Method for separating secondary batteries

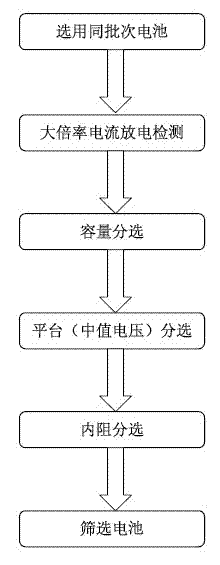

A secondary battery and sorting technology, applied in sorting and other directions, can solve the problems of high cost, complex battery sorting process, long sorting cycle, etc., to improve production efficiency, simplify sorting process and sorting equipment, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

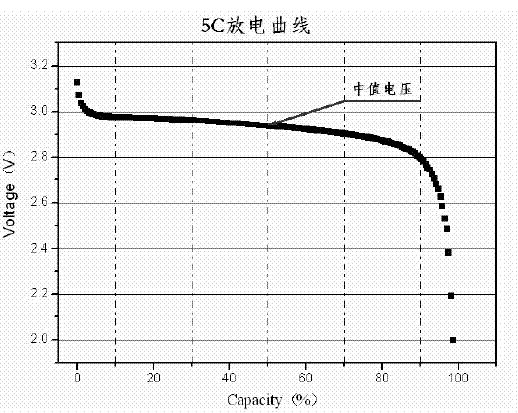

[0037] (1) Select 10 fully charged 32650-3.2V-5Ah-LR lithium iron phosphate power batteries from the same batch, place them in the lithium-ion battery detection cabinet, set the 5C rate current to discharge to 2.0V, and use the computer Record data;

[0038] (2) Make sure the capacity range of the selected secondary battery is 5000-5400mAh, set the lower limit discharge time to 12 minutes, select the battery that is greater than the lower limit discharge time, and divide it by 30 seconds;

[0039] (3) For secondary batteries within the selected capacity range, set the lower limit of 2.80V discharge platform time to 10 minutes, and select batteries greater than the lower limit of 2.80V discharge platform time;

[0040] (4) Sorting the batteries obtained in step (3) by internal resistance. In this embodiment, the internal resistance is required to be less than 10Ω. After the discharge is over, a current signal is given to the battery, and the internal resistance of the secondar...

Embodiment 2

[0051] In this embodiment, in step (3), the lower median voltage of the secondary battery within the selected capacity range can also be set to 2.93V, and the battery with a lower median voltage greater than 2.93V is regarded as a qualified battery. Specifically:

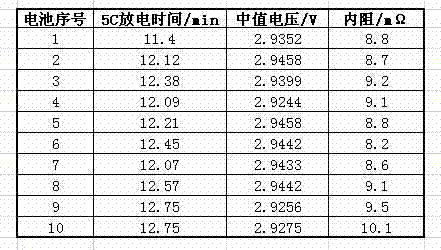

[0052] Take 10 32650-5Ah-LR secondary batteries to be tested and place them in the battery charge and discharge detection device. The computer controls the discharge test, collects and records the 5C discharge time of each battery, the median voltage and the internal resistance of the battery, and at the same time For data comparison, if the battery labels are: 1, 2, 3..., 10, the data records are shown in Table 2 below:

[0053]

[0054] Table 2

[0055]The sorting standard for determining the battery type is: the lower limit discharge time is 12 minutes, divided into 30 seconds (ie 0.5 minutes) according to the set range, the lower limit median voltage is 2.93V, and the internal resistance is 8-10mΩ.

[0056]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com