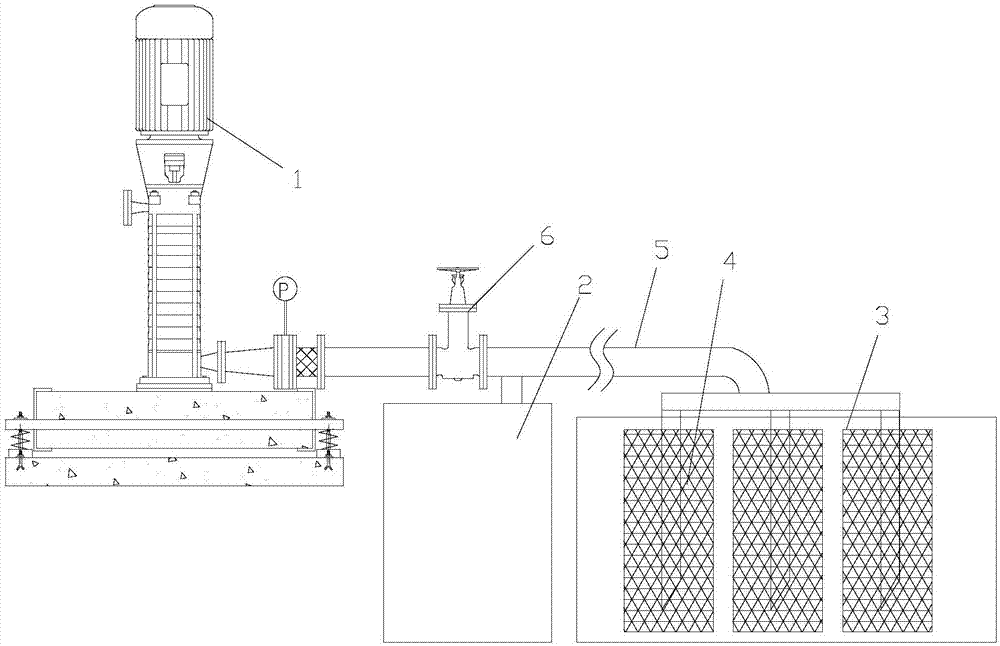

[0016] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. Such as figure 1 Shown, a kind of mud separation device on site, comprises vacuum pump 1, water storage tank 2, support cage 3, filter cloth 4, suction pipe 5, described vacuum pump communicates with one end of the suction pipe, and described water storage tank is connected in the On the side wall of the water storage tank, the other end of the suction pipe goes deep into the bottom of the support cage, and the filter cloth is wrapped around the outside of the support cage.

[0017] In order to facilitate the control of the gas flow in the water suction pipe, a manual valve 6 is provided on the water suction pipe.

[0018] In the present invention, there is at least one supporting cage. Choose according to the size of the foundation pit.

[0019] The working principle of the device is as follows: step 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com