Optical sorting processing system and processing method for construction waste

A construction waste and treatment system technology, applied in sorting and other directions, can solve the problems of failing to realize the rational utilization and recycling of construction waste, manual sorting is dirty and dangerous, and achieves the perfect sorting production line and improving efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

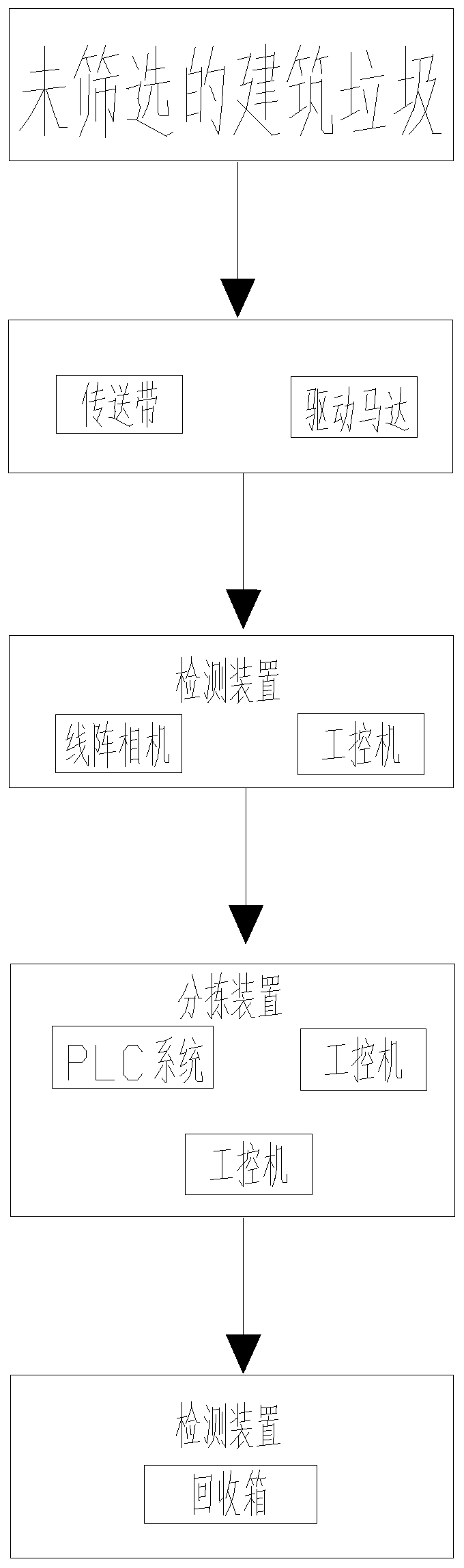

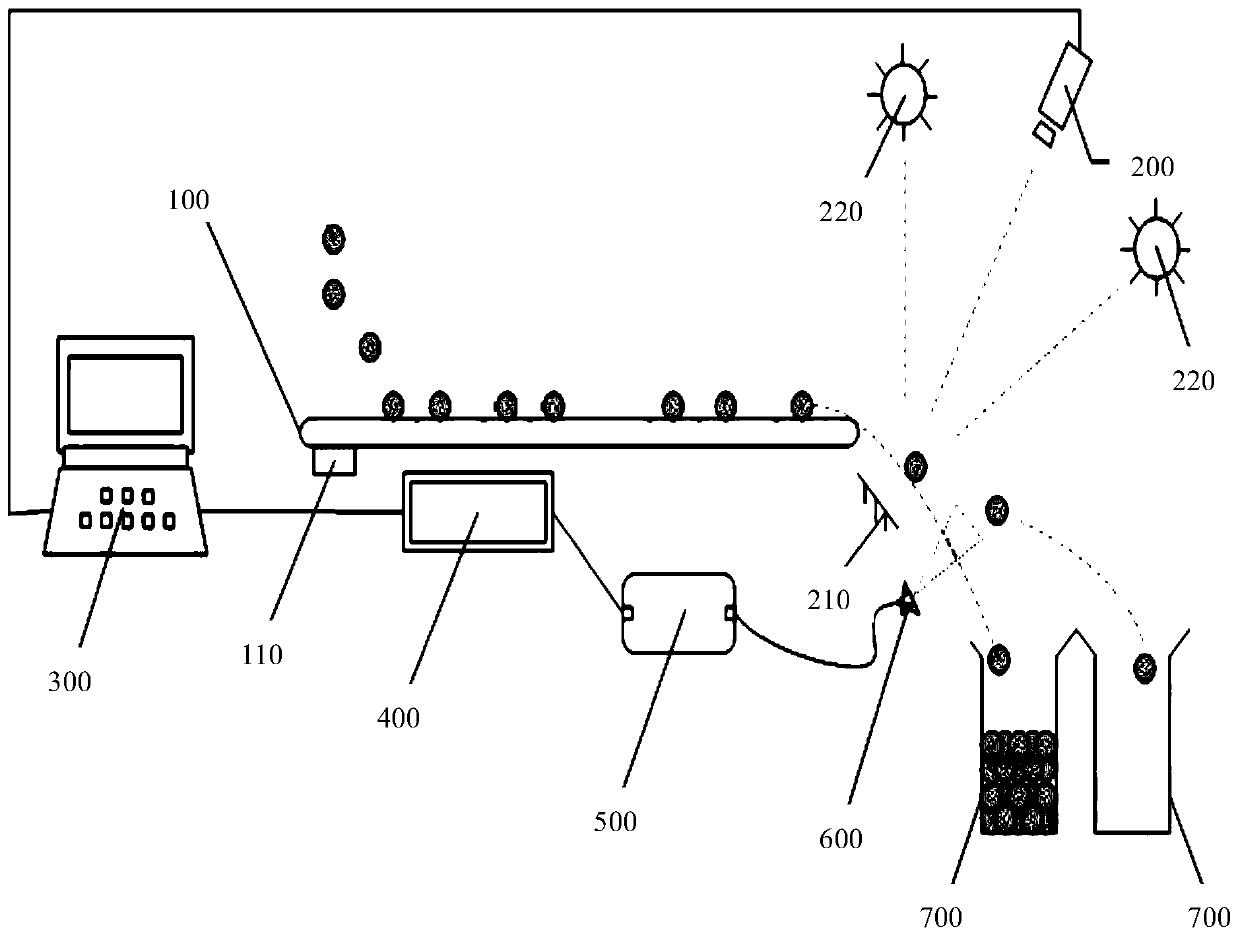

[0023] The present invention provides an optical sorting and processing system for construction waste, which includes a conveyor belt 100, a detection device, a sorting device and a collection device.

[0024] The conveyor belt 100 is used to transport materials, which are unscreened construction waste, including mixed aggregates mainly composed of red bricks and concrete blocks, with a particle size of 20-60 mm, wherein the proportion of red bricks is 20-60 mm. 40%.

[0025] In addition, a drive motor 110 is also installed below the conveyor belt 100 to drive the conveyor belt 100 to be transported. In this embodiment, the material is conveyed from the left side of the conveyor belt 100, driven clockwise along the conveyor belt 100, and falls freely at the right end of the conveyor belt 100. whereabouts.

[0026] The detection device includes a line-scan camera 200 and an industrial computer 300. In this embodiment, the line-scan camera 200 is arranged on the upper right sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com