Patents

Literature

49 results about "Optical sorting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Optical sorting (sometimes called digital sorting) is the automated process of sorting solid products using cameras and/or lasers. Depending on the types of sensors used and the software-driven intelligence of the image processing system, optical sorters can recognize objects' color, size, shape, structural properties and chemical composition. The sorter compares objects to user-defined accept/reject criteria to identify and remove defective products and foreign material (FM) from the production line, or to separate product of different grades or types of materials.

Optical sorting method

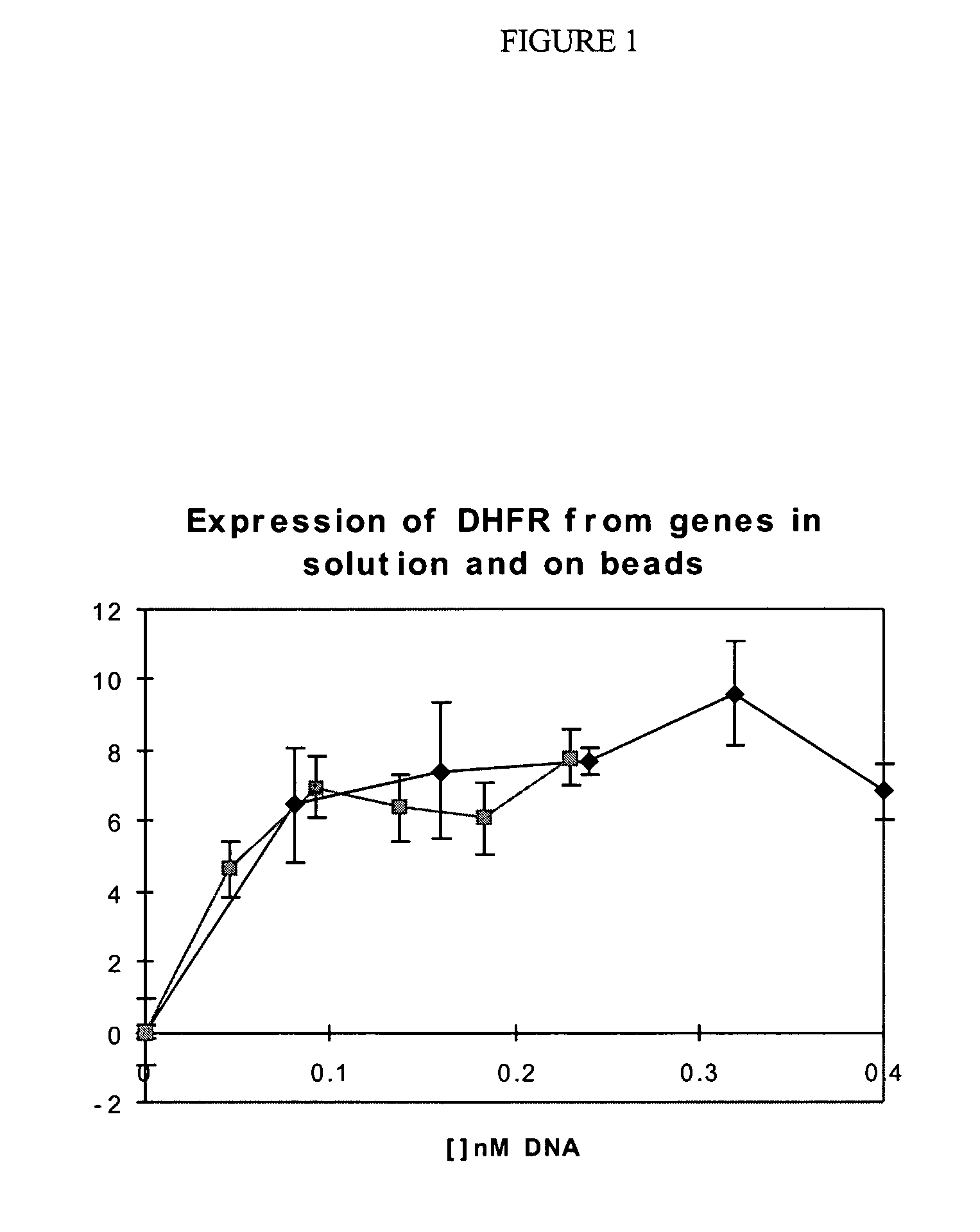

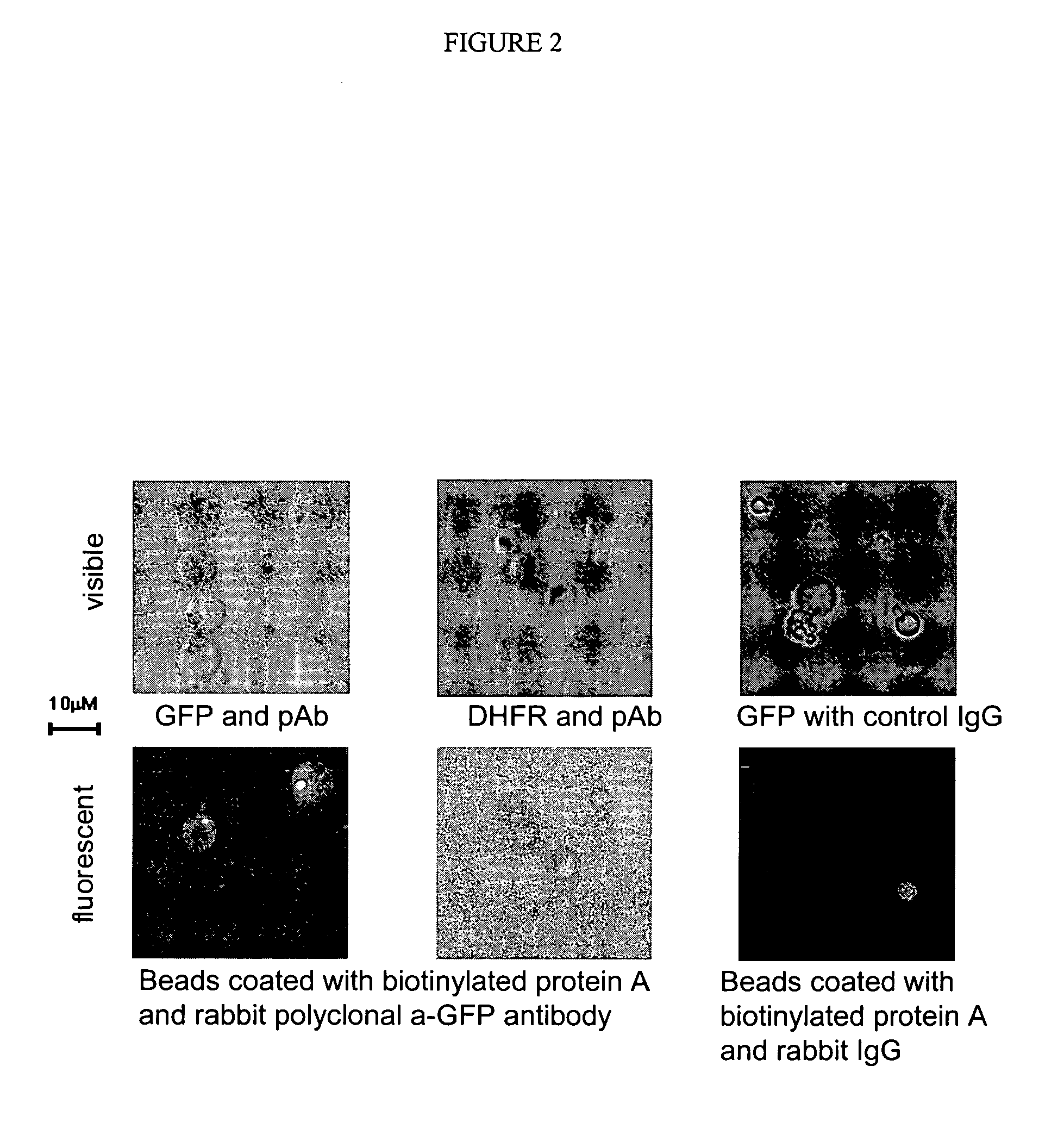

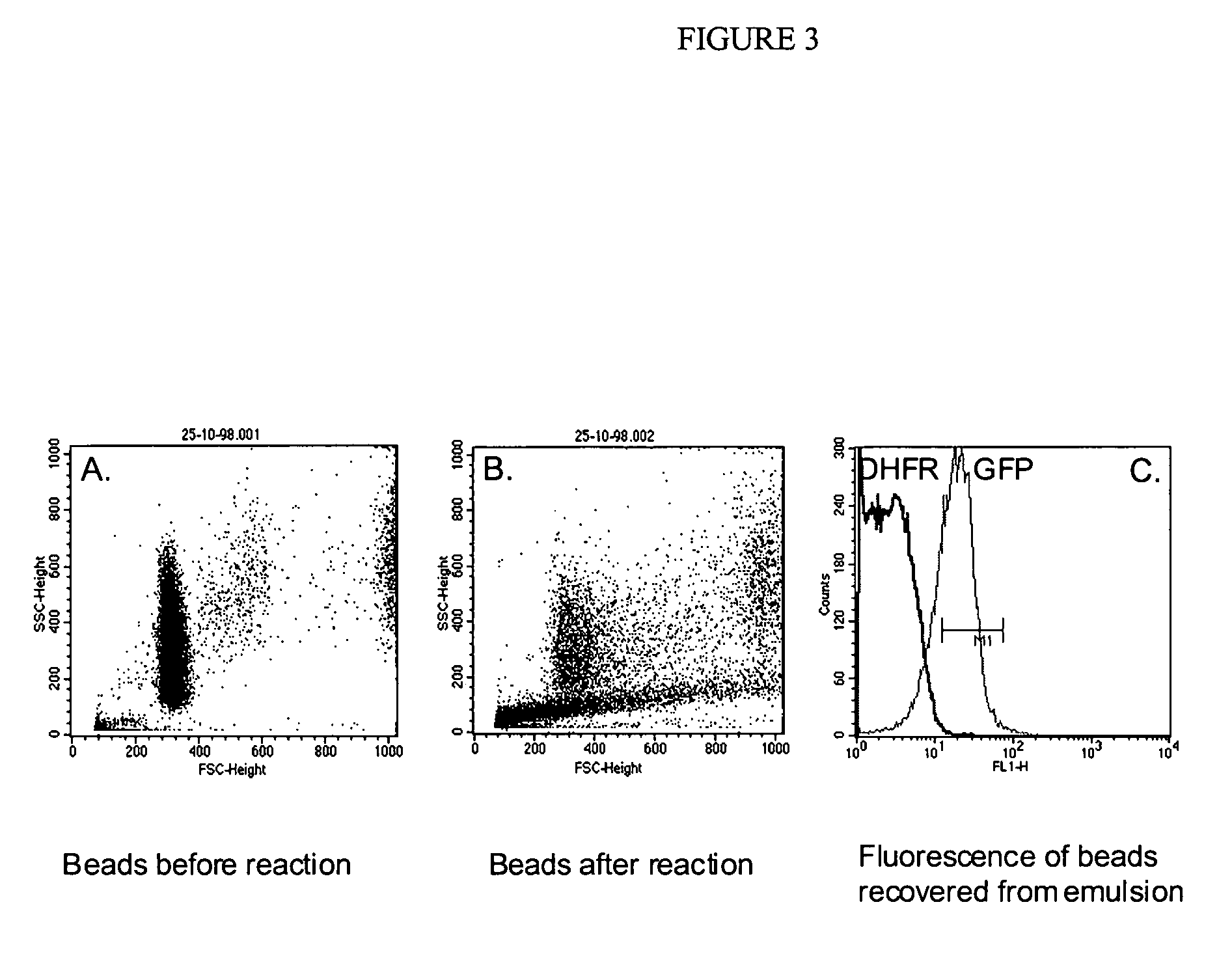

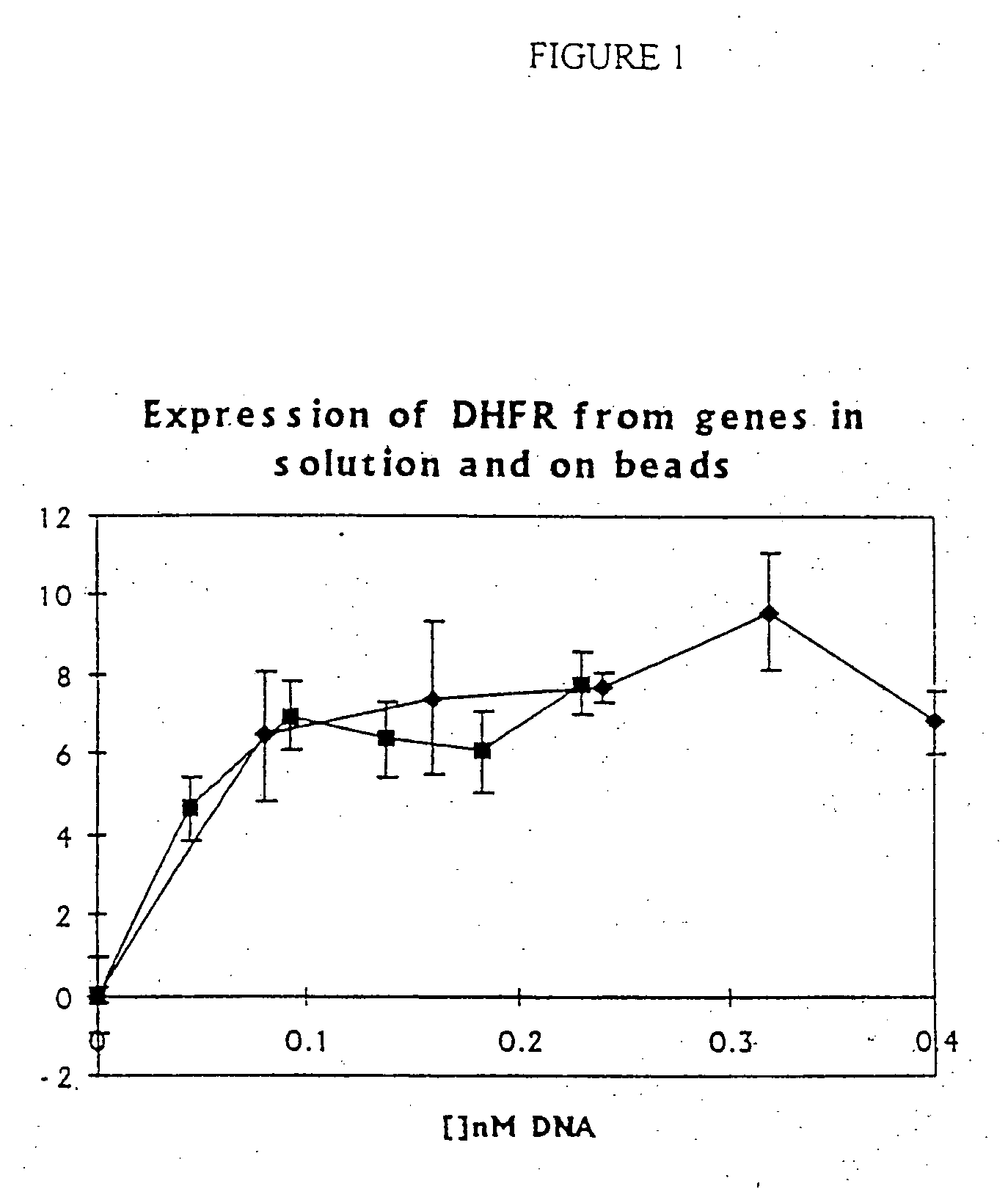

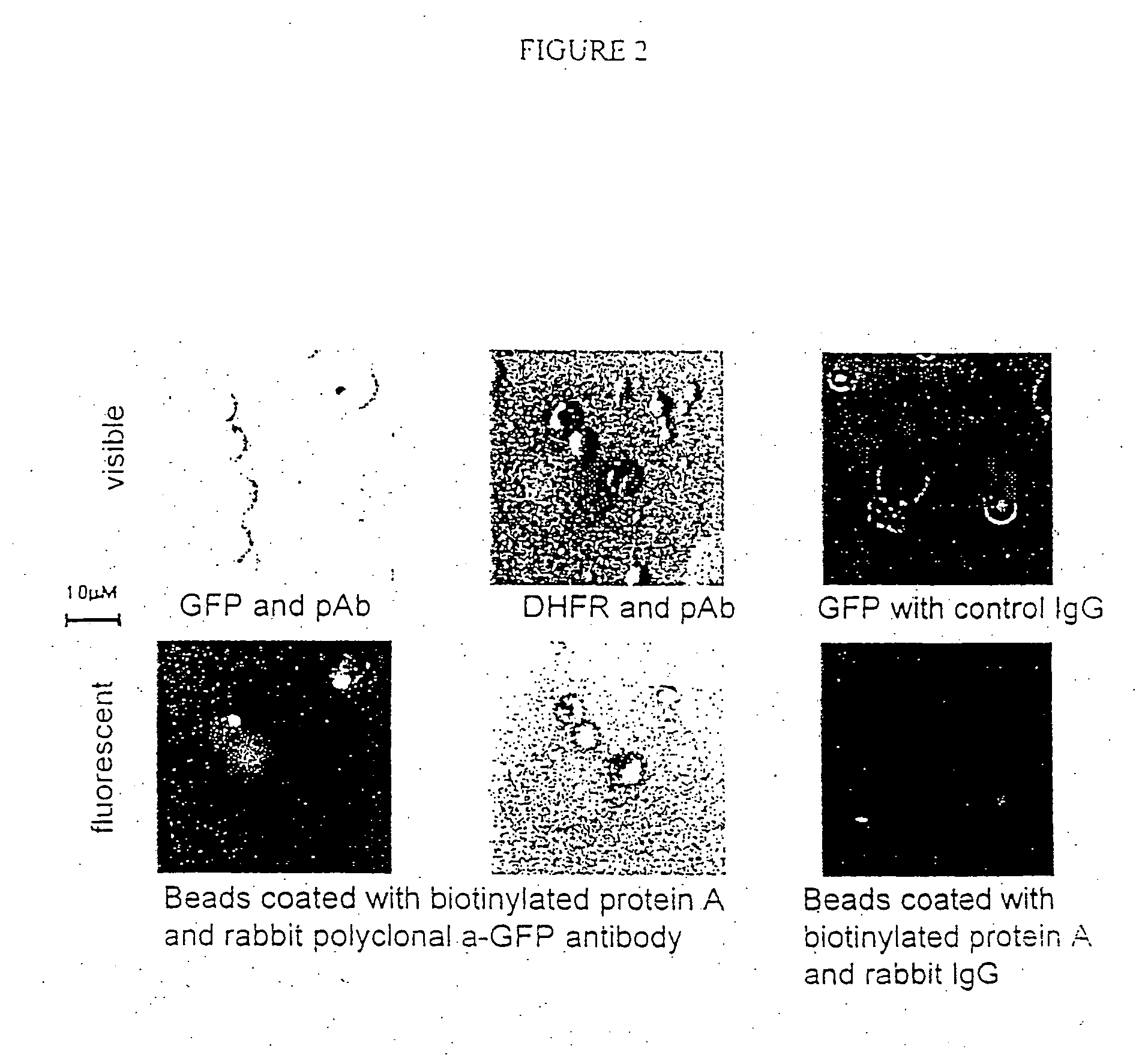

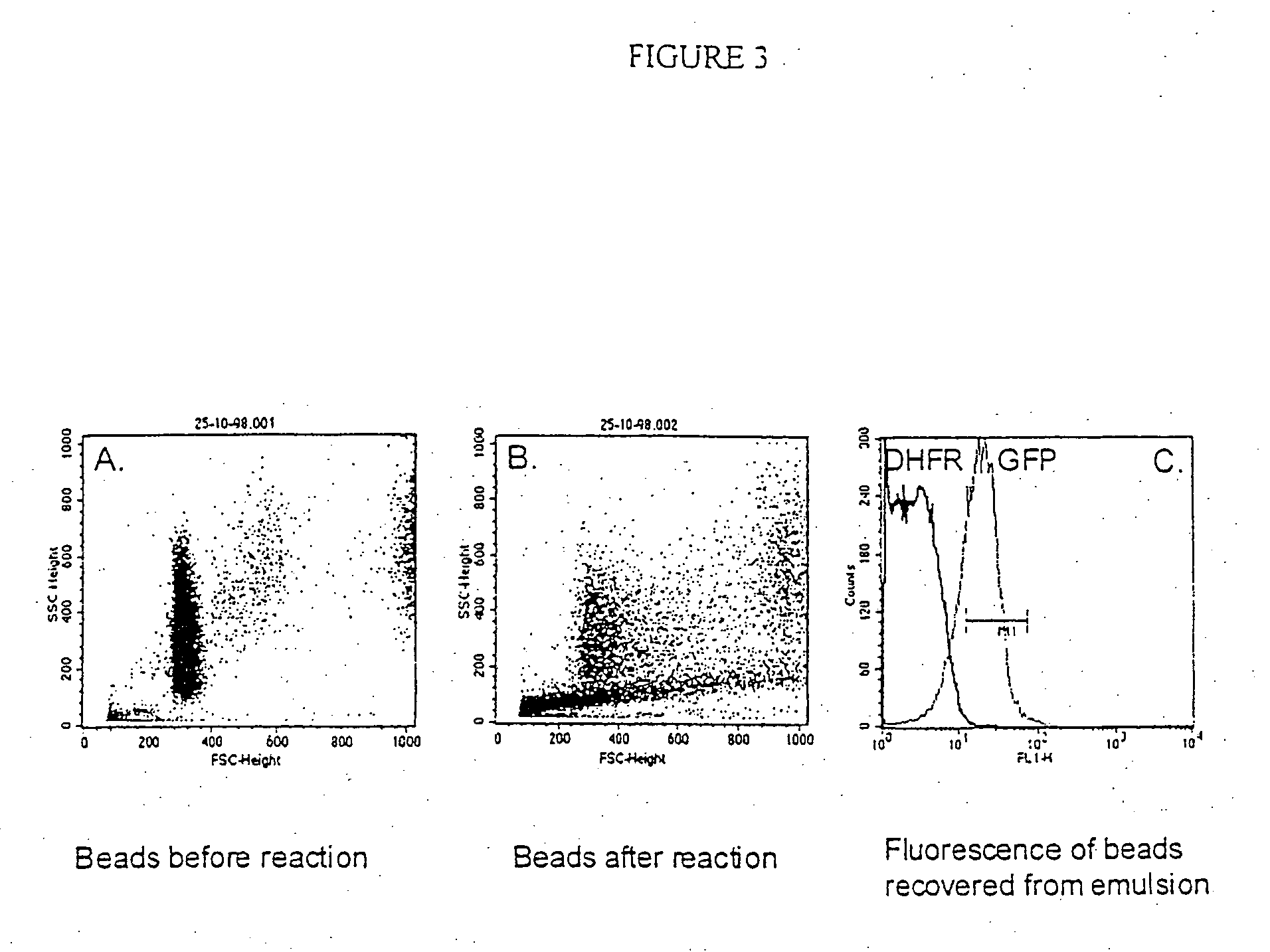

InactiveUS20050037392A1High activityMaterial analysis by observing effect on chemical indicatorMicrobiological testing/measurementOptical propertyGene product

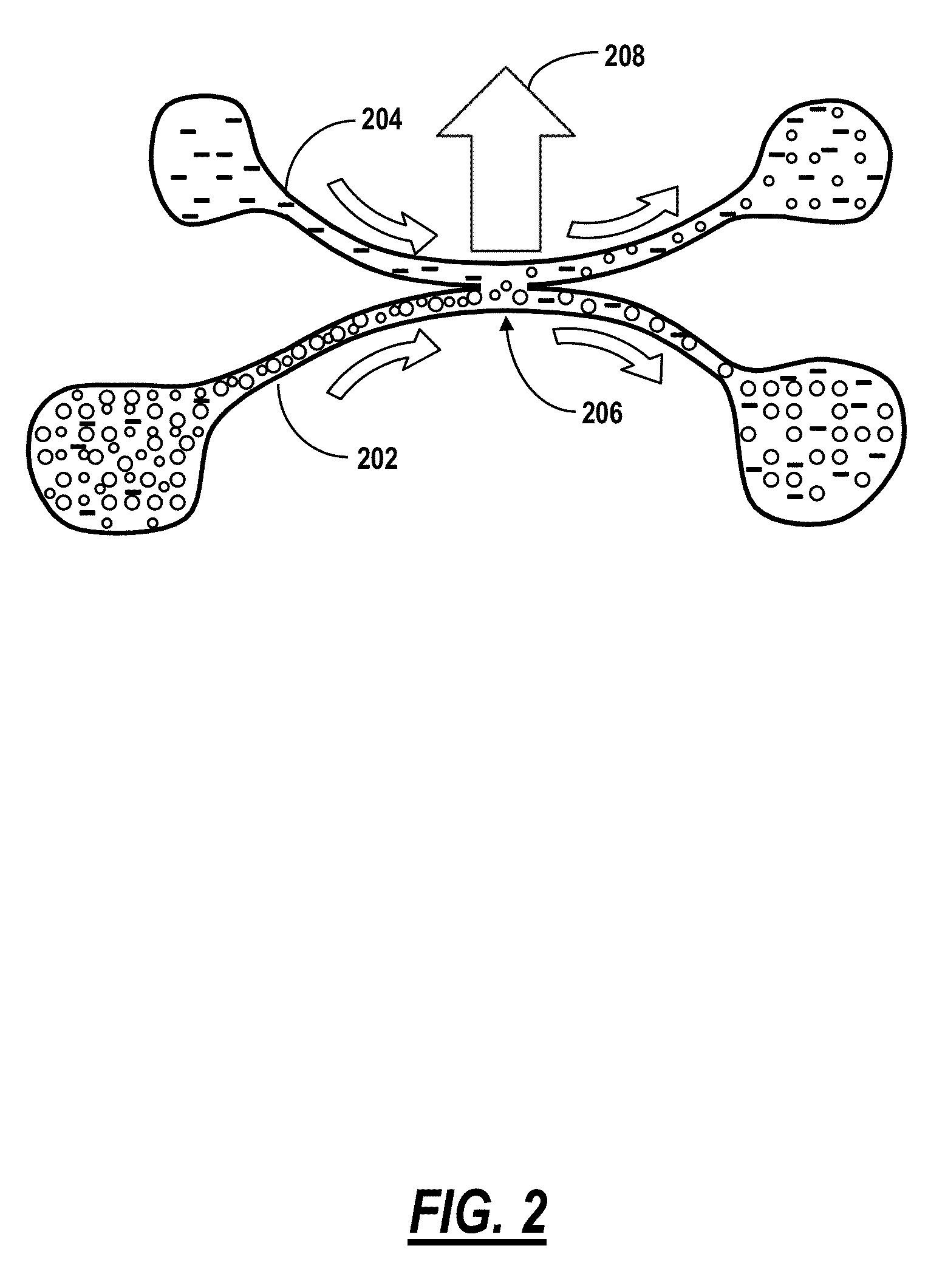

The invention describes a method for isolating one or more genetic elements encoding a gene product having a desired activity, comprising the steps of: (a) compartmentalising genetic elements into microcapsules; (b) expressing the genetic elements to produce their respective gene products within the microcapsules; (c) sorting the genetic elements which produce the gene product having the desired activity using a change in the optical properties of the genetic elements. The invention enables the in vitro evolution of nucleic acids and proteins by repeated mutagenesis and iterative applications of the method of the invention.

Owner:MEDICAL RESEARCH COUNCIL

Optical sorting method

InactiveUS20050164239A1High activityMaterial analysis by observing effect on chemical indicatorPeptidesOptical propertyGene product

Owner:MEDICAL RESEARCH COUNCIL

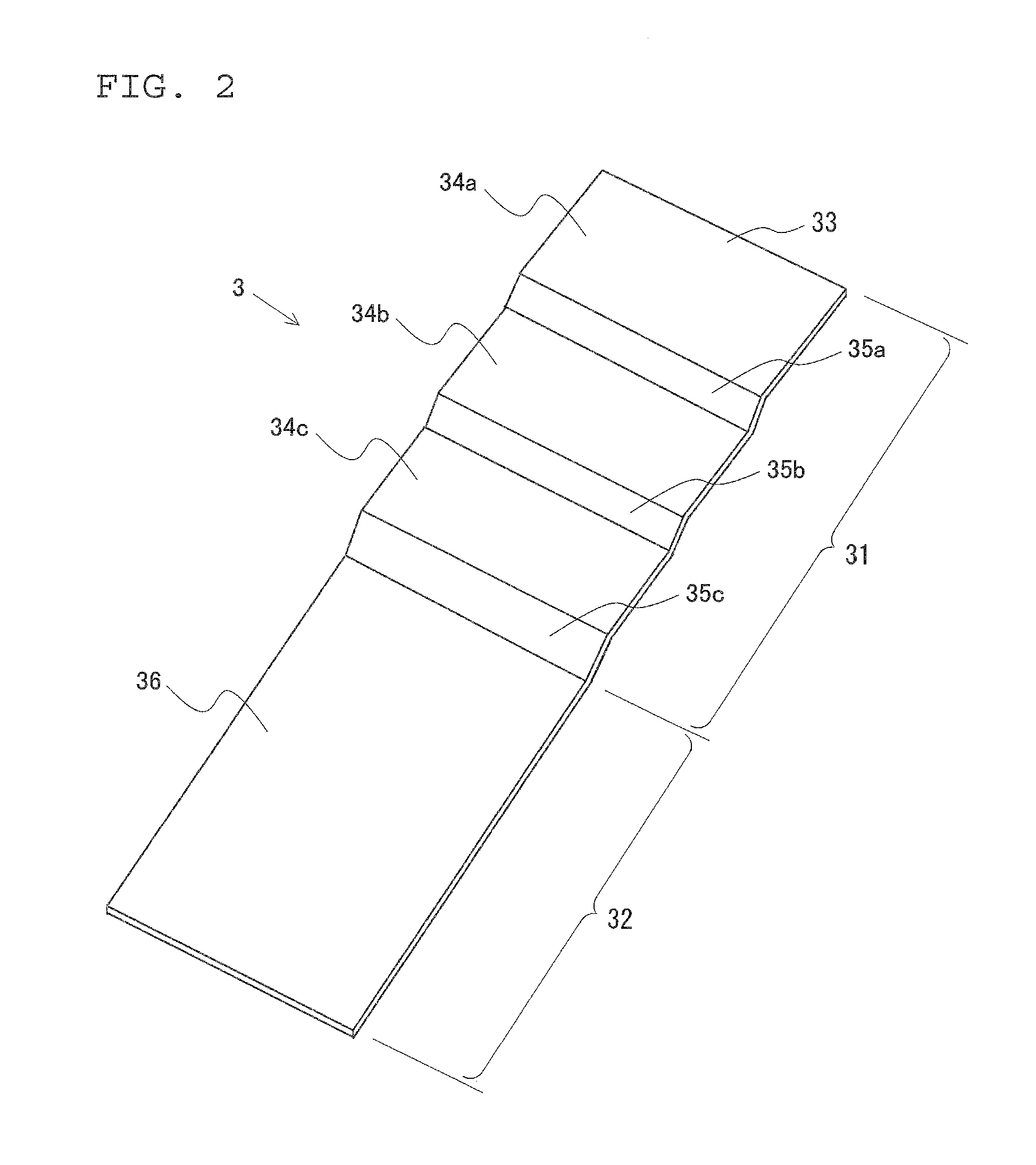

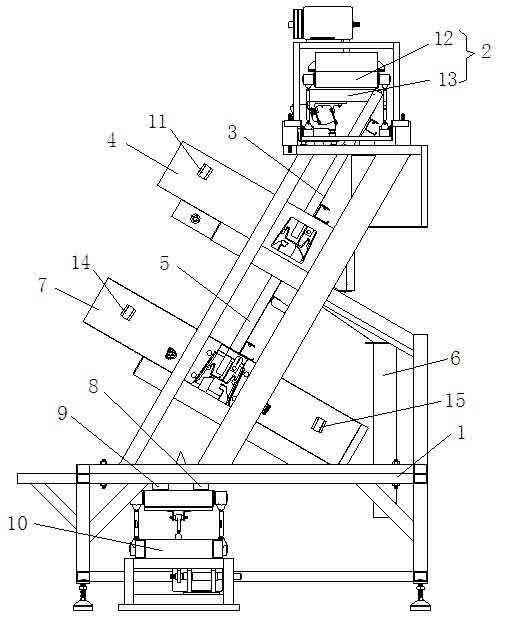

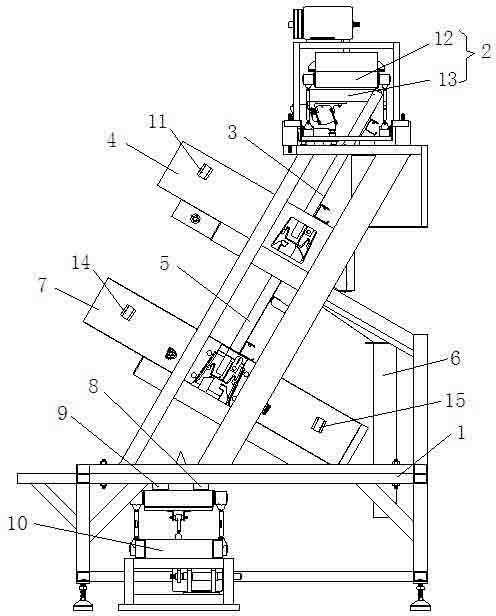

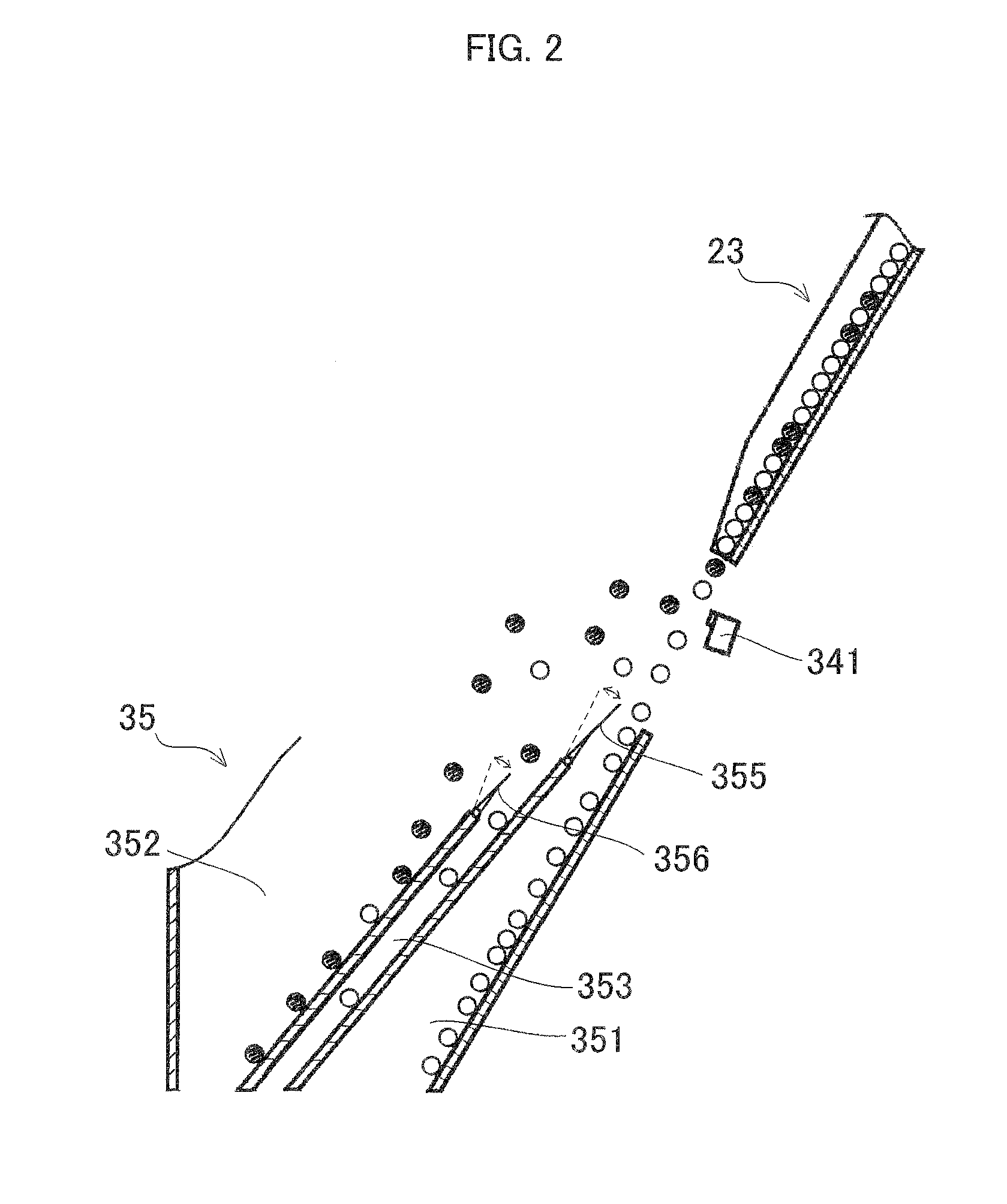

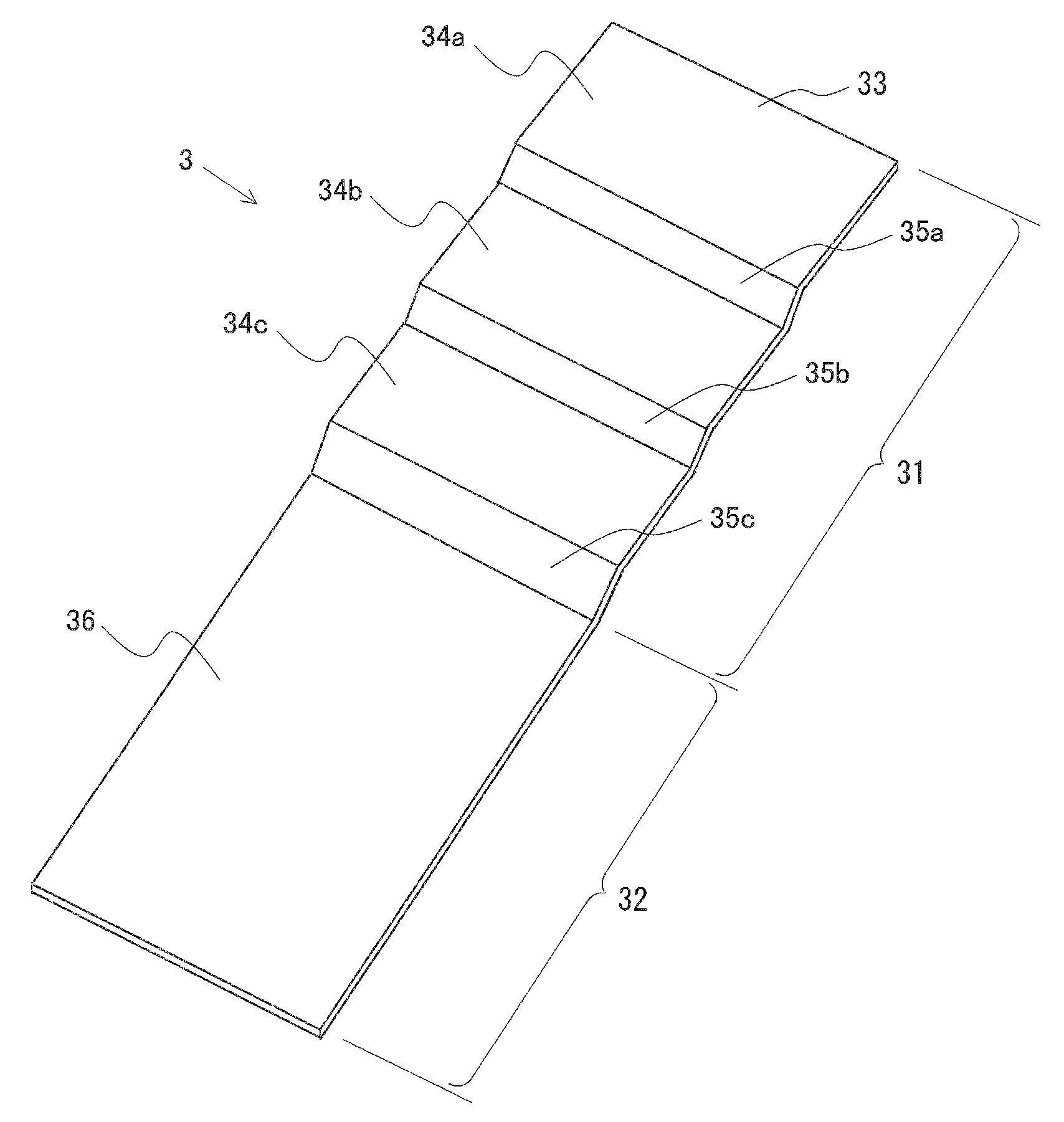

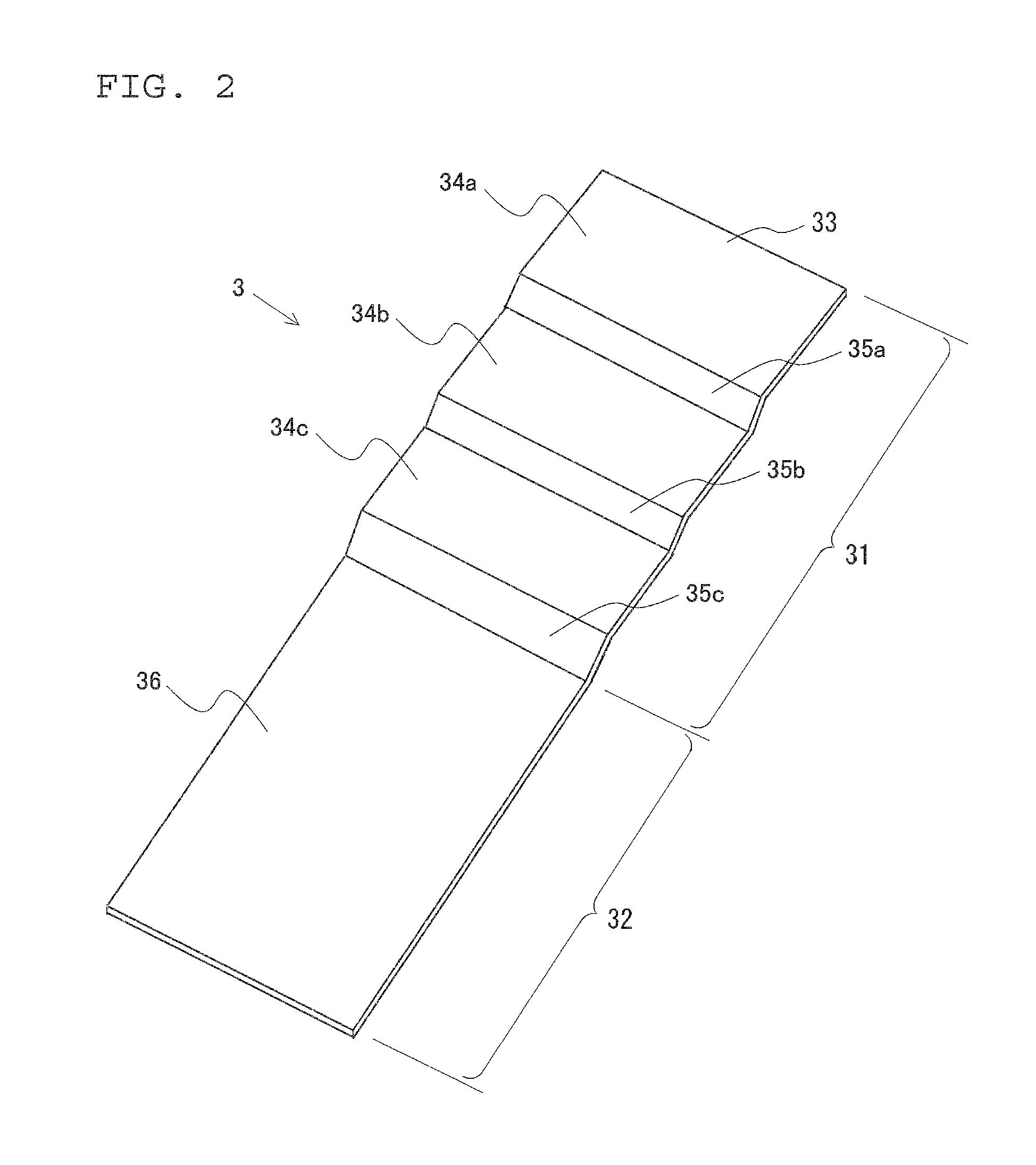

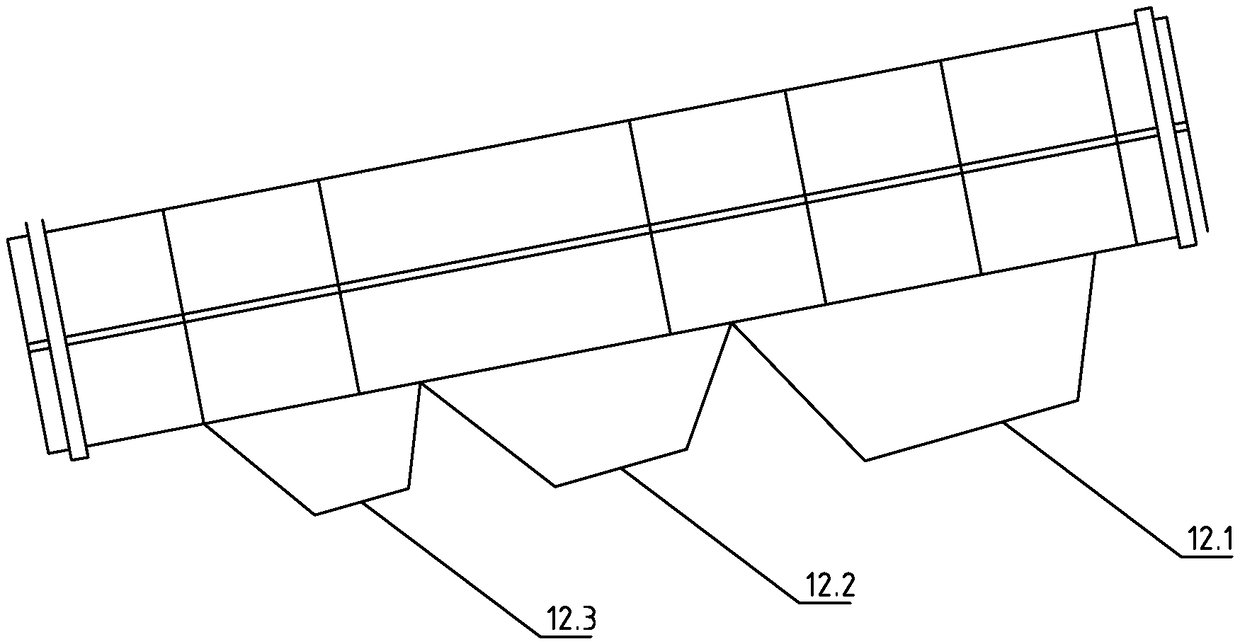

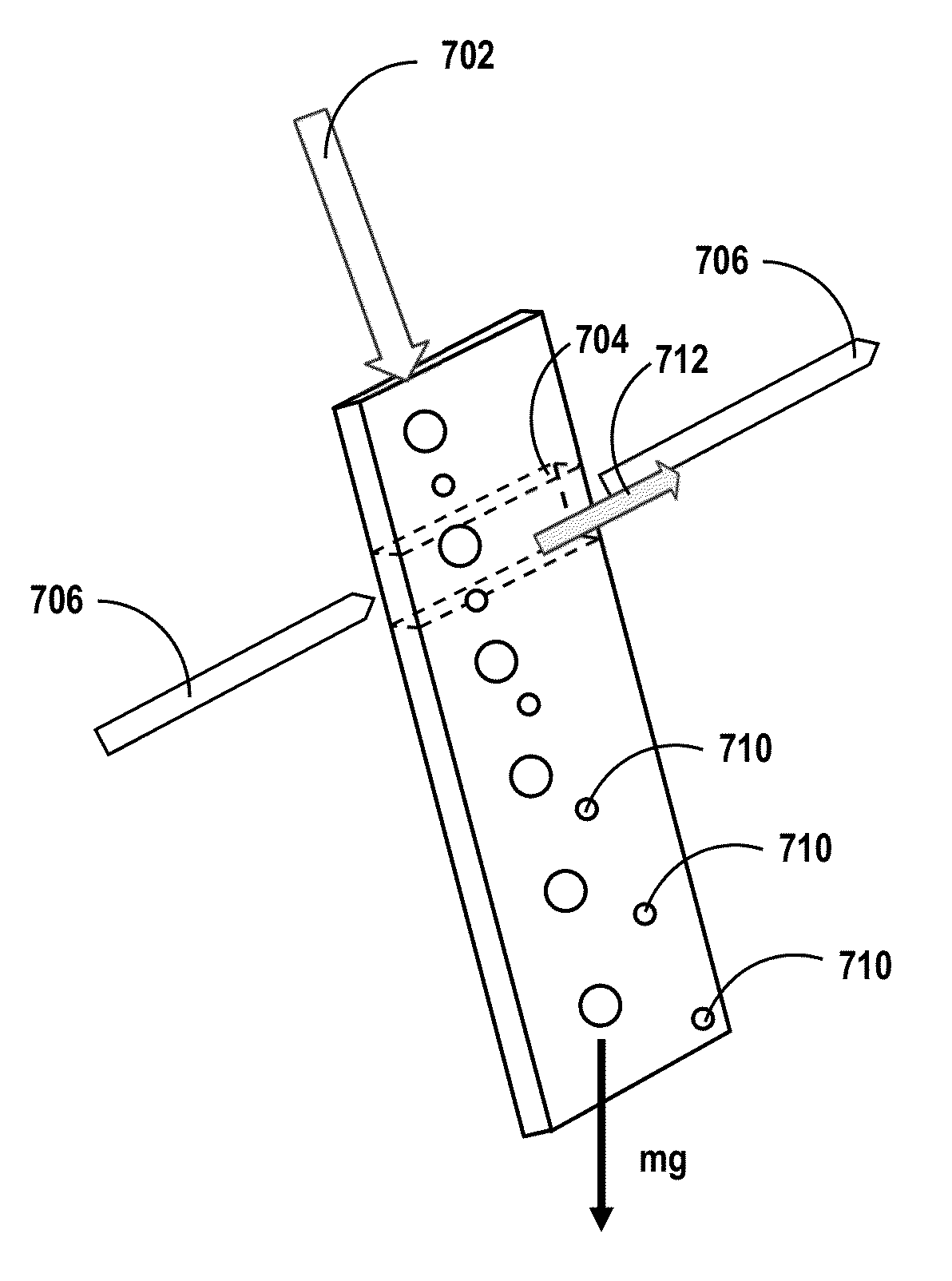

Chute for optical sorting machine

InactiveUS20140166549A1Avoid unevennessModerate impactSortingChutesEngineeringMechanical engineering

A chute for an optical sorter sorting machine allows objects to be sorted to drop under gravity from the lower end of the chute, thereby supplying the objects to an optical detection section. The chute is provided with: a first portion which includes a portion for receiving the objects to be sorted which are supplied from a supply section; and a second portion which continues from the first portion The first portion is composed of a single part and has: flat surfaces along which the objects to be sorted flow down; and connection surfaces. The flat surfaces located upstream are bent downward, and the connection surfaces located downstream are is bent upward to form a smooth undulation in the surface along which the objects to be sorted flow down.

Owner:SATAKE CORP

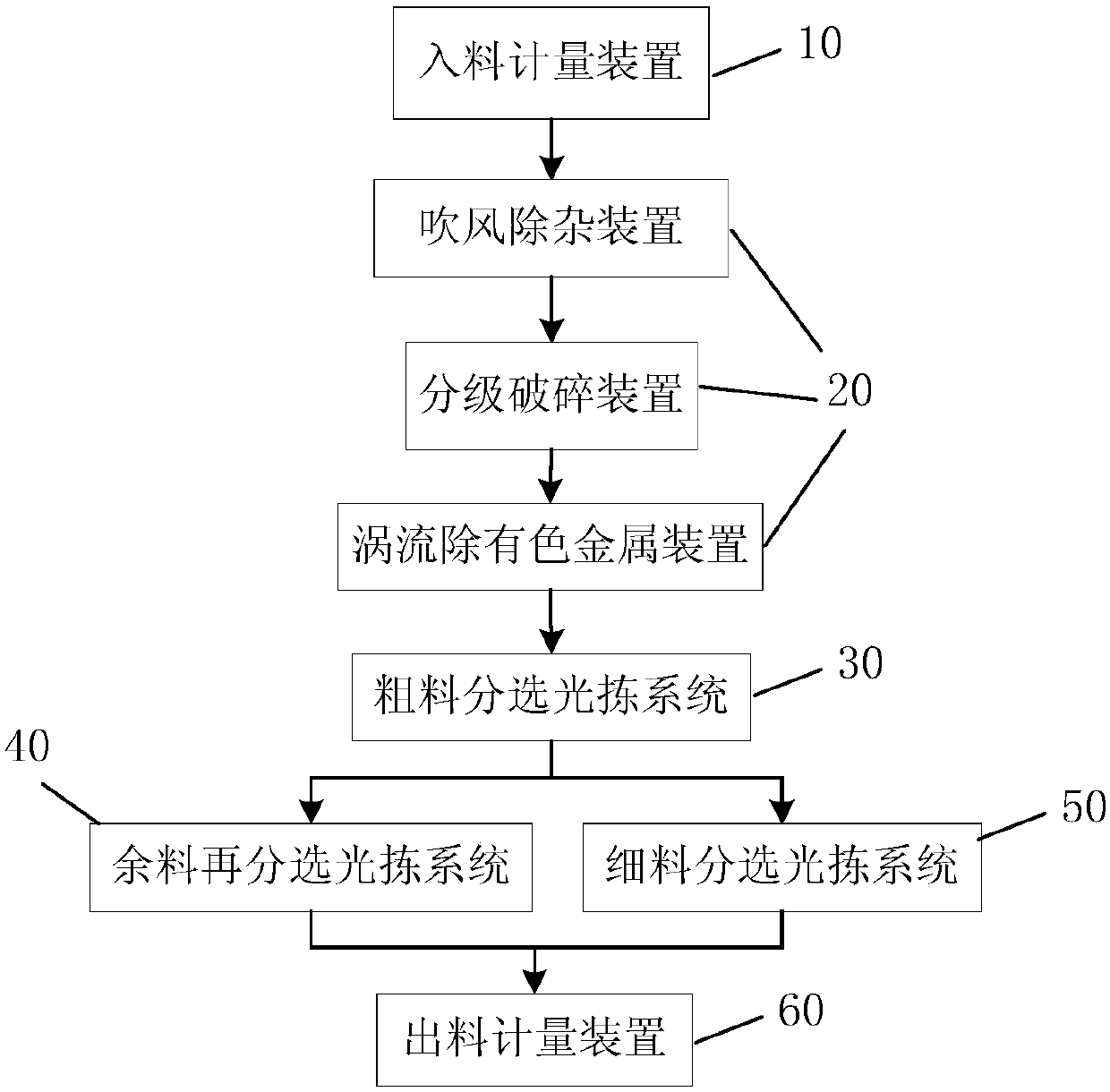

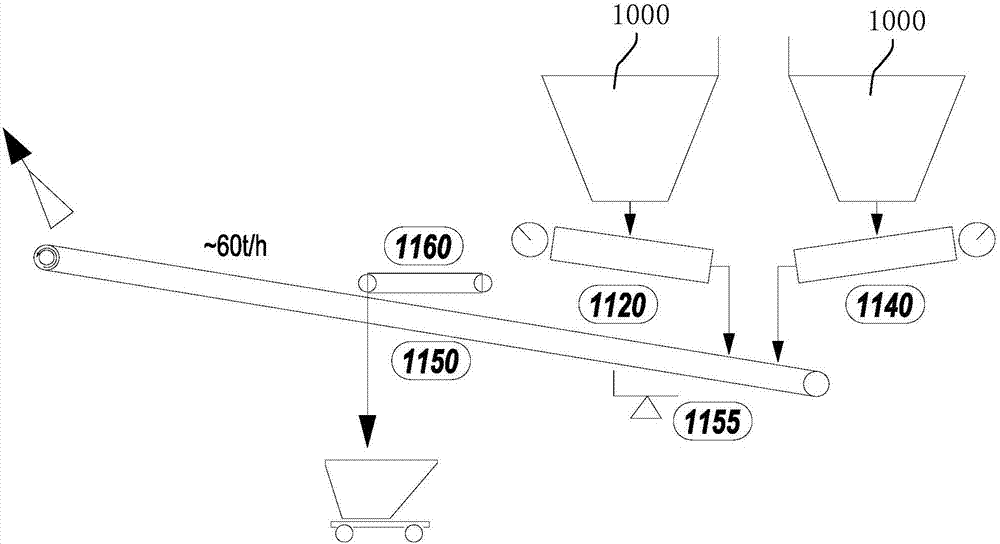

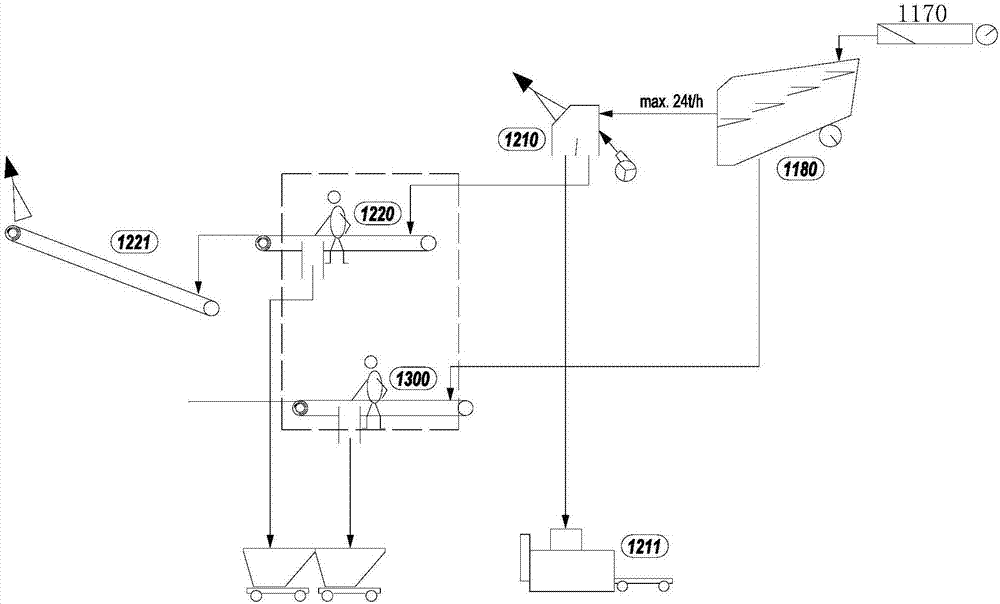

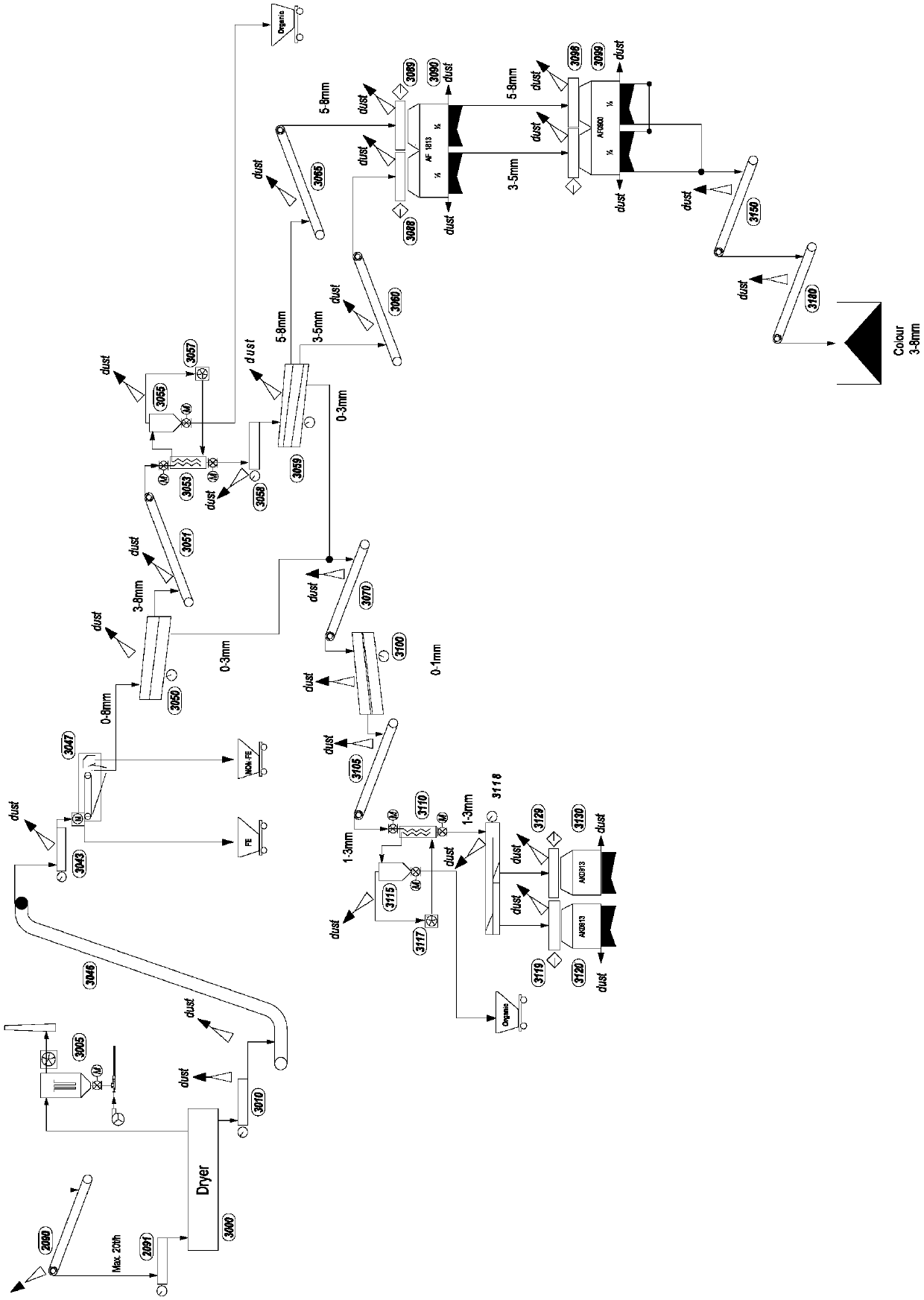

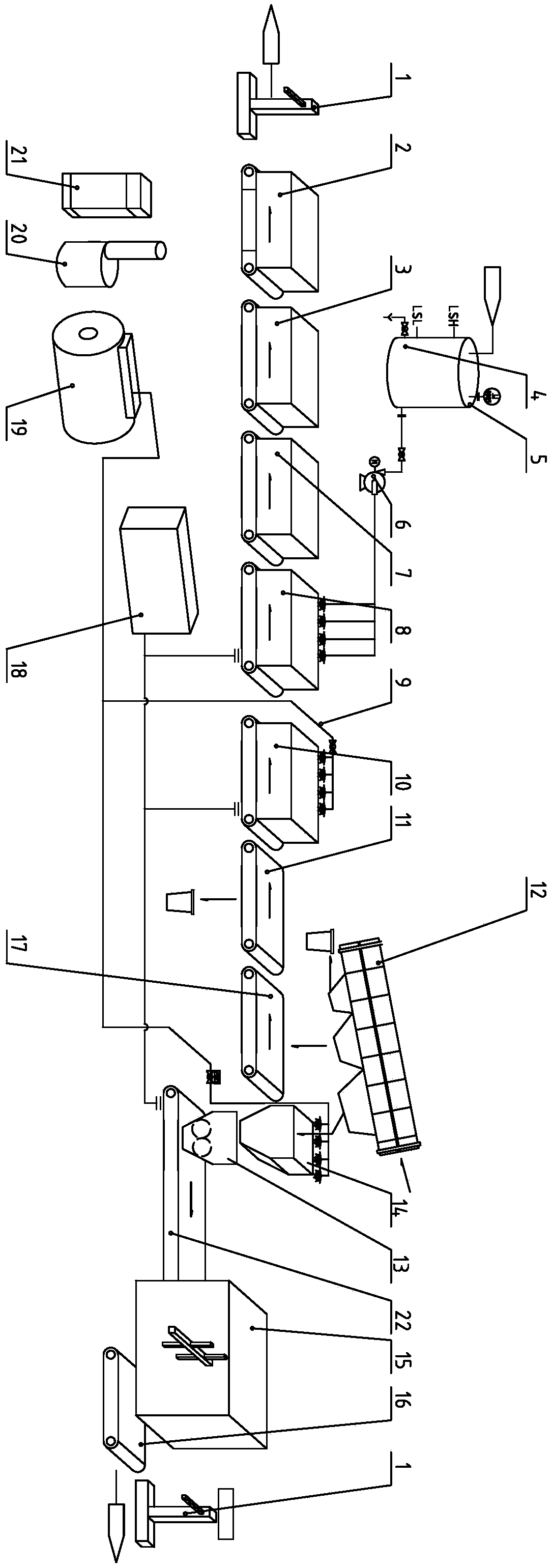

Automatic waste glass sorting system and control method thereof

ActiveCN107755410AImprove sorting qualityImprove sorting efficiencySievingGas current separationNonferrous metalProcess engineering

The invention discloses an automatic waste glass sorting system and a control method thereof. The automatic waste glass sorting system comprises a feed metering device, a crushing and impurity removing system, a coarse waste optical sorting system, a residue optical sorting system, a fine waste separating and sorting system and a discharge metering device which are connected in sequence, wherein the crushing and impurity removing system comprises a graded crushing device; a graded vibrating screen in the graded crushing device separates materials and transports the material to the graded crushing device; a winnowing impurity removal device is arranged at the front end of the graded crushing device; a vortex nonferrous metal removing device is arranged at the rear end of the graded crushingdevice; the coarse waste optical sorting system is used for classifying the impurity-removed materials according to different particle specifications and respectively feeding the classified materialsto the residue optical sorting system or the fine waste separating and sorting system respectively; and a label removing machine is arranged between the coarse waste optical sorting system and the residue optical sorting system. According to the automatic waste glass sorting system disclosed by the invention, multiple different specifications can be subdivided, all the impurities and sundries canbe removed, the sorting quality is greatly improved, and the sorting efficiency and capacity are improved.

Owner:上海燕龙基再生资源利用有限公司

Tea sorting method and sorting machine

The invention relates to a tea sorting method and a sorting machine. The end of the first chute is provided with a first optical sorting chamber, and a first pneumatic actuator system is provided between the outlet of the first optical sorting chamber, the second chute and the first hopper, and the second optical sorting A second pneumatic actuator system is provided between the discharge port of the chamber and the second discharge hopper and the third discharge hopper, and the discharge port of the second optical separation chamber is connected with the second discharge hopper and the third discharge hopper respectively. The first imaging system is a single-sided camera imaging, the second imaging system is a double-sided camera imaging, and the first and second pneumatic execution systems are connected with the signal processing system. It can be seen from the above technical solution that the second imaging system of the present invention adopts double-sided camera imaging, which can observe the front and back sides of the material at the same time, without missing the material with defects on one side, improving the sorting accuracy of the material, and at the same time improving the Daily output.

Owner:CHINA HEFEI TAIHE OPTOELECTRONICS TECH

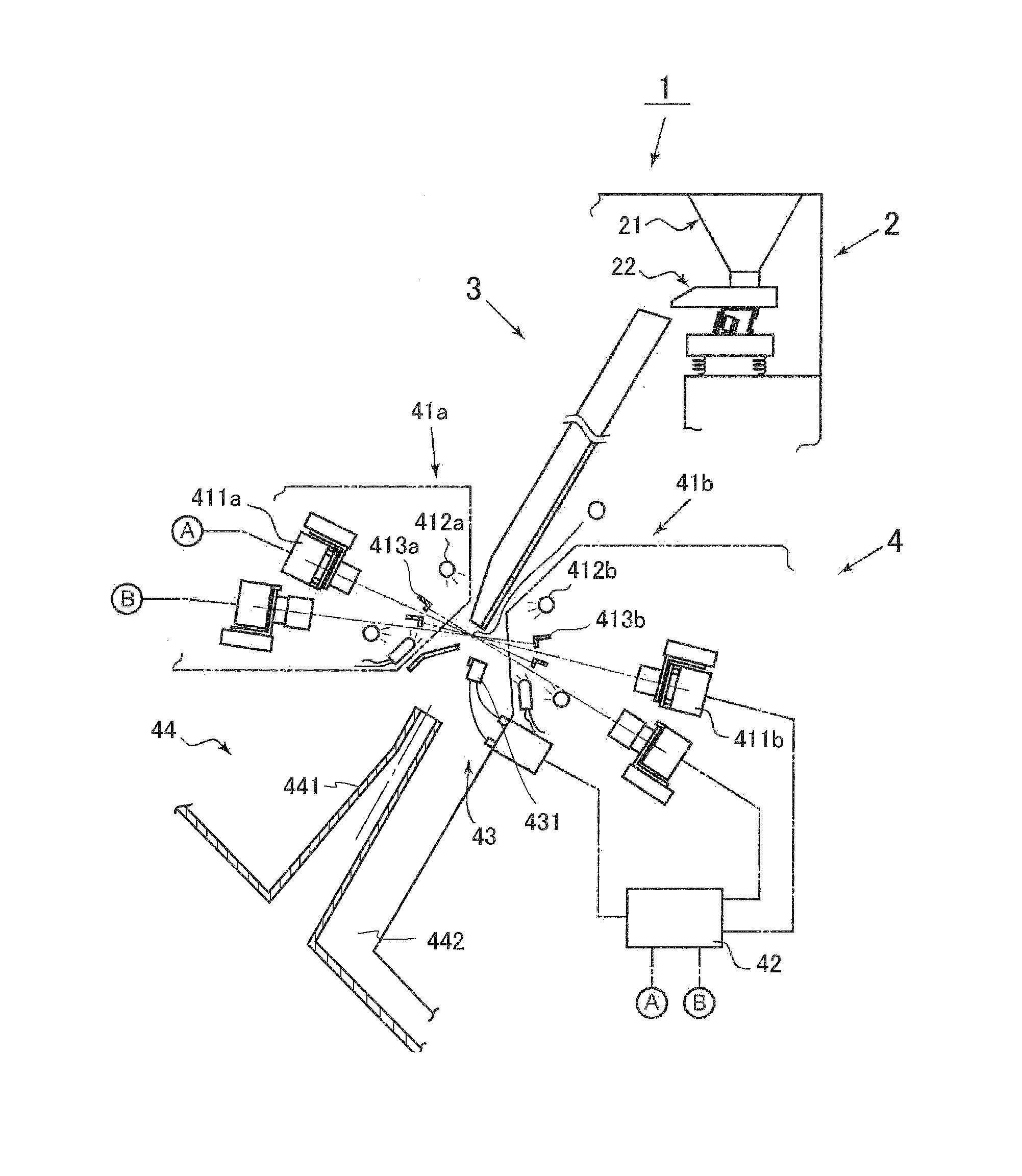

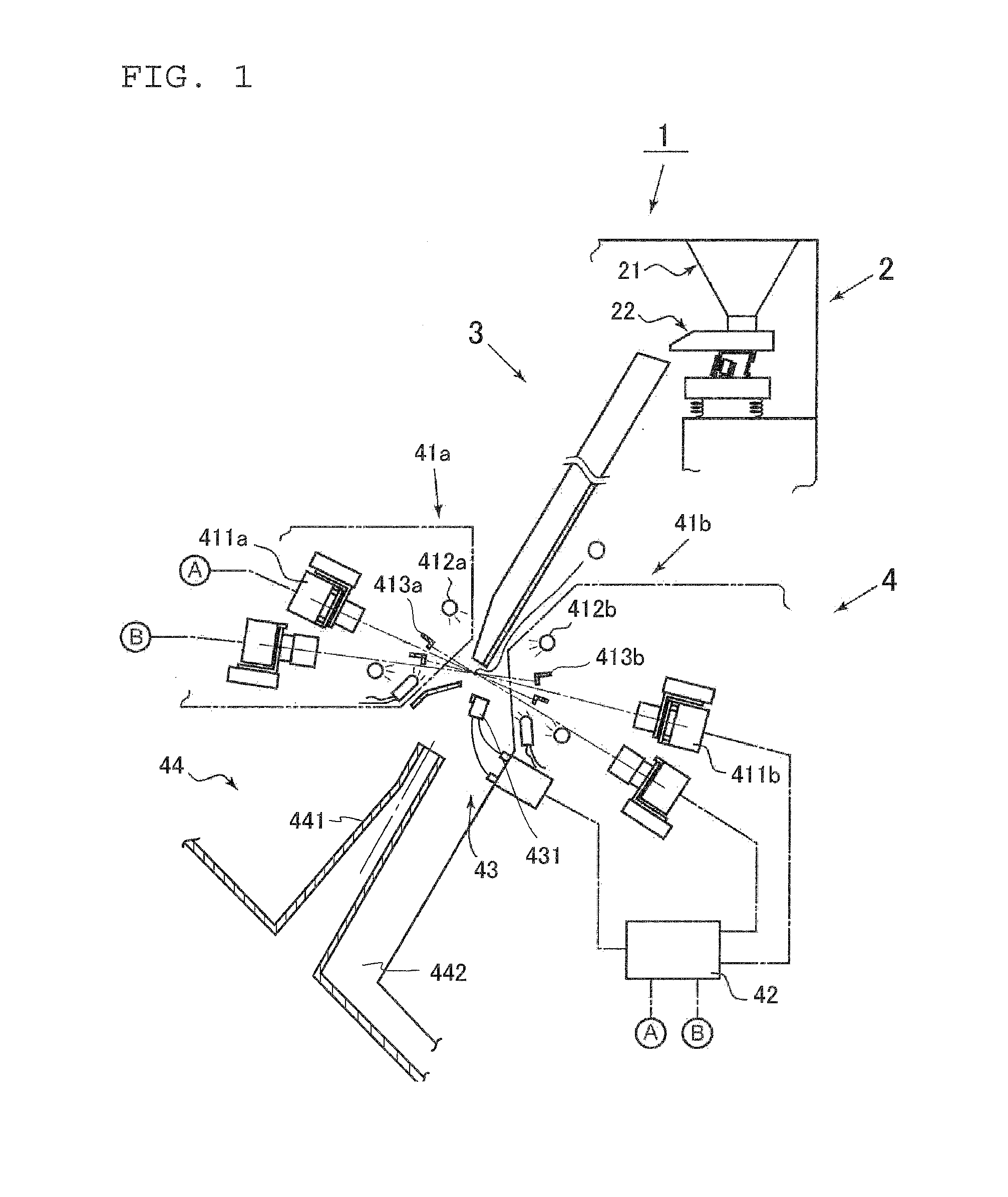

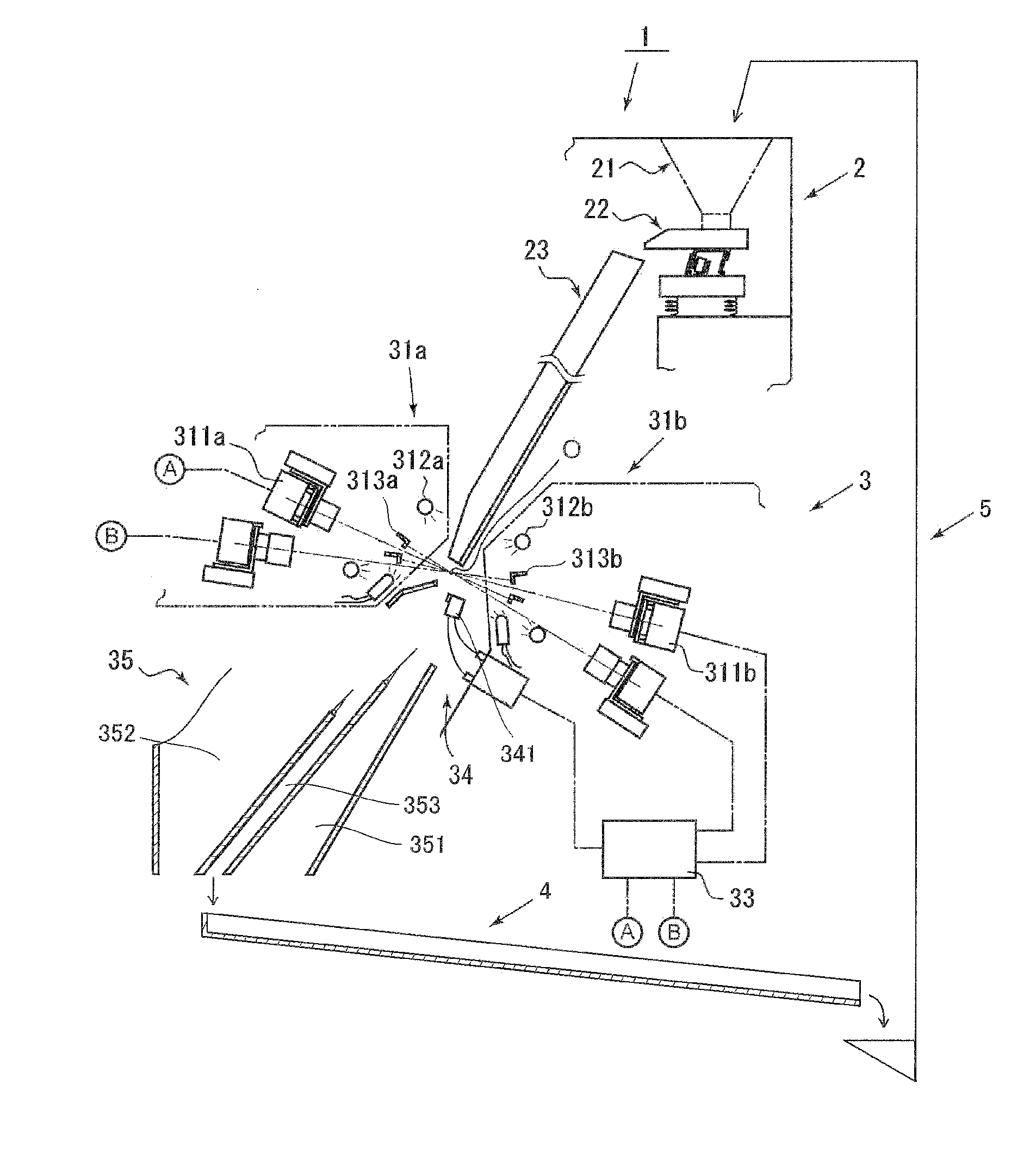

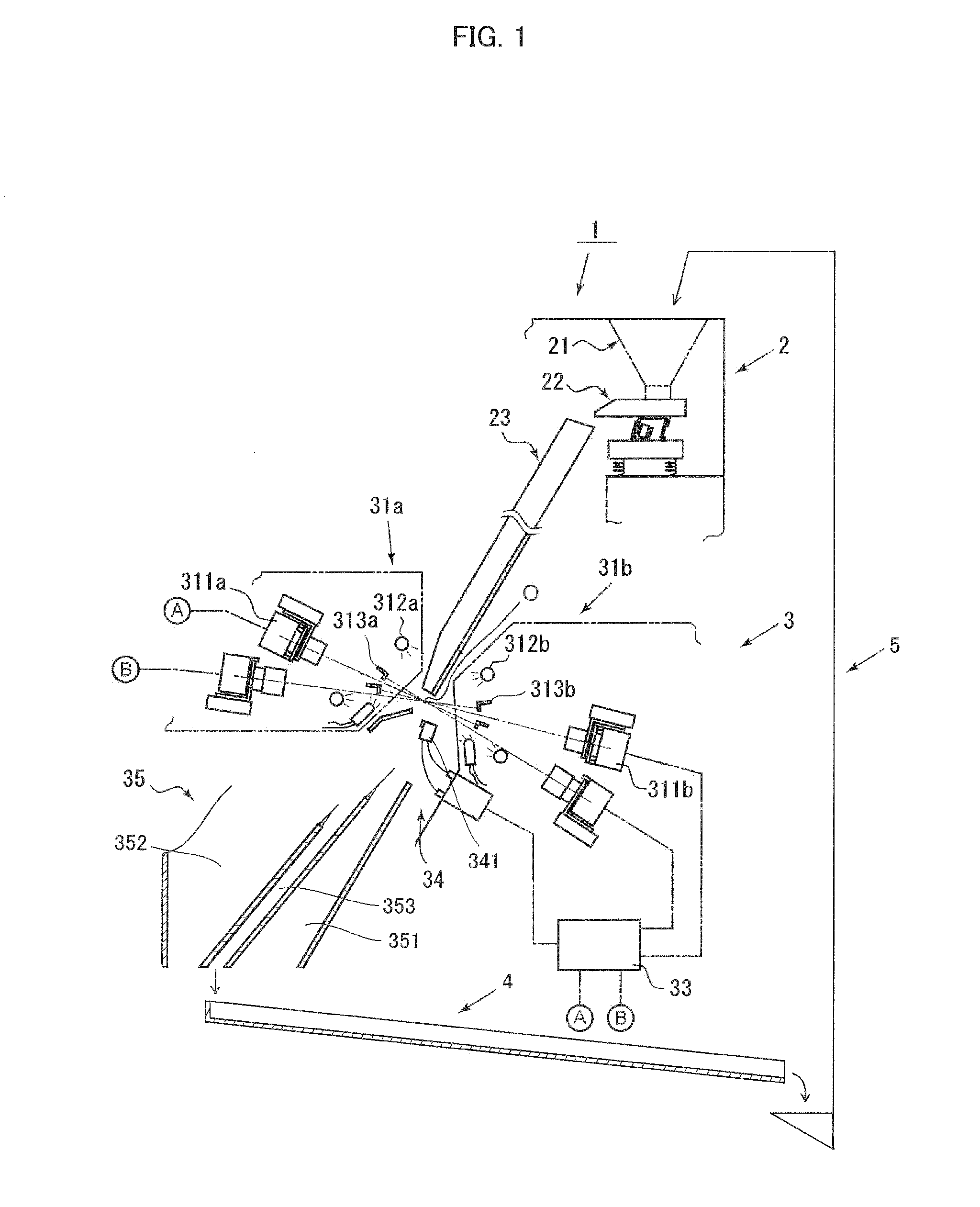

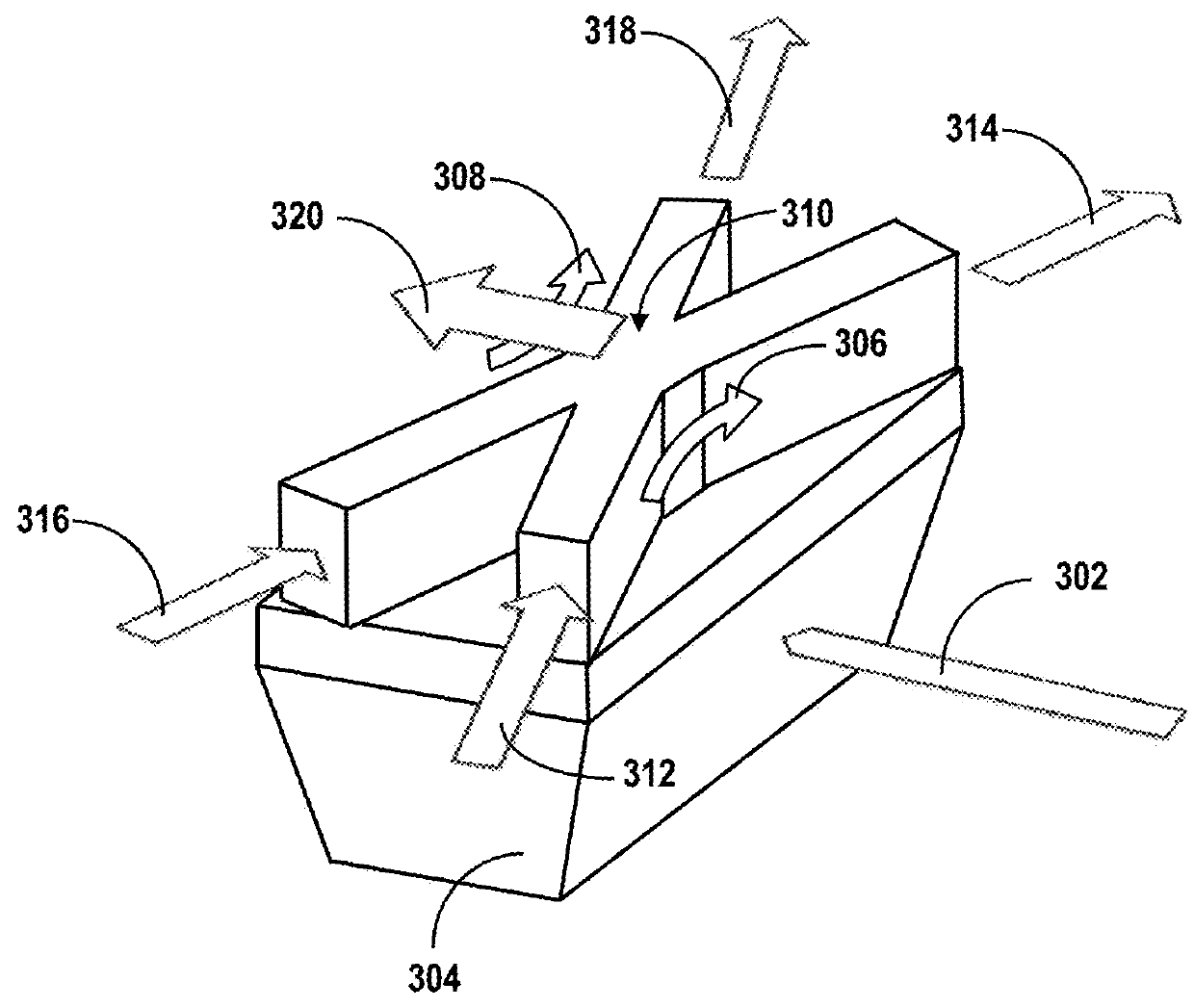

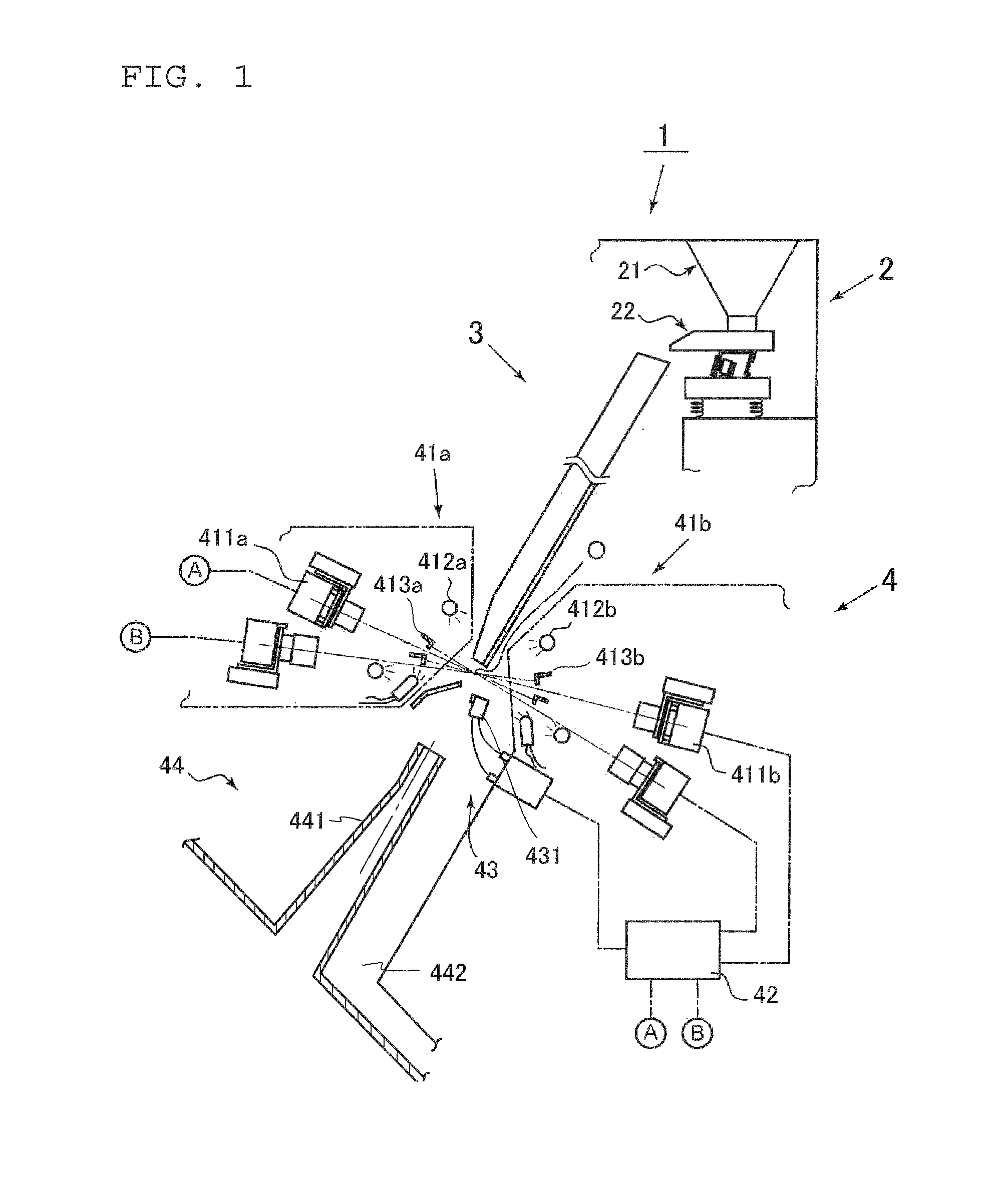

Optical sorting machine

ActiveUS20140061103A1Increase collection rateIncreases size of machineSortingComputer scienceOptical sorting

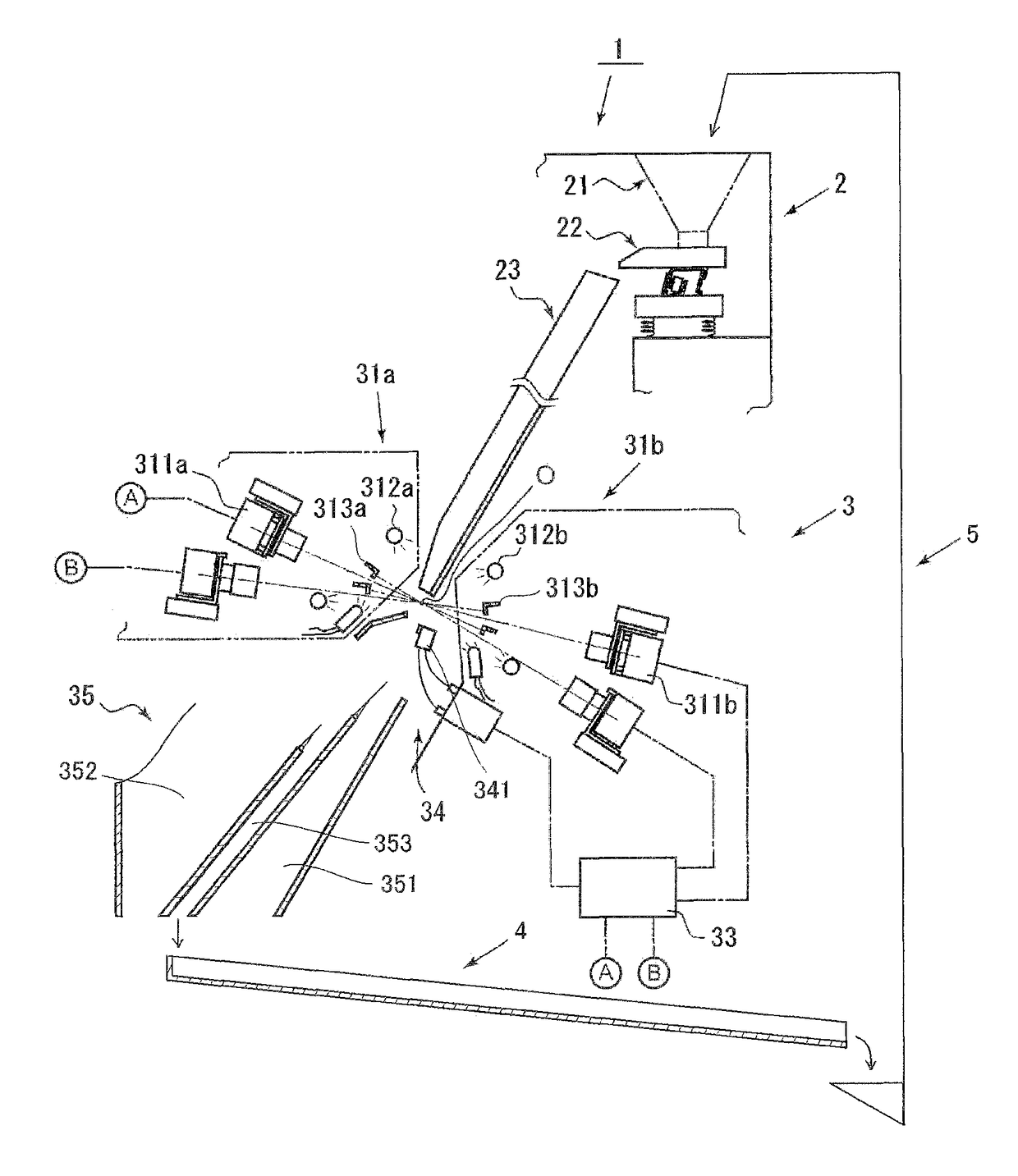

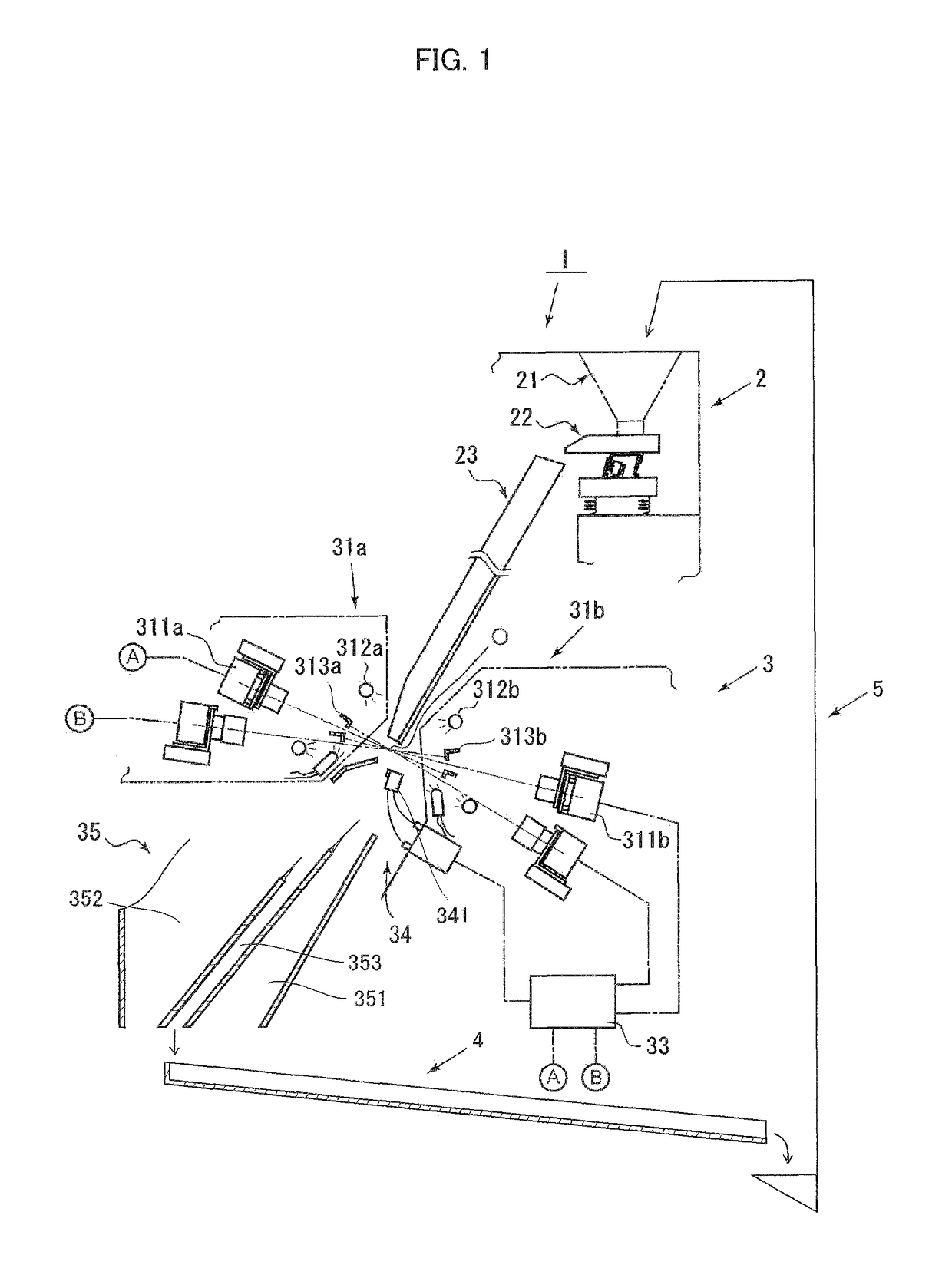

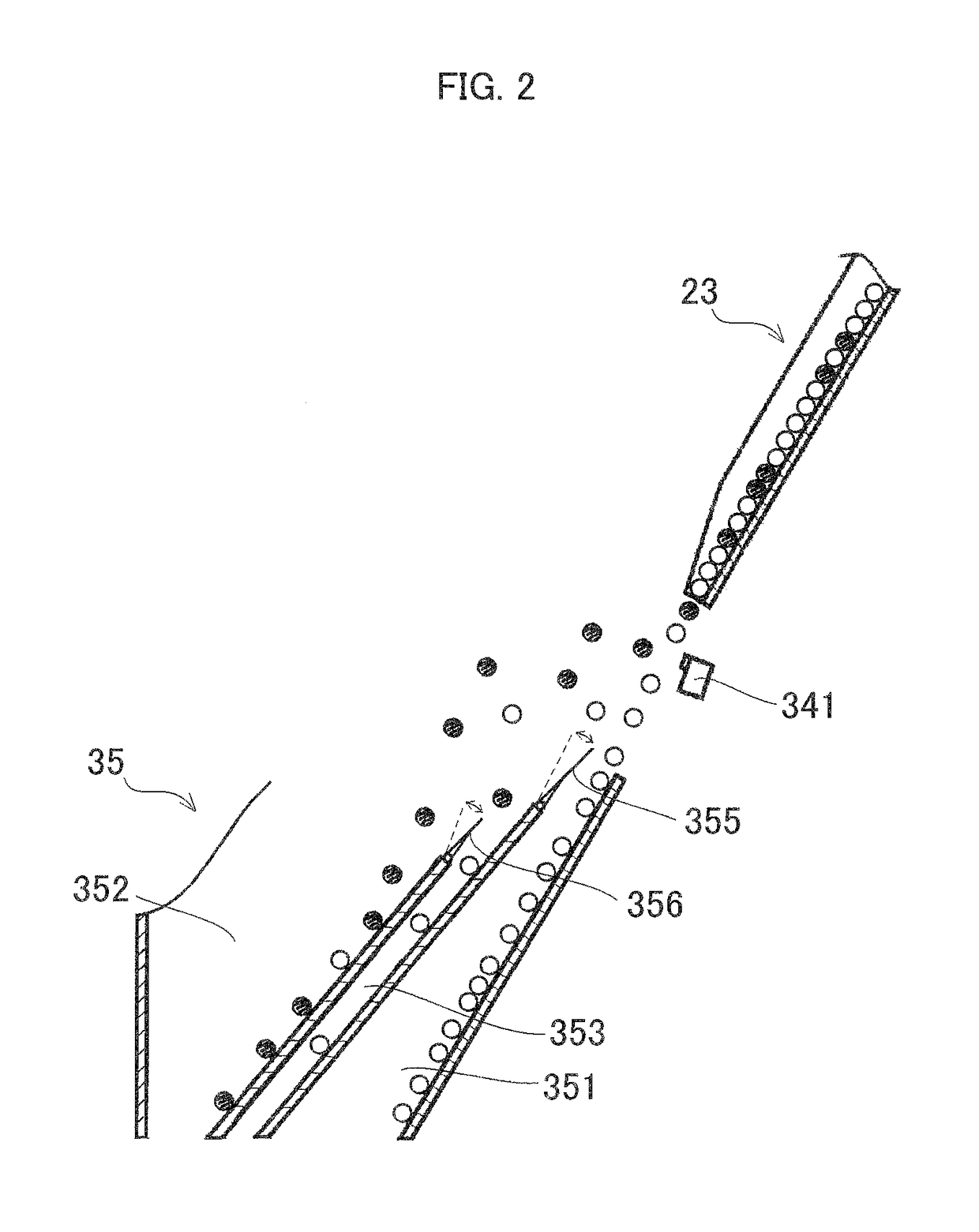

The present invention intends to provide an optical sorting machine which can improve the collection rate of non-defective products without increasing the size of the machine. The optical sorting machine of the present invention includes a granular object feed unit including storage means that stores an object to be sorted, and transfer means that transfers the object to be sorted from the storage means; an optical sorting unit including optical detection means that detects an object to be sorted falling along a predetermined trajectory from an end portion of the transfer means, determination means that determines a type of the object to be sorted based on a detection signal from the optical detection means, an ejector that removes an object to be sorted determined as a specific type from the predetermined falling trajectory based on a determination result by the determination means, and a discharge hopper having a first discharge passage provided at a falling position of the object to be sorted falling along the predetermined trajectory, a second discharge passage provided at a falling position of the object to be sorted removed from the predetermined falling trajectory, and a third discharge passage formed between the first discharge passage and the second discharge passage; and conveyance means that conveys an object to be sorted discharged from the third discharge passage of the discharge hopper in the optical sorting unit to the storage means of the granular object feed unit.

Owner:SATAKE CORP

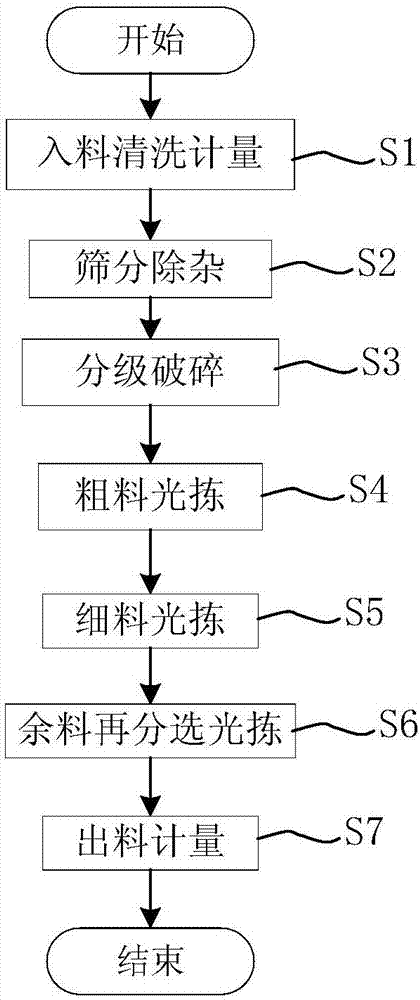

Automatic wet-process sorting control method for waste glass

InactiveCN107952781AImprove sorting qualityImprove sorting efficiencyGas current separationSolid waste disposalThree stageEngineering

The invention discloses an automatic wet-process sorting control method for waste glass. The method comprises the following steps that S1, feeding, cleaning and metering are carried out, specifically,the waste glass is cleaned, water is removed, and then feeding is carried out by adopting a vibration feeding machine; S2, screening and impurity removal are carried out; S3, staged crushing is carried out, specifically, two-stage crushing is carried out on separated materials; S4, optical sorting is carried out on coarse materials, specifically, non-ferrous metals are removed by an eddy currentsorting machine, and three-stage screening is completed according to the granular size of 1-3mm, 3-8mm and 8-50mm; S5, optical sorting is carried out on fine materials; S6, optical sorting is carriedout on excess materials, specifically, screening is carried out continuously on materials with the granular size of 8-50 mm by adopting a three-stage broken glass optical sorting machine to carry outimpurity and mixed-color separation so as to obtain materials with the granular size of 8-16mm, 16-22mm and 22-50mm; and 7, discharging and metering are carried out, specifically, separated main-colorglass, colored glass pieces and stone ceramics are metered and discharged separately. The method has the advantages that various specifications can be subdivided, all the impurities can be removed, the sorting quality can be greatly improved, and the sorting efficiency and the productivity can be improved.

Owner:上海燕龙基再生资源利用有限公司

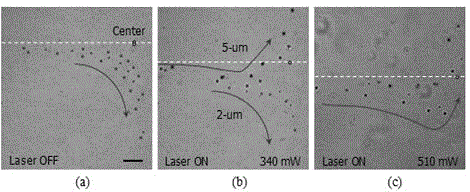

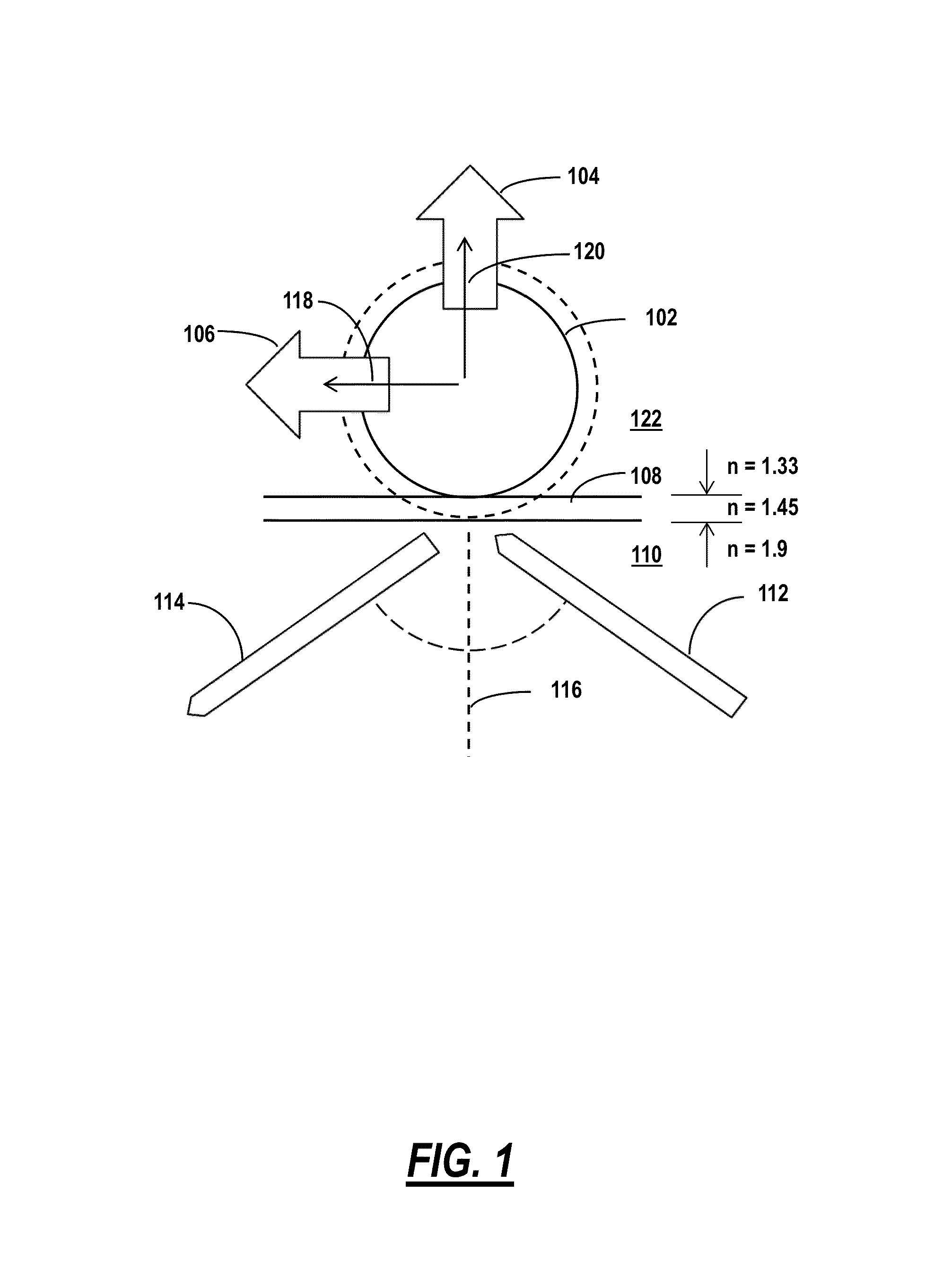

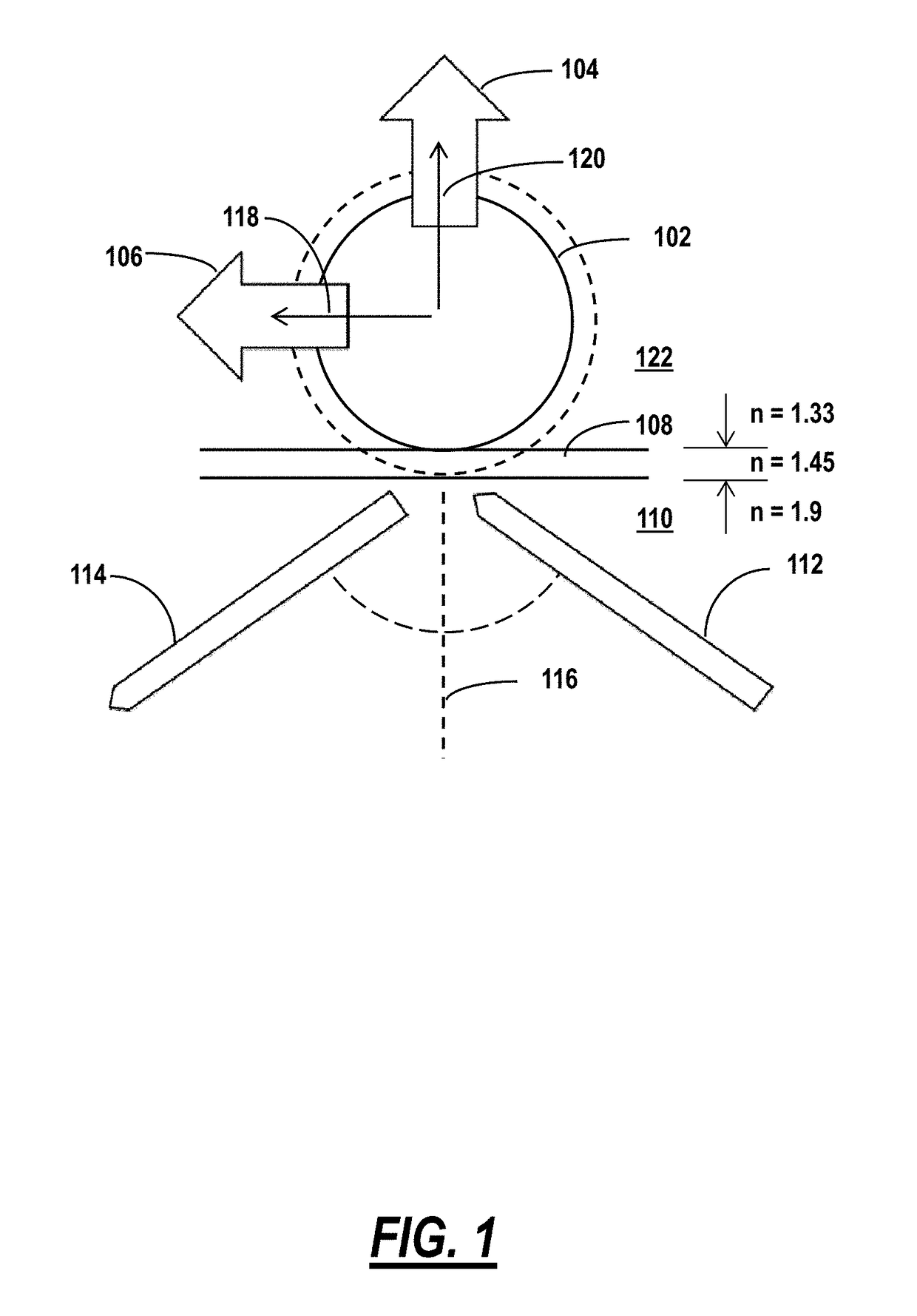

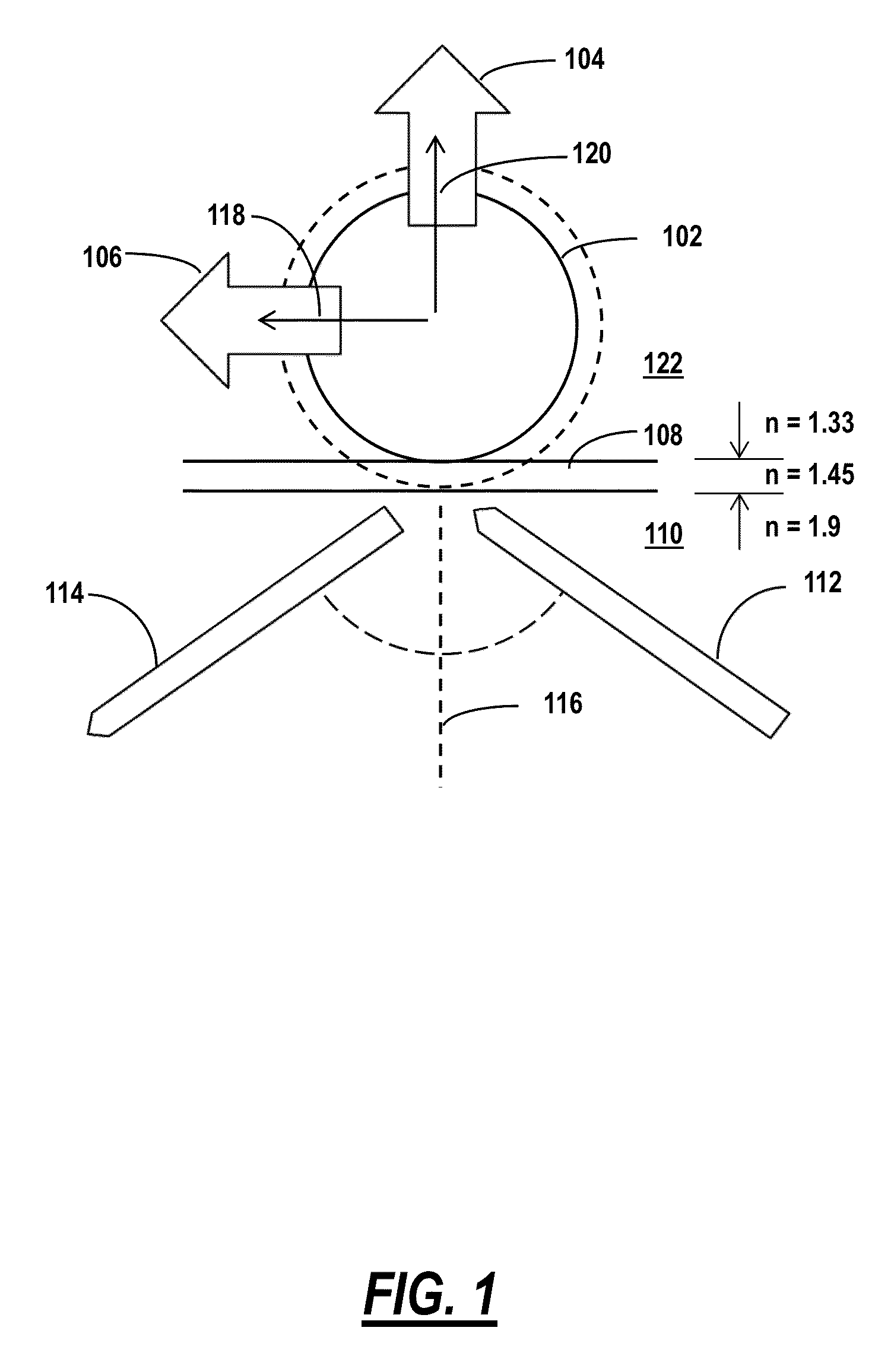

Methods and devices for optical sorting of microspheres based on their resonant optical properties

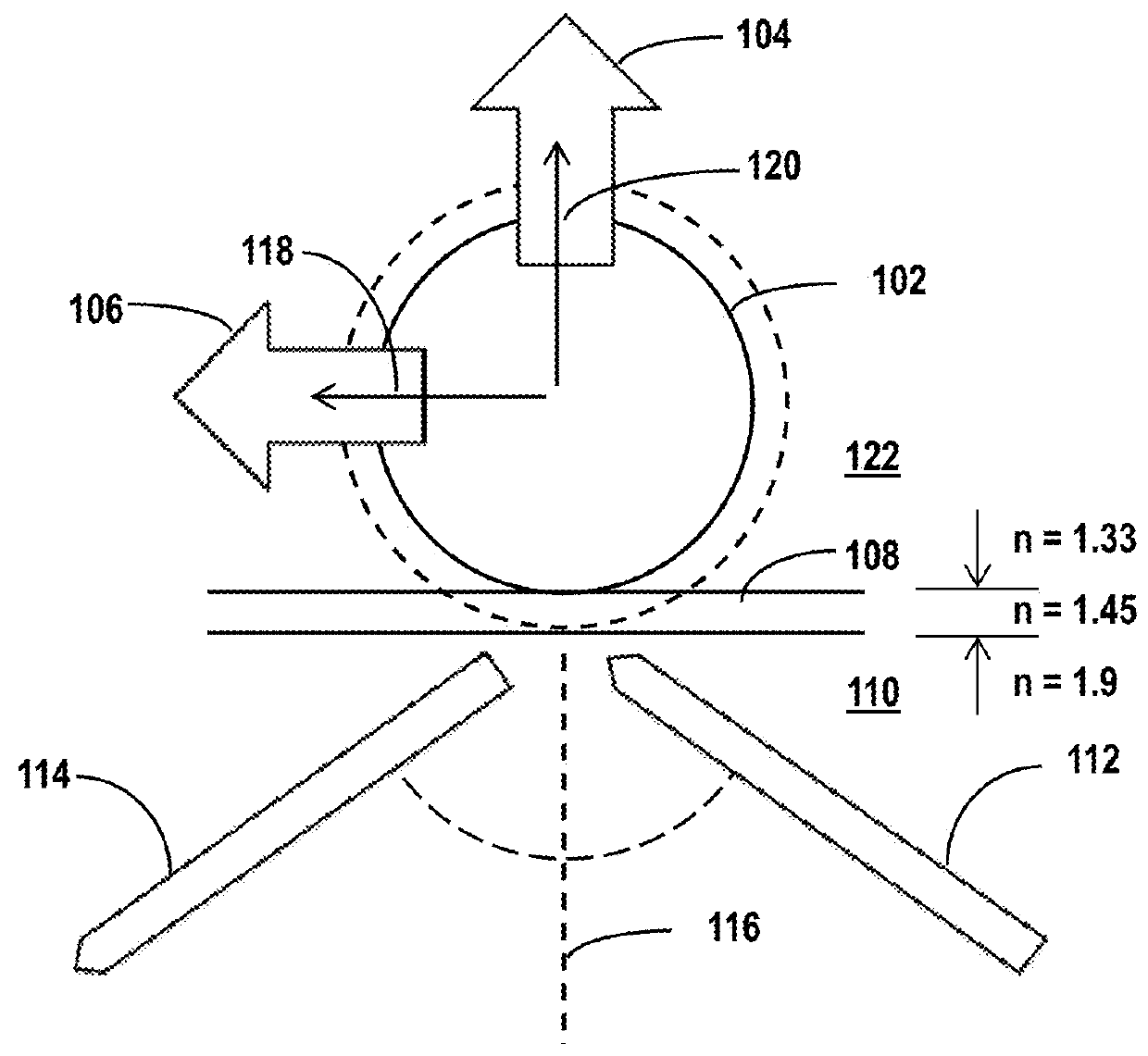

ActiveUS20160030981A1Scattering properties measurementsLaboratory glasswaresWhispering galleryMicrosphere

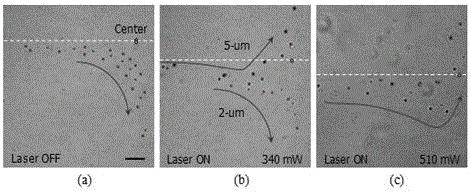

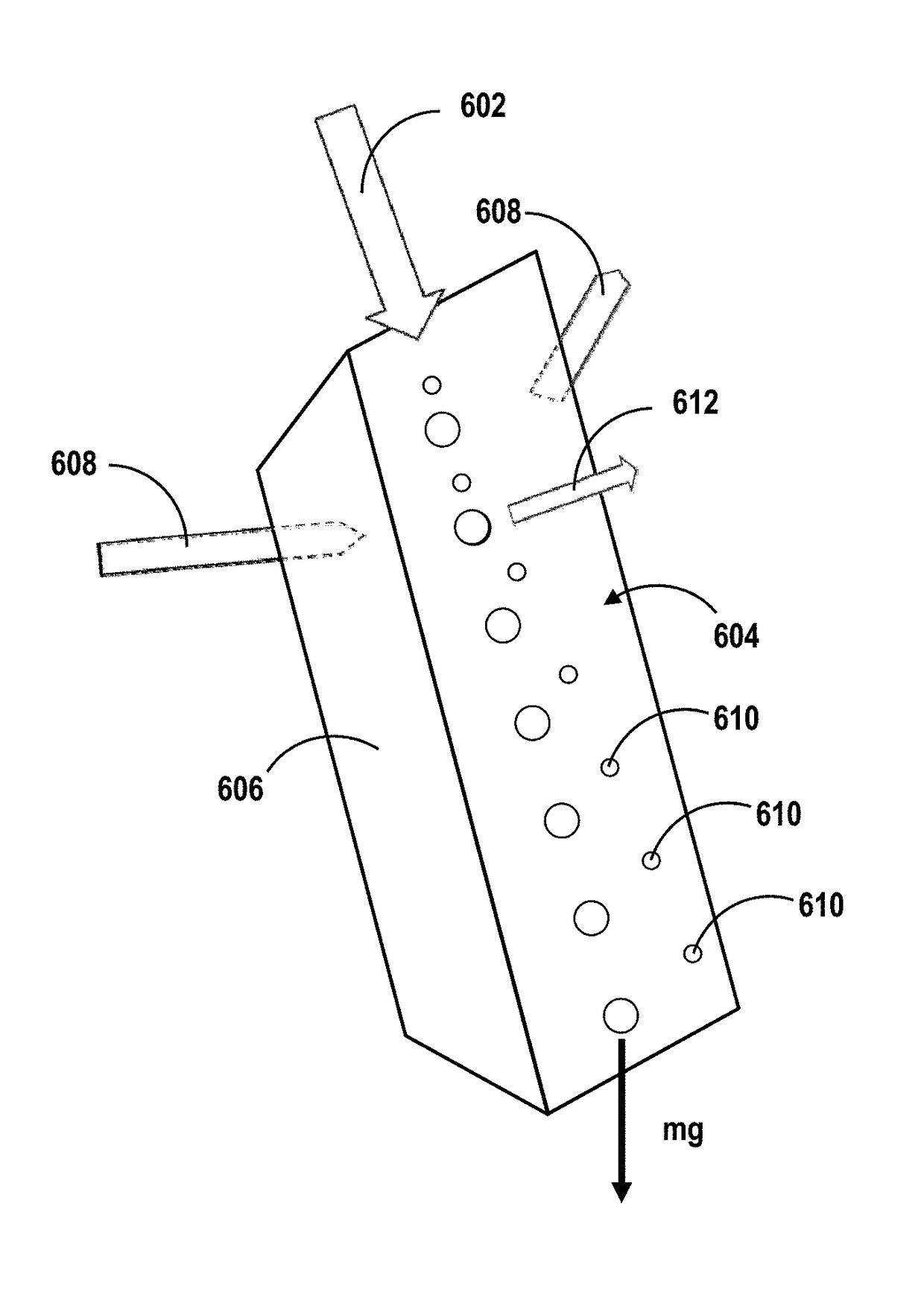

Microspheres are sorted by resonant light pressure effects. An evanescent optical field is generated when light is confined within the interior of an optical element such as a surface waveguide, a tapered microfiber, or a prism. Microspheres brought within vicinity of the surface are subjected to forces that result from a coupling of the evanescent field to whispering gallery modes (WGM) in the microspheres. Alternatively, a focused laser beam is directed close to the edge of the microspheres to exert resonant optical forces on microspheres. Alternatively, standing optical waves are excited in the optical element. Optical forces are resonantly enhanced when light frequencies match WGM frequencies in the microspheres. Those microspheres for which resonance is obtained are more affected by the evanescent field than microspheres for which resonance does not occur. Greater forces are applied to resonating microspheres, which are separated from a heterogeneous mixture according to size.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

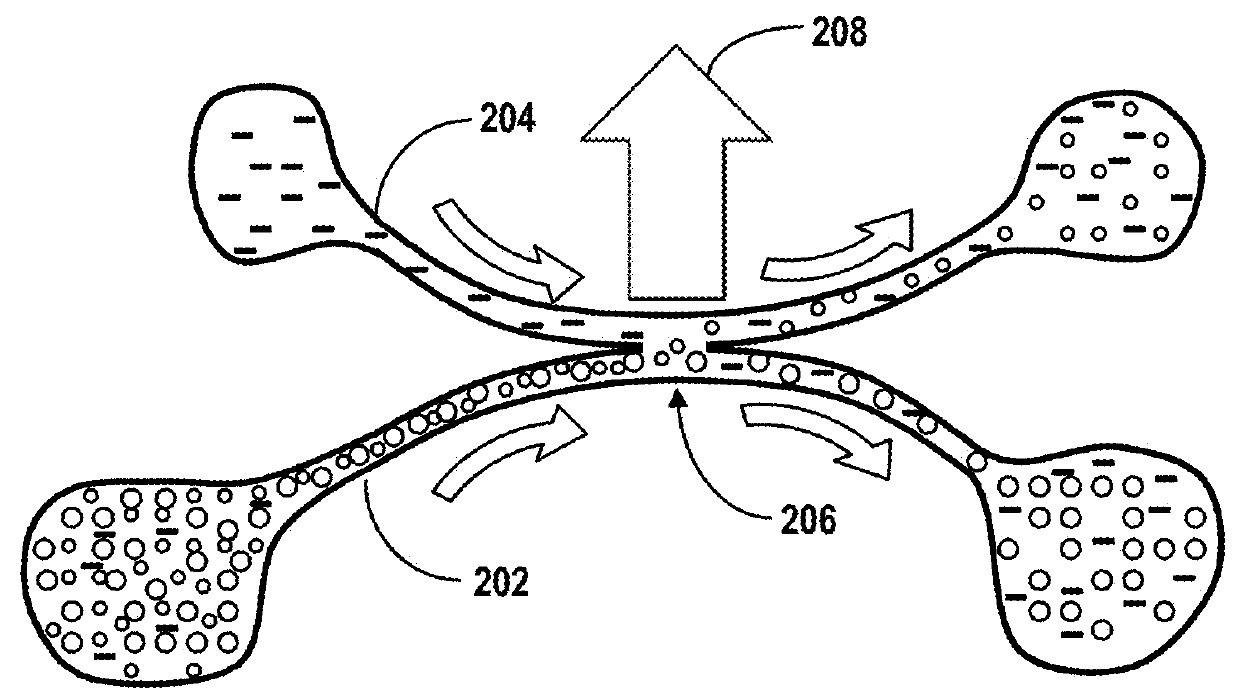

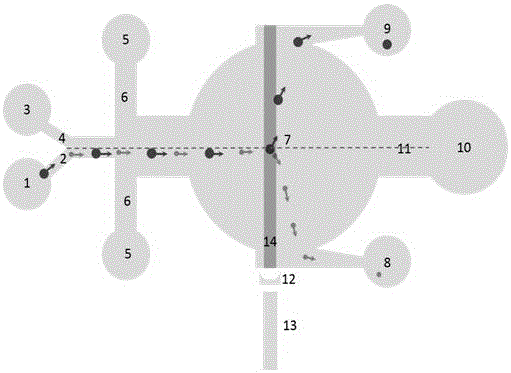

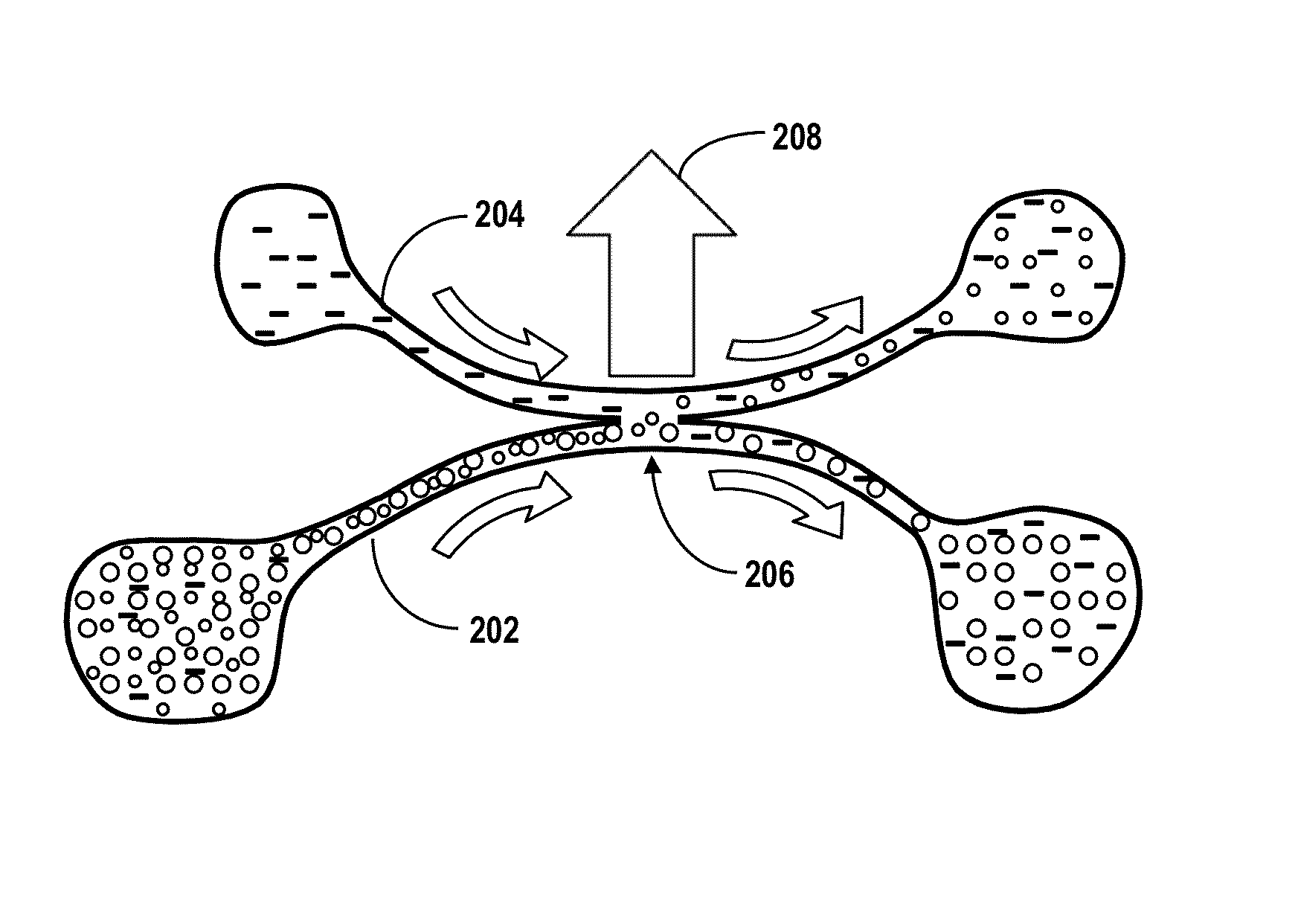

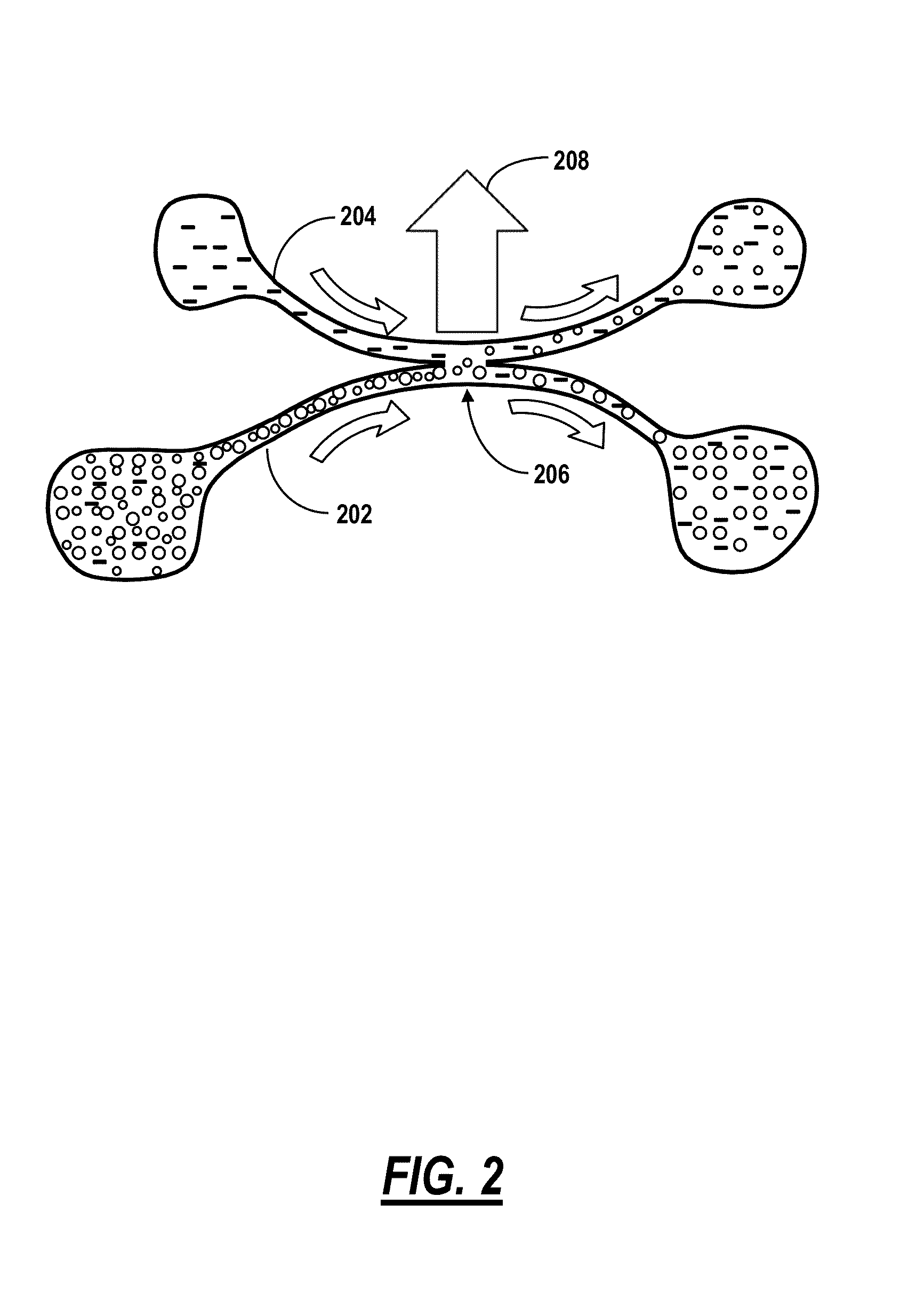

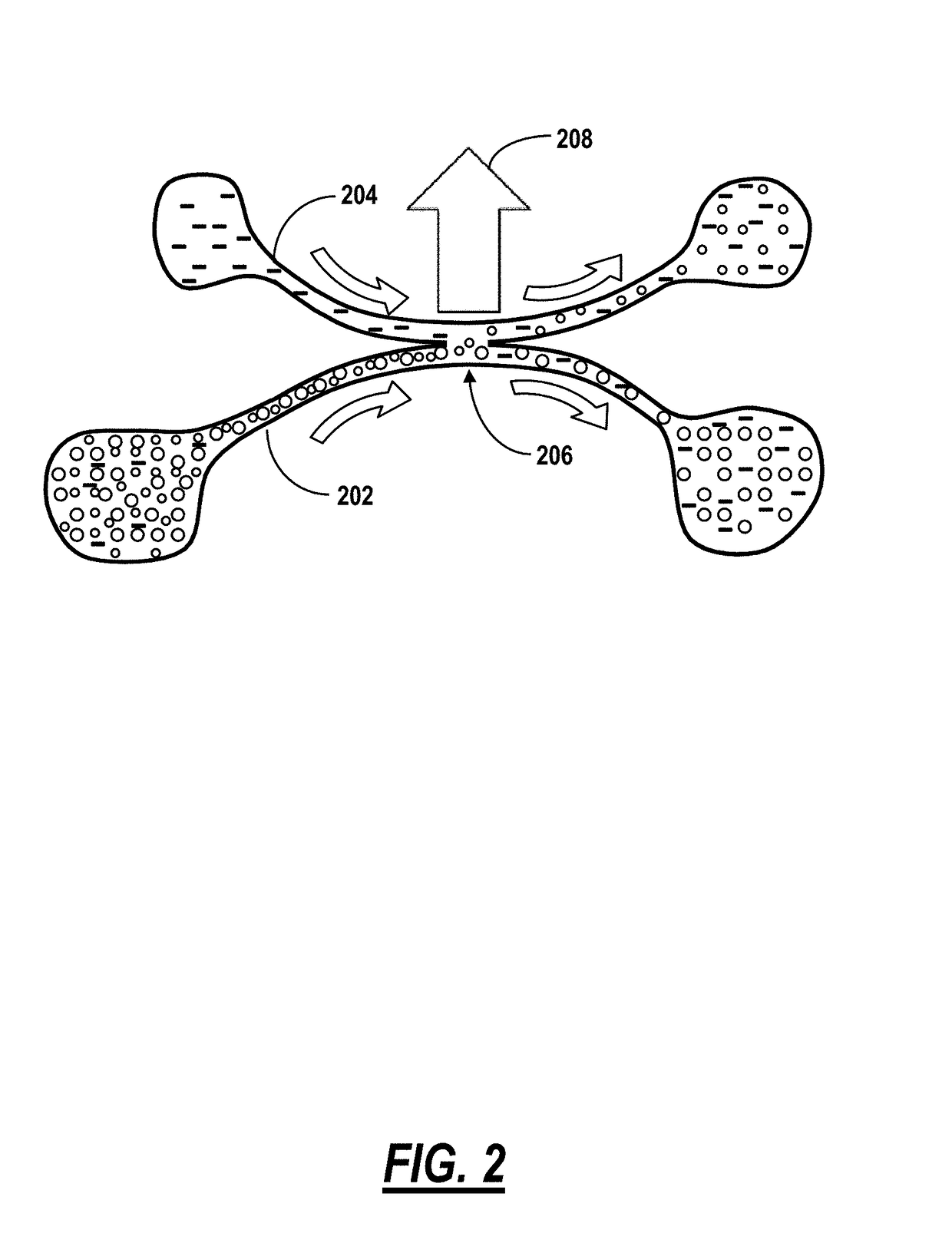

Optical flow control chip utilizing impinging stream and optical scattering force and application thereof for sorting micro-nano particles

ActiveCN104971788AEfficient and orderly separationWith little successLaboratory glasswaresGradingMicro nanoOptical flow

The invention relates to an optical flow control chip utilizing impinging stream and optical scattering force and application thereof for sorting micro-nano particles, belonging to the field of optical flow control chips. The optical flow control chip comprises a cylindrical optical separation cavity, wherein one side of the optical separation cavity is connected with an impinging stream inlet through an impinging stream channel, the other side of the optical separation cavity is provided with an auxiliary flow inlet and a sample flow inlet, the center line of a channel formed by converging of an auxiliary flow channel and a sample flow channel and the center line of the impinging stream channel are positioned on the same straight line, and two sides of the channel formed by converging of the auxiliary flow channel and the sample flow channel are respectively connected with an inlet of sheath flow through a sheath flow channel, and then are connected with the optical separation cavity; an optical fiber groove with a collimating lens, as well as a large-particle outlet and a small-particle outlet, is further formed in the optical separation cavity. According to the invention, a point with the minimal speed value is formed at the center of an optical sorting cavity, so that an optical scattering force can be used for sorting particles at the point, the average speed of sorting operation by the optical force is greatly improved, and the sorting precision and efficiency are improved.

Owner:WUHAN UNIV

Chute for optical sorting machine

InactiveUS8944255B2Unevenness of the flow of the sorted articles on the chute surface can be preventedUneven flowSortingChutesMechanical engineeringOptical sorting

A chute for an optical sorting machine allows objects to be sorted to drop under gravity from the lower end of the chute, thereby supplying the objects to an optical detection section. The chute is provided with: a first portion which includes a portion for receiving the objects to be sorted which are supplied from a supply section; and a second portion which continues from the first portion. The first portion is composed of a single part and has: flat surfaces along which the objects to be sorted flow down; and connection surfaces. The flat surfaces located upstream are bent downward and the connection surfaces located downstream are bent upward to form a smooth undulation in the surface along which the objects to be sorted flow down.

Owner:SATAKE CORP

Optical sorting device and optical sorting equipment for sorting deteriorated rice seeds

The application discloses an optical sorting device for sorting deteriorated rice seeds. The optical sorting device comprises an optical system, an analysis system and a transfer system, wherein the optical system comprises a light source and an image acquisition component; the wavelength provided by the optical source is 600 to 650nm; light emitted by the light source penetrates through rice seeds in an image acquisition area and then is acquired by the image acquisition component; the analysis system is used for receiving an image acquired by the image acquisition component and analyzing theimage; the transfer system is connected with the analysis system and respectively transfers the rice seeds to corresponding sorting areas according to the analysis result of the analysis system. Theapplication also provides optical sorting equipment for the rice seeds. According to the scheme provided by the application, recognition and sorting of the deteriorated rice seeds such as preharvest sprouting, rice grain powder and mildew are realized, and the effect of improving the germination percentage of the rice seeds is obvious.

Owner:YUAN LONGPING HIGH TECH AGRI CO LTD +2

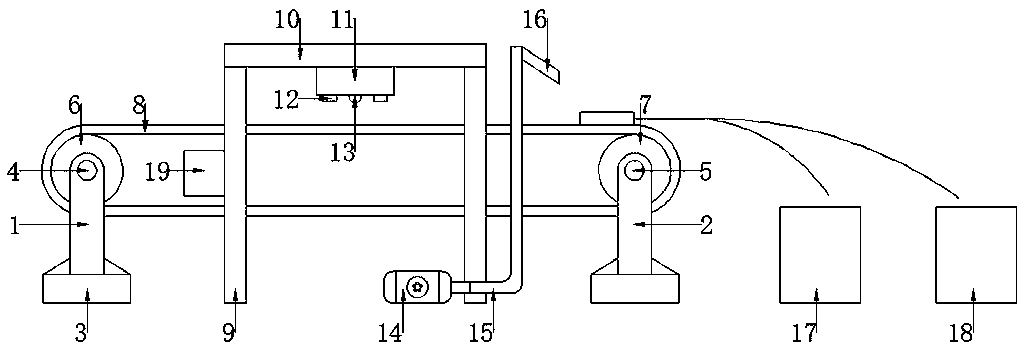

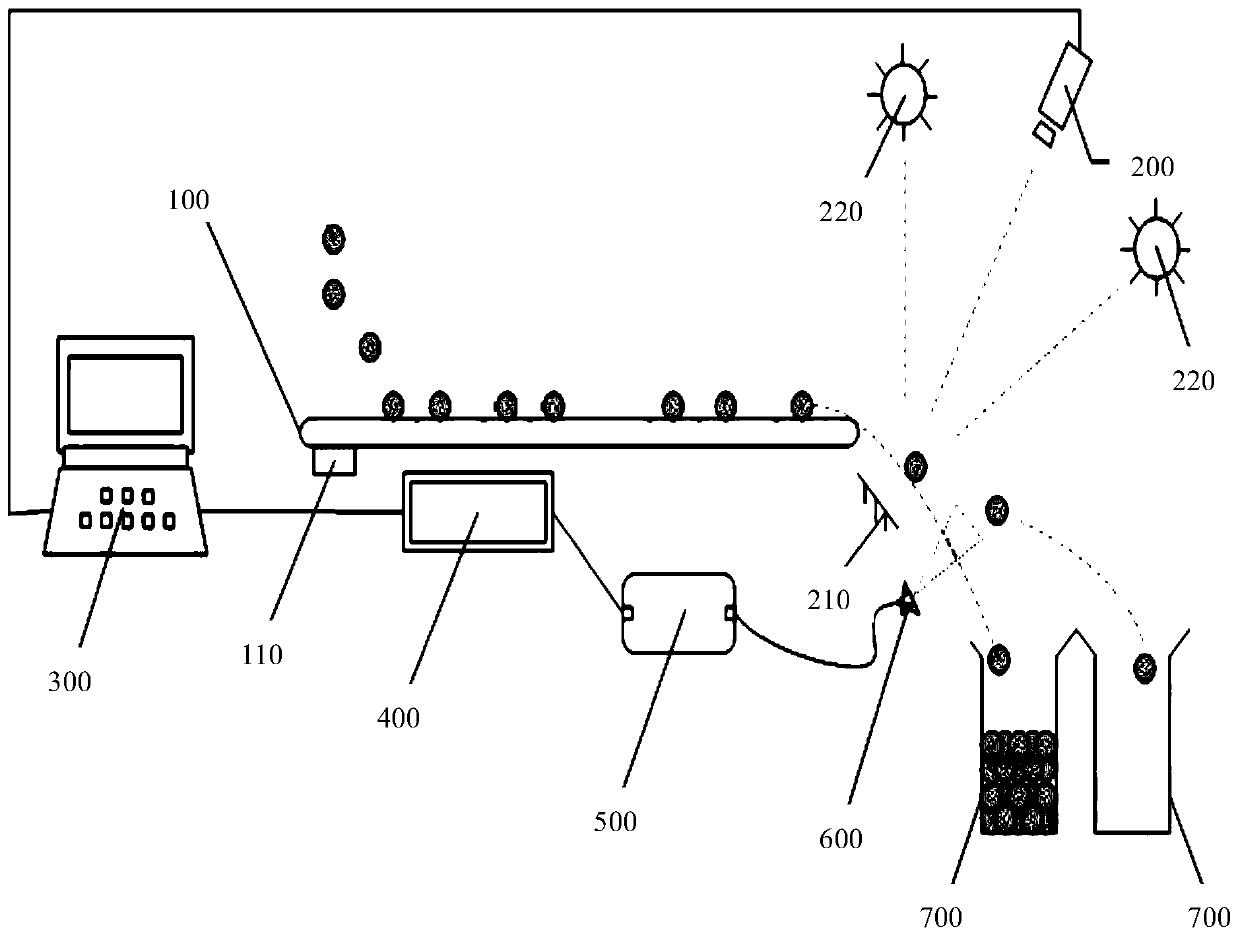

Sorting system through infrared light

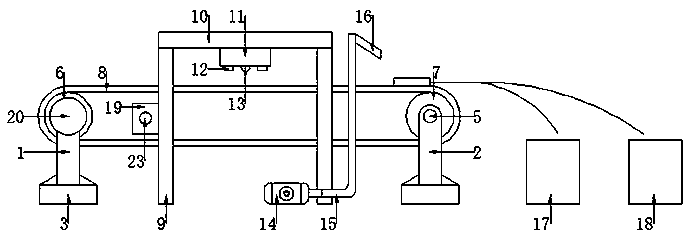

The invention discloses an sorting system through infrared light, and belongs to the technical field of garbage classification. The system involves a conveying system, a sorting system, a dischargingsystem, a mounting device and a PLC, wherein the conveying system comprises a first supporting leg, a second supporting leg, a driving shaft, a driven shaft, a driving roller, a driven roller, a conveyor belt and a motor; the system is characterized in that the mounting device comprises supporting columns, a mounting base, wherein the two pairs of supporting columns are arranged on the front sideand the rear side of the conveyor belt correspondingly, the mounting base is fixedly connected to the upper ends of the four supporting columns, the PLC is fixedly connected to the left end of one supporting column, and the sorting system comprises an optical sorting machine, halogen lamps, a camera and a photodiode, wherein the optical sorting machine is fixedly connected to the lower end of themounting base, and the halogen lamps are provided with a pair. Intelligent classification is carried out on garbage according to types and characteristics of the materials of the garbage, accurate positioning is achieved, and garbage sorting is completed

Owner:DEZHOU QUNFENG MACHINERY MFG

Glass powder classification optical separation and sorting system

InactiveCN107931304AEasy to removeImprove sorting qualitySievingGas current separationEddy current separatorComputer science

The invention discloses a glass powder classification optical separation and sorting system. The glass powder classification optical separation and sorting system comprises a Mogensen vibrating screenprovided with two sorting channels. A material of 3-8 mm in the first sorting channel is sorted through a first-grade vibrating screen and a first set of cullet optical sorting machines. A first cullet Z-shaped screen and a first cyclone separator are arranged between the first-grade vibrating screen and the first set of cullet optical sorting machines. A first wind circulating device is arrangedon the first set of cullet optical sorting machines. A eddy current separator and a drying machine are arranged in front of the Mogensen vibrating screen. An outlet of the first-grade vibrating screen is connected with a metal classification packing device. A fine material of 0-3 mm in the second sorting channel is sorted through a second-grade vibrating screen, a second cullet zigzag screening machine, a second cyclone separator and a second set of cullet optical sorting machines. The glass powder classification optical separation and sorting system can provide multiple kinds of finely sorted powder, facilitates removal of all impurities and sundries, greatly improves the sorting quality and production capacity and cannot affect the sorting efficiency.

Owner:上海燕龙基再生资源利用有限公司

Unhulled rice sorting device and equipment

The invention discloses an unhulled rice sorting device and equipment and relates to the technical field of sorting equipment. The unhulled rice sorting device comprises a feeding device, an optical sorting module, a controller, a rejection device and a material chute. The feeding device communicates with the material chute through a sliding chute. The optical sorting module comprises first lightsources, second light sources, a first image collector and a second image collector; the wave length of the first light sources is 600 nm-650 nm, and the wave length of the second light sources is 380nm-760 nm; the first image collector is arranged corresponding to the first light sources and used for collecting rice transmission signals; the second image collector is arranged corresponding to the second light sources and used for collecting rice diffuse reflection signals; and the controller is electrically connected with the rejection device and the optical sorting module and used for controlling start and stop of the rejection device according to the transmission signals and / or diffuse reflection signals to sort rice to corresponding to sorting areas of the material chute. The unhulledrice sorting device can sort out bad rice with the defects such as internal damage, color difference and not full particles simultaneously.

Owner:CHINA HEFEI TAIHE OPTOELECTRONICS TECH

An optofluidic chip utilizing impinging flow and optical scattering force and its use for sorting micro-nano particles

ActiveCN104971788BEfficient and orderly separationWith little successLaboratory glasswaresGradingMicro nanoOptical flow

The invention relates to an optical flow control chip utilizing impinging stream and optical scattering force and application thereof for sorting micro-nano particles, belonging to the field of optical flow control chips. The optical flow control chip comprises a cylindrical optical separation cavity, wherein one side of the optical separation cavity is connected with an impinging stream inlet through an impinging stream channel, the other side of the optical separation cavity is provided with an auxiliary flow inlet and a sample flow inlet, the center line of a channel formed by converging of an auxiliary flow channel and a sample flow channel and the center line of the impinging stream channel are positioned on the same straight line, and two sides of the channel formed by converging of the auxiliary flow channel and the sample flow channel are respectively connected with an inlet of sheath flow through a sheath flow channel, and then are connected with the optical separation cavity; an optical fiber groove with a collimating lens, as well as a large-particle outlet and a small-particle outlet, is further formed in the optical separation cavity. According to the invention, a point with the minimal speed value is formed at the center of an optical sorting cavity, so that an optical scattering force can be used for sorting particles at the point, the average speed of sorting operation by the optical force is greatly improved, and the sorting precision and efficiency are improved.

Owner:WUHAN UNIV

Optical Inspection Apparatus and Optical Sorting Apparatus

InactiveUS20150219570A1Simple and cost-effective arrangementEfficient and correctOptically investigating flaws/contaminationSortingFree fallingLight beam

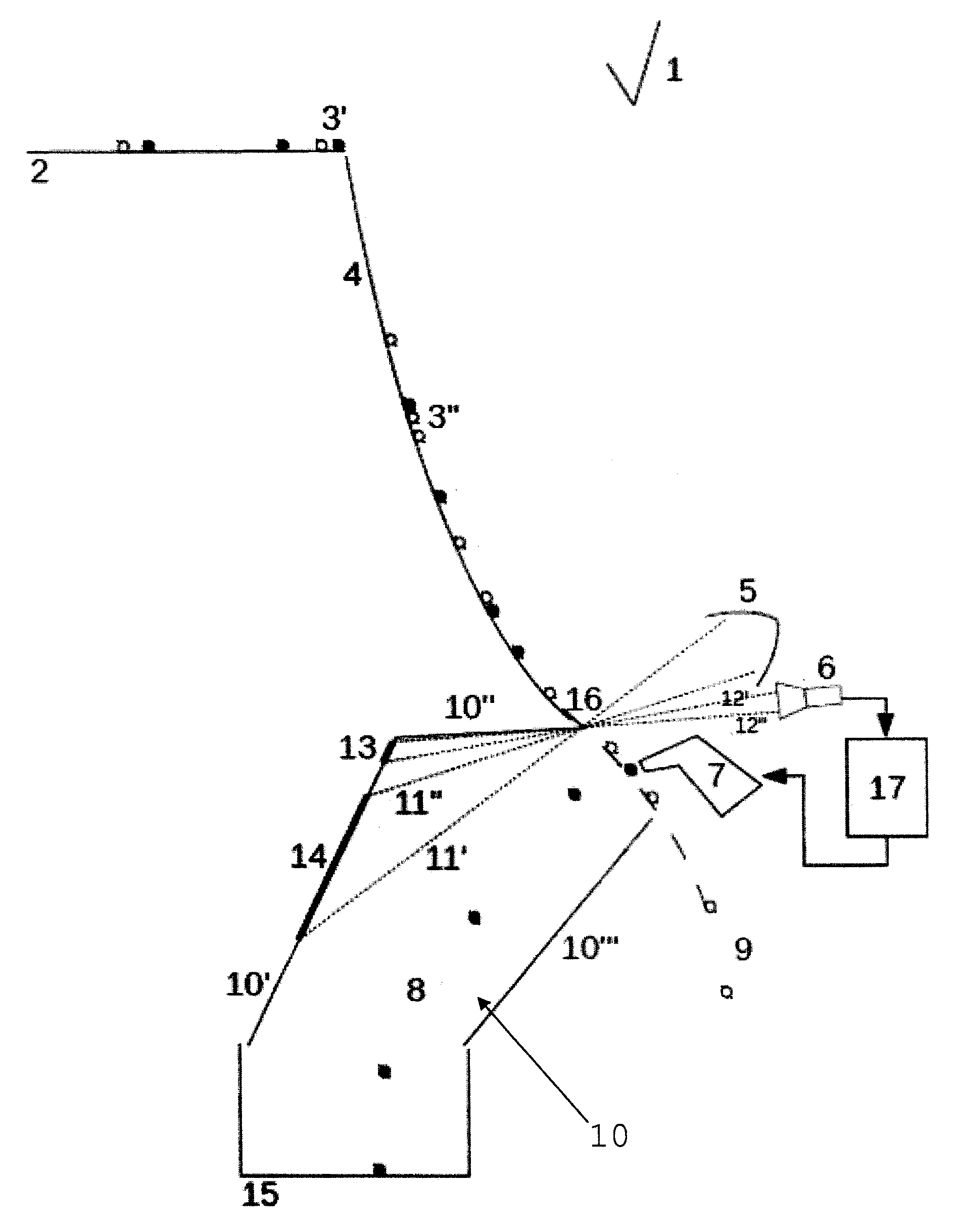

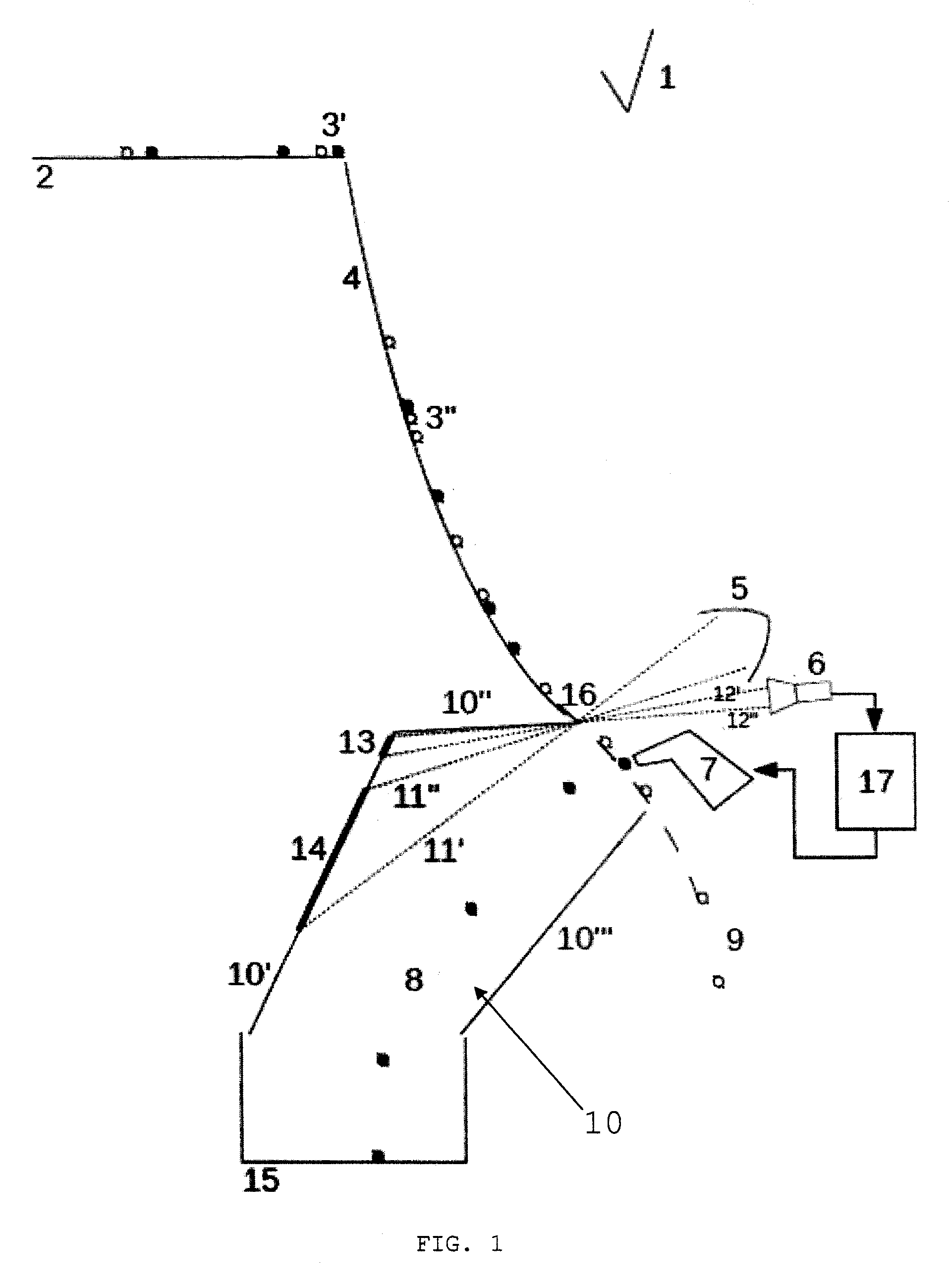

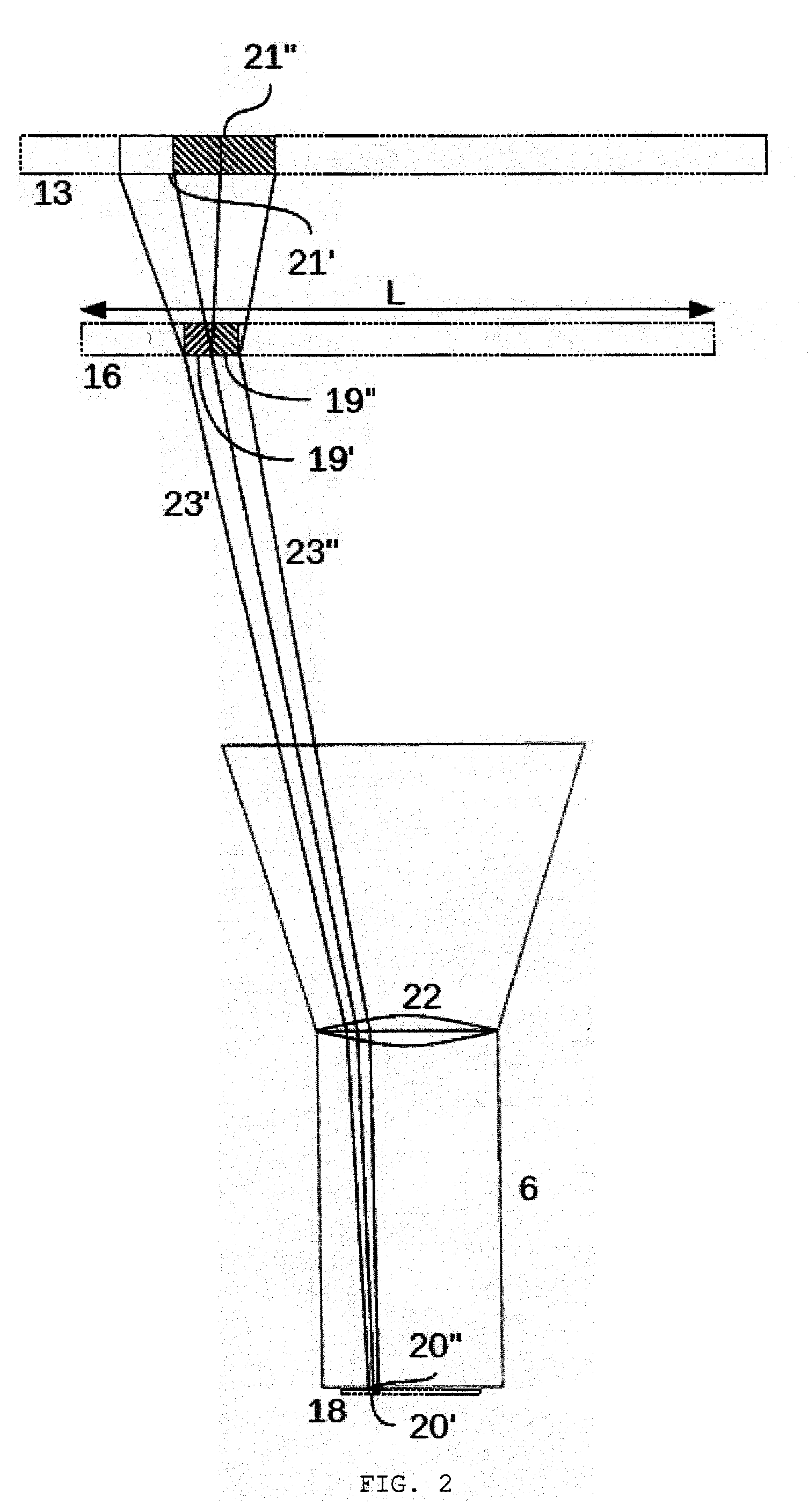

The invention concerns an apparatus for inspection of products (3′, 3″), provided with a transport mechanism (2) configured to transport a continuous stream of products (3′, 3″) so that, on leaving the transport mechanism, the product stream (3′, 3″) follows a free-fall path along which it is fed in a single product layer through an inspection zone (16), which has a length (L) that at least corresponds to the width of the aforementioned single product layer, a light source (5, 5′) configured to illuminate said inspection zone (16), a detection unit (6), configured to optically scan the illuminated inspection zone (16), an analysis unit (17) and possibly a removal unit (7) and also a background element (10′), which is situated behind the falling product stream, seen from the position of the detection unit, positioned so that:—light beams from the light source impinge on an illumination zone (14) of the background element when these beams do not impinge on a product from the product stream (3′, 3″),—the detection unit can only receive an image of a detection zone (13) of the background element, characterized in that the background element is mounted so that the illumination zone (14) and the detection zone (13) are separated from each other.

Owner:KII TEKU INC

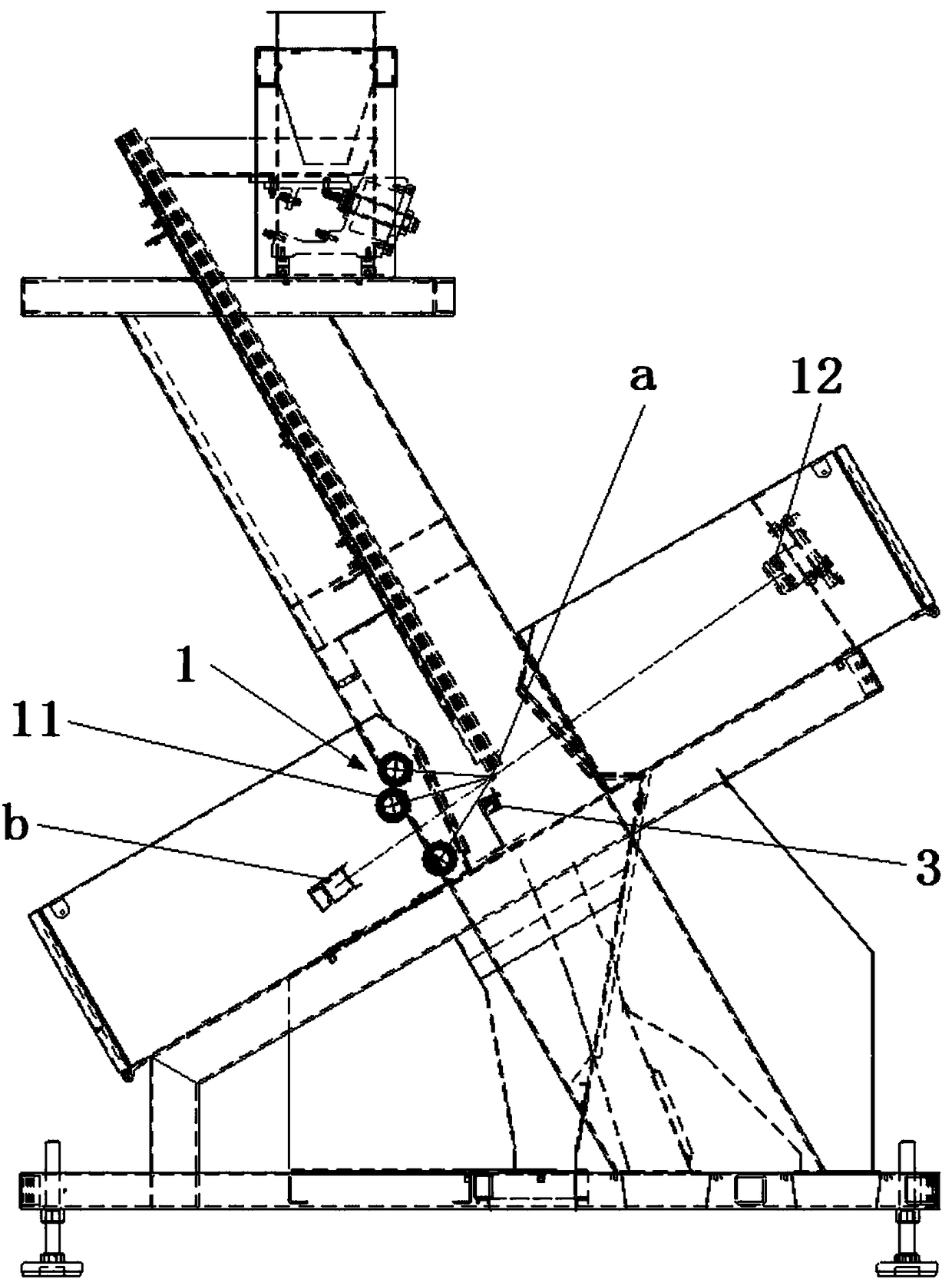

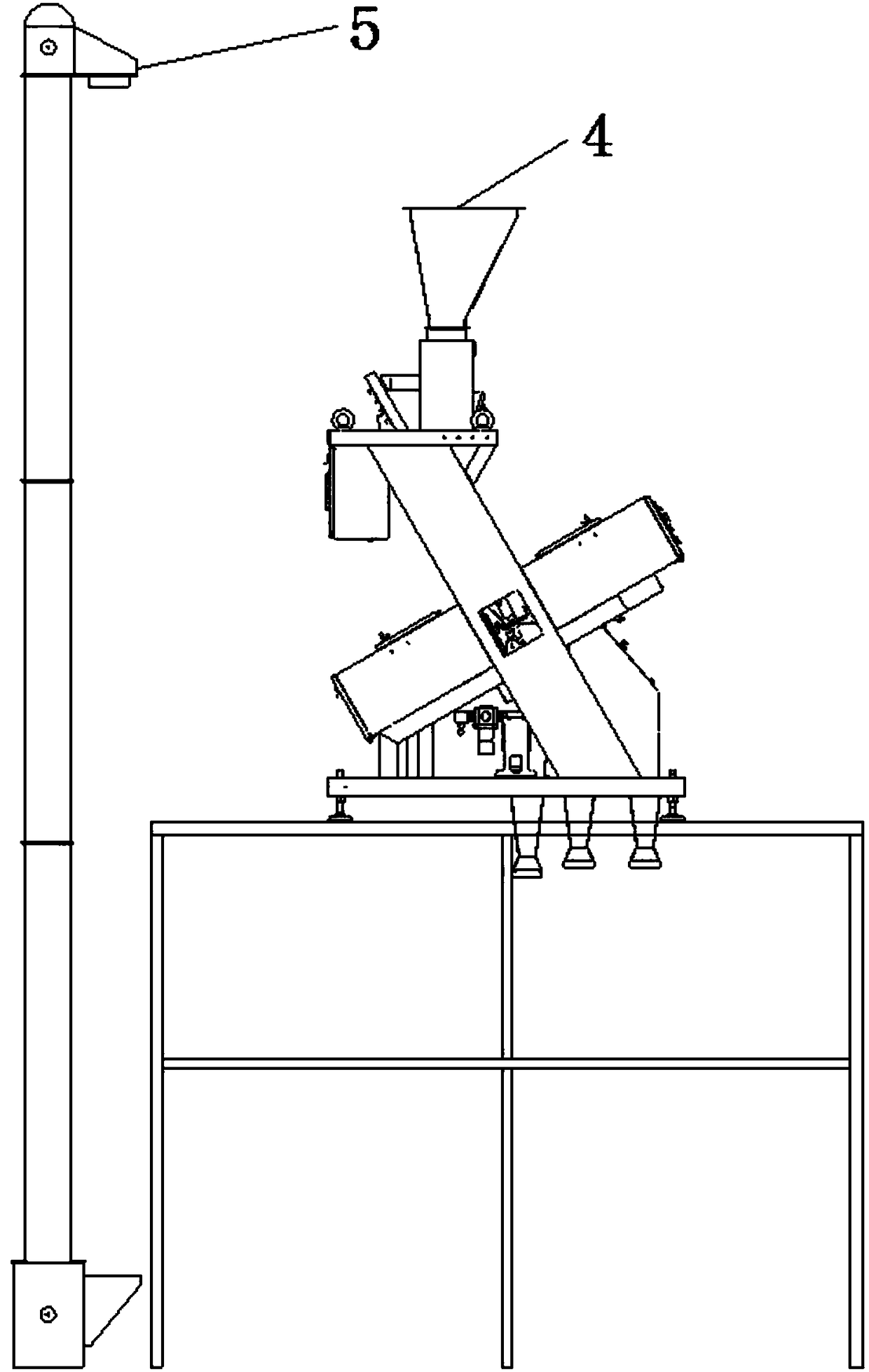

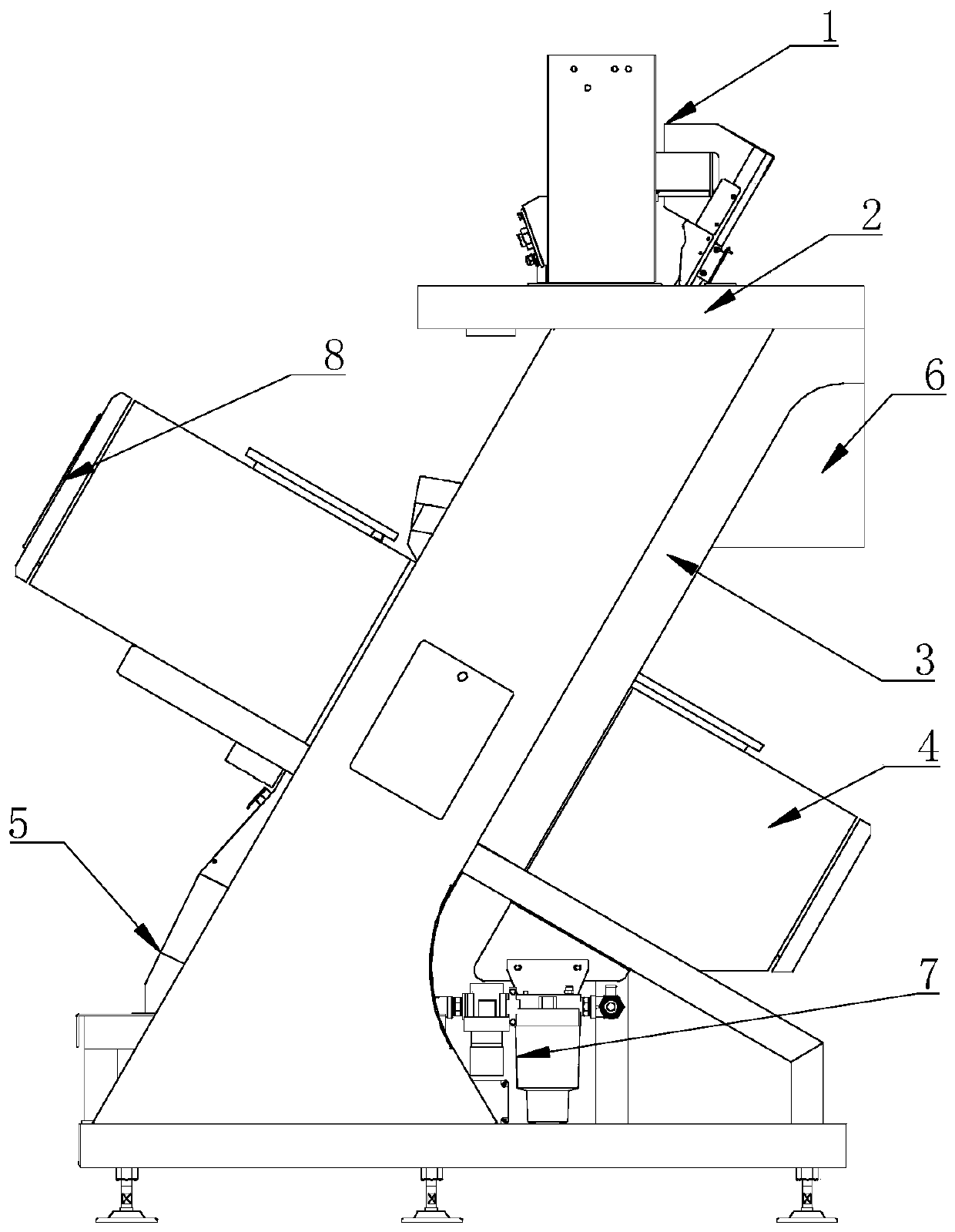

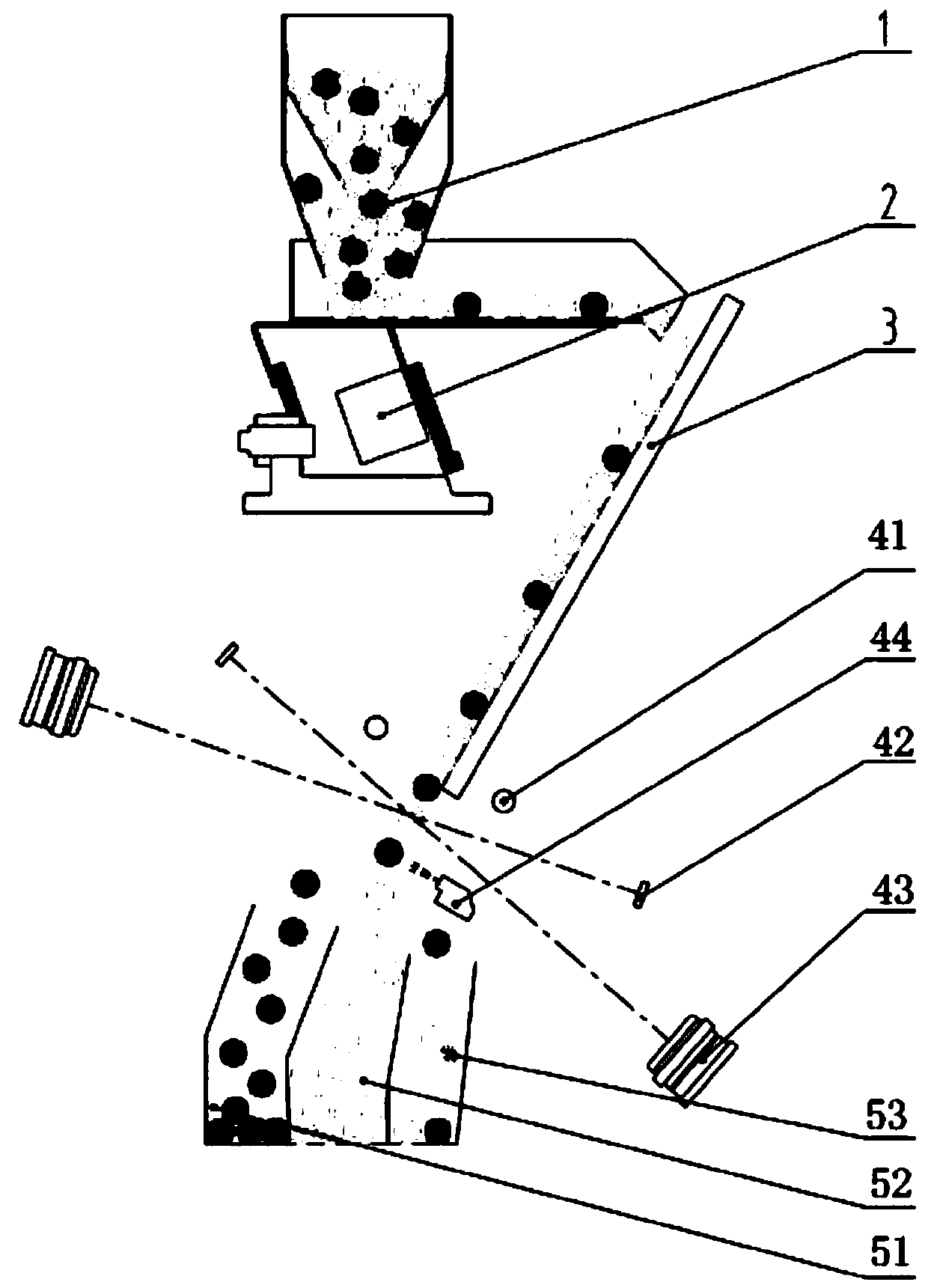

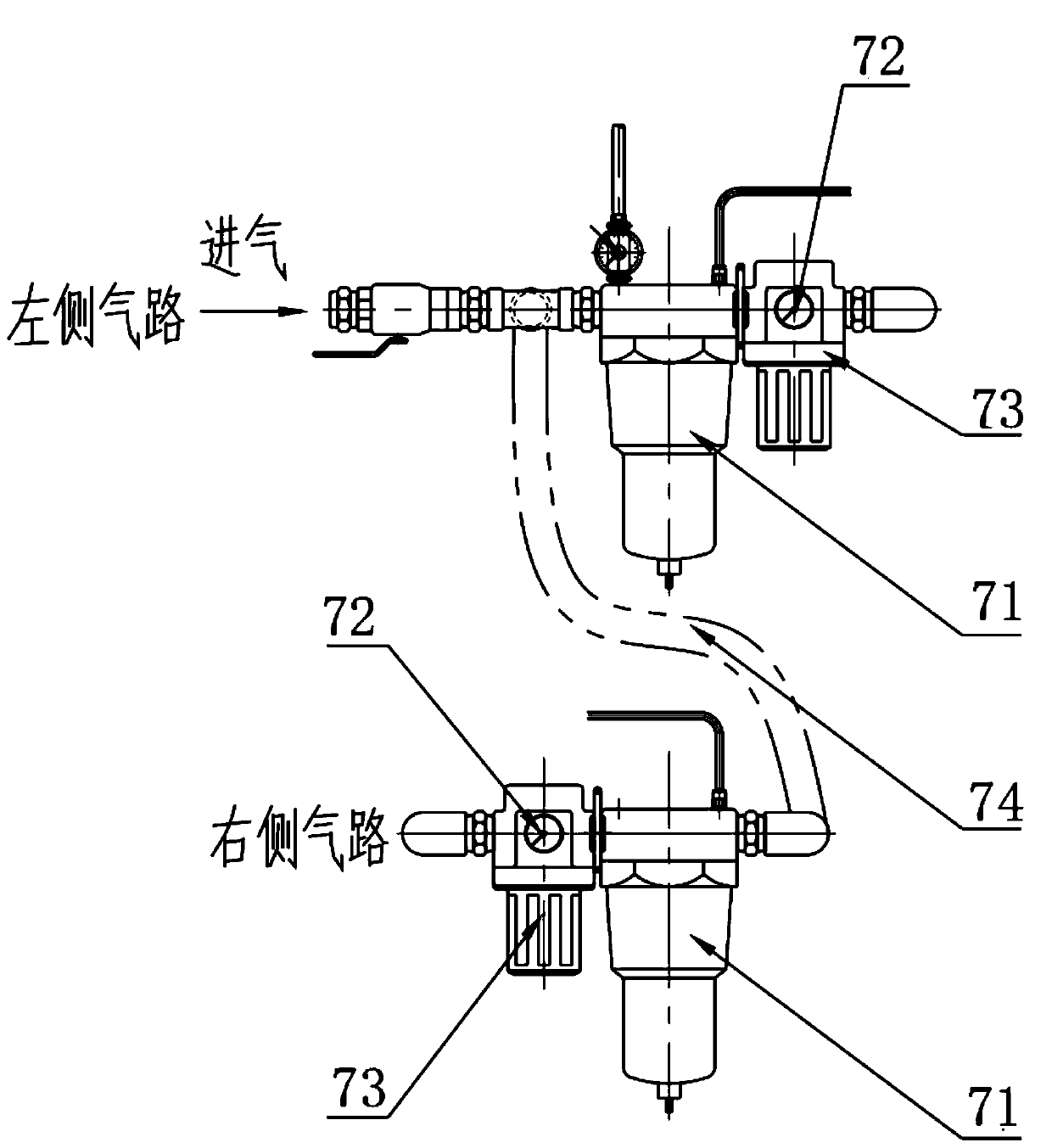

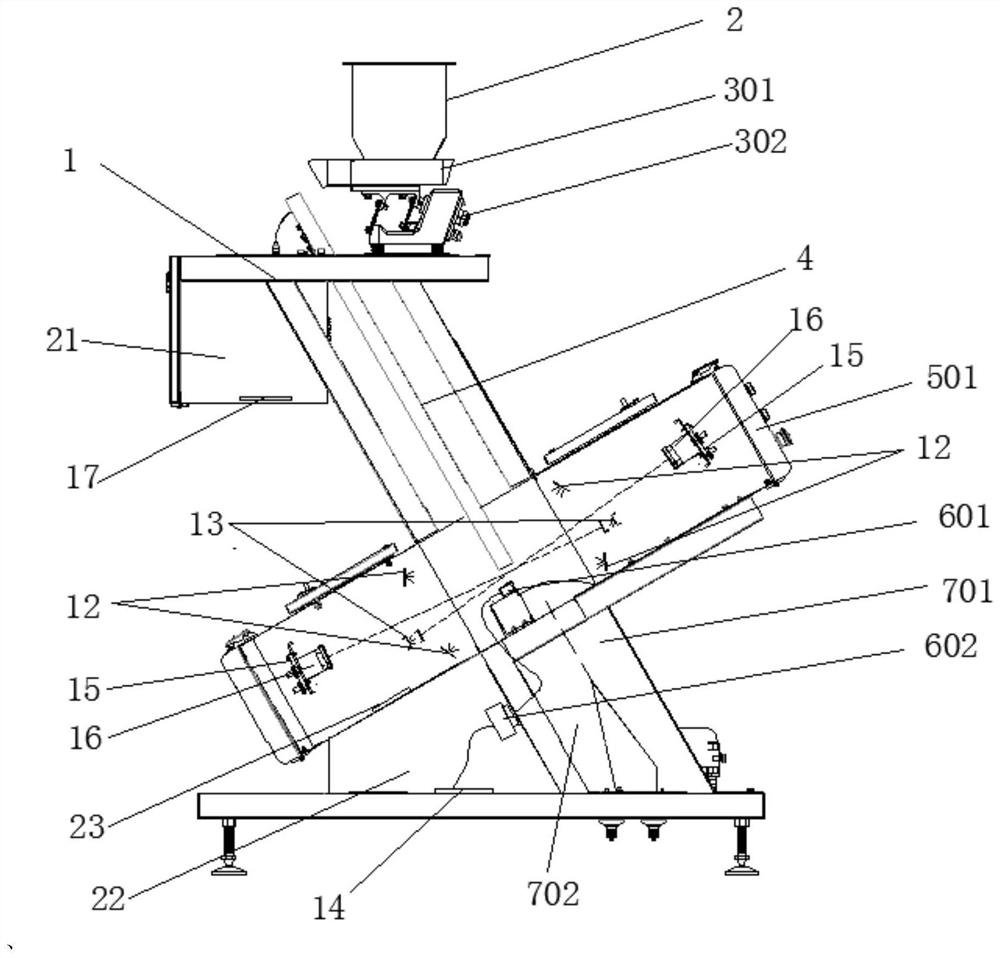

Sichuan pepper color-sorting and sundry removing equipment

InactiveCN111375567ASimple structural designImprove sorting effectSortingControl systemElectrical control

The invention discloses Sichuan pepper color-sorting and sundry removing equipment. The Sichuan pepper color-sorting and sundry removing equipment structurally comprises a mechanical part and a control system part. A feeding mechanism is arranged on the upper part of a Z-shaped rack of the mechanical part, a vibrator is mounted perpendicular to a discharge outlet of the feeding mechanism, a sorting channel is obliquely arranged at a material outlet of the vibrator, an optical sorting box is arranged at the bottom of the part, located in the middle of the Z-shaped rack, of the sorting channel,and a receiving bucket is arranged at the bottom of the sorting box. An air path system is arranged at the bottom of the rack and located on one side of the receiving bucket, and the bottom of the receiving bucket is connected with a dust collection system. An electrical control cabinet is arranged on a shell of the part, located in the middle of the Z-shaped rack, of the sorting channel, and a control panel is arranged on a shell of the optical sorting box. The Sichuan pepper color-sorting and sundry removing equipment is simple and reasonable in structure design, the sorting effect can be improved through the design of the control system, and the equipment is expanding technical innovation to the prior art, and has good popularization value and use value.

Owner:天水禾丰农业综合开发有限公司

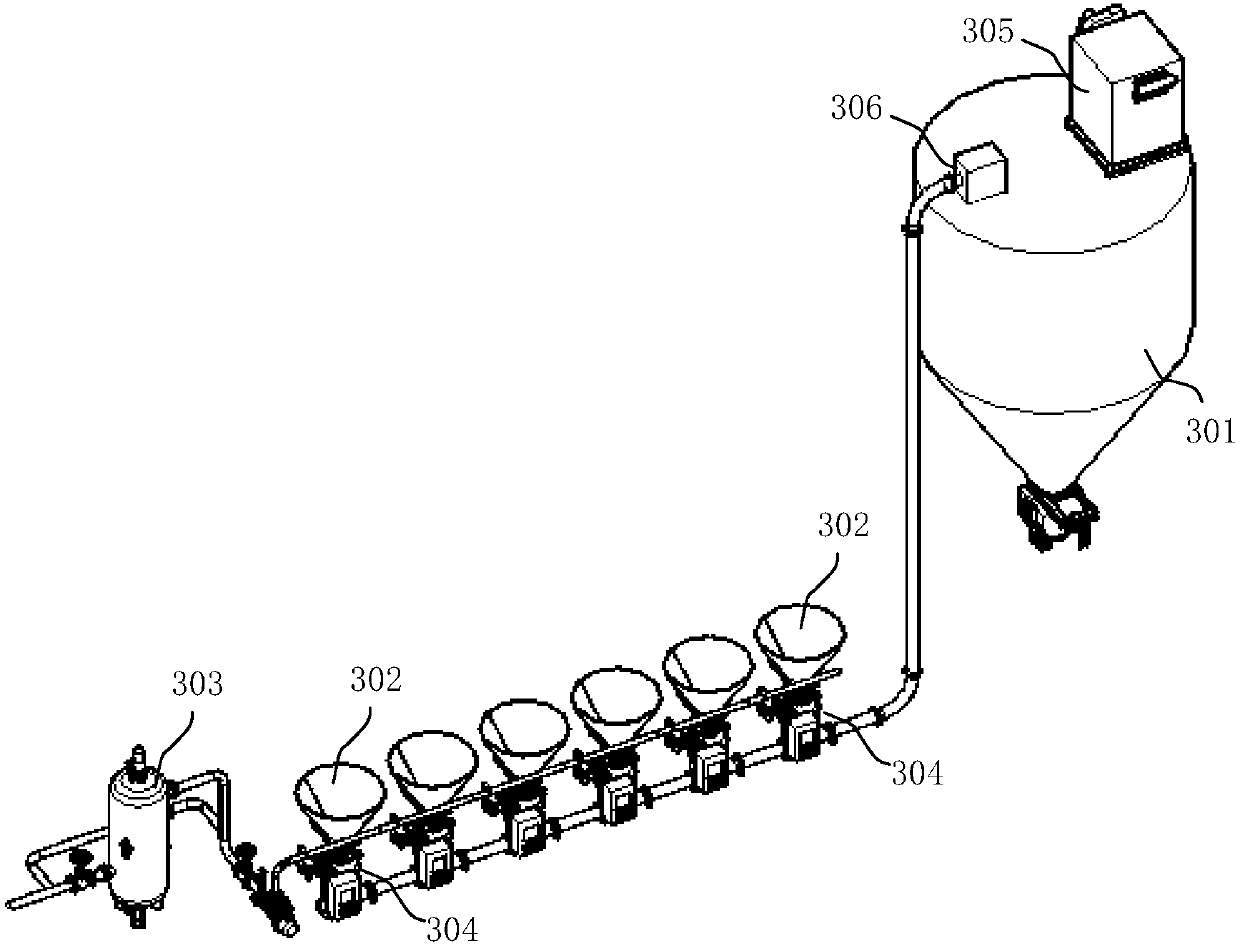

After-treatment system for kitchen wastes and method

PendingCN108889765AFully fermentedRich in nutrientsSolid waste disposalClimate change adaptationAfter treatmentAdditional values

The invention relates to an after-treatment system for kitchen wastes and a method. The after-treatment system comprises a frass rotary screen; a frass separating section, a worm separating section and a waste separating section are arranged in the frass rotary screen; the frass separated from the frass separating section enters into a tempering machine; a grinder is connected with a discharging port of the tempering machine; a frass conveying device is arranged under the discharging port of the grinder; a discharging end of the frass conveying device is connected with an aerobic fermentationworkshop; a waste conveying device is arranged at the discharging end of the aerobic fermentation workshop; the separated worms enter into an imago conveying device; an optical sorting machine is arranged at the discharging end of the imago conveying device; a blanching machine is arranged at the discharging end of the optical sorting machine; a cleaning machine is arranged at the discharging endof the blanching machine; a refrigerator is arranged at the discharging end of the cleaning machine; an instant freezer is arranged at the discharging end of the refrigerator; a worm grinder is arranged at the discharging end of the instant freezer; a packer is connected with the worm grinder. The after-treatment system has the advantages that the materials after breeding worms are fully utilized,a scientific and reasonable treating system is combined with a full automatic procedure assisted by precise instruments, the degree of automation is 95% or above and the additional value of rear-endoutput is ultrahigh.

Owner:七禾河(上海)生态科技有限公司

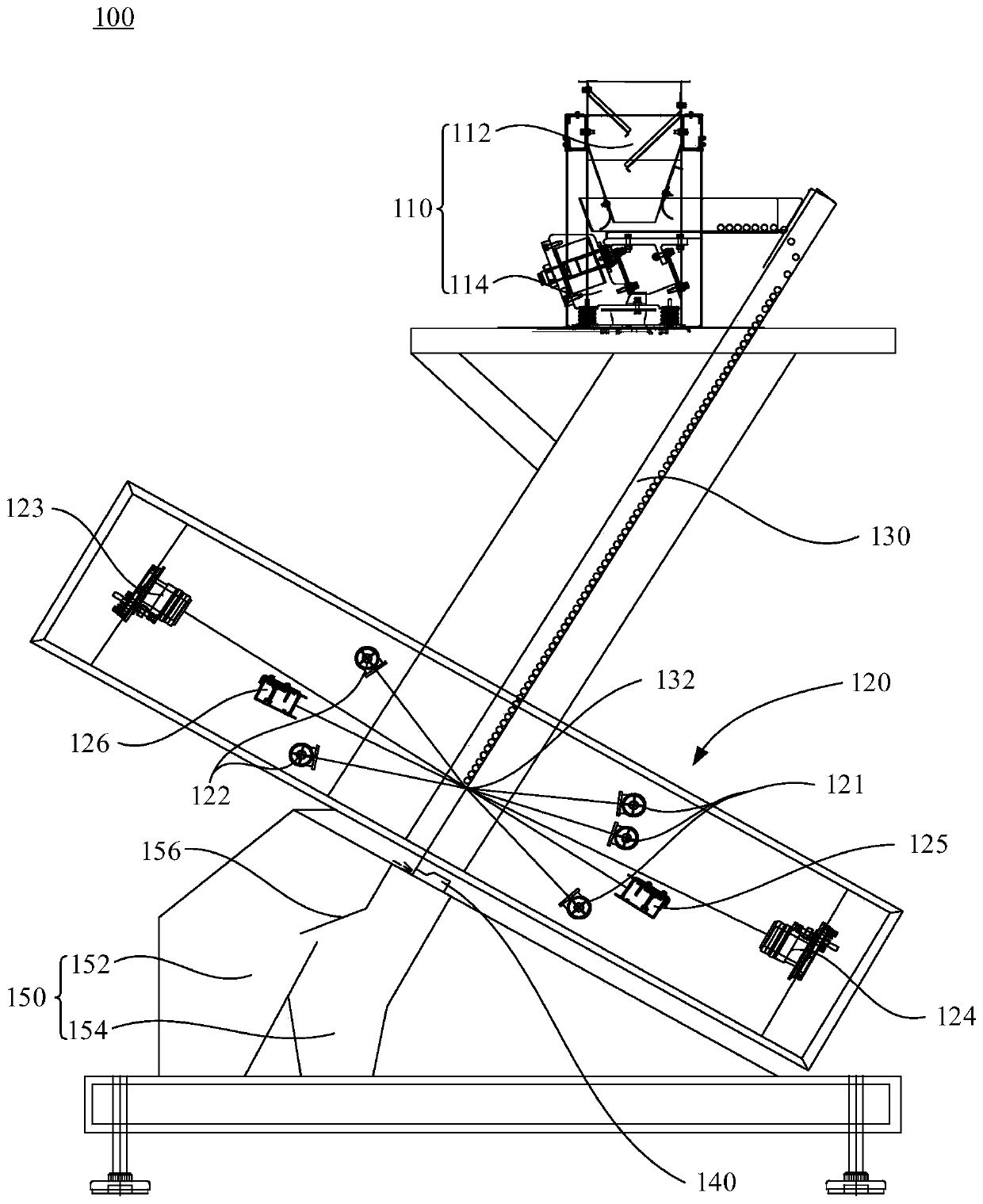

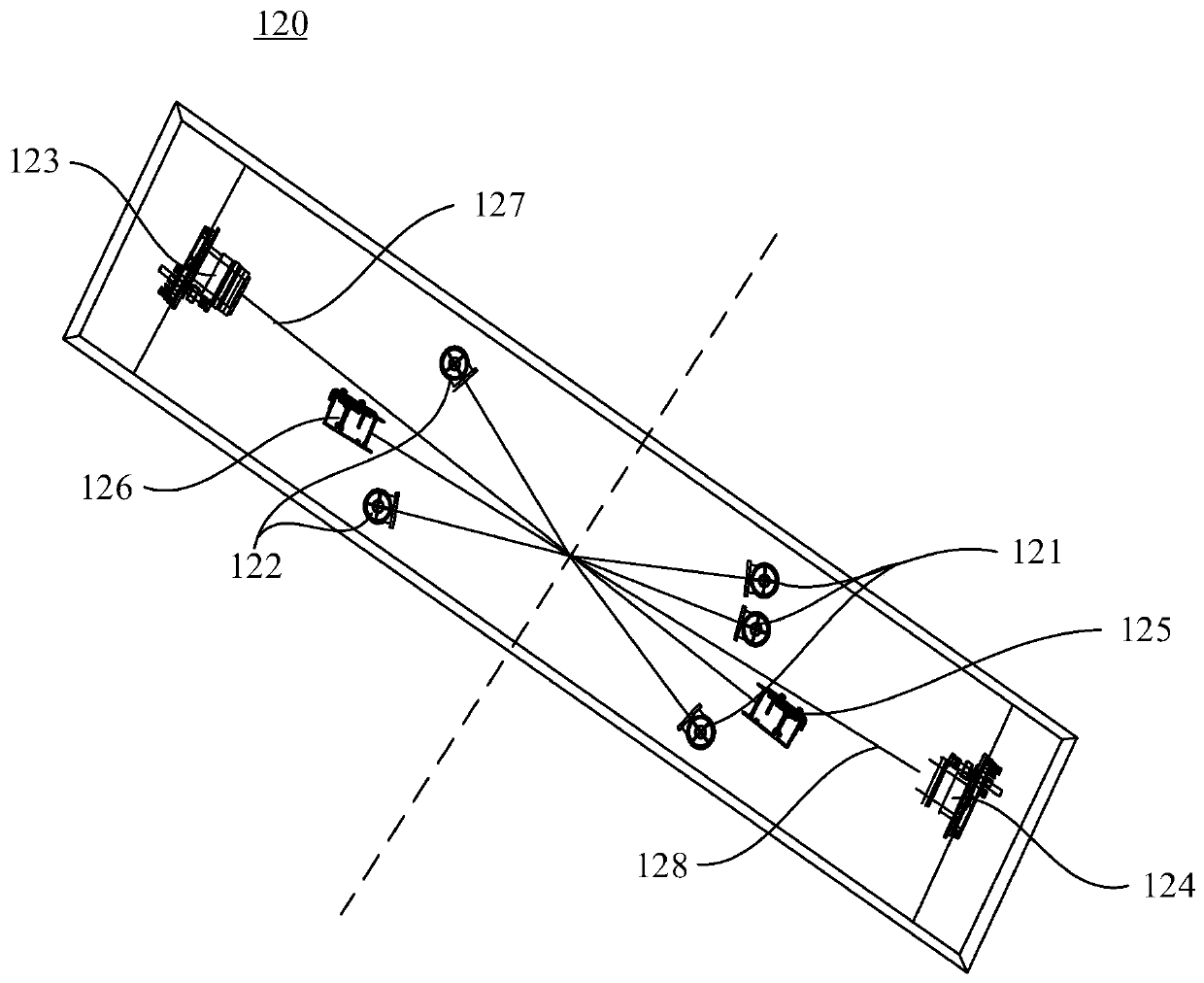

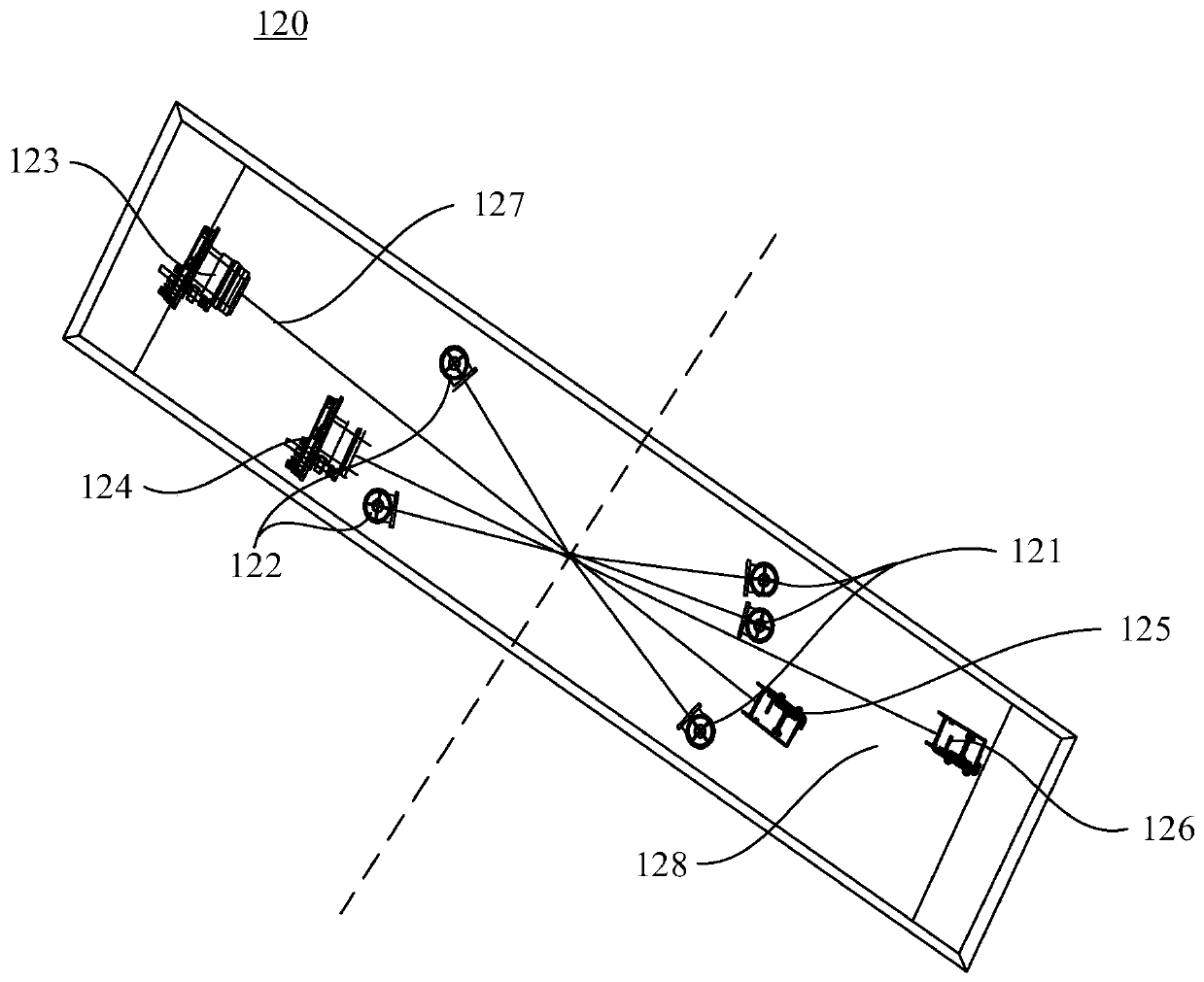

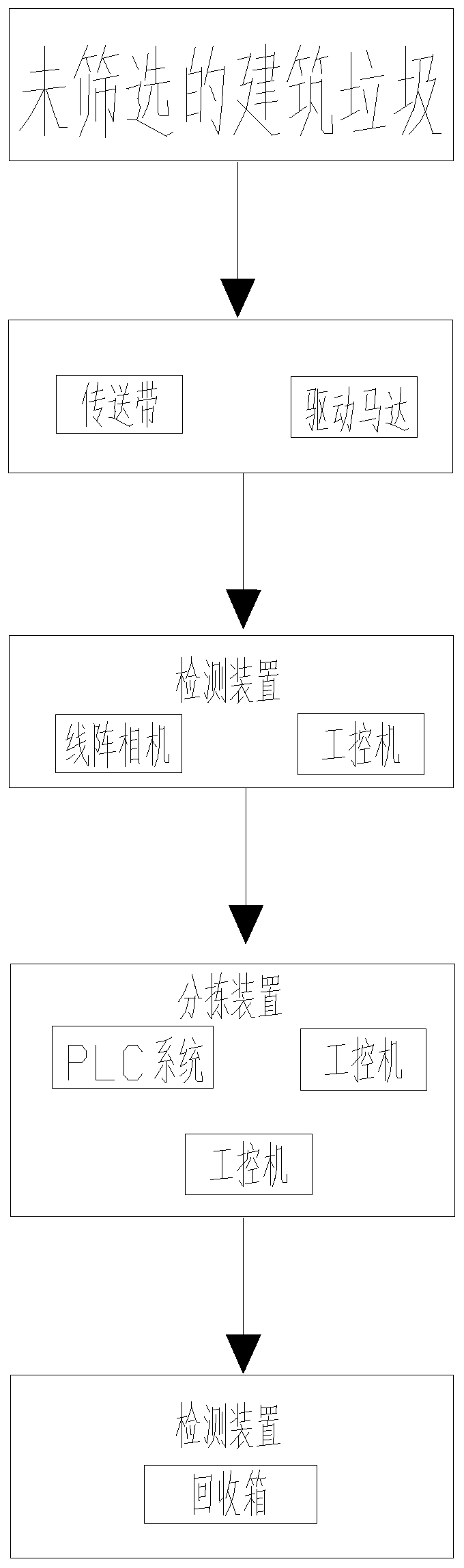

Optical sorting processing system and processing method for construction waste

The invention discloses an optical sorting processing system and a processing method for construction waste. The optical sorting processing system for construction waste comprise a conveyor belt, a detection device, a sorting device and a collection device, wherein the conveyor belt is used for conveying materials; the detection device comprises a linear array camera and an industrial personal computer; the linear array camera is arranged above one side of the conveyor belt; the industrial personal computer is connected with the linear array camera; the sorting device comprises a PLC system, an air pump and a blowing valve group; the PLC system is connected with the air pump and the blowing valve group; the blowing valve group is arranged below one side of the conveyor belt; the collectiondevice comprises a plurality of recovery boxes; the recovery boxes are arranged at one side of the blowing valve group; and the industrial personal computer is connected with the PLC system. According to the optical sorting processing system for construction waste, the linear array camera is matched with the industrial personal computer, the PLC system and the blowing valve group to sort and process the construction waste, the linear array camera collects picture information and feeds back the picture information to the industrial personal computer, the industrial personal computer analyzes and processes the picture information and sends an instruction to the PLC system, and the PLC system controls the blowing valve group to blow the falling materials into the corresponding recycling boxes, so that the sorting efficiency is greatly improved.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

Methods and devices for optical sorting of microspheres based on their resonant optical properties

Microspheres are sorted by resonant light pressure effects. An evanescent optical field is generated when light is confined within the interior of an optical element such as a surface waveguide, a tapered microfiber, or a prism. Microspheres brought within vicinity of the surface are subjected to forces that result from a coupling of the evanescent field to whispering gallery modes (WGM) in the microspheres. Alternatively, a focused laser beam is directed close to the edge of the microspheres to exert resonant optical forces on microspheres. Optical forces are resonantly enhanced when light frequencies match WGM frequencies in the microspheres. Those microspheres for which resonance is obtained are more affected by the evanescent field than microspheres for which resonance does not occur. Greater forces are applied to resonating microspheres, which are separated from a heterogeneous mixture according to size.

Owner:JUNIVERSITI OF NORT KAROLINA EHT SHARLOTT

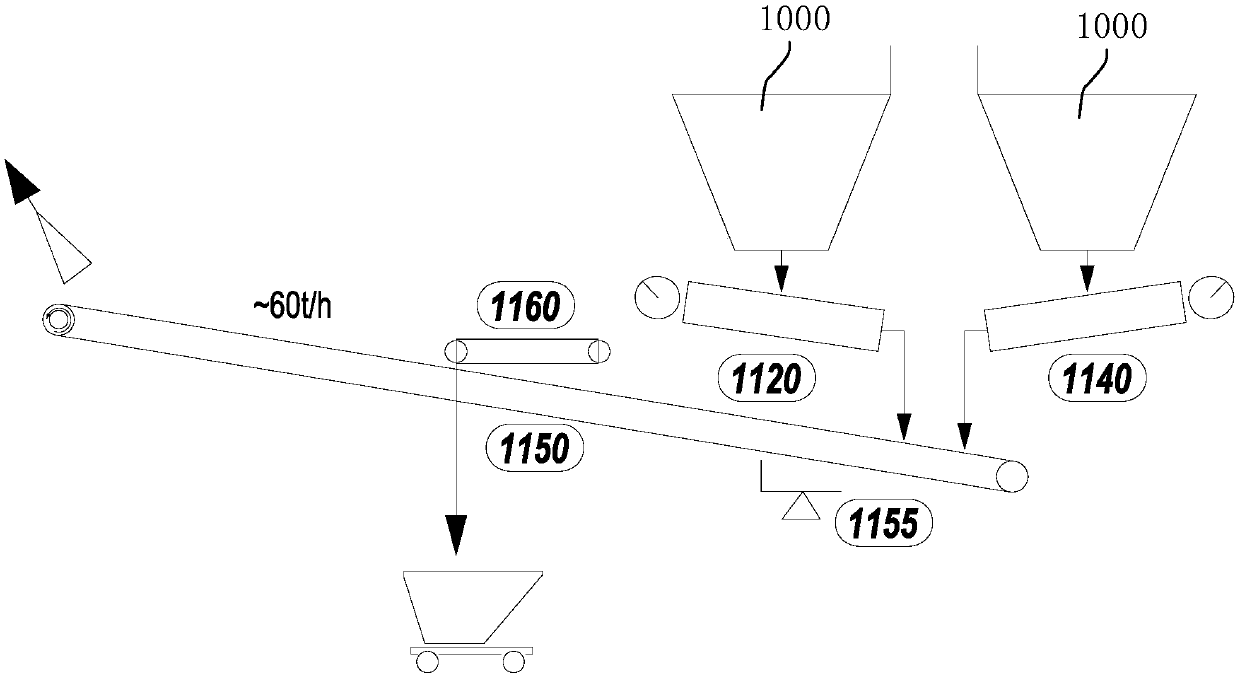

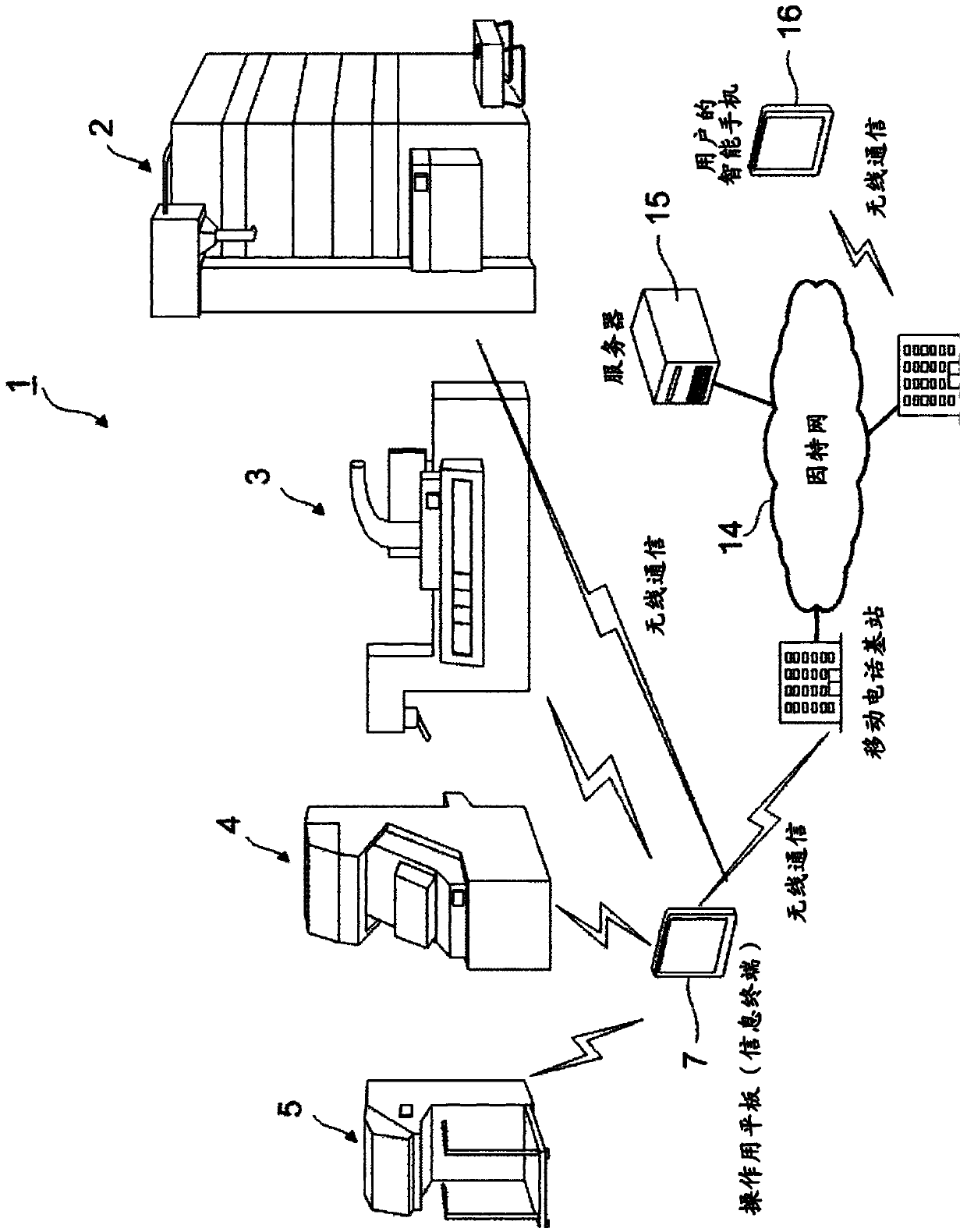

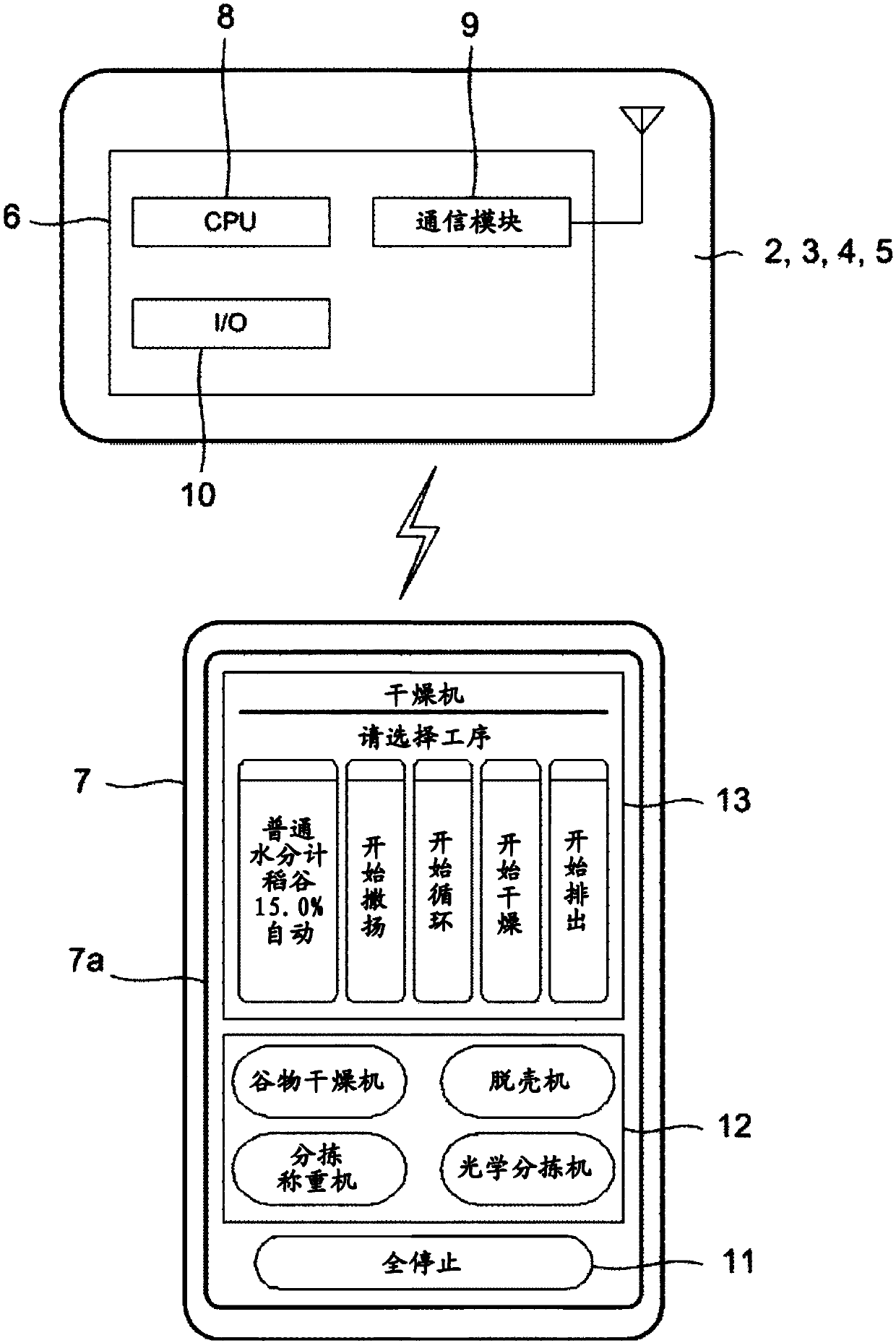

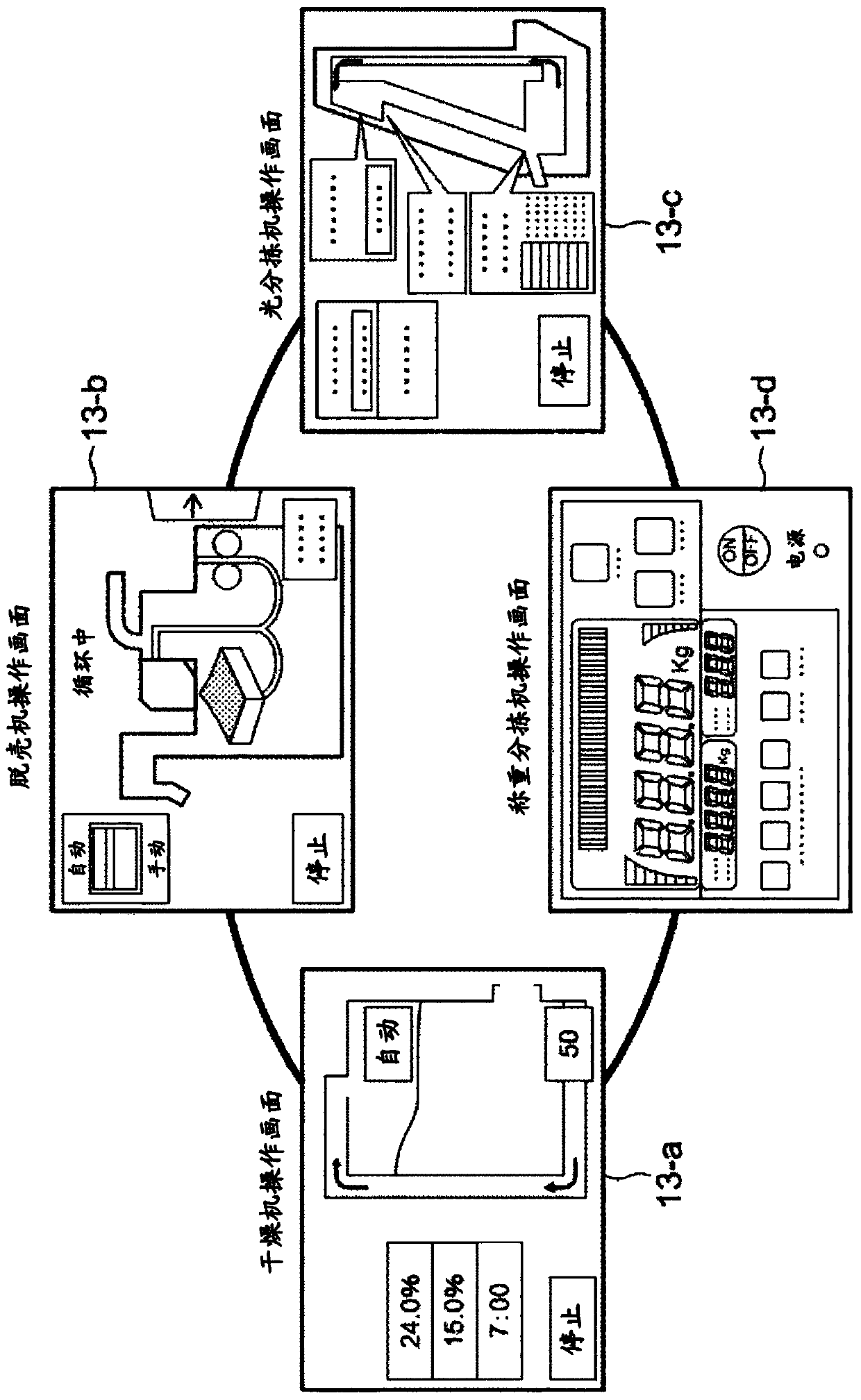

Grain preparation machine control device

Provided is a control device which is capable of operating a plurality of grain preparation machines by way of a single terminal without comprising a separate operation unit for each of the grain preparation machines. The control device is configured from: a main substrate which is capable of controlling various types of motors and sensors of each grain preparation machine; and an operation terminal which is capable of wireless remote operation at a site which is removed from the grain preparation machines. The main substrate is treated as a standardized main substrate which may be used with any of the grain preparation machines, whether a grain drying machine, a husking machine, an optical sorting machine, a grain sorting and weighing machine, or a rice milling machine.

Owner:SATAKE CORP

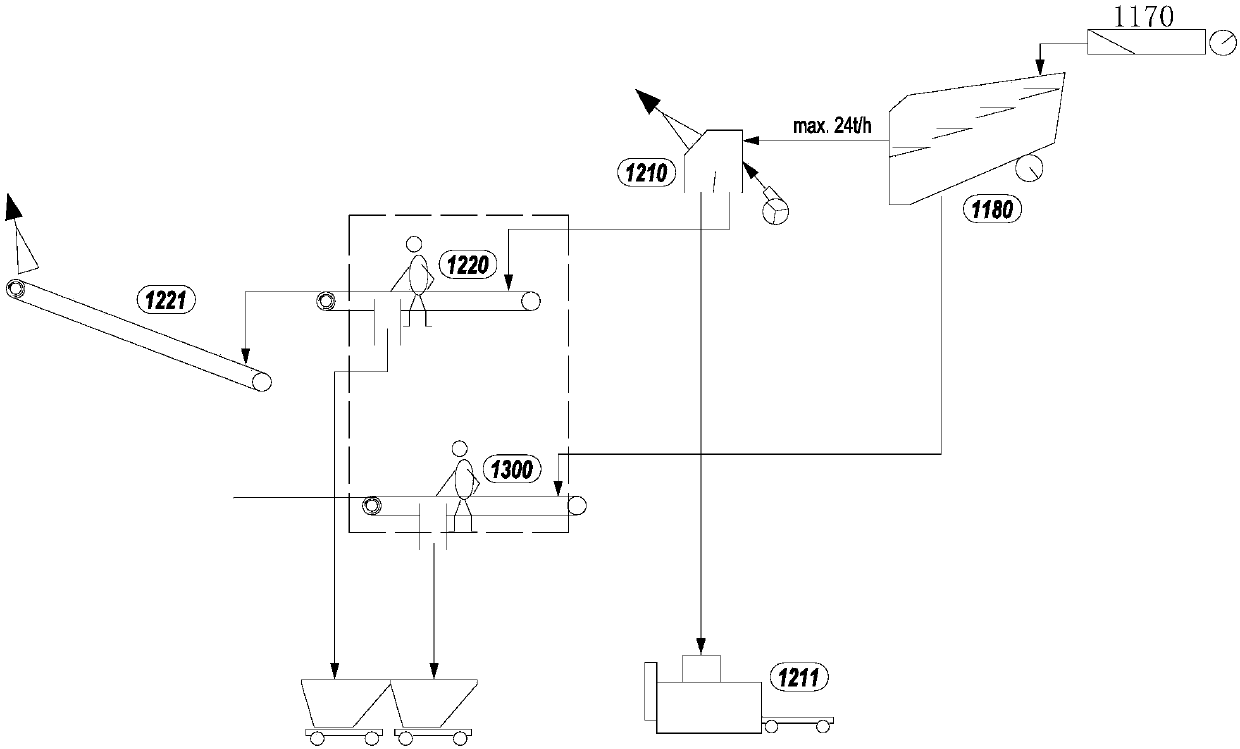

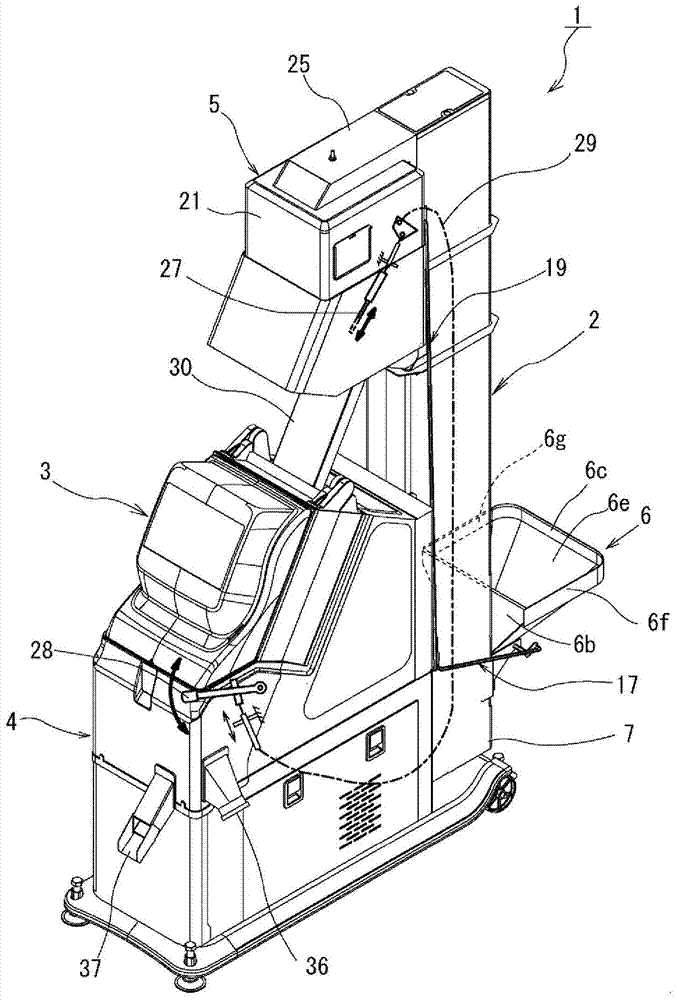

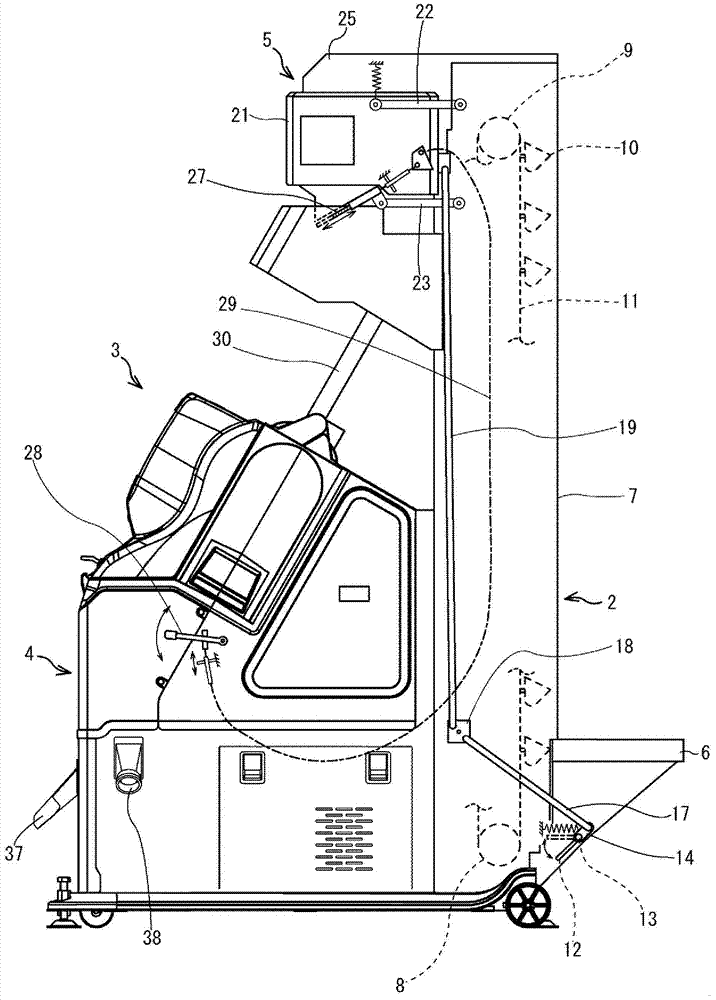

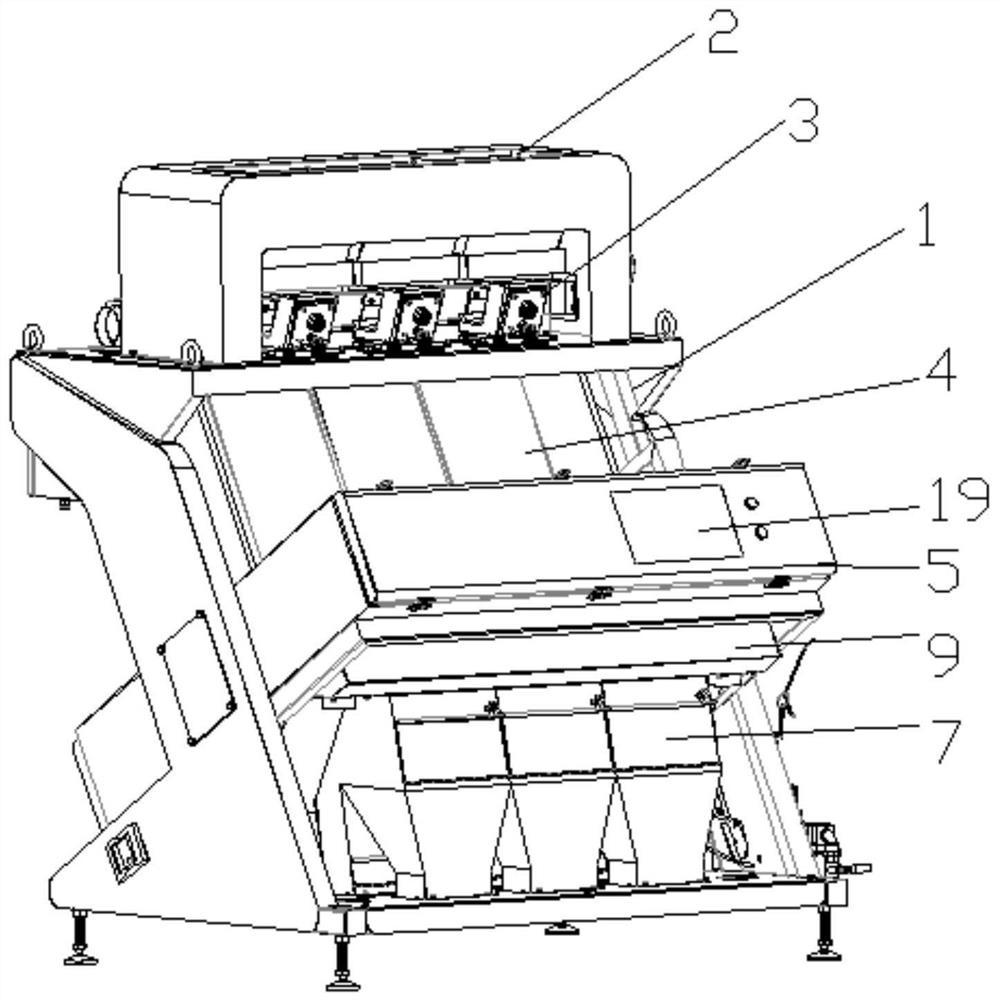

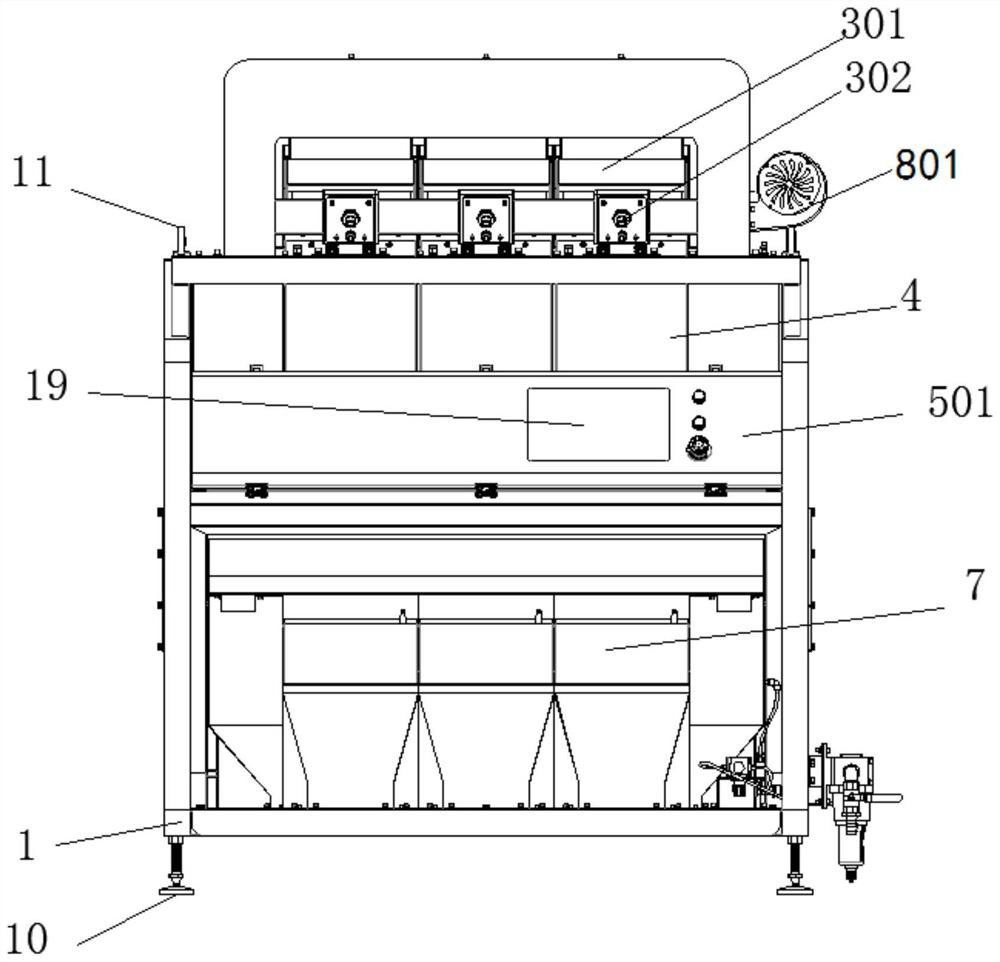

Color sorter

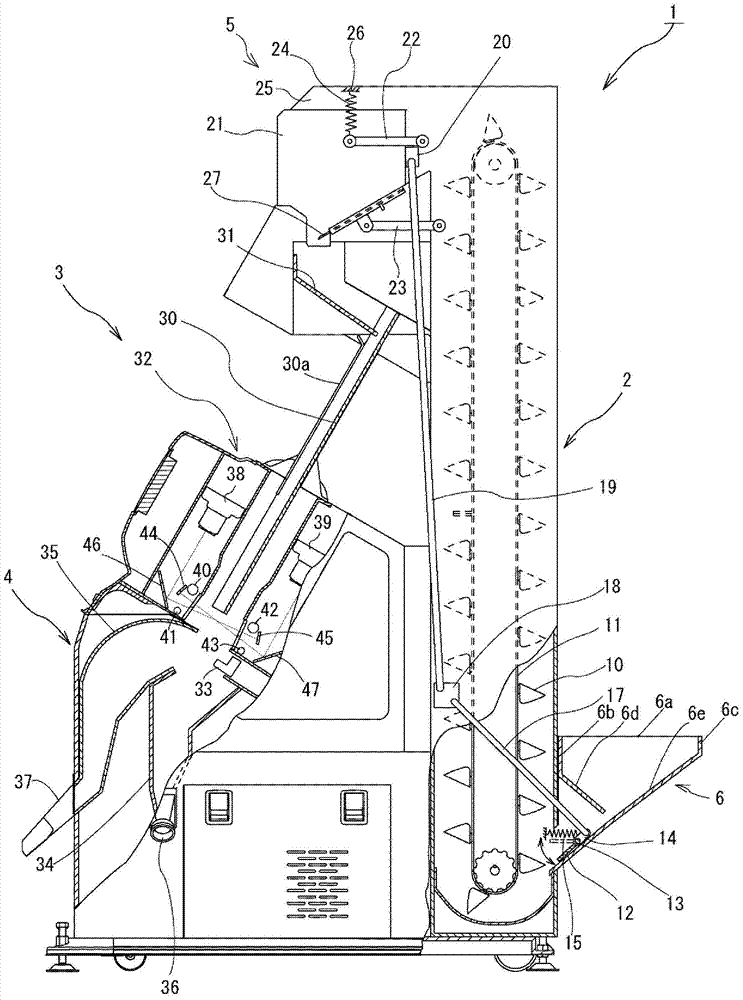

Provided is a color sorter that easily carries out flow rate adjustments for raw materials in a slip flow on a shoot for an optical sorting unit and, when the raw material is supplied from a huller at a rate greater than the maximum throughput, automatically restricts the amount input to an input hopper and can prevent damage and burn out of a delivery system motor. An input hopper (6) for receiving the raw material is formed from: a left and right pair of side walls; an elevator unit housing (7) side front wall (6b); a back wall (6c) facing the front wall (6b); an inclined shelf plate (6d) extending at an incline from the lower part of the front wall (6b); and an inclined shelf plate (6e) positioned lower than the inclined shelf plate (6d) and provided so as to extend at an incline towards a supply opening (7a) of the elevator unit housing (7) from the lower part of the back wall (6c). In addition, a flow rate adjusting valve (12) that adjusts the amount of raw material received is provided on the lower part of the inclined shelf plate (6e), and a temporary retaining tank (21) and the flow rate adjusting valve (12) are connected so as to restrict the received flow of raw material when the temporary retaining tank (21) moves downward.

Owner:SATAKE CORP

Optical sorting machine

The present invention intends to provide an optical sorting machine which can improve the collection rate of non-defective products without increasing the size of the machine. The optical sorting machine of the present invention includes a granular object feed unit including storage means that stores an object to be sorted, and transfer means that transfers the object to be sorted from the storage means; an optical sorting unit including optical detection means that detects an object to be sorted falling along a predetermined trajectory from an end portion of the transfer means, determination means that determines a type of the object to be sorted based on a detection signal from the optical detection means, an ejector that removes an object to be sorted determined as a specific type from the predetermined falling trajectory based on a determination result by the determination means, and a discharge hopper having a first discharge passage provided at a falling position of the object to be sorted falling along the predetermined trajectory, a second discharge passage provided at a falling position of the object to be sorted removed from the predetermined falling trajectory, and a third discharge passage formed between the first discharge passage and the second discharge passage; and conveyance means that conveys an object to be sorted discharged from the third discharge passage of the discharge hopper in the optical sorting unit to the storage means of the granular object feed unit.

Owner:SATAKE CORP

Color sorter

PendingCN113649311AInterfering dust reductionImprove processing precisionGas current separationSortingDust controlEngineering

The invention discloses a color sorter. The color sorter comprises a main body frame, a feeding hopper is installed at the top of the main body frame, a vibration feeding device is located below the feeding hopper and is opposite to the upper part of a chute, and the chute is obliquely fixed to the main body frame; an optical sorting box comprises a front sorting box and a rear sorting box which are independently sealed, and color sorting cameras, material LED light sources and background LED light sources are installed in the front sorting box and the rear sorting box correspondingly; the front sorting box and the rear sorting box are correspondingly located on the front side and the rear side below the chute, and light-transmitting glass is installed on the chute side; a material removing device is arranged below the chute, and a material sorting discharging hopper is arranged below the material removing device; the color sorter further comprises a feeding and discharging dust removal device; the feeding dust removal device is installed on the main body frame and is close to the vibration feeding device; and the discharging dust removal device communicates with the material sorting discharging hopper. The color sorter further adopts a low-power-consumption material LED light source, a material removal execution unit electromagnetic valve and a flat plate type chute. The color sorter has the advantages of high precision, low power consumption and wide application range, and is suitable for popularization and application.

Owner:BEIJING SUPVAN ELECTRONIC TECH CO LTD

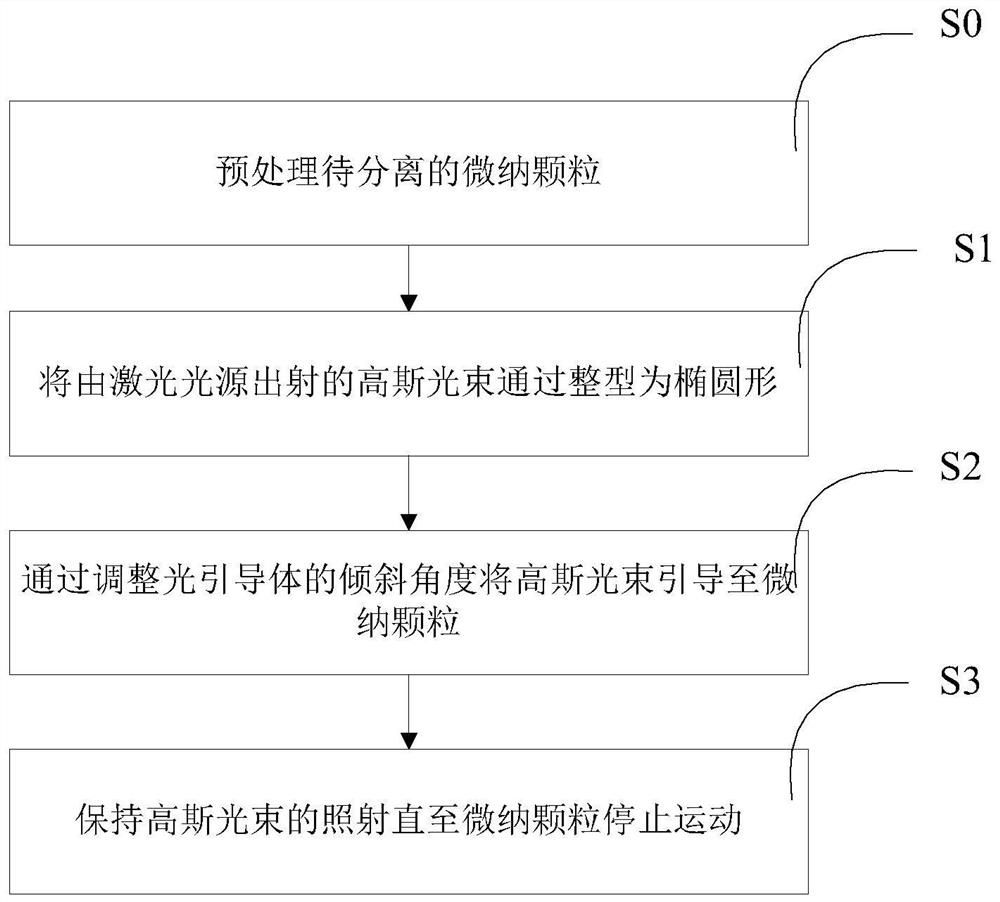

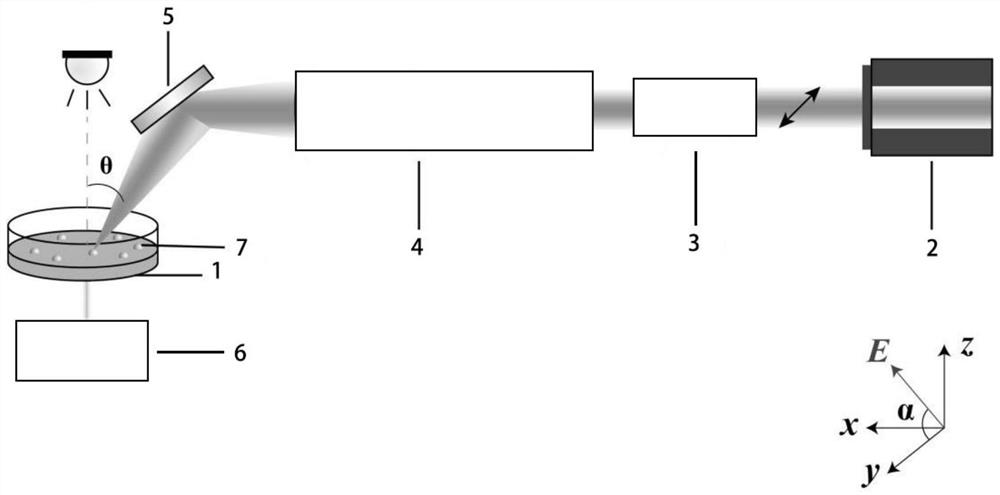

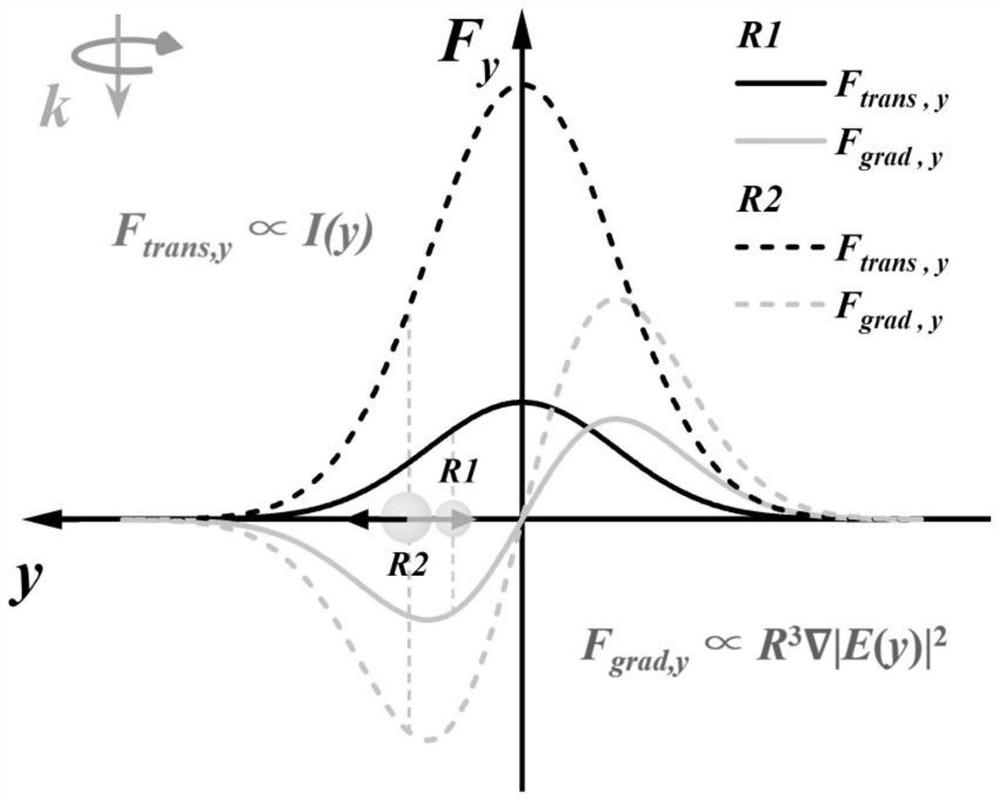

All-optical sorting method and device for micro-nano particles

PendingCN114496335AHigh precisionEasy to operateNeutron particle radiation pressure manipulationGaussian beamLight spot

The invention relates to the technical field of micro-nano particle separation, and discloses an all-optical sorting method and device for micro-nano particles. The all-optical sorting method of the micro-nano particles comprises the steps of irradiating the micro-nano particles above the surface of the liquid by using a linearly polarized Gaussian beam at an inclination angle theta to form an elliptical light spot on the surface of the liquid, and to form a lateral light force on the micro-nano particles, enabling the micro-nano particles to move to a balance position in the liquid along the long axis of the elliptical light spot and stop at the balance position; the inclination angle theta is an angle formed by the Gaussian beam and the normal of the surface of the liquid; the lateral light force is parallel to the long axis of the oval light spot. The invention provides a novel micro-nano particle sorting mechanism, separation is completed completely through an optical assembly, a special separation liquid or a micro-nano structure does not need to be manufactured in advance, high-precision particle size sorting is achieved, and the application prospect is considerable.

Owner:JINAN UNIVERSITY

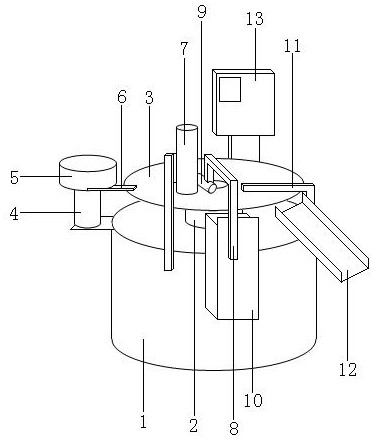

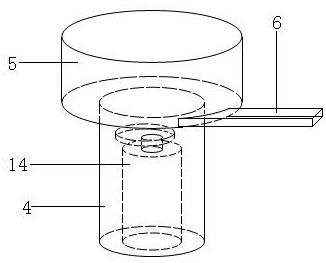

Optical sorting machine for magnetic steel of miniature disc type motor

The invention relates to an optical sorting machine for magnetic steel of a miniature disc type motor, and belongs to the field of machining facilities. A cylindrical servo motor is vertically mounted in the center of the upper face of a base, and a disc-shaped glass tray is horizontally mounted at the top end of a middle shaft on the upper face of the servo motor; a cylindrical vibration disc base is vertically installed on the upper face of the left side of the base through a support, a cylindrical vibration motor is installed in the vibration disc base, a disc-shaped vibration disc is installed on the upper face of the vibration disc base, and a cylindrical camera is vertically installed on the left side of the front face of the base through a support; and a cylindrical electric air valve is longitudinally and horizontally installed above the center of the front face of the base through a J-shaped support, and an L-shaped baffle is installed above the right side of the base. After the magnetic steel falls onto the upper face of the glass tray through the vibration disc, a camera quickly photographs the magnetic steel and transmits pictures to a controller for treatment, and the controller controls an electric control air valve to blow the unqualified magnetic steel into a waste box.

Owner:湖北凯龙机电有限公司

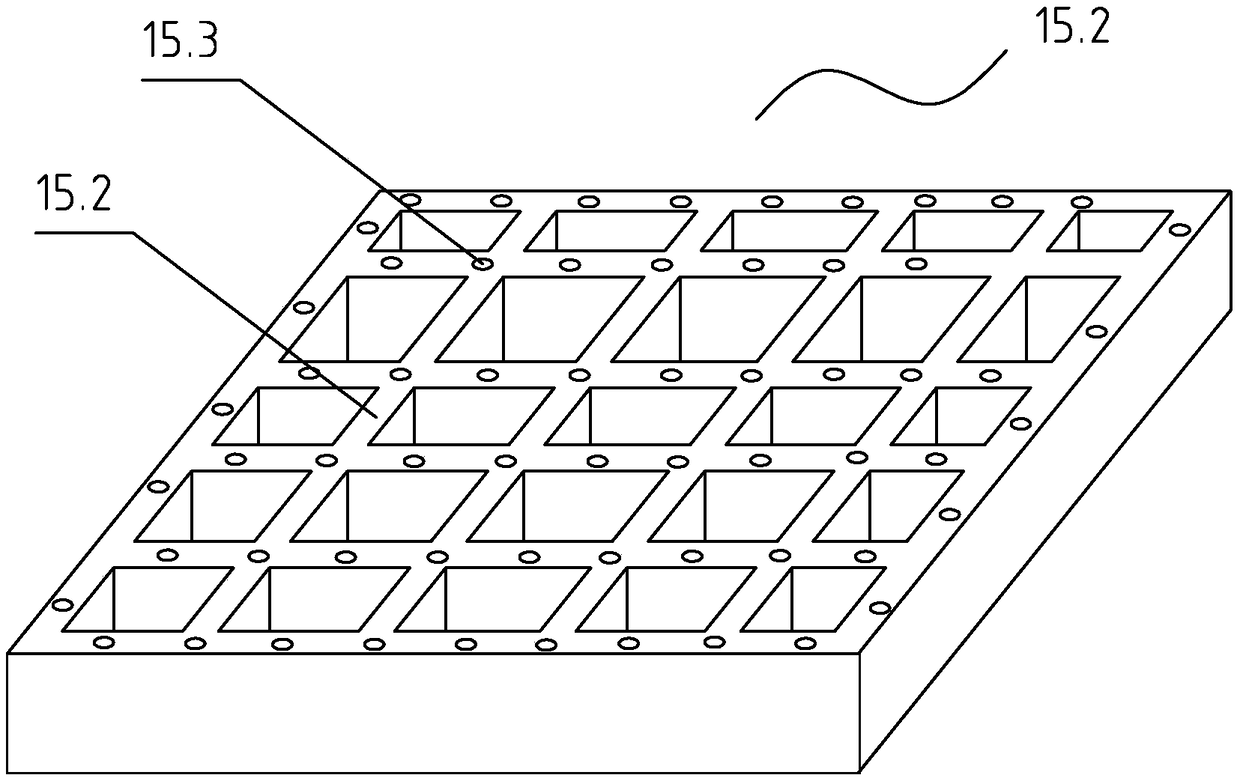

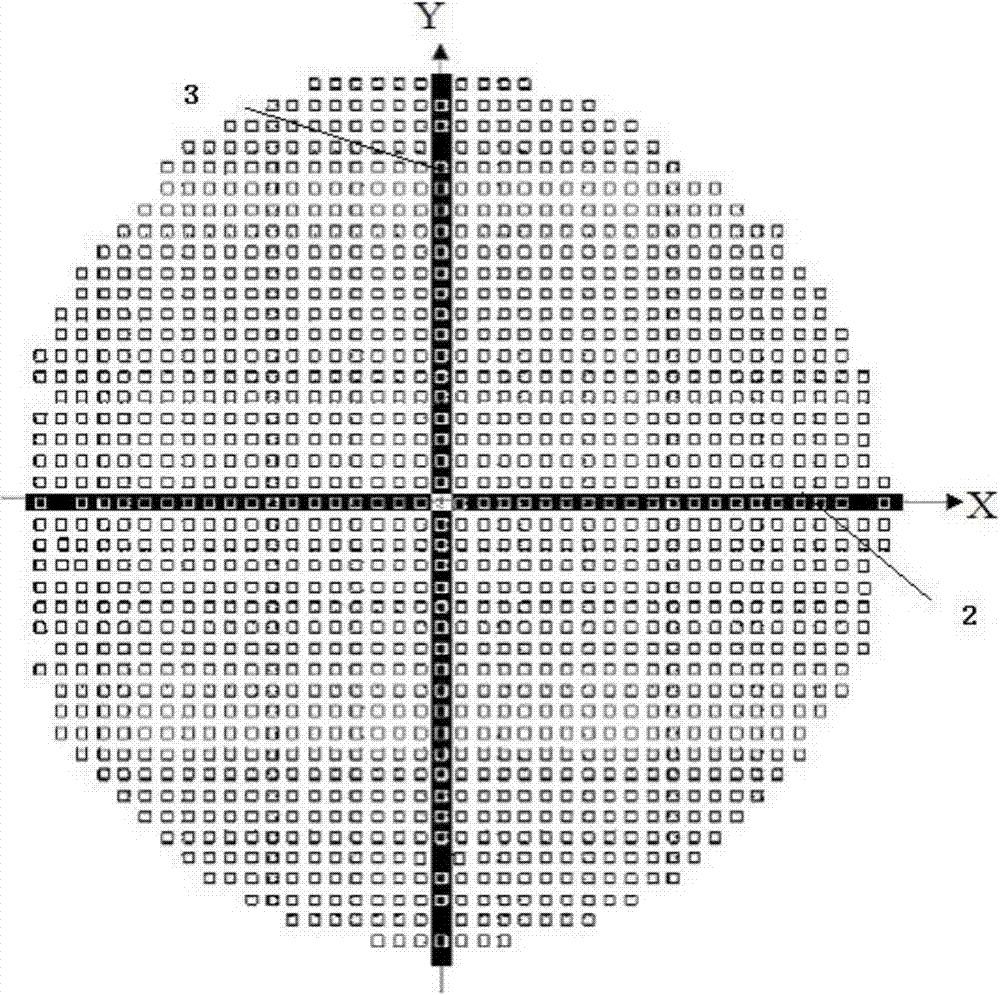

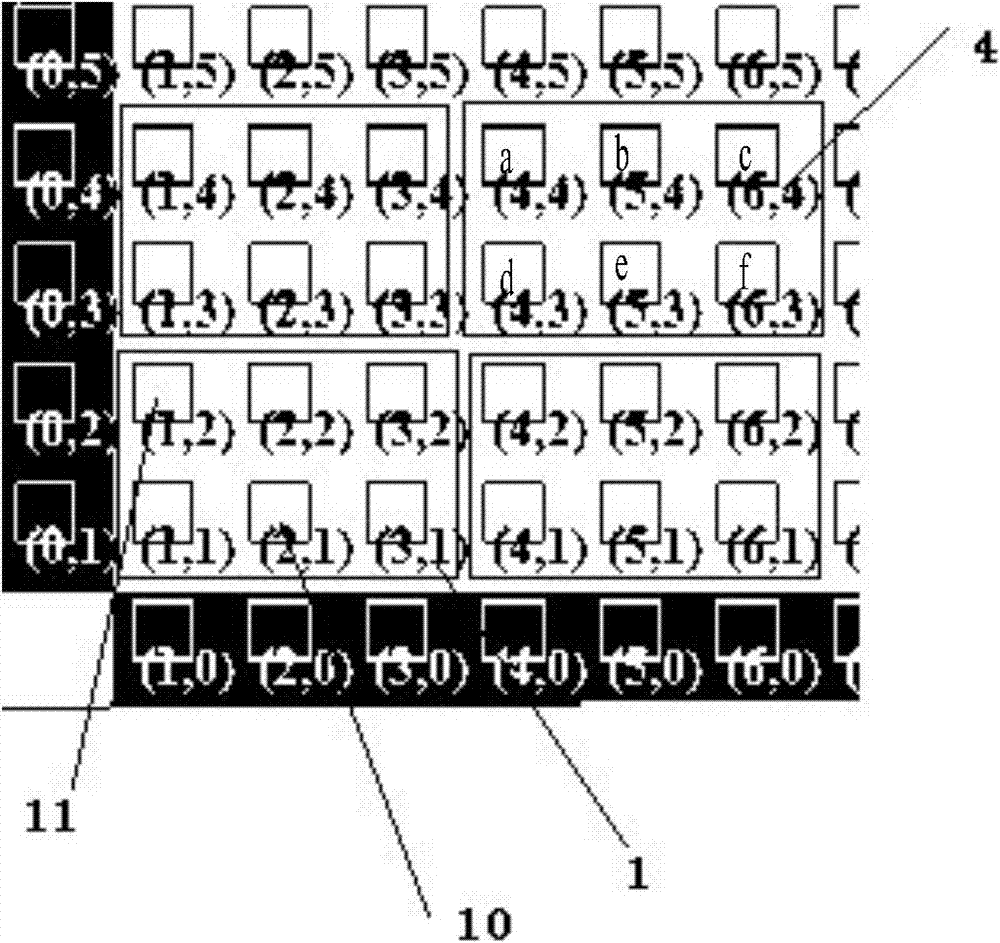

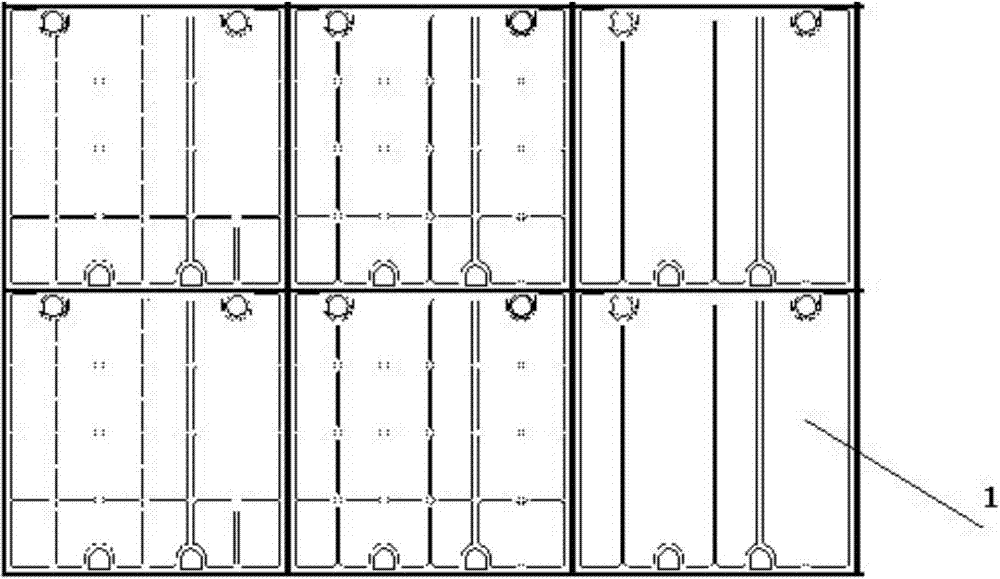

Method for manufacturing integrated photolithography plate and method for sorting LED chip grains

ActiveCN103969942BEasy to separateOriginals for photomechanical treatmentSemiconductor devicesFour quadrantsSplit lines

The invention provides an integrated photolithography plate manufacturing method and a sorting method for producing LED chips. Wherein the method for making the integrated photoresist comprises the following steps: 1) two dividing lines arranged perpendicular to each other on the integrated photoresist divide the photoresist into four quadrants, and use the two dividing lines as abscissa lines and The ordinate forms a coordinate system; 2) in any quadrant, taking the zero point of the coordinate system as a reference, extending to the abscissa line and the ordinate direction to form a square standard cell area containing at least one grain template; 3) in four quadrants , consecutively set a plurality of comparison unit areas with the same graphics and specifications as the grain templates in the standard unit area, and the arrangement position of each grain template in each comparison unit area is the same as that of each grain template in the standard cell area , so as to obtain an integrated photolithography plate. This method quickly separates the crystal grains of the LED chip by designing the pattern and specification of the crystal grains on the integrated photolithography board.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

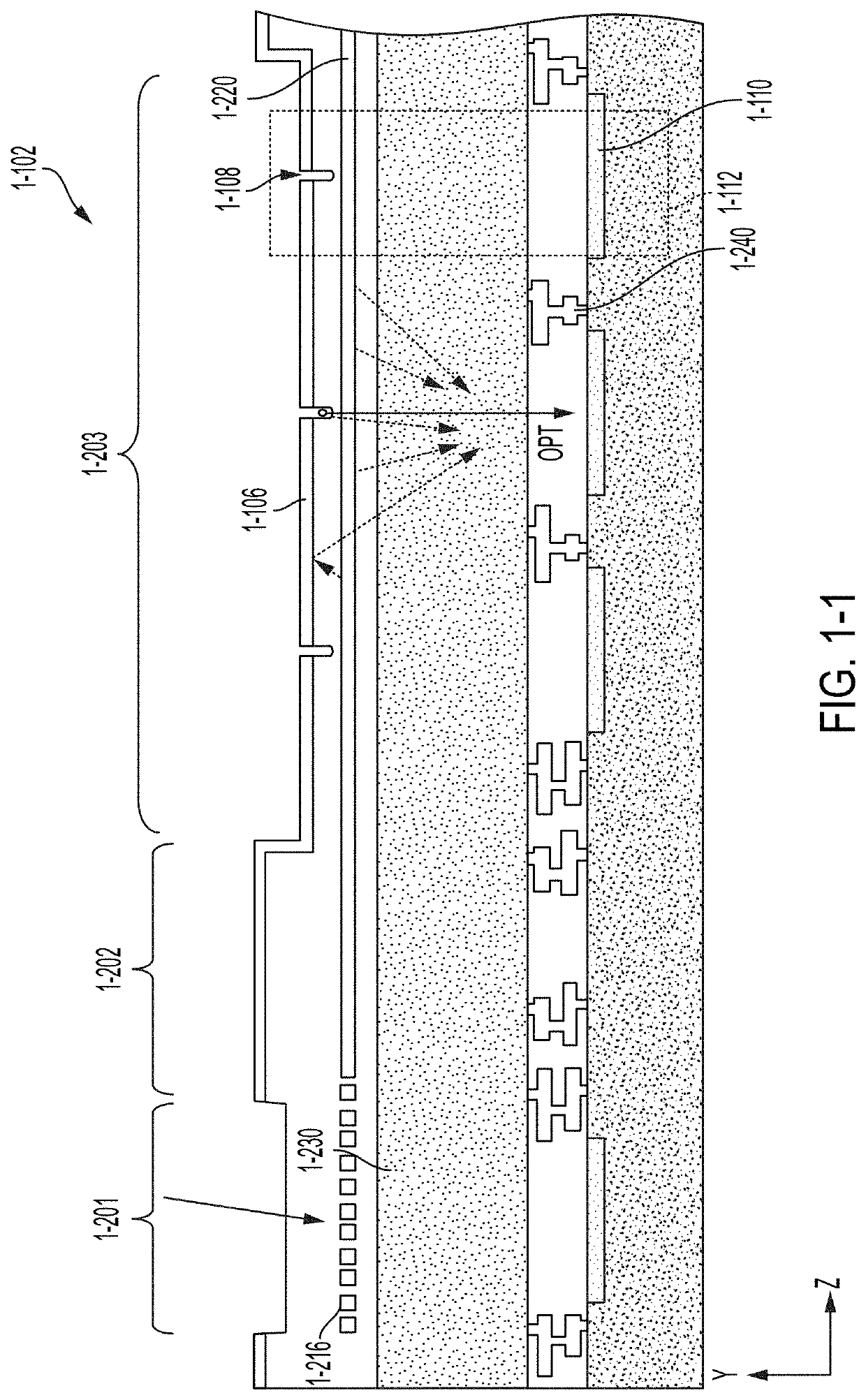

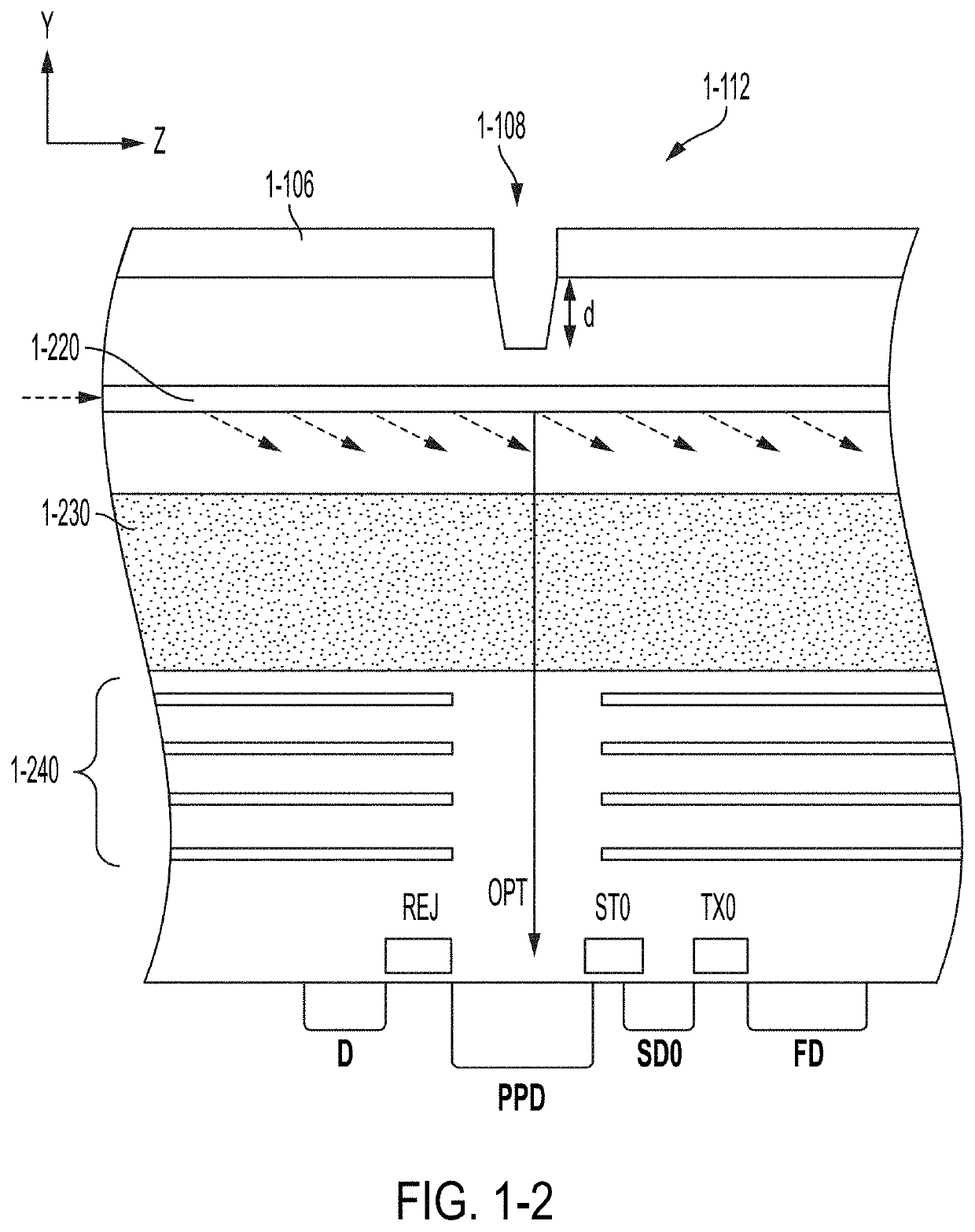

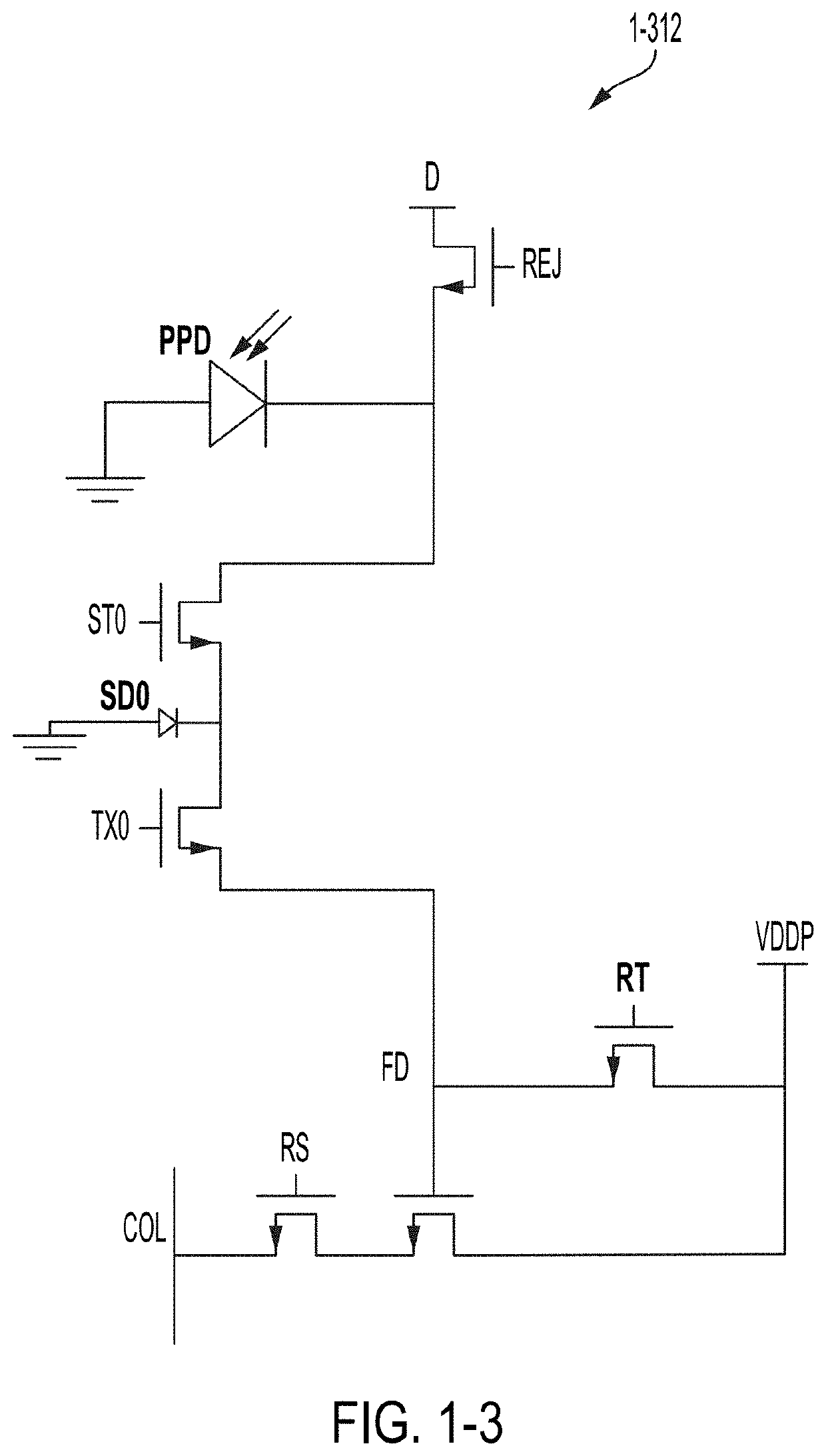

Sensor for lifetime plus spectral characterization

Some aspects relate to integrated devices for obtaining timing and / or spectral information from incident light. In some embodiments, a pixel may include one or more charge storage regions configured to receive charge carriers generated responsive to incident photons from a light source, with charge carriers stored in the charge storage region(s) indicative of spectral and timing information. In some embodiments, a pixel may include regions having different depths, each configured to generate charge carriers responsive to incident photons. In some embodiments, a pixel may include multiple charge storage regions having different depths, and one or more of the charge storage regions may be configured to receive the incident photons and generate charge carriers therein. In some embodiments, a pixel may include an optical sorting element configured to direct at least some incident photons to one charge storage region and other incident photons to another charge storage region.

Owner:QUANTUM SI

Methods and devices for optical sorting of microspheres based on their resonant optical properties

ActiveUS9841367B2Scattering properties measurementsLaboratory glasswaresWhispering galleryMicrosphere

Microspheres are sorted by resonant light pressure effects. An evanescent optical field is generated when light is confined within the interior of an optical element such as a surface waveguide, a tapered microfiber, or a prism. Microspheres brought within vicinity of the surface are subjected to forces that result from a coupling of the evanescent field to whispering gallery modes (WGM) in the microspheres. Alternatively, a focused laser beam is directed close to the edge of the microspheres to exert resonant optical forces on microspheres. Alternatively, standing optical waves are excited in the optical element. Optical forces are resonantly enhanced when light frequencies match WGM frequencies in the microspheres. Those microspheres for which resonance is obtained are more affected by the evanescent field than microspheres for which resonance does not occur. Greater forces are applied to resonating microspheres, which are separated from a heterogeneous mixture according to size.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

Methods and devices for optical sorting of microspheres based on their resonant optical properties

ActiveUS9242248B2Scattering properties measurementsIndividual particle analysisWhispering galleryMicrosphere

Microspheres are sorted by resonant light pressure effects. An evanescent optical field is generated when light is confined within the interior of an optical element such as a surface waveguide, a tapered microfiber, or a prism. Microspheres brought within vicinity of the surface are subjected to forces that result from a coupling of the evanescent field to whispering gallery modes (WGM) in the microspheres. Alternatively, a focused laser beam is directed close to the edge of the microspheres to exert resonant optical forces on microspheres. Optical forces are resonantly enhanced when light frequencies match WGM frequencies in the microspheres. Those microspheres for which resonance is obtained are more affected by the evanescent field than microspheres for which resonance does not occur. Greater forces are applied to resonating microspheres, which are separated from a heterogeneous mixture according to size.

Owner:JUNIVERSITI OF NORT KAROLINA EHT SHARLOTT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com