Grading technique for cutting cured leaf head and selecting slice on-line and device

A technology of sheet selection and handle, applied in tobacco, sorting, tobacco preparation, etc., can solve the problems of inconsistent sorting grades, mixed grades, and high labor intensity, and achieve the effect of easy handling and sorting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

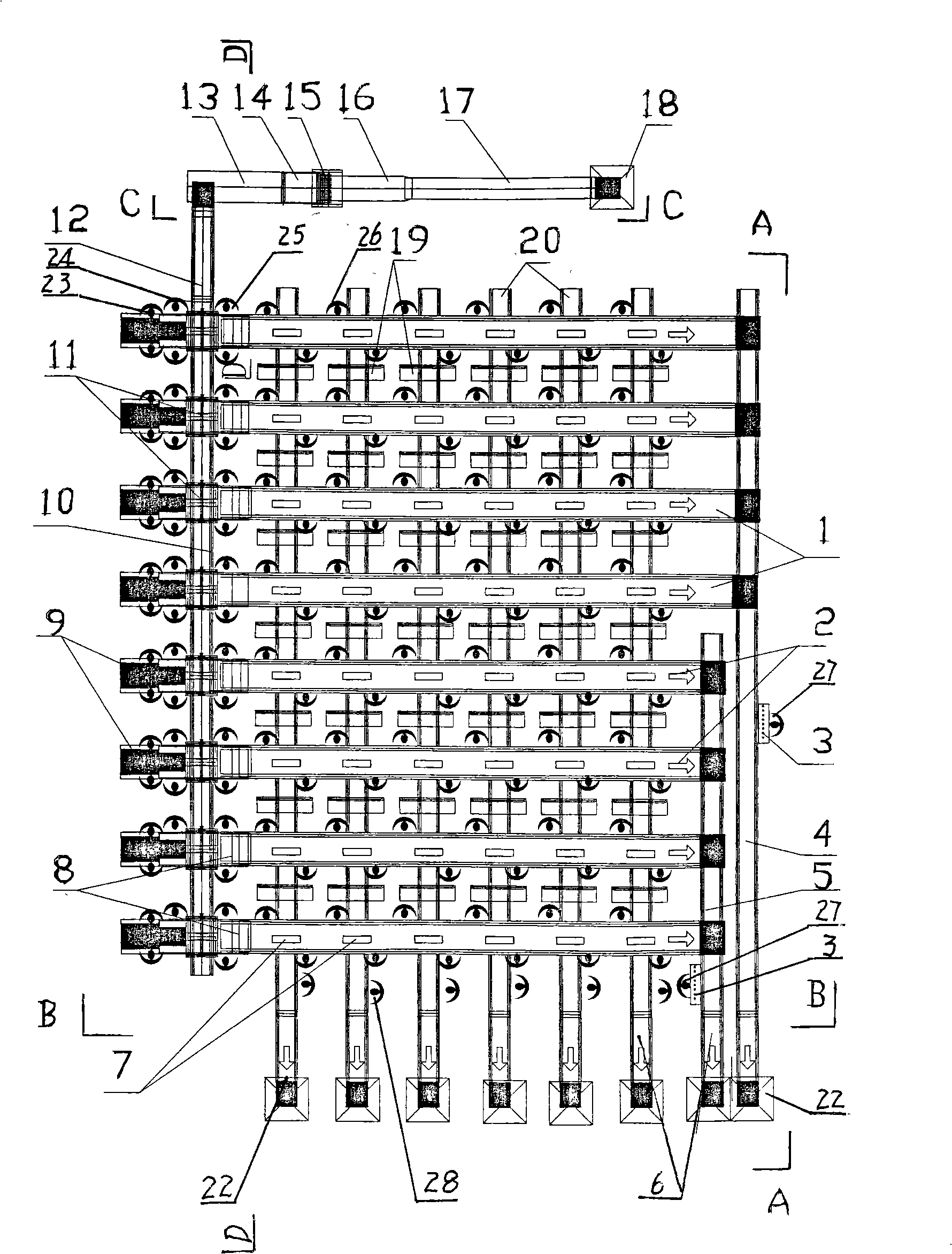

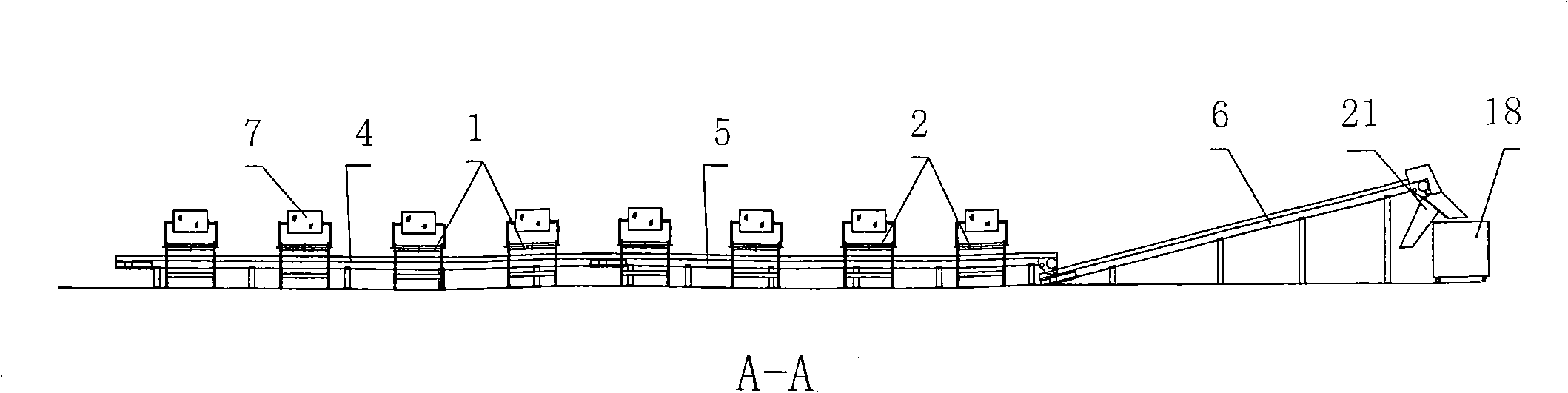

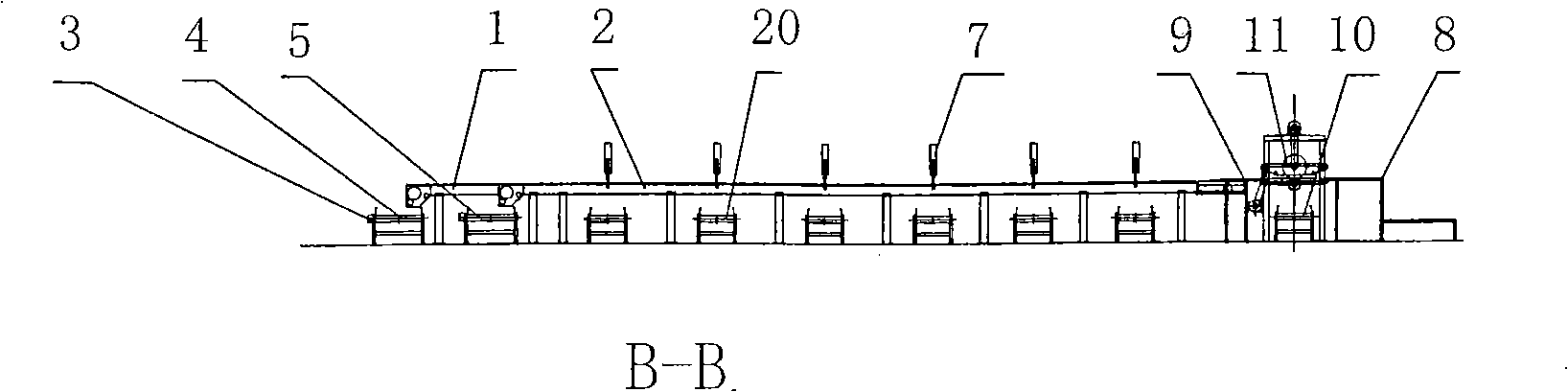

[0015] There are 8 handlebars (9), and each handlebar is connected to a head cutting machine (11). The head cutting machine is provided with a set of upper and lower cutters. The handle conveyor belt, the other end of the handle conveyor belt is connected with the tobacco leaf handle processing device, the handle conveyor belt is made up of a handle conveyor belt (10) arranged horizontally and an inclined lift handle conveyor belt (12). The head cutting machine is connected with the leaf swing table (8), and the other end of the leaf swing table is connected with a leaf selection conveyor belt, which is provided with 4 long leaf selection conveyor belts (1) and 4 short leaf selection conveyor belts (2). 6 model cases (7) are arranged on the top of the leaf conveyor belt, and the tobacco leaf model samples of each leaf selection station (26) are respectively placed in each model case, on both sides of the leaf conveyor belt, facing the model case (7) 6 manual leaf selection sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com