Method for predicting industrial applicability of separated tobacco leaves through appearance characteristic indexes of tobacco leaves

A technology with characteristic indicators and applicability, applied in measurement devices, analytical materials, instruments, etc., can solve the problems of industrial applicability of the appearance quality prediction of no batches of tobacco leaves, high requirements for operators' grading level, etc., to achieve easy prediction and quantification, Improve the sorting effect and strengthen the mastering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

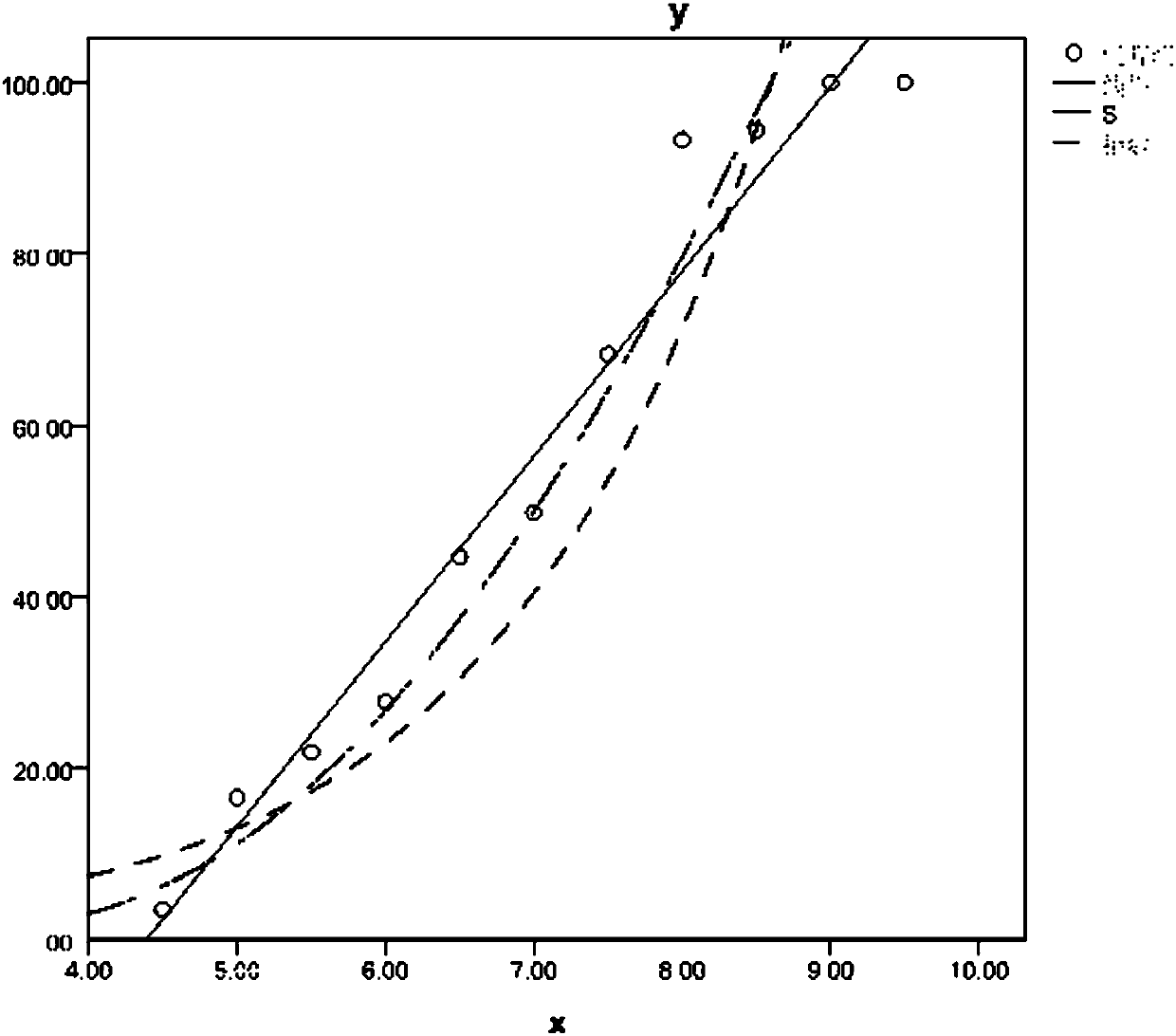

[0031] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0032] 1) Sampling

[0033] Select a C2F grade in a certain production area as the test sample, and the number of sampling packages is determined according to 0.1% of the total load of the goods (for example, if the large sample is 20,000 loads, the number of sampling packages = 20,000*0.1%, that is, 20 packages are selected for sampling); each package Take 5-7 samples from the center to the surroundings, and take 10-15 tobacco leaves from each place. A total of 14 kg of samples were taken for this test.

[0034] 2) Industrial sorting of sample appearance

[0035] Industrial sorting was carried out on the test samples of C2F grade, and the appearance quality of the test samples was classified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com