Optical flow control chip utilizing impinging stream and optical scattering force and application thereof for sorting micro-nano particles

An optofluidic and impinging flow technology, which is applied to laboratory containers, grading, and solid separation, can solve problems such as simple, non-invasive, high-speed, and high-efficiency sorting, and achieve simple, Improve the separation speed and efficiency, the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

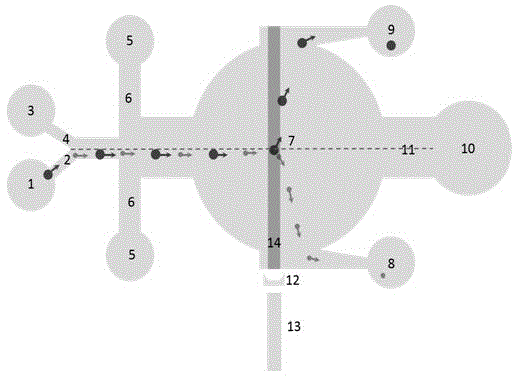

[0018] The optofluidic chip of the present invention is manufactured by standard photolithography method. First, use L-Edit to draw the template picture according to the previously designed chip structure. Then coat a layer of SU-8 photoresist on the silicon wafer to obtain a PDMS mold. After obtaining the PDMS layer and irreversibly binding it to the PDMS-attached glass slide with oxygen plasma, the optofluidic chip was baked at 75°C for 1 hour to enhance hydrophobicity and eliminate residual water.

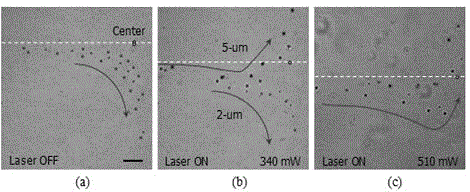

[0019] An application example of the optofluidic chip of the present invention, wherein the flow rate of the auxiliary inlet and the sample inlet is 0.06 μL / min, the flow rate of the sheath inlet is 0.96 μL / min, and the flow rate of the impingement inlet is 2.04 μL / min. The optimal separation power of the laser is 560 mW (considering about 40% dissipation, the actual power is about 340 mW).

[0020] The optofluidic chip of the present invention generally utilizes the combined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com