Automatic waste glass sorting system and control method thereof

An automatic sorting system and control method technology, applied in sorting, chemical instruments and methods, solid separation, etc., can solve the problems of extensive sorting in recycling, low mechanization and automation in processing and utilization, and lack of refined sorting technology and other issues to achieve the effect of improving sorting quality, sorting efficiency and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

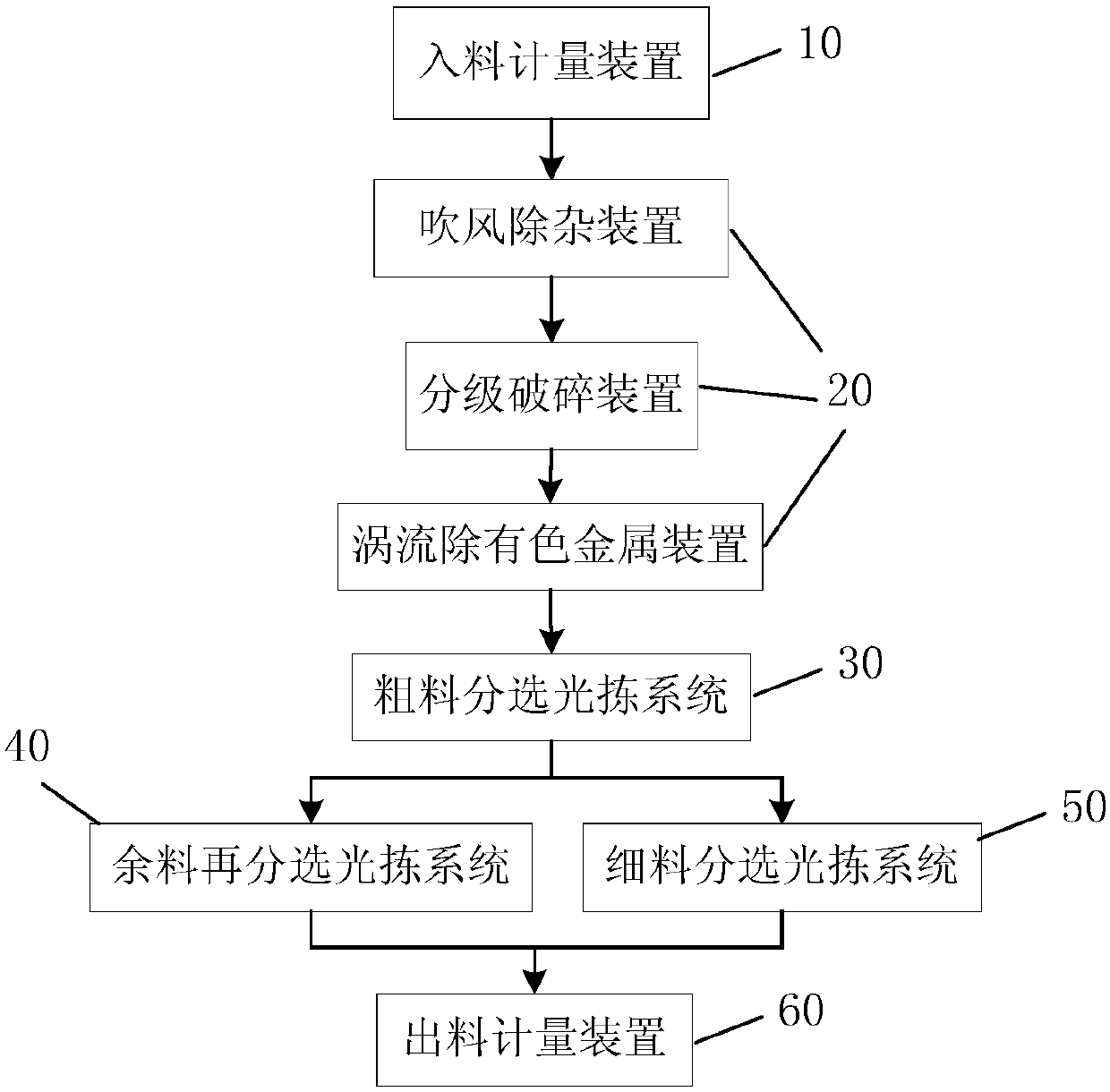

[0028] figure 1 It is a schematic diagram of the structure of the waste glass automatic sorting system of the present invention.

[0029] See figure 1, the waste glass automatic sorting system provided by the present invention includes a material feeding metering device 10, a crushing and impurity removal system 20, a coarse material sorting optical sorting system 30, a residual material re-sorting optical sorting system 40, and a fine material sorting system connected in sequence. Selecting the light sorting system 50 and the discharge metering device 60, the discharge metering device includes meter verification;

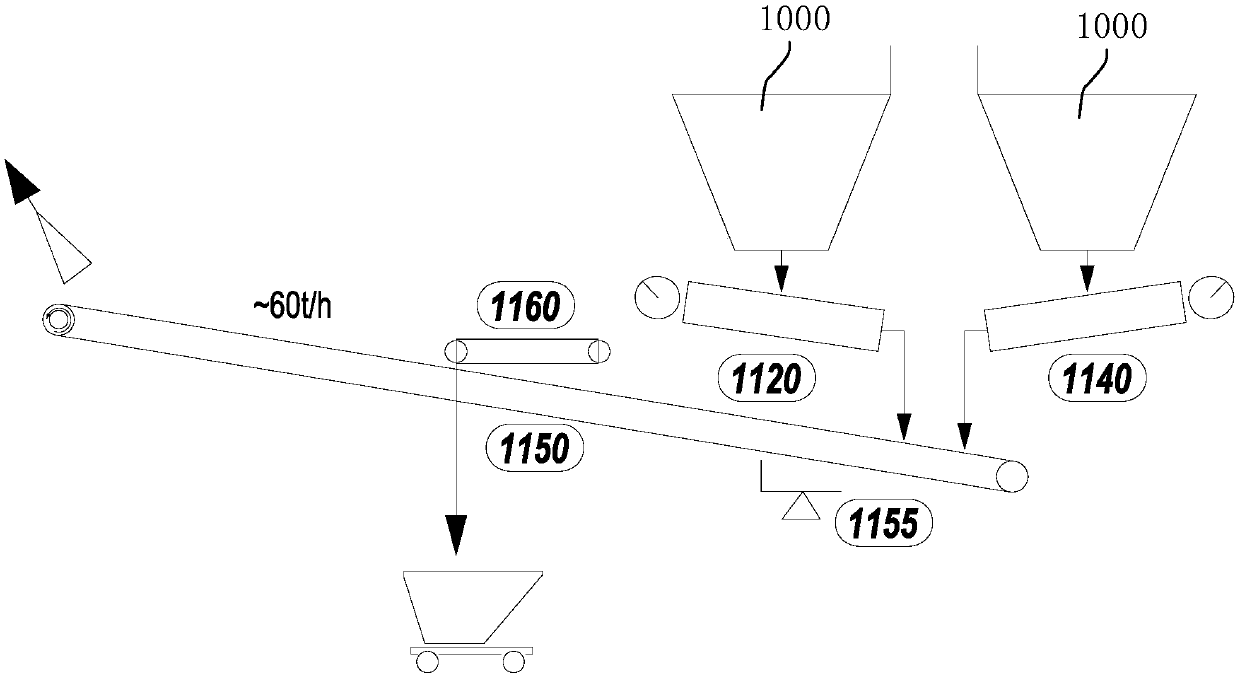

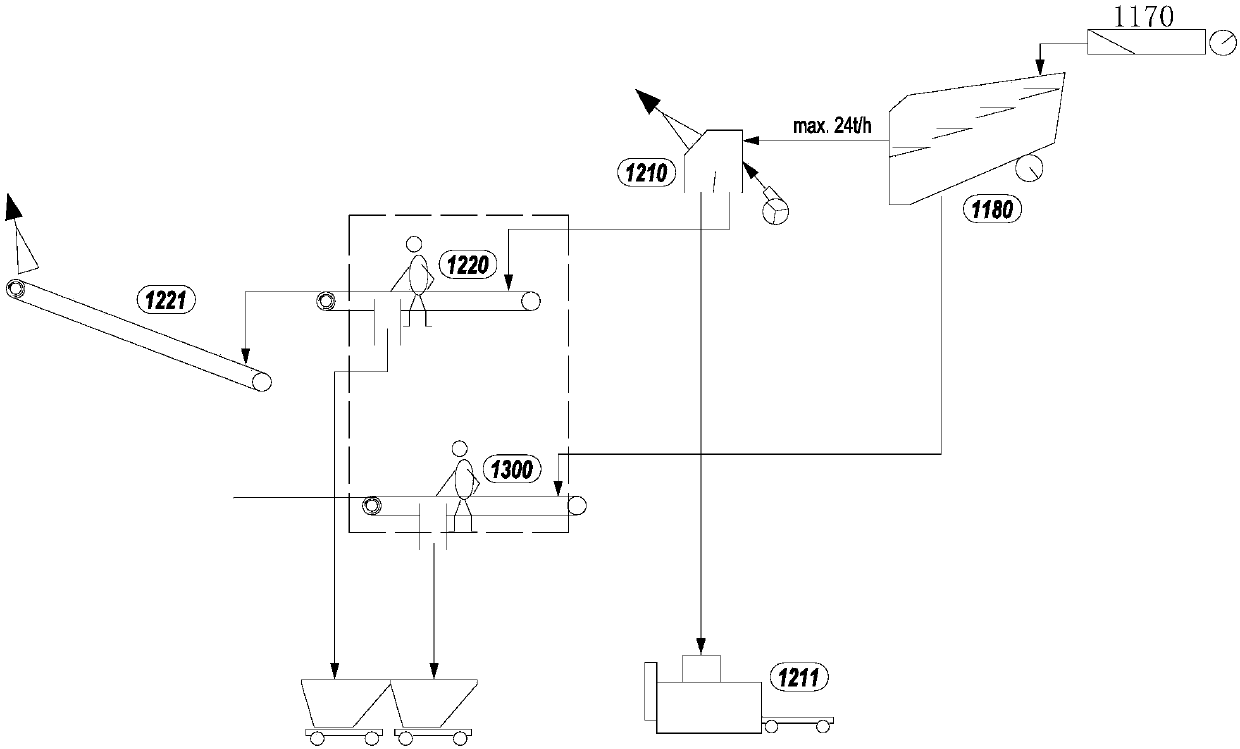

[0030] The crushing and impurity removal system includes a grading and crushing device. The grading vibrating screen in the grading and crushing device separates the material (<60mm is filtered out by grading vibration) and sends it to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com