Patents

Literature

93 results about "Eddy current separator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An eddy current separator uses a powerful magnetic field to separate non-ferrous metals from waste after all ferrous metals have been removed previously by some arrangement of magnets. The device makes use of eddy currents to effect the separation. Eddy current separators are not designed to sort ferrous metals which become hot inside the eddy current field. This can lead to damage of the eddy current separator unit belt.

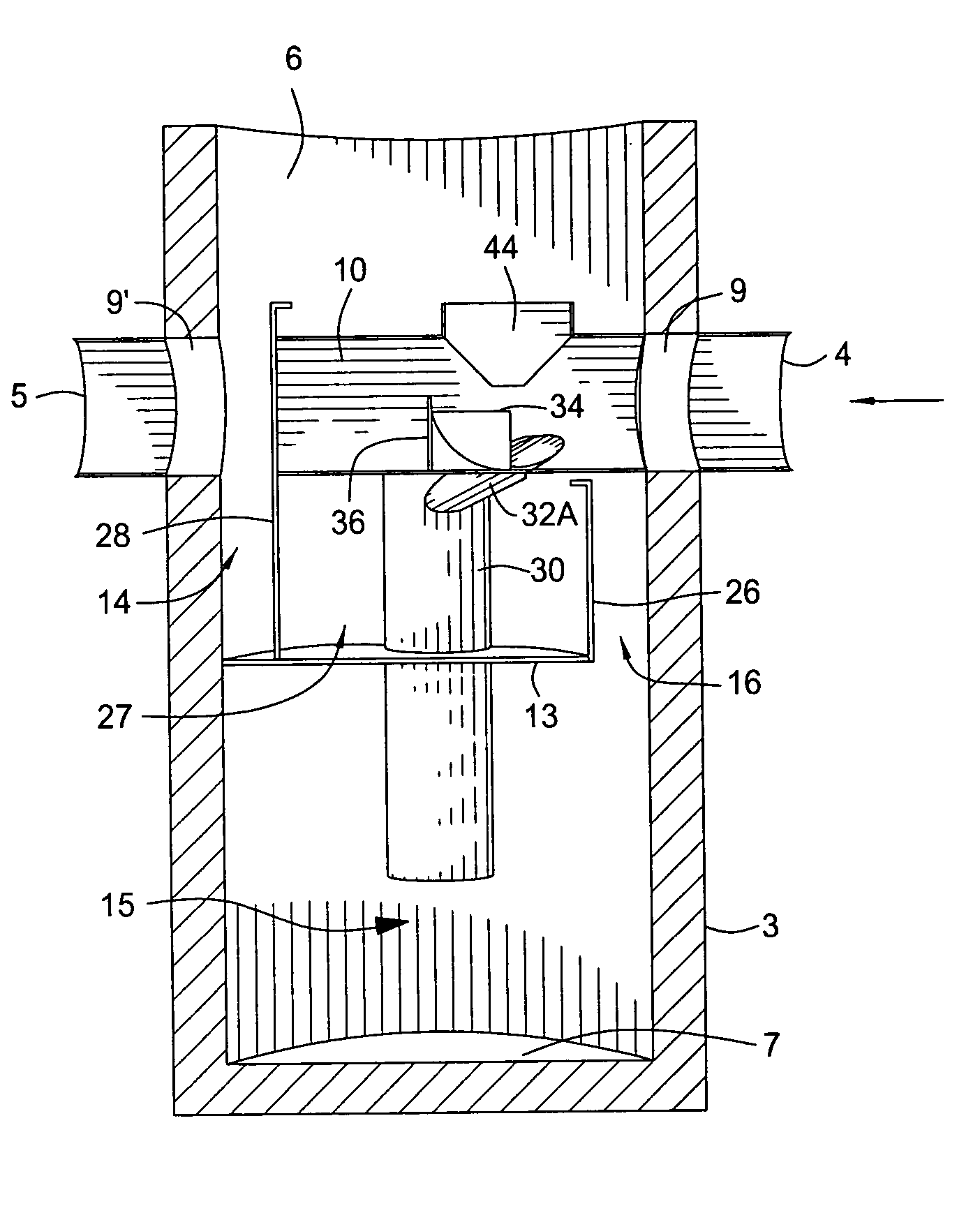

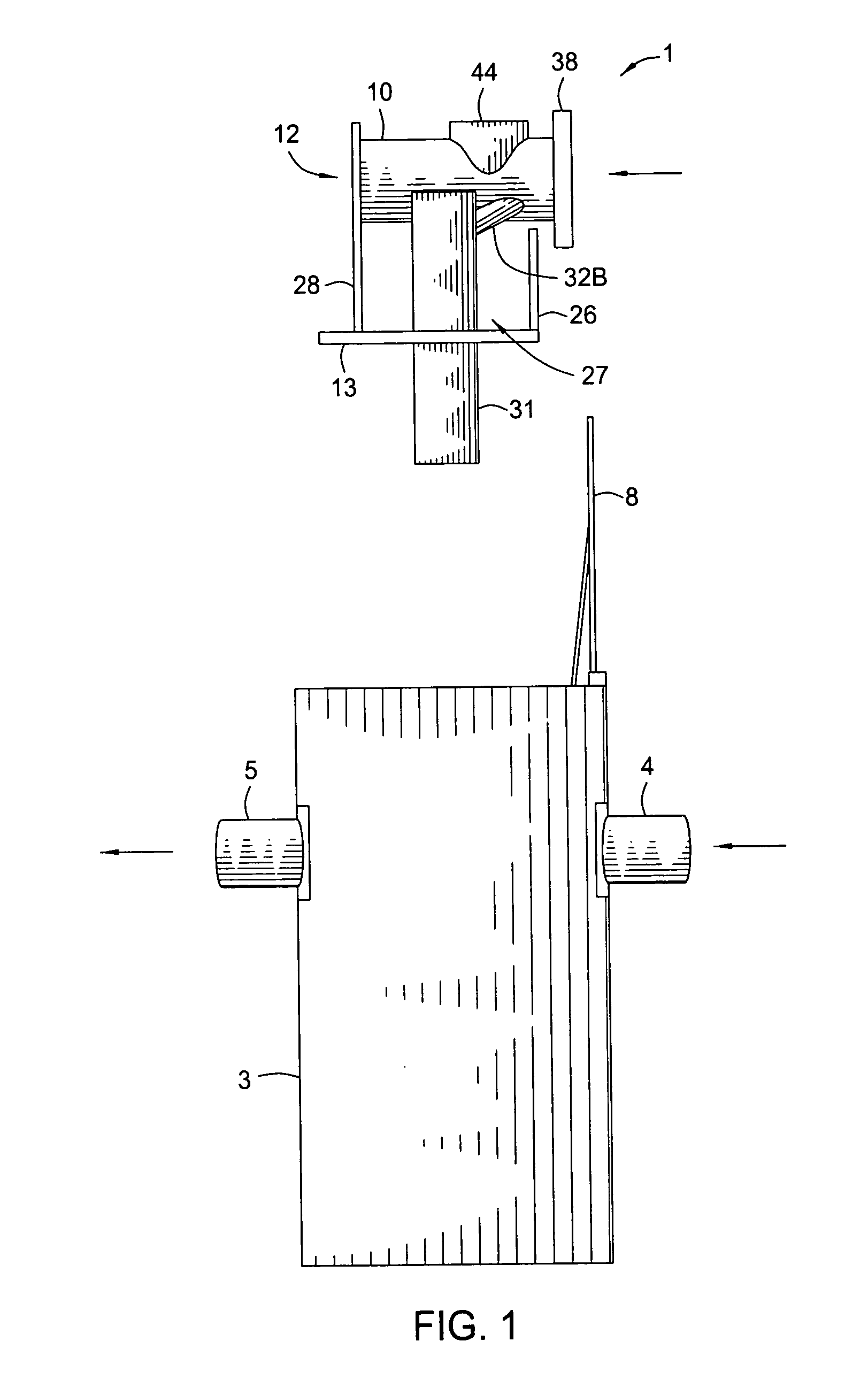

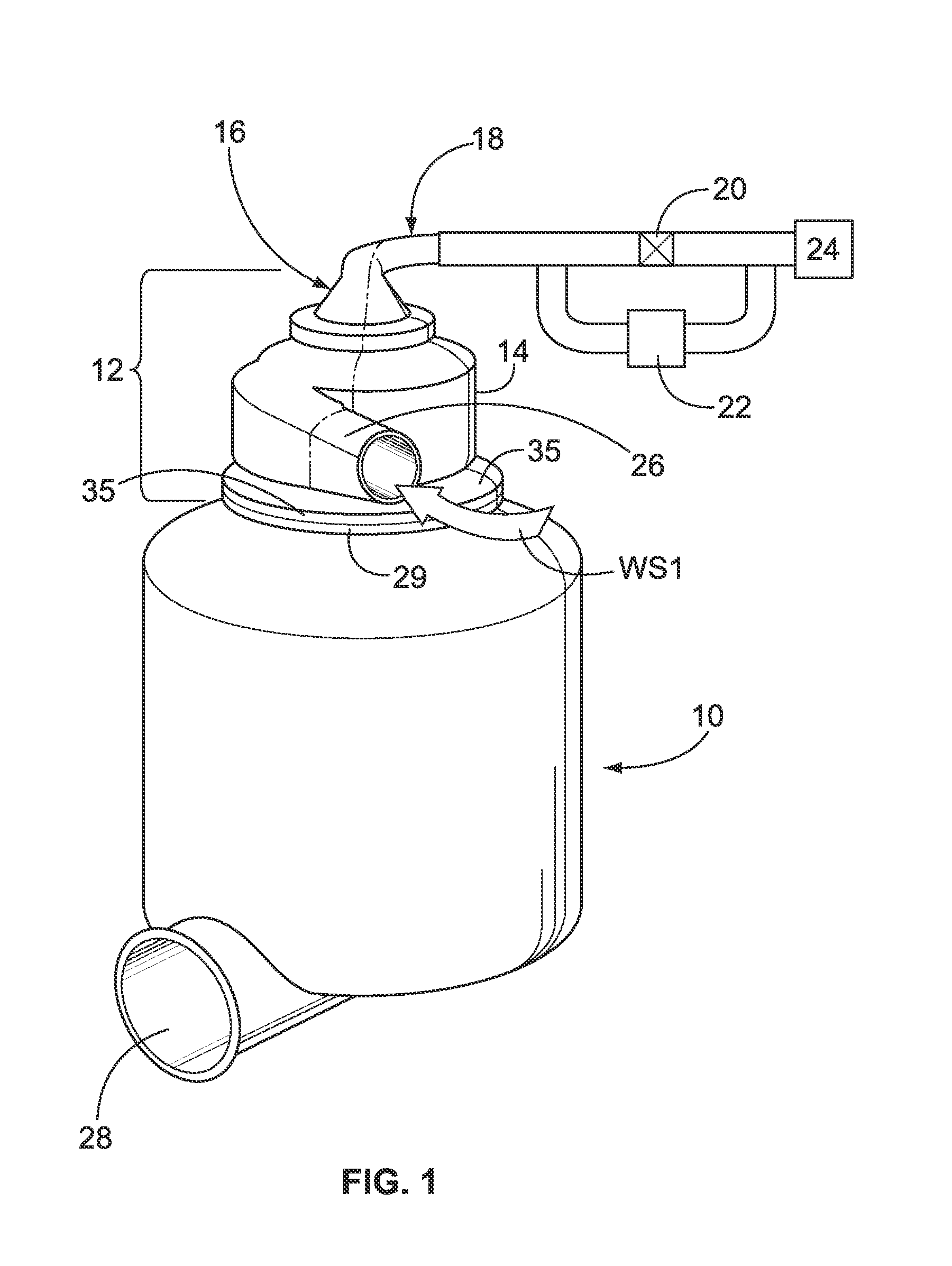

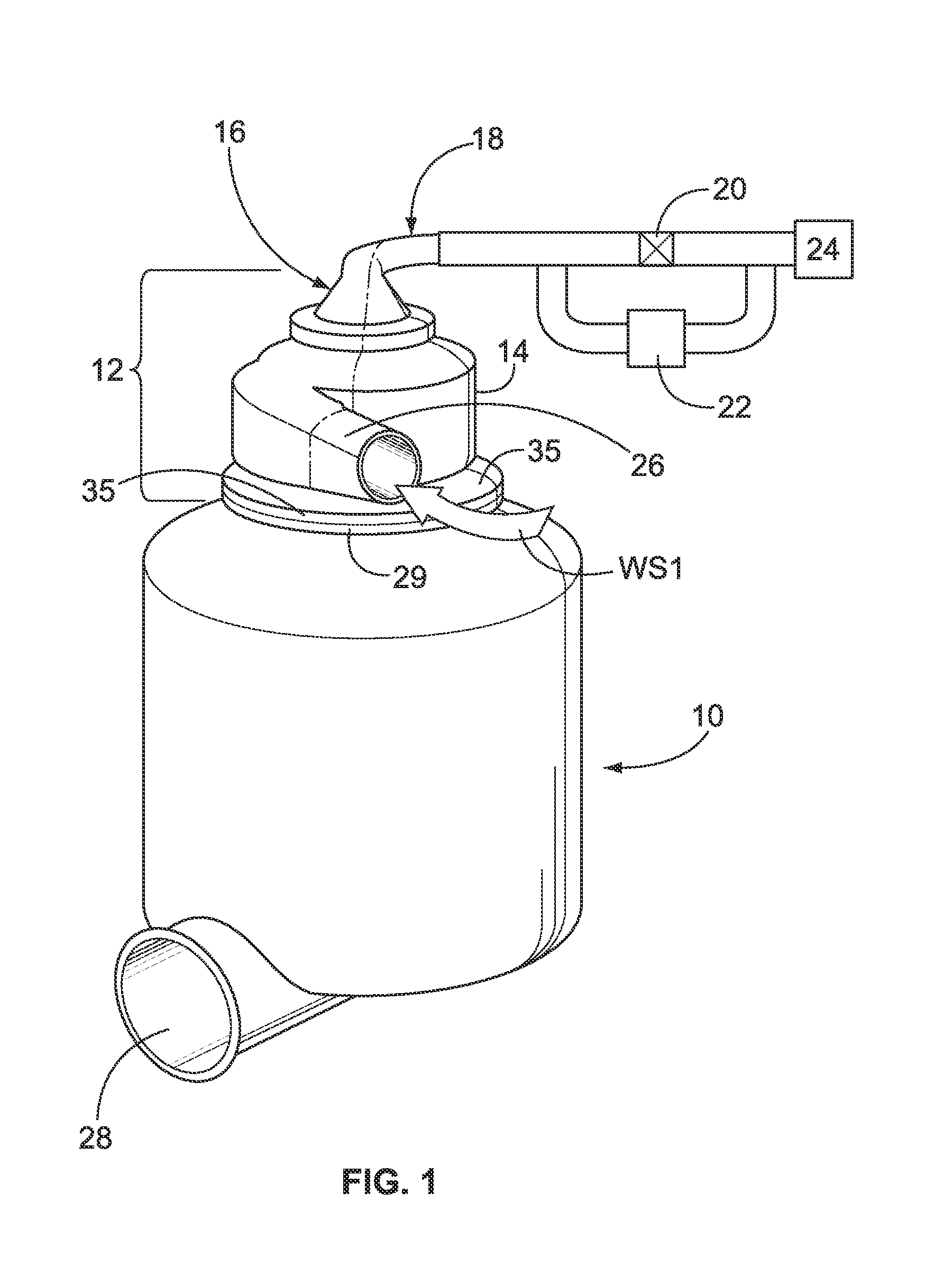

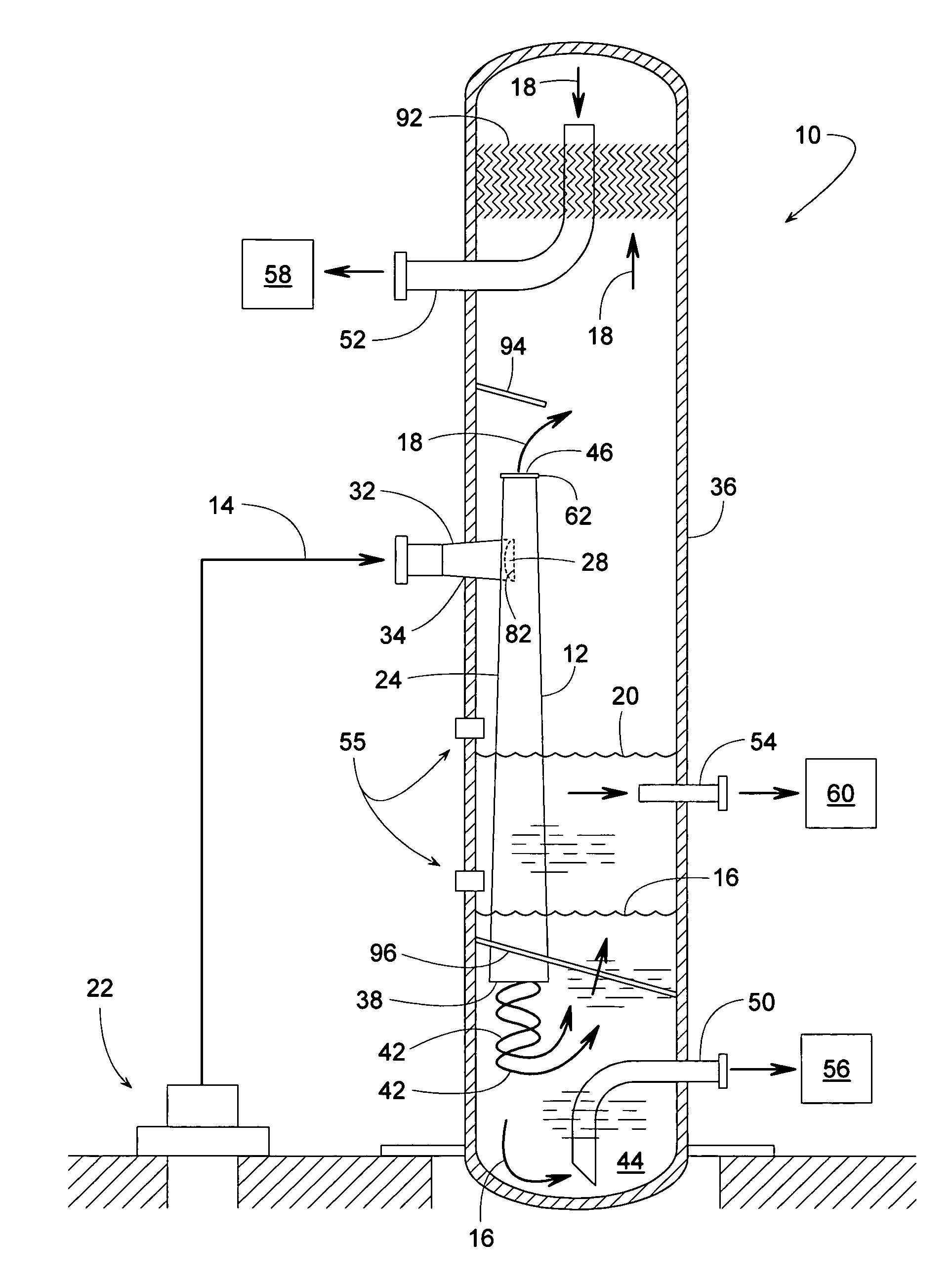

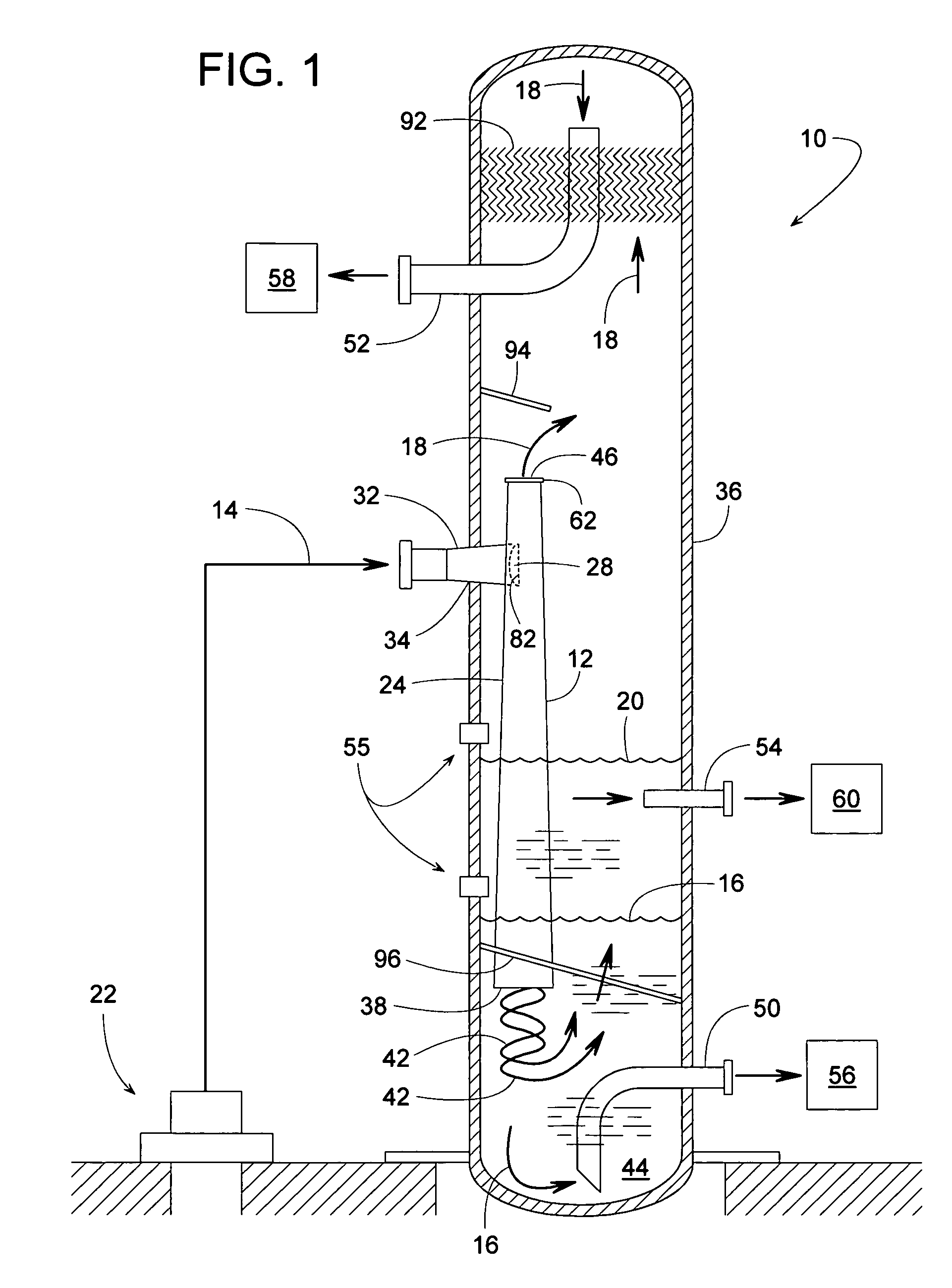

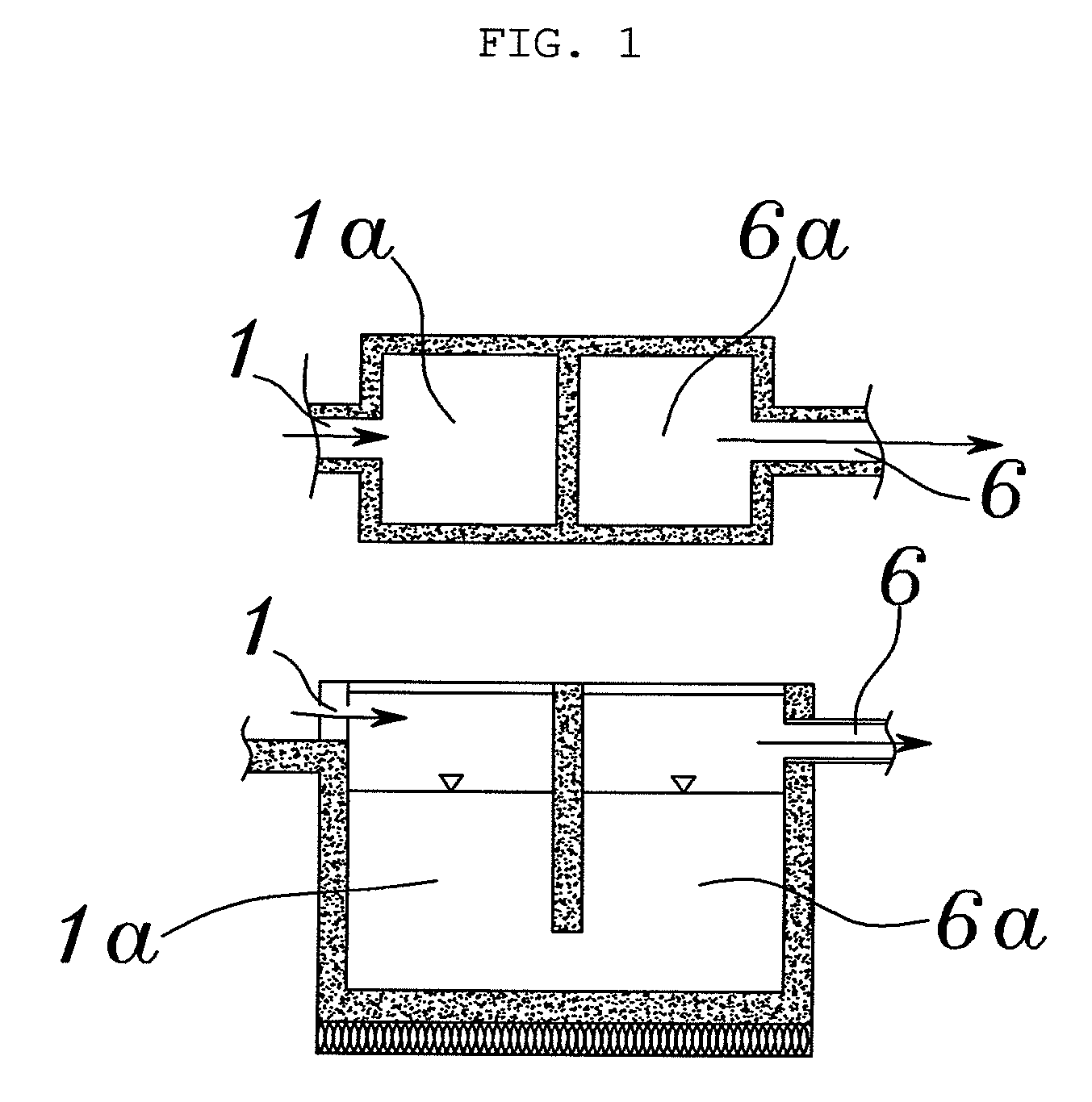

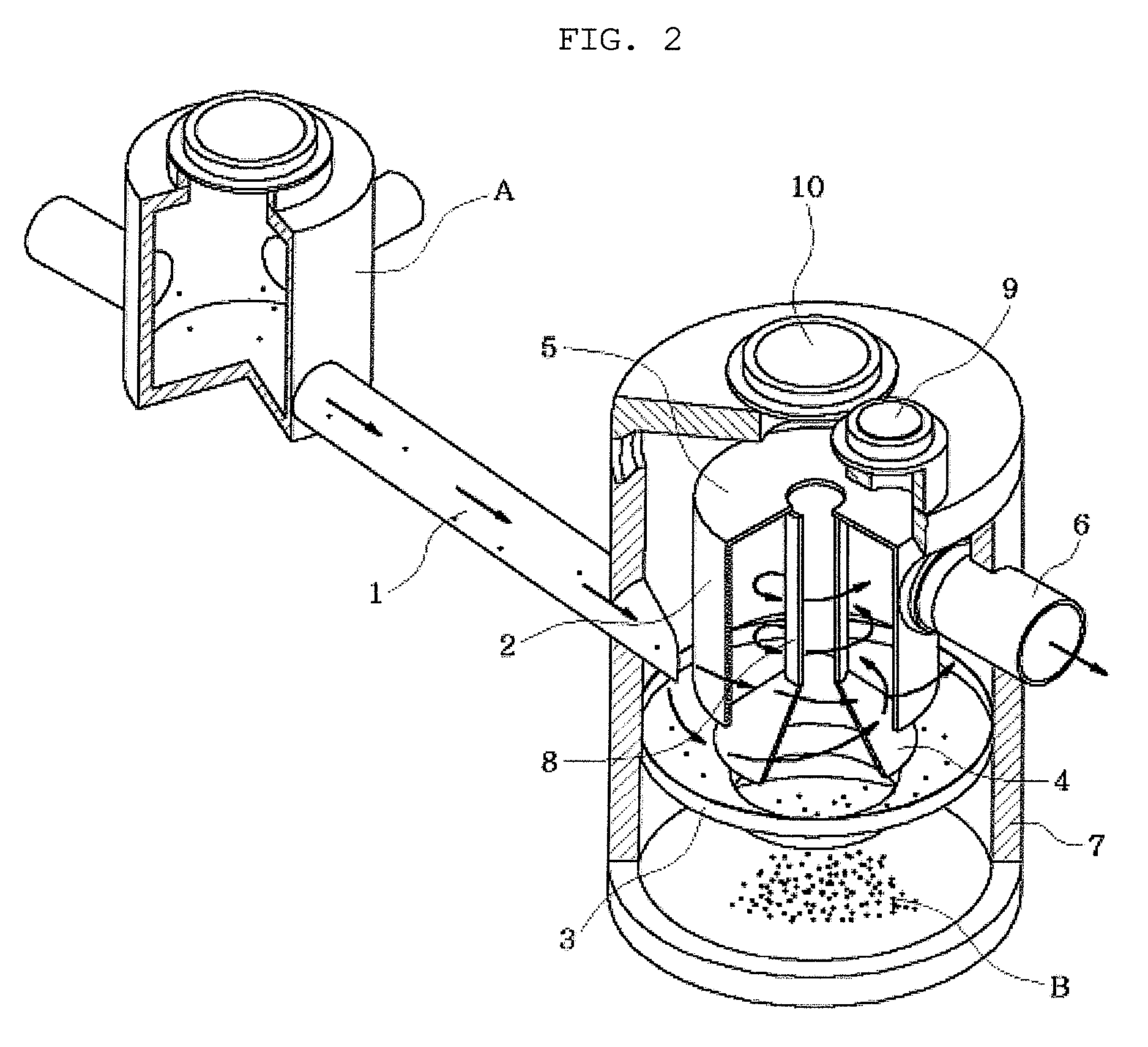

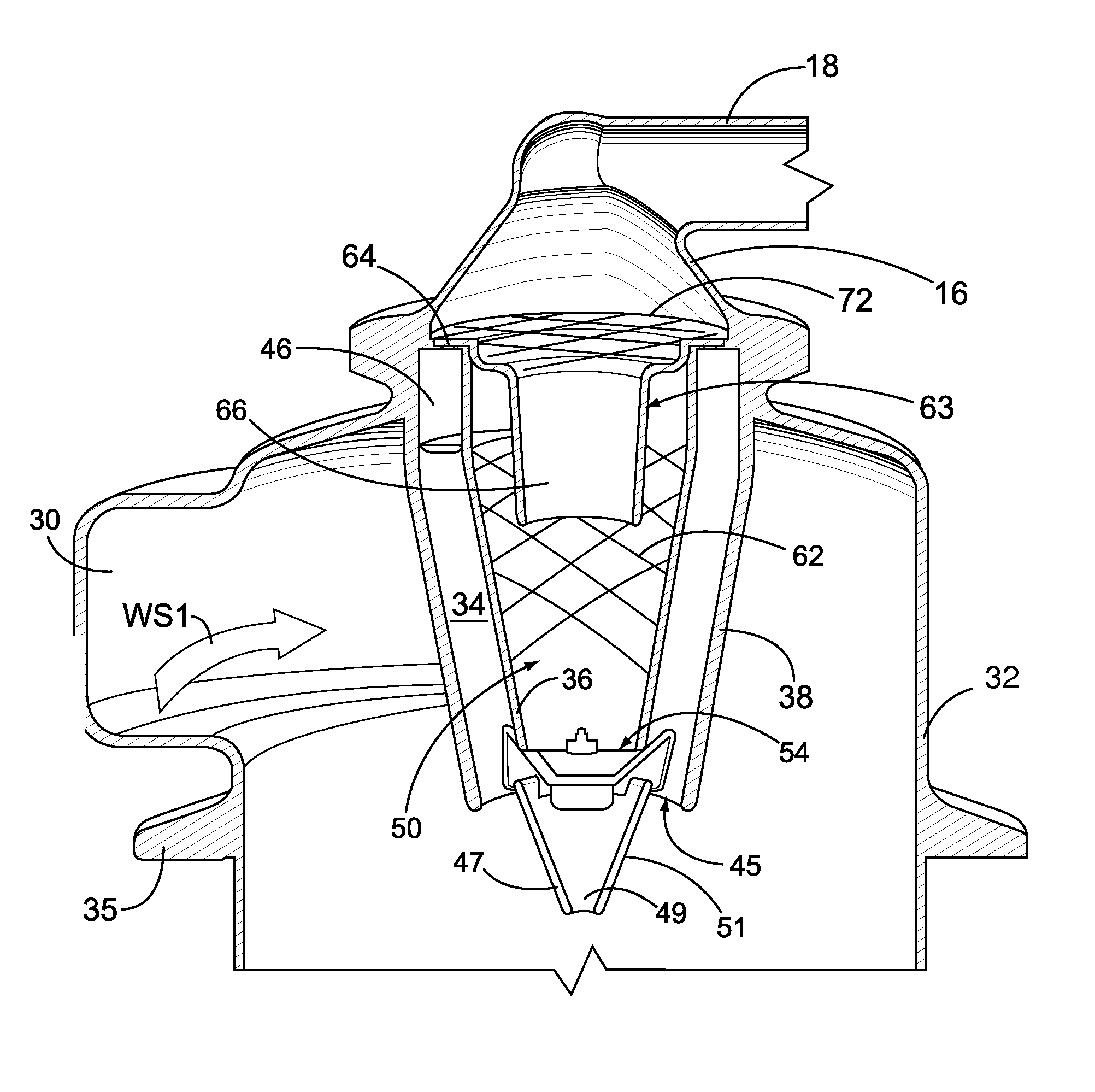

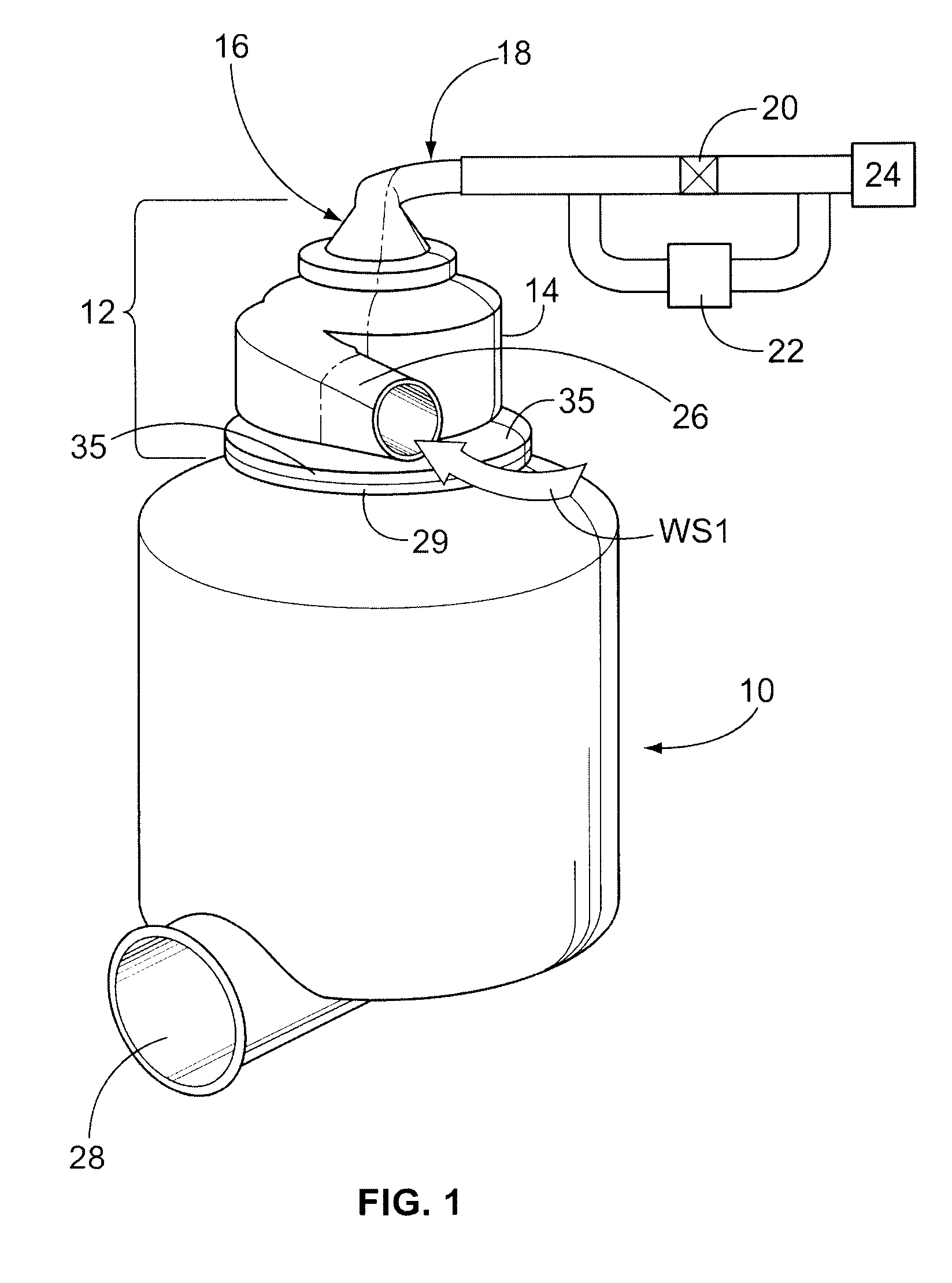

Storm water treatment apparatus employing dual vortex separators

ActiveUS20050184007A1Avoid backupImprove liquidityReversed direction vortexLiquid displacementSuspended particlesEddy current separator

A stormwater treatment device for removing floatables, solids and suspended particles and the like from stormwater run off, whereby a removable assembly is provided for installation into a manhole basin, the assembly including a pass-through member which receives stormwater from an incoming drainage system, and diverts low flows to at least one or more vortex separators, while allowing for high flows to bypass the separators and flow through the assembly untreated to exit the basin without diversion.

Owner:OLDCASTLE PRECAST

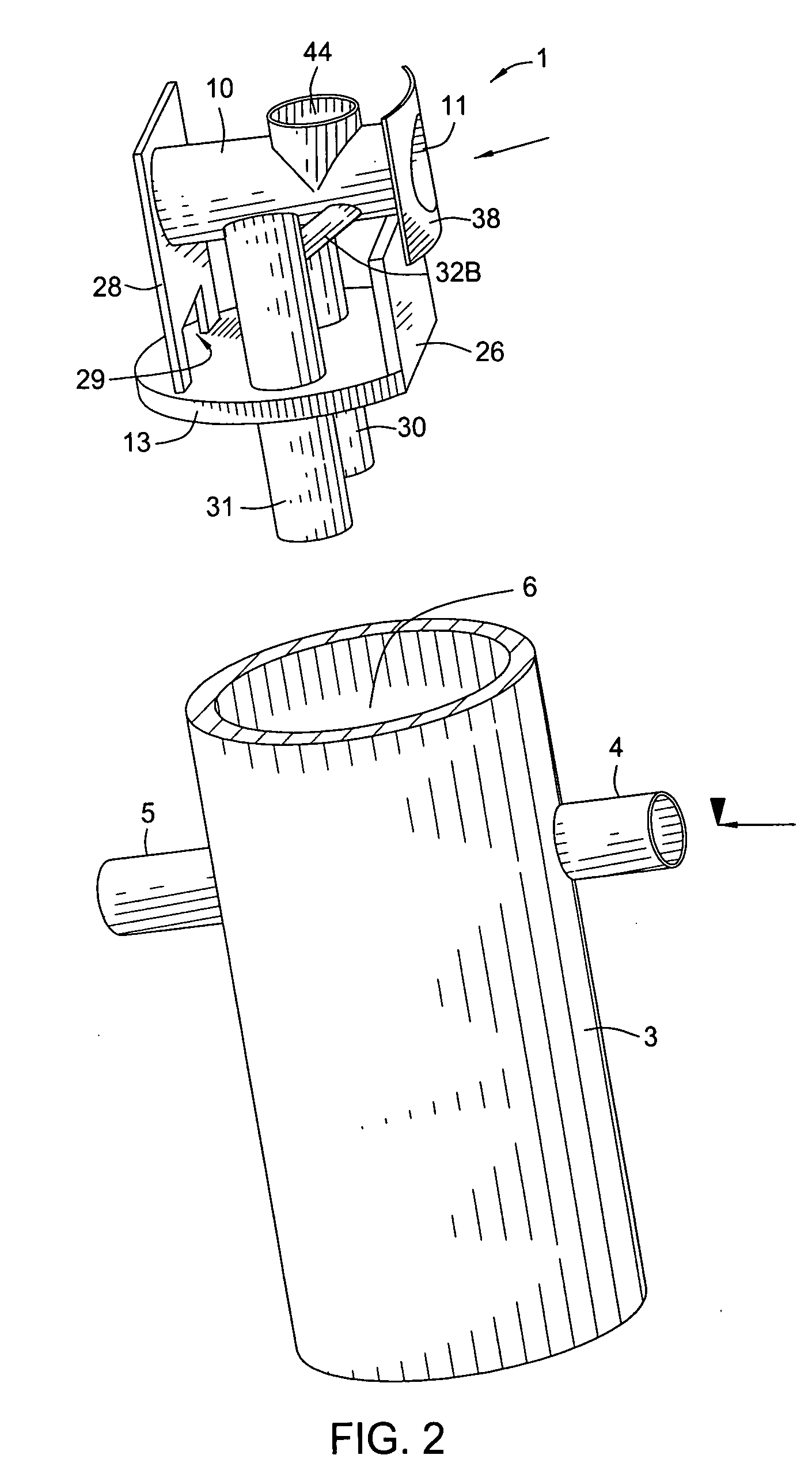

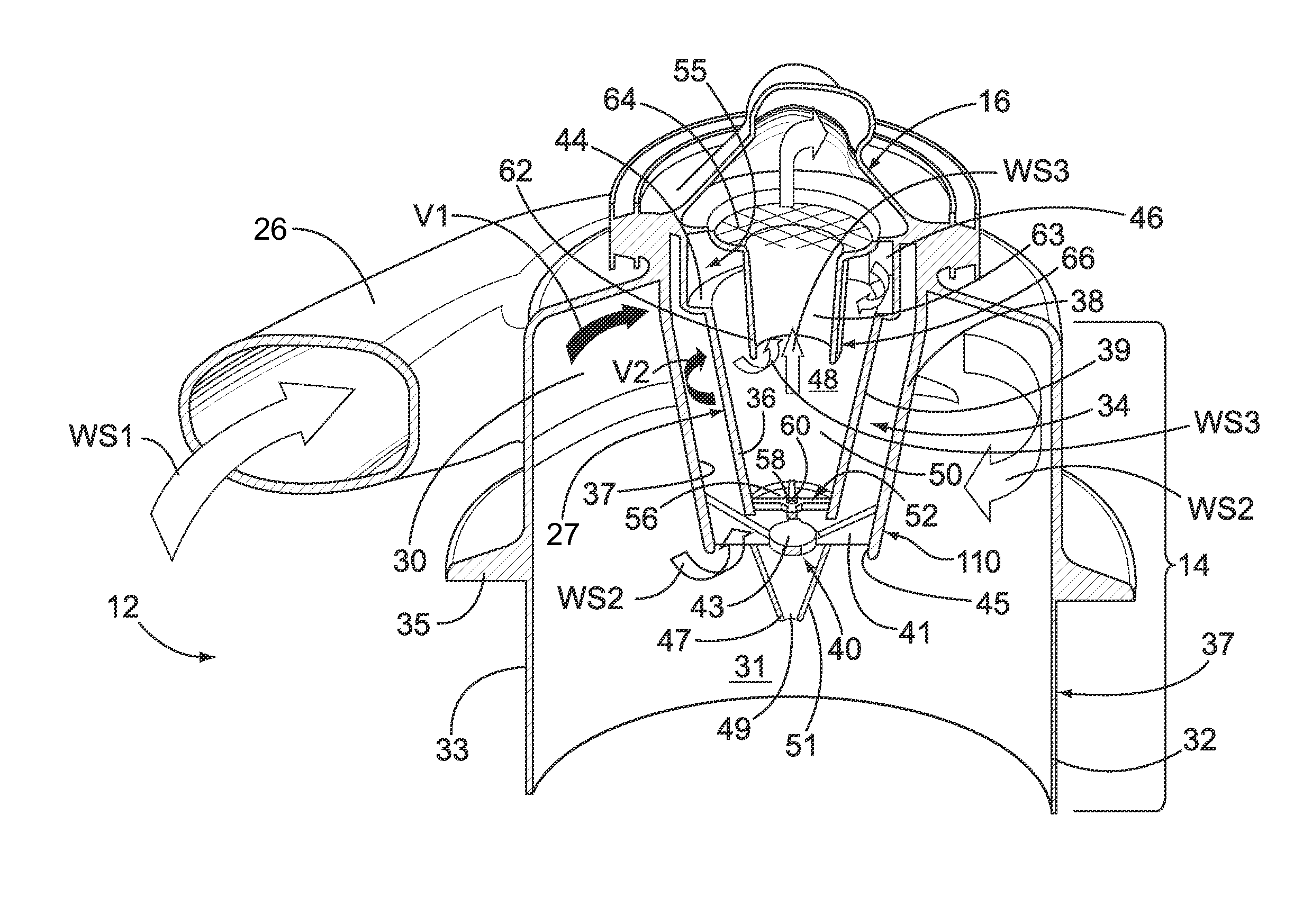

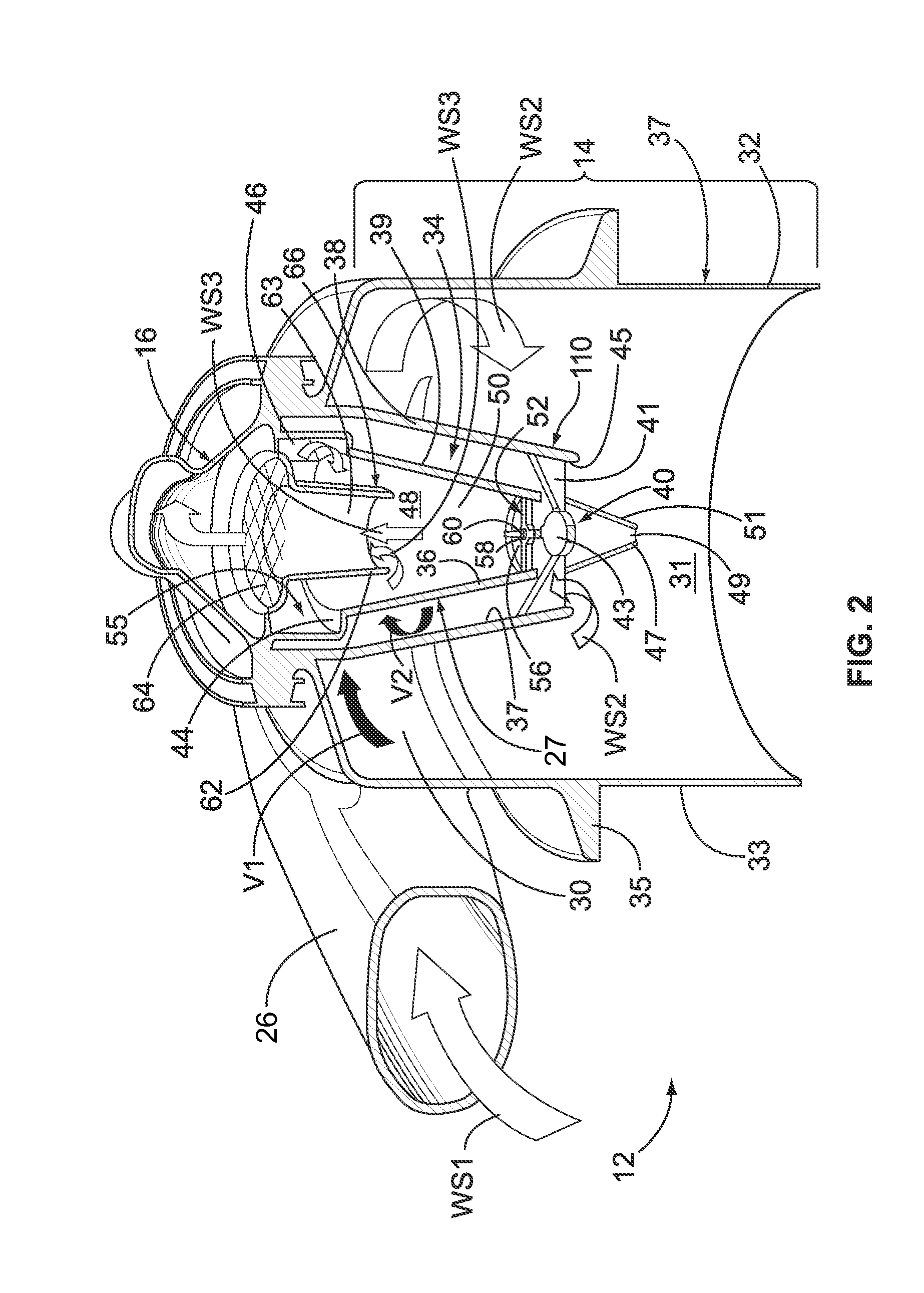

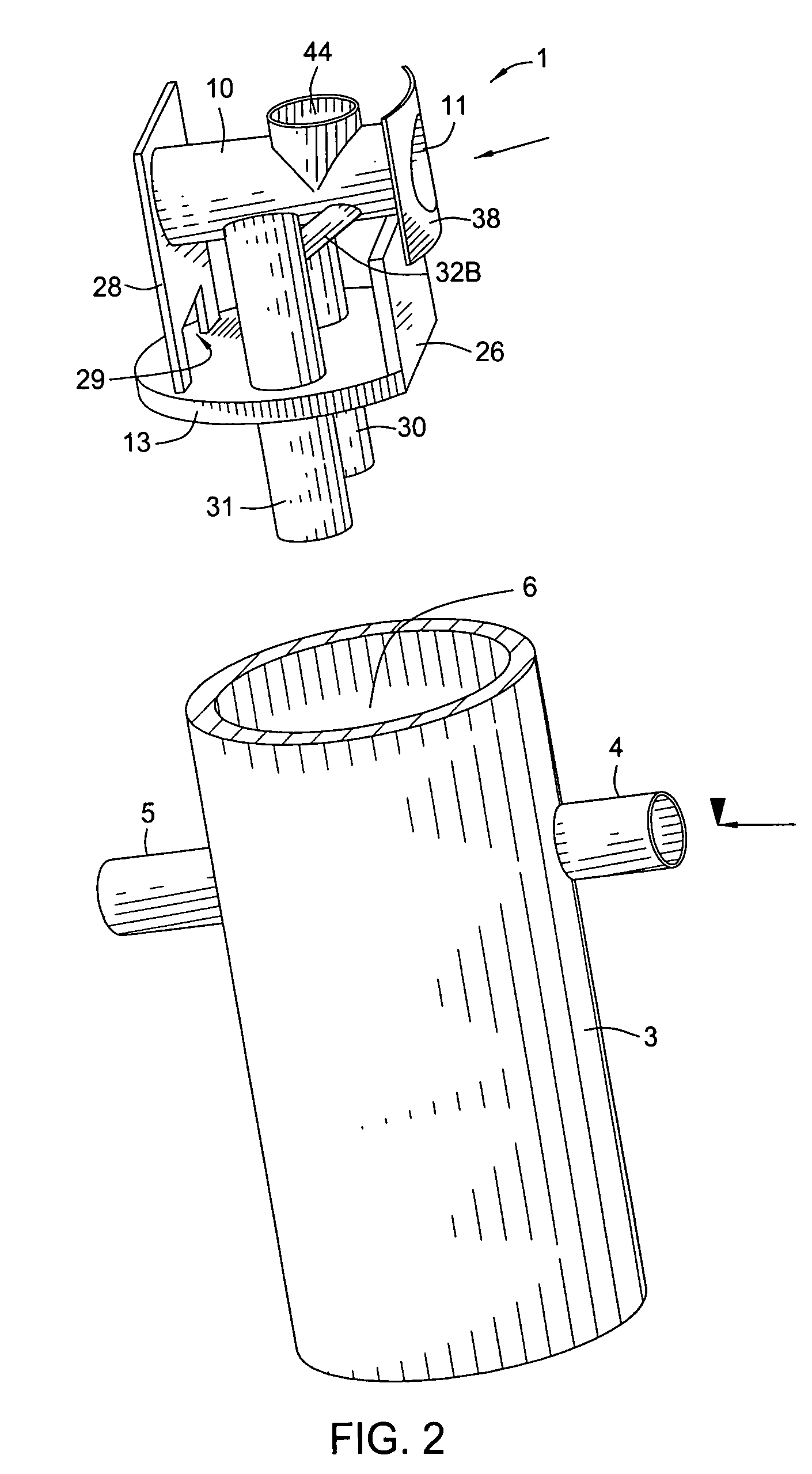

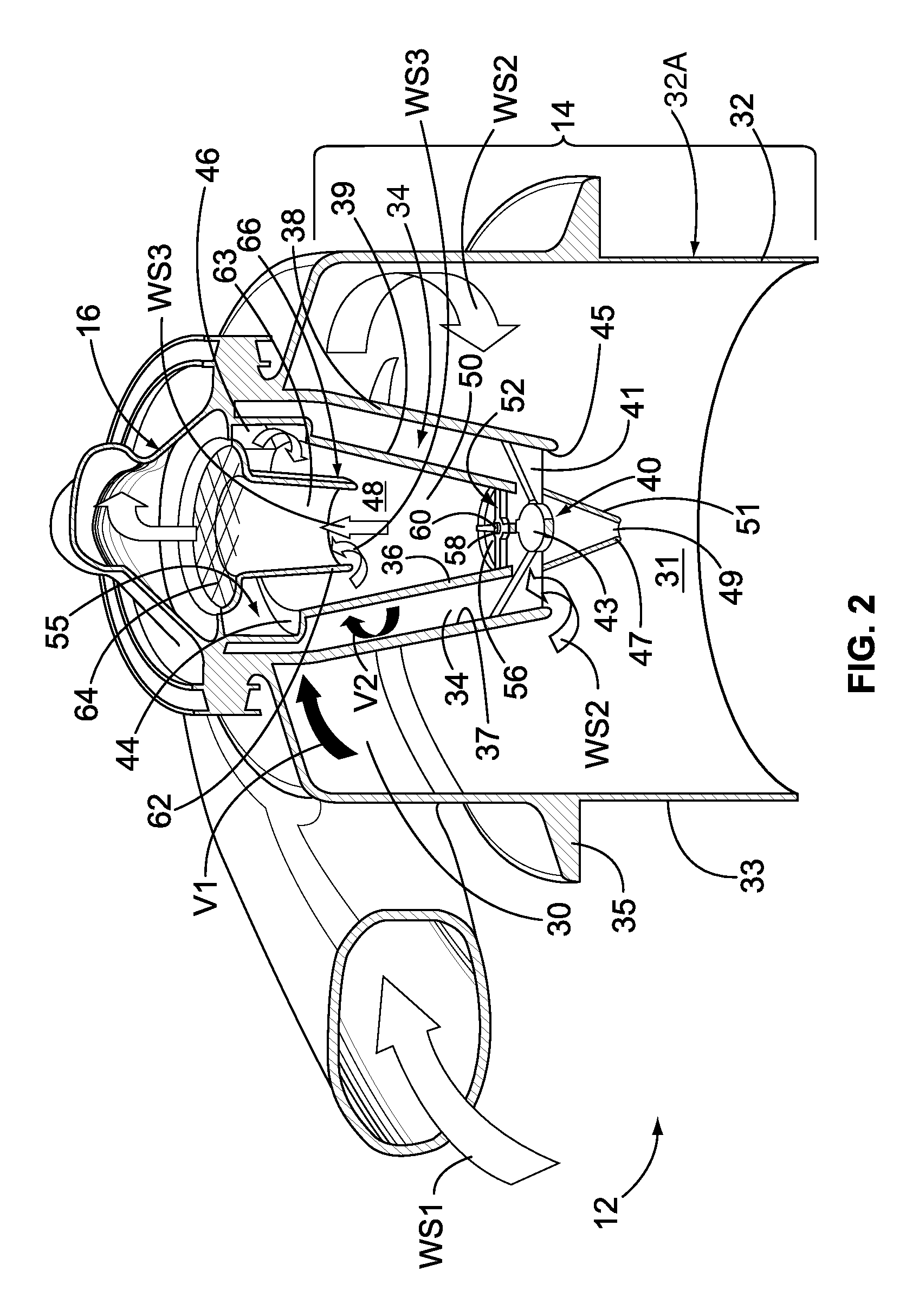

Vortex waste separator apparatus

ActiveUS20100083832A1Avoid cross contaminationWater/sewage treatment by centrifugal separationLiquid degasificationEddy current separatorWaste stream

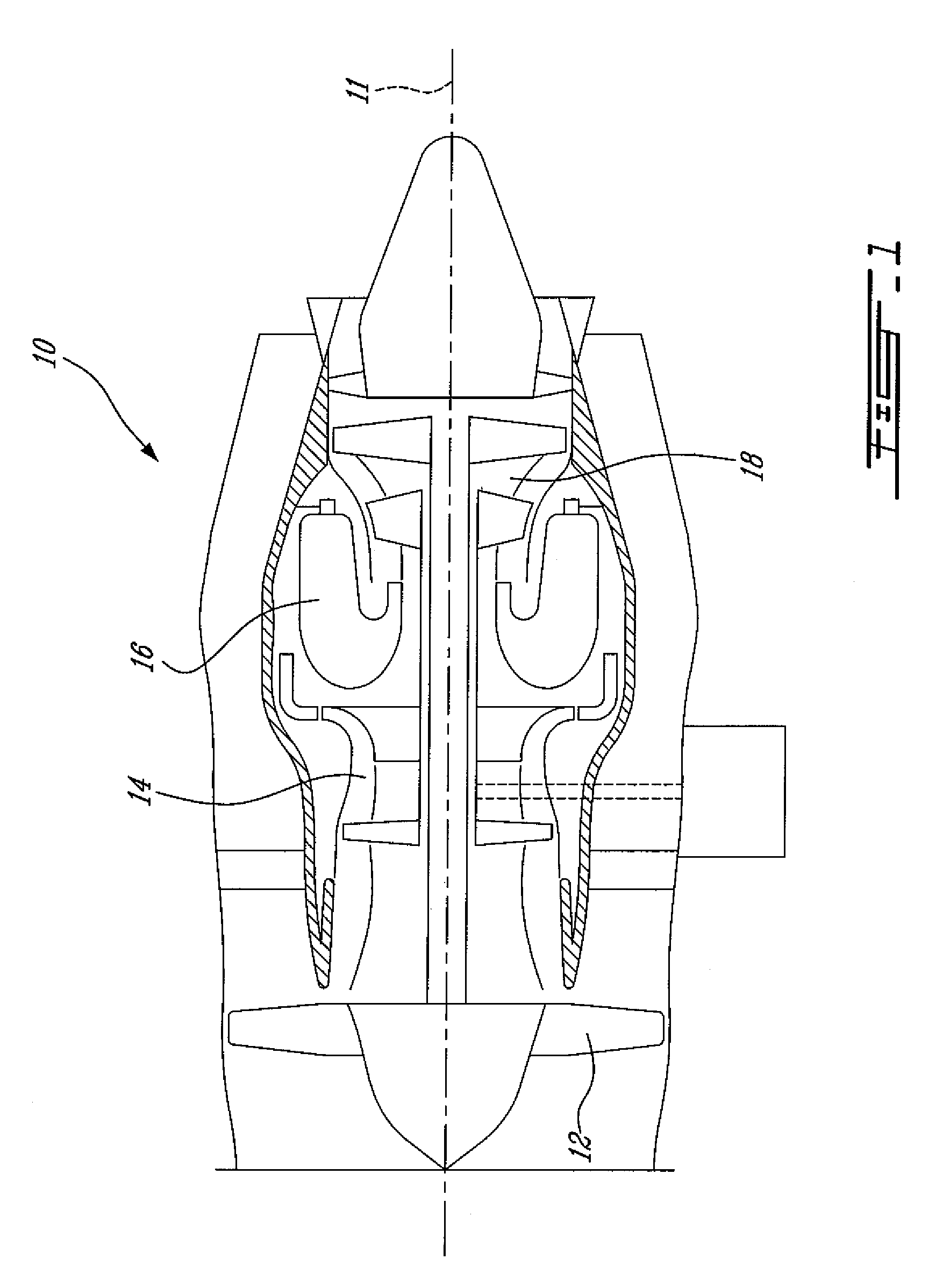

A vortex separator for drawing a substantially moisture-free airstream from a waste stream having an annular channel defining a first vortex flow path for separating liquid and solid waste from this waste stream and preferably a filter unit with an inverted conical cavity between nested inverted cones defining a second vortex flow path that is isolated from the first vortex flow path for separating additional liquid and solid waste from the waste stream before it exits the vortex separator. In preferred embodiments, the separator includes a removable filter unit cartridge positioned within the outer cone and a helix isolator to respectively make use of the separator more convenient to use and more efficient.

Owner:BE AEROSPACE INCORPORATED

Storm water treatment apparatus employing dual vortex separators

ActiveUS7182874B2Avoid backupImprove liquidityReversed direction vortexLiquid displacementSuspended particlesEddy current separator

A stormwater treatment device for removing floatables, solids and suspended particles and the like from stormwater run off, whereby a removable assembly is provided for installation into a manhole basin, the assembly including a pass-through member which receives stormwater from an incoming drainage system, and diverts low flows to at least one or more vortex separators, while allowing for high flows to bypass the separators and flow through the assembly untreated to exit the basin without diversion.

Owner:OLDCASTLE PRECAST

Vortex waste separator apparatus

ActiveUS7998251B2Avoid cross contaminationWater/sewage treatment by centrifugal separationLiquid degasificationEddy current separatorWaste stream

Owner:BE AEROSPACE INCORPORATED

Double-vortex fluid separator

InactiveUS7811344B1Facilitate separation of oilAvoid mixingCombination devicesAuxillary pretreatmentEddy current separatorEngineering

A fluid separator includes a side-by-side double-vortex fluid generator installed within a pressure vessel. The vortex generator separates the liquid and gas components of the incoming fluid mixture, and the vessel itself helps further separate the liquid into water and oil components, which makes the fluid separator particularly suited for processing fluids extracted from an oil well. The generator includes two diverging vortex tubes each having a polygonal cross-section. Such a cross-section allows the tubes to be formed using a conventional press brake. The vortex tubes also have diverging longitudinal centerlines to help spread the liquid flow pattern discharging into the vessel.

Owner:DUKE BOBBY RAY +1

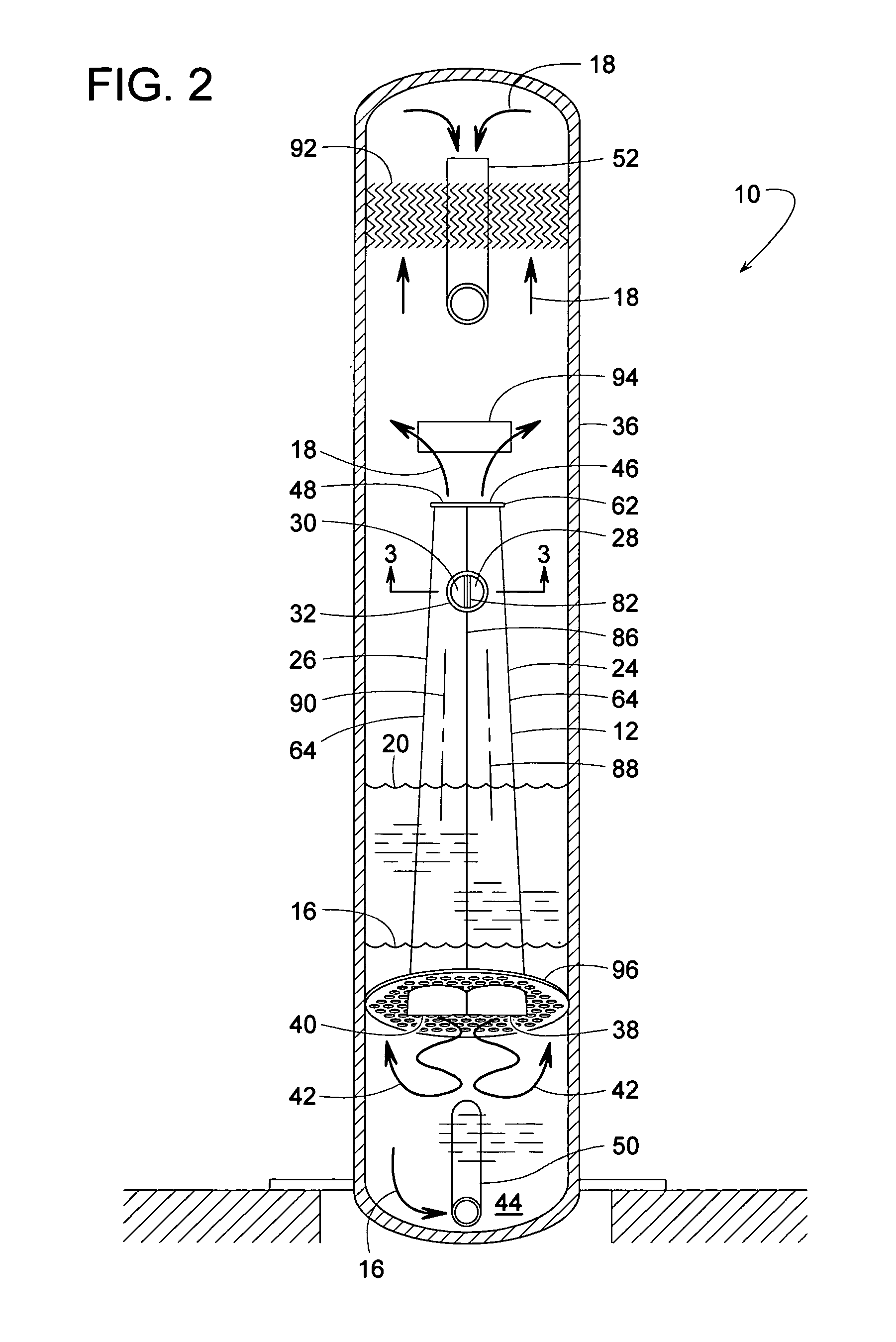

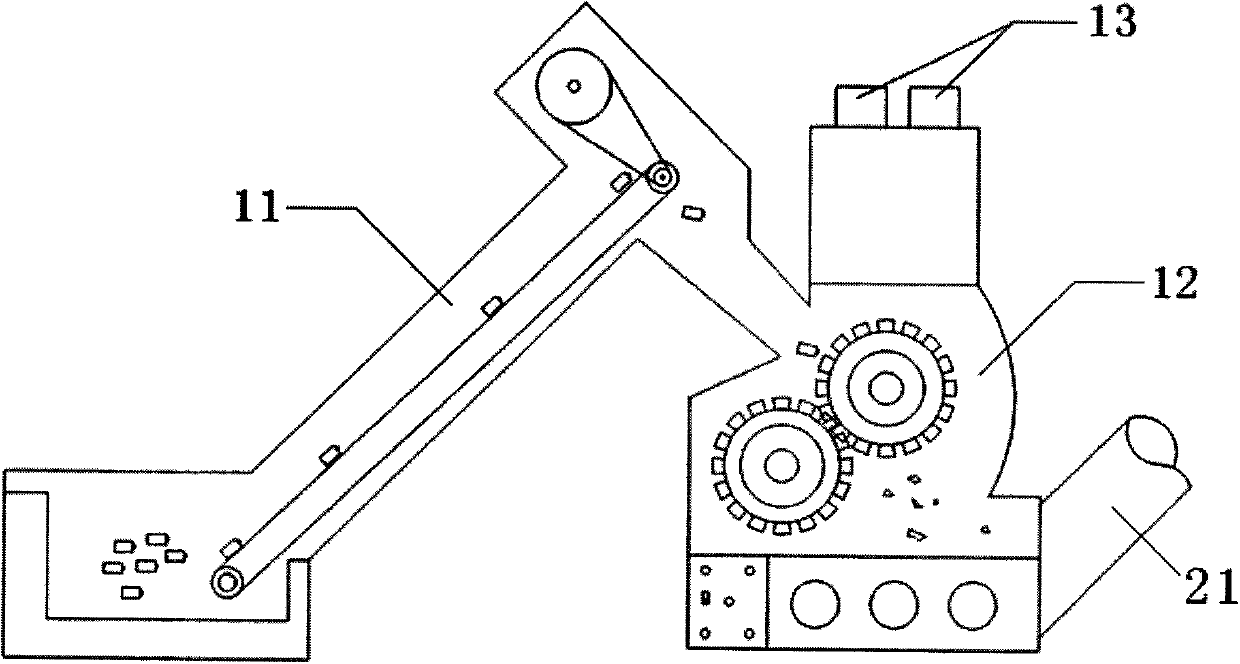

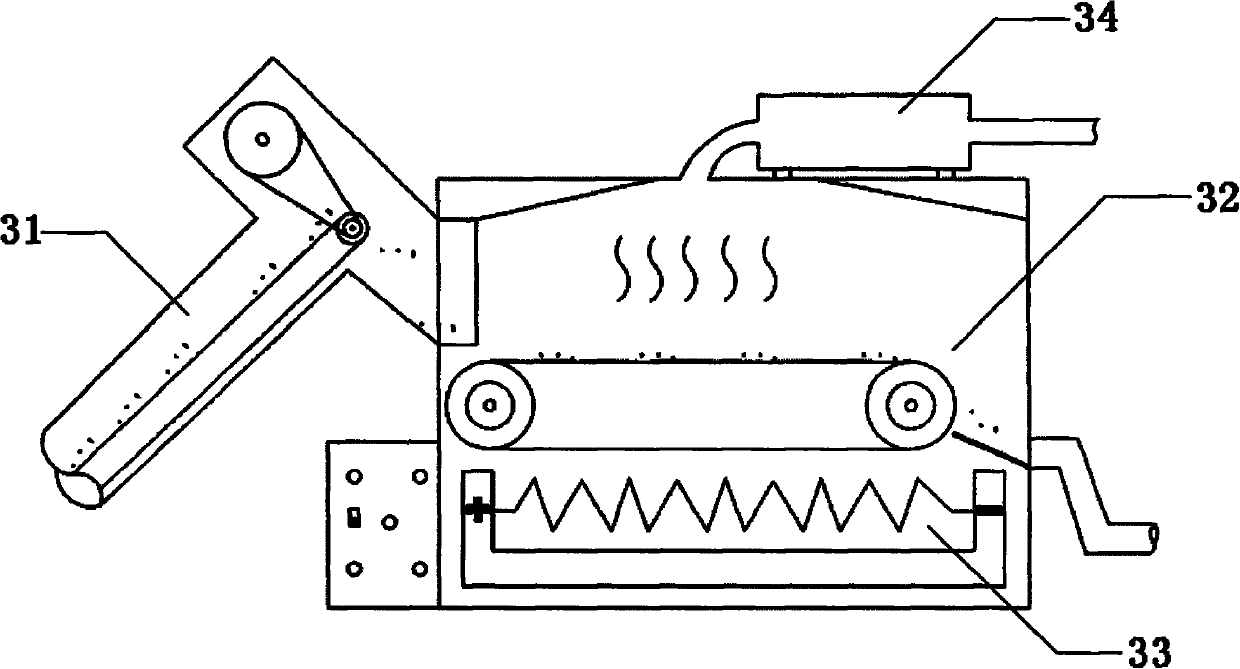

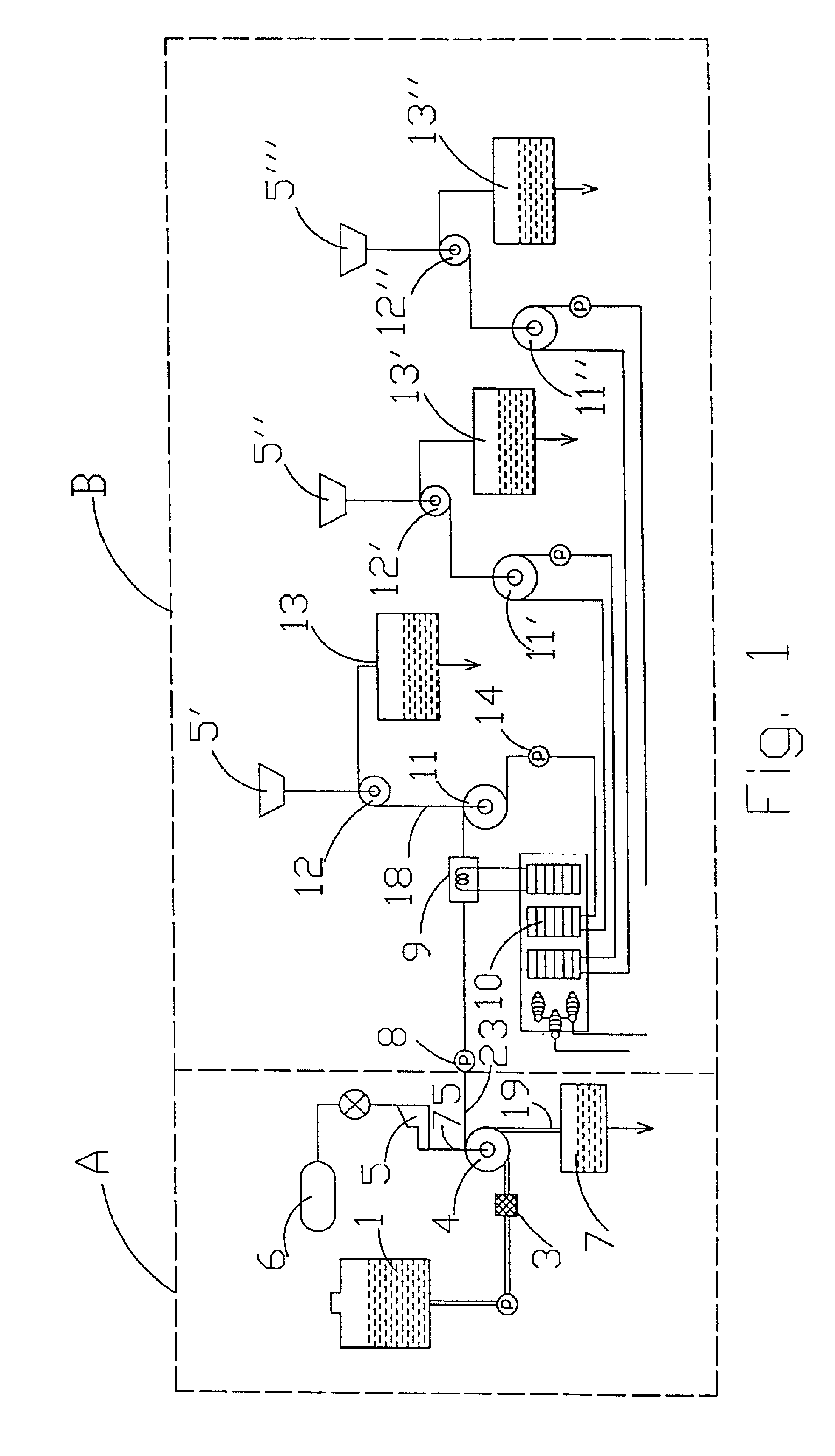

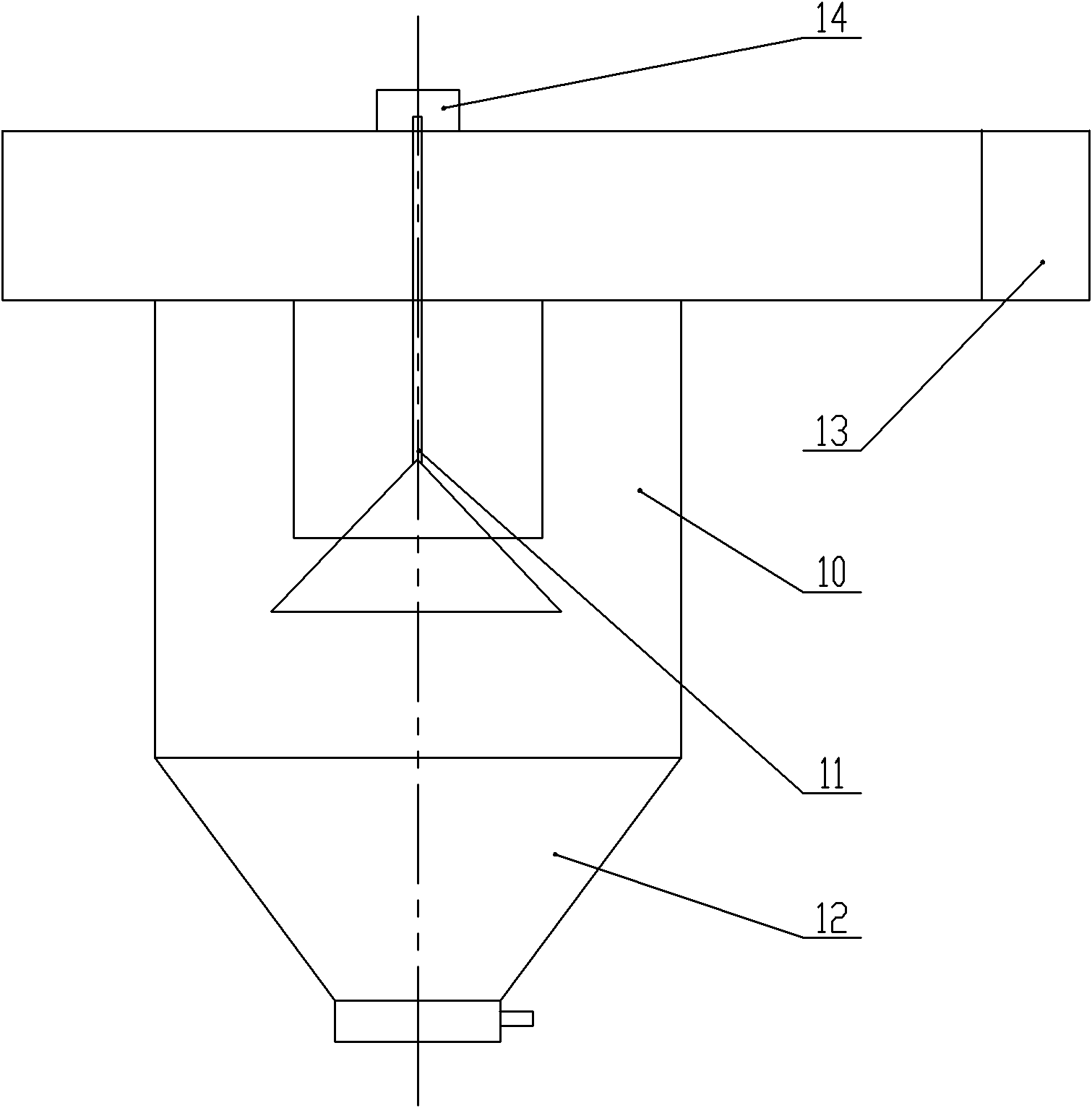

Harmless treatment and resource recovery method and harmless treatment and resource recovery equipment for waste circuit board with components

InactiveCN102962242AScientific recycling processReasonable recycling processSolid waste disposalElectronic waste recyclingActivated carbonEddy current separator

The invention relates to harmless treatment and resource recovery method and harmless treatment and resource recovery equipment for waste circuit boards with components. The equipment comprises a first-level conveyor belt, a compound crusher, a two-level conveyor belt, a permanent magnet deironing separator, an eddy current separator, a three-level conveyor belt, a two-level hammer crusher, a four-level conveyor belt, a three-level hammer flake type crusher, a material conveying fan, a vibrating separator, a cyclone separator, a bag type dust collector, a draught fan and activated carbon adsorption tower. The method comprises the steps that: crushing the waste circuit boards with components into fragments in the compound crusher, separating out irons through the permanent magnet deironing separator, and separating out copper, aluminum and other nonferrous metals on a belt of the eddy-current separator; entering the two-level hammer crusher for further dissociation and crushing, and separating out irons; and driving the balance of materials to enter the three-level hammer flake type crusher, and fully crushing the materials into powder with 60-100 meshes to the vibrating separator. The method and equipment have the advantages that the investment is few, the energy consumption is low, the running cost is low, and the process and the operation are simple, and the production efficiency can be greatly improved and no secondary pollution is caused.

Owner:汨罗万容电子废弃物处理有限公司

Vortex separator for separating floating and settling substances from centrally inflowing storm-water

ActiveUS7422683B2Easy to disassembleReduce obstaclesFatty/oily/floating substances removal devicesWater cleaningEddy current separatorEngineering

Owner:CONTECH ENGINEERED SOLUTIONS

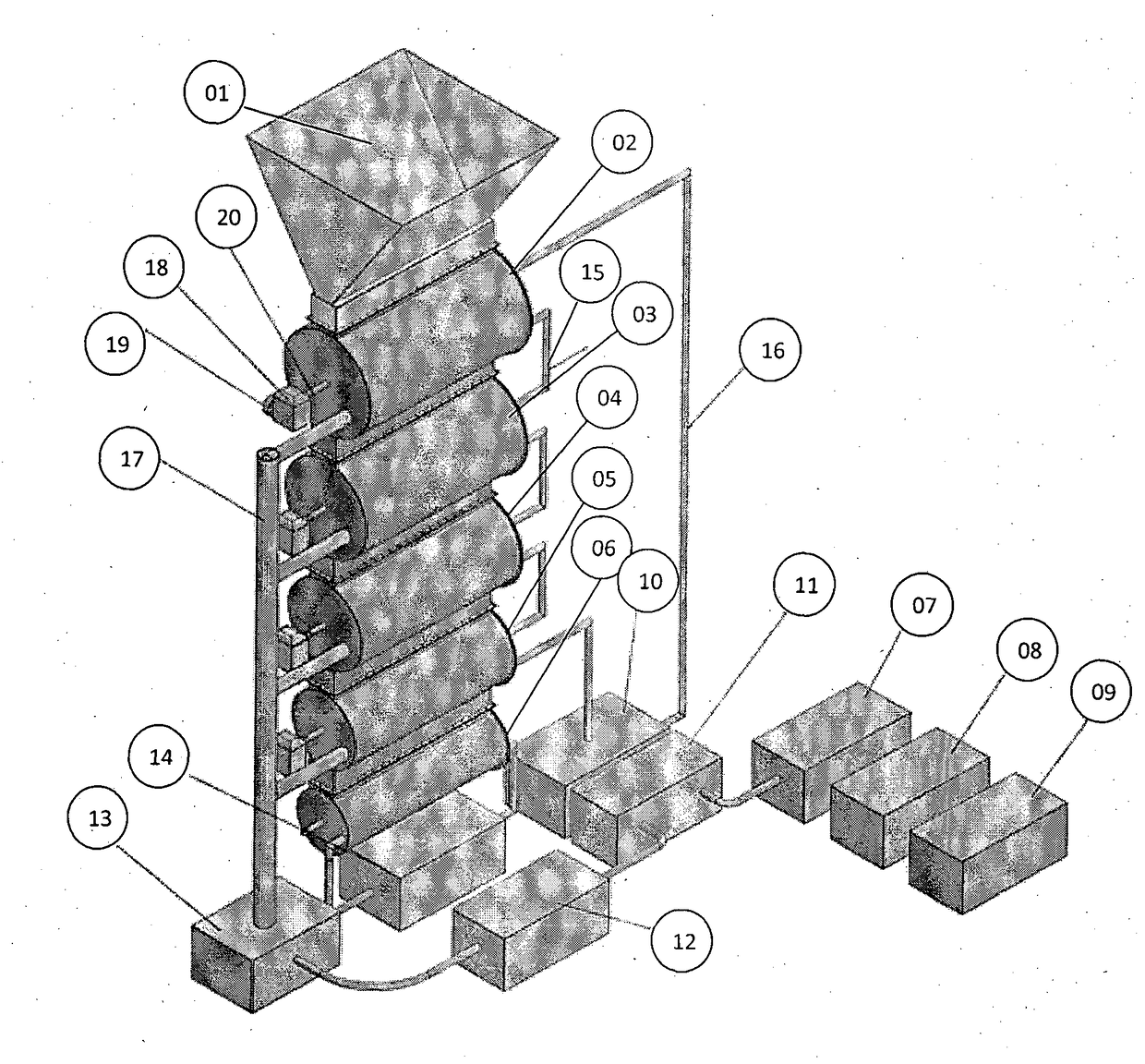

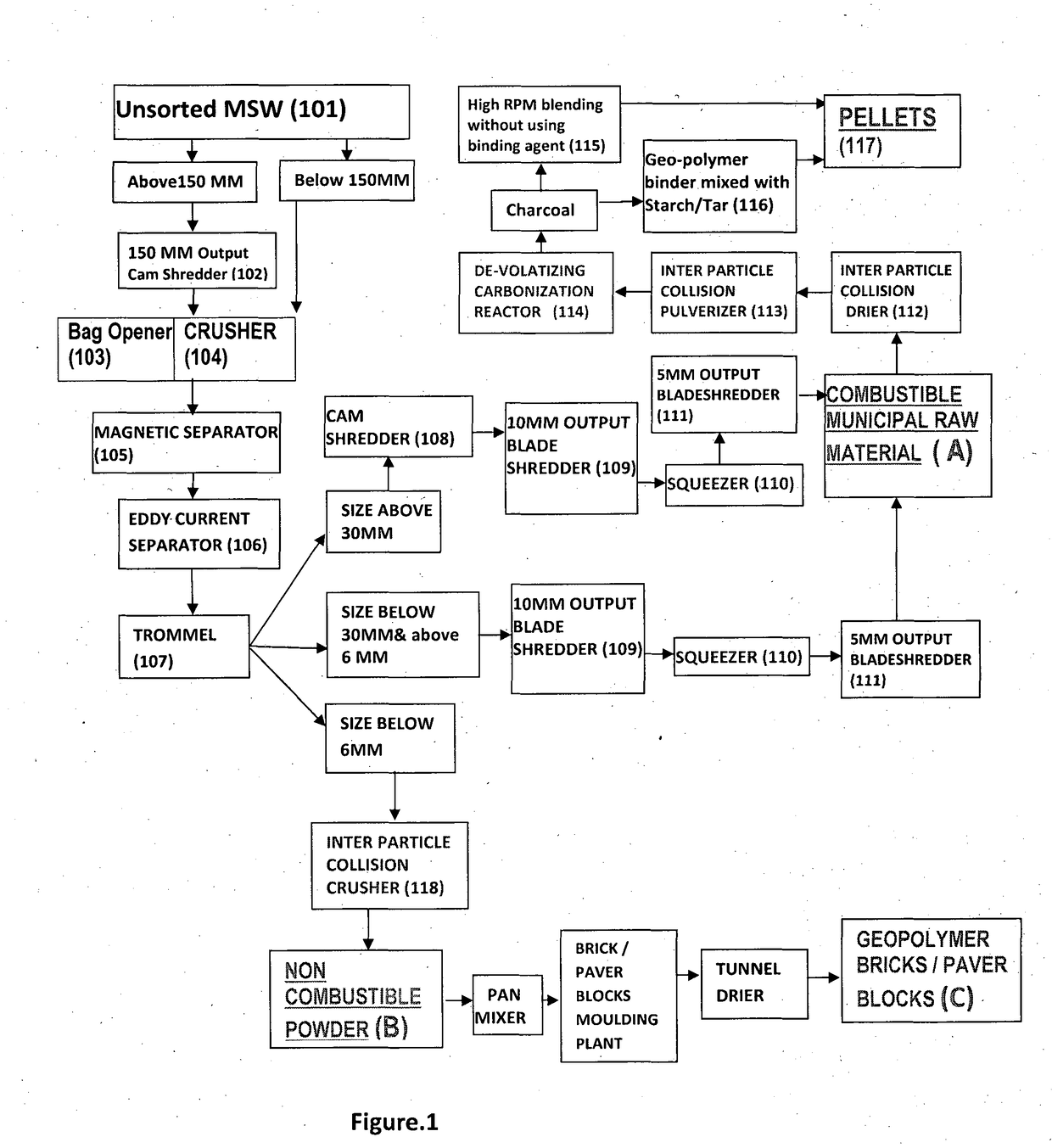

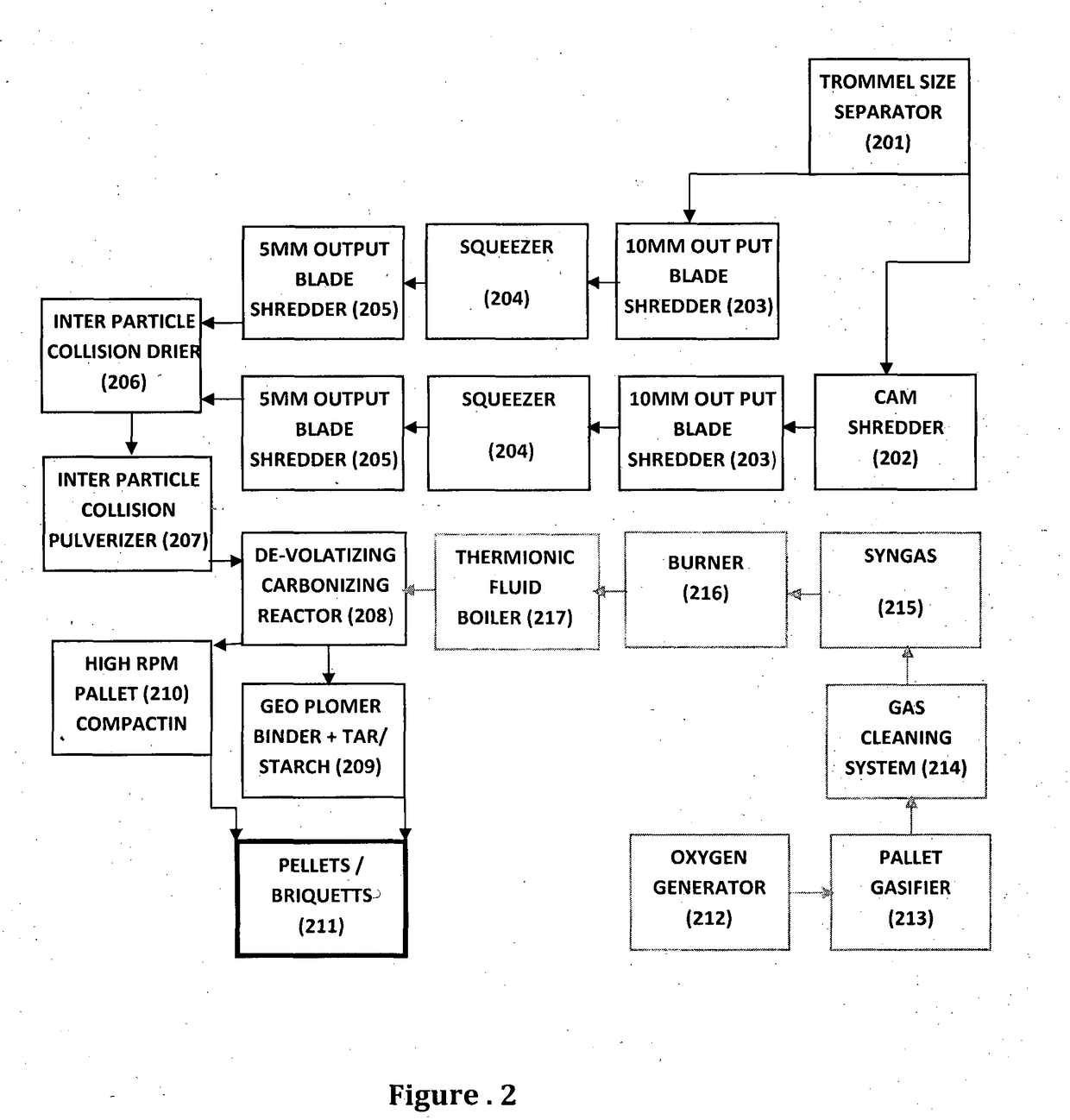

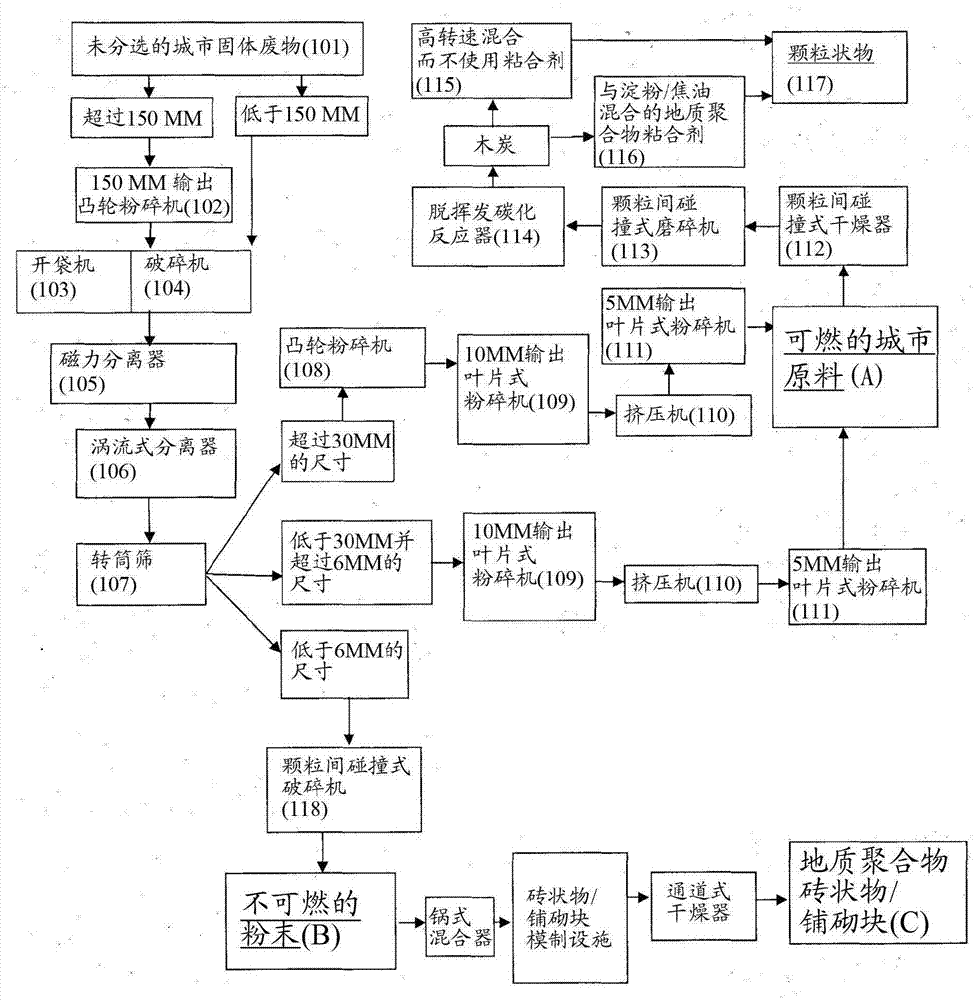

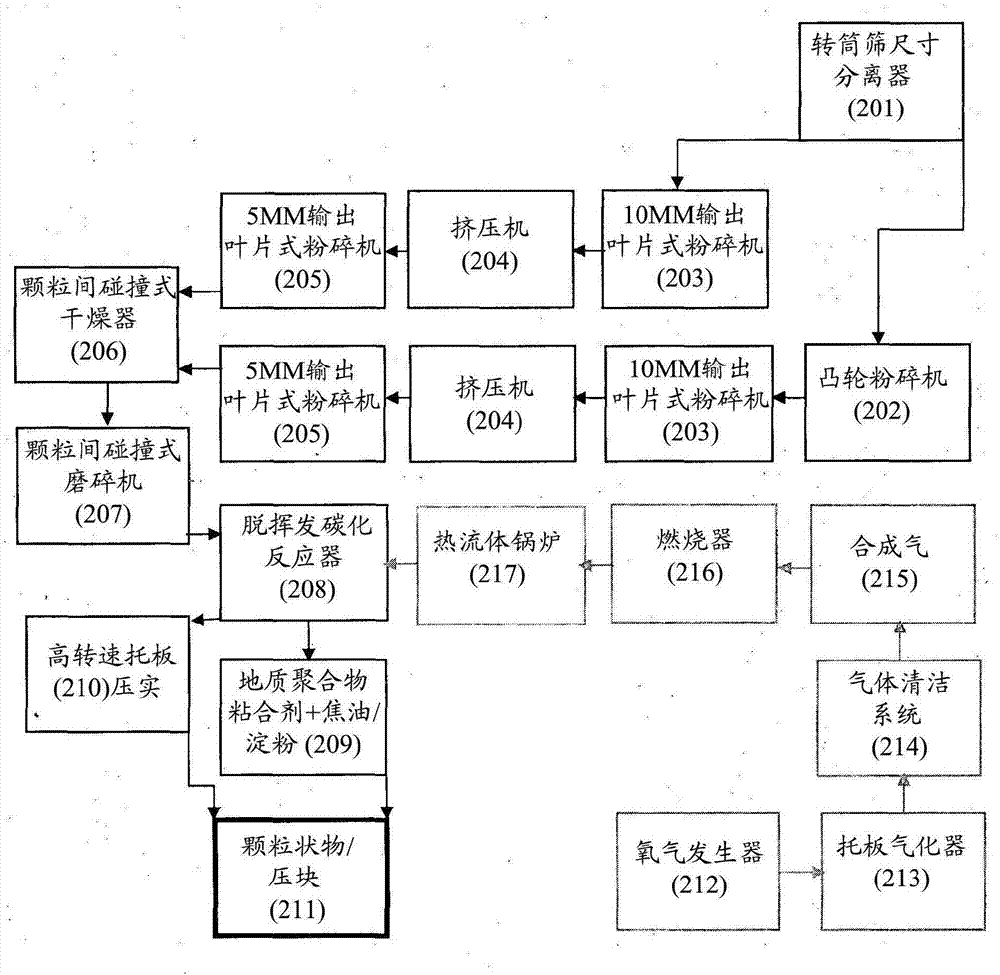

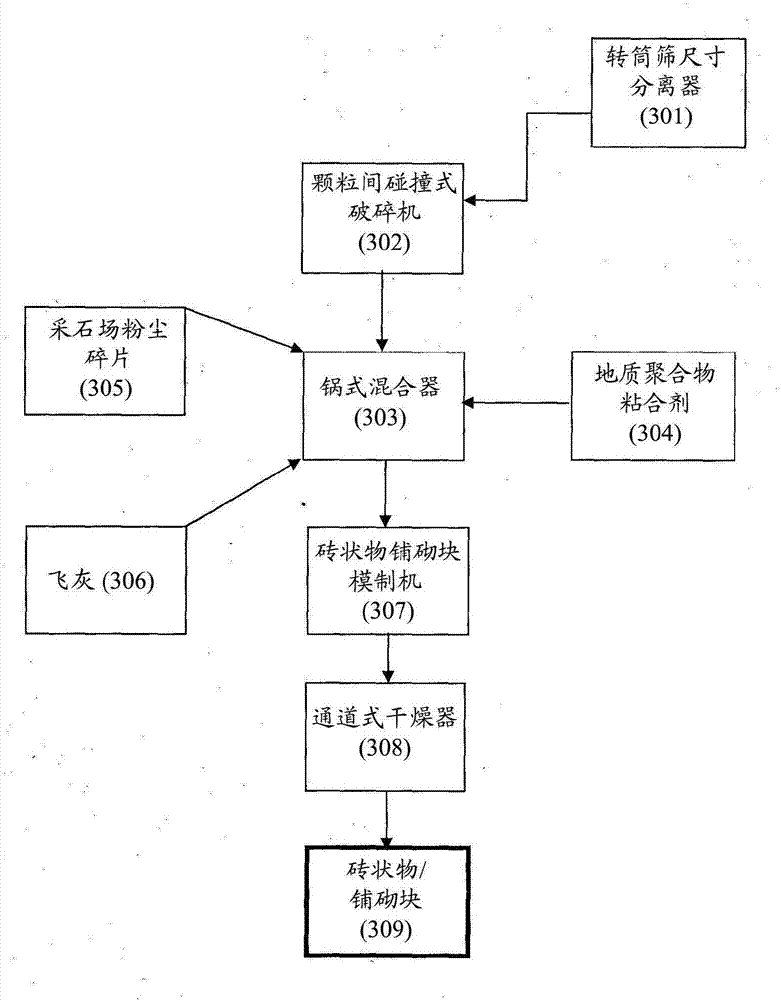

A novel method and an apparatus in converting unsorted municipal solid waste into geo-polymer pellets/briquettes and geo-polymer bricks/paver blocks

InactiveUS20180015515A1High calorific valueLow ashSolid waste disposalTransportation and packagingBrickCarbonization

Apparatus and method in converting municipal solid waste into geo-polymer briquettes and geo-polymer bricks comprising bag opener cum crushers, magnetic separators for ferrous and-eddy current separators for non-ferrous things; squeezer for removing liquid content; inter particle collision driers for drying; pulverizer for pulverizing, and devolatizing carbonization reactor for carbonisation of combustible MSW to produce solid char with low water content. Solid char is mixed with geo-polymer binding agent / starch / tar / to form combustible pellet / briquette. These highly combustible briquette / pellets have high calorific value. The pellet / briquette is formed by rotating combustible char at high rpm and compaction. Pellet has a water content of less than 5% by weight and fuel value of 5500 to 6500 KCAL. This process produces non-combustible geo-polymer brick. The non-combustible MSW separated by a trommel is crushed by inter particle collision crusher and pan mixers mixing with geo-polymer binding agent / fly ash / quarry dust / chips or china clay and moulded.

Owner:NEWAY MSW IP HLDG LLP

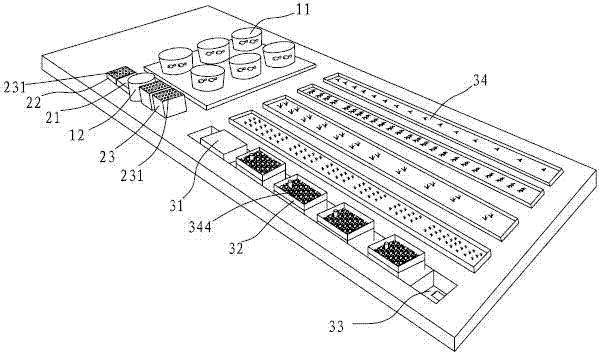

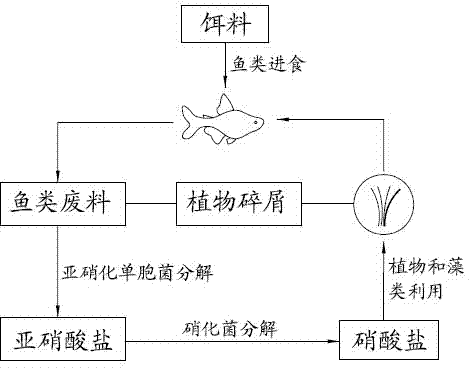

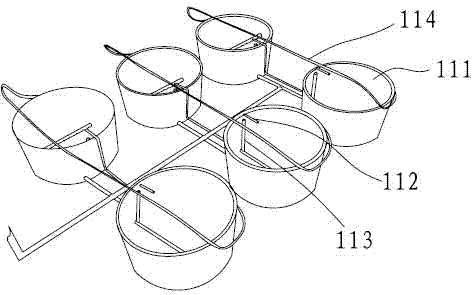

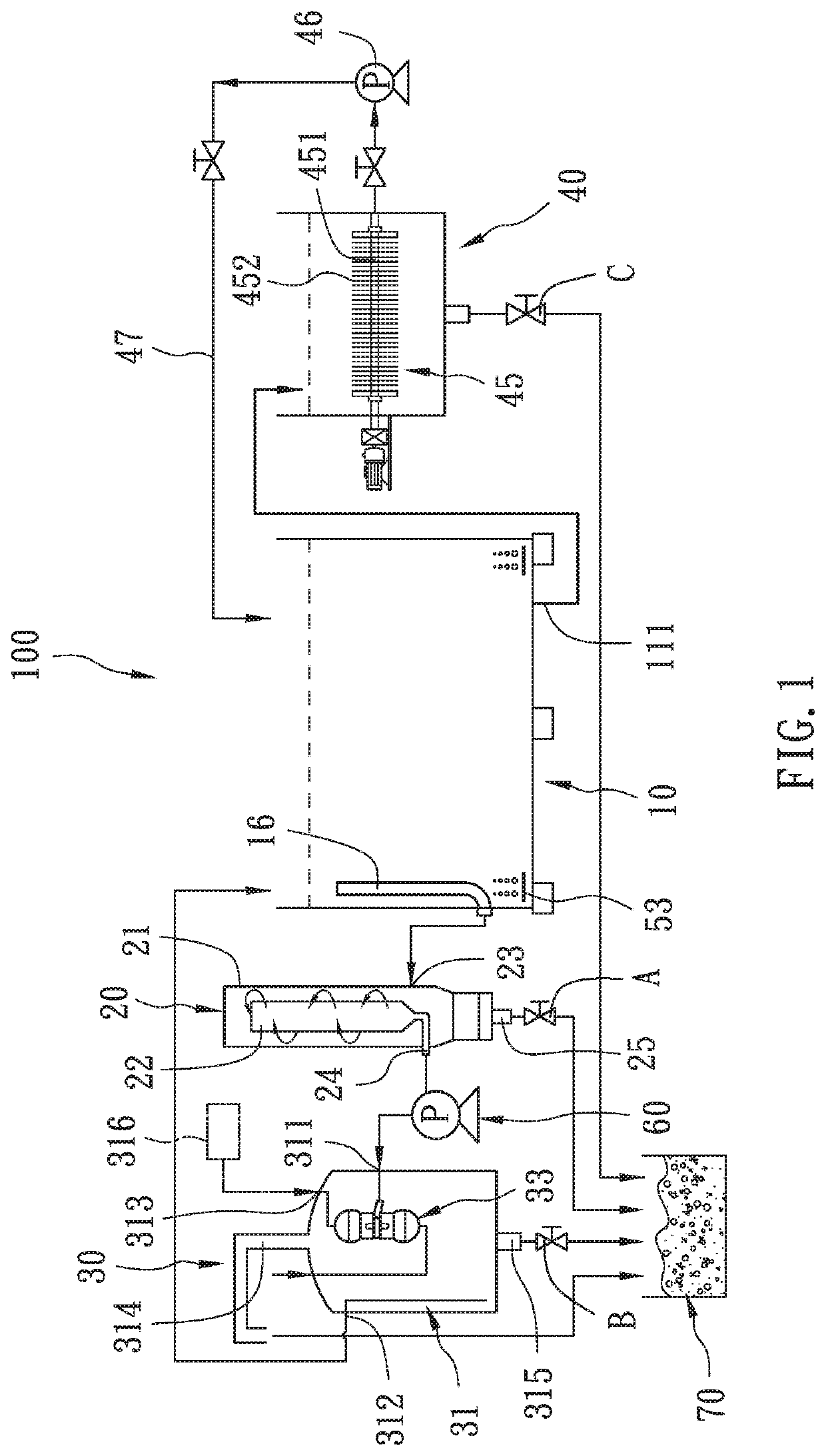

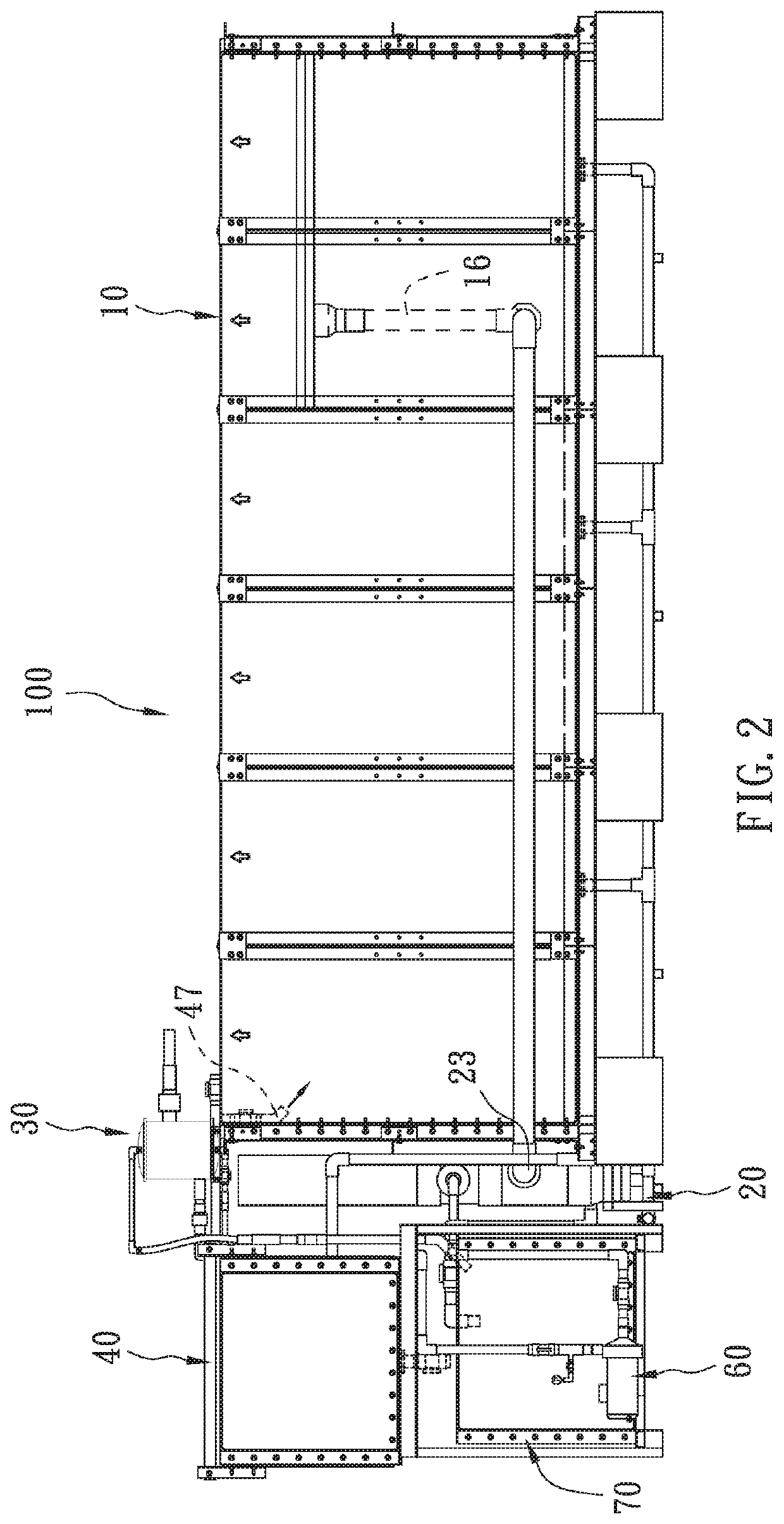

Fish and vegetable co-existing system and use and control method thereof

InactiveCN104488686ASave spaceEasy to operateClimate change adaptationAgricultural fishingSocial benefitsRaft culture

The invention discloses a fish and vegetable co-existing system which comprises a circulating water culture system, a biofilter, a water culture system, a water pump, a gas pump, a transmission pipeline and an electric control box. The circulating water culture system comprises a fish pond device and a whirlpool separator; the biofilter comprises an anaerobic mineralization pond, an aerobic mineralization pond and a moving bio-membrane reactor; the water culture system comprises a second low-land pond, a dry-wet medium bed, a first low-land pond and a plurality of deepwater floating raft culture beds; the fish pond device, the biofilter, the second low-land pond, the dry-wet medium bed, the first low-land pond and the deepwater floating raft culture beds are sequentially communicated; a water source of the first low-land pond is pumped out to enter the fish pond device to form a circulating system. The invention also discloses a use and control method of the system, so that two culture modes are mutually coordinated to operate in the same system, thereby reaching ecological balance and generating high economic and social benefits.

Owner:创新互联(厦门)科技有限公司

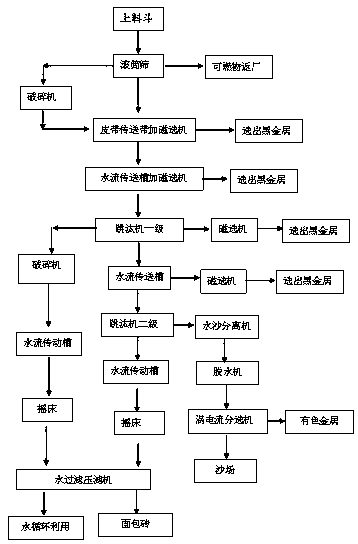

Garbage incinerator slag treatment process

The invention discloses a garbage incinerator slag treatment process. Furnace slag is conveyed to a drum screen for screening through a feeding hopper, the screened out insufficiently-burnt combustible materials return to a plant to be used as fuel, and the screened out large furnace slag is crushed by a crusher; the screened and crushed slag is gathered and conveyed to a jigging machine through aconveying belt, a magnetic separator is installed above the conveying belt, and black metal is extracted from the furnace slag through magnetic separation in the furnace slag conveying process; particulate matters and sand in the furnace slag are separated by the jigging machine; the separated solid granular slag is pressed into bloated bricks through a water filtering filter press; and the sandis subjected to water-sand separation through a water-sand separator, the separated water is recycled for cyclic utilization, the sand is further dewatered through a dewatering machine and then is subjected to separation through an eddy current separator to separate nonferrous metals from the sand, and finally the sand is sent into a sand field to be used. According to the process, the slag is subjected to multi-stage separation treatment, and thus the recyclable metal and sand are separated; and the solid granular slag is made into the bloated bricks for building, and thus economical and environment-friendly effects are achieved.

Owner:DEZHOU QUNFENG MACHINERY MFG

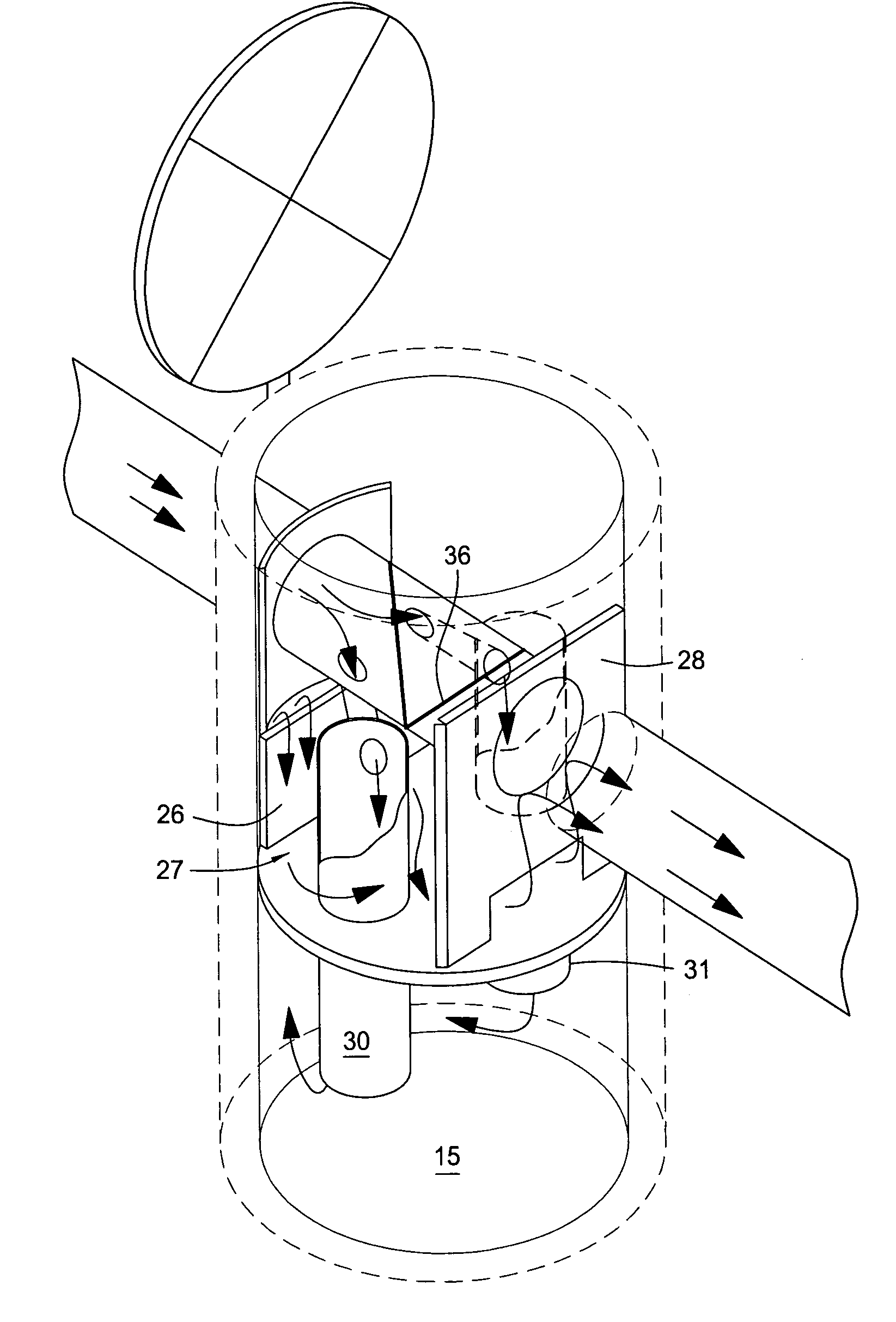

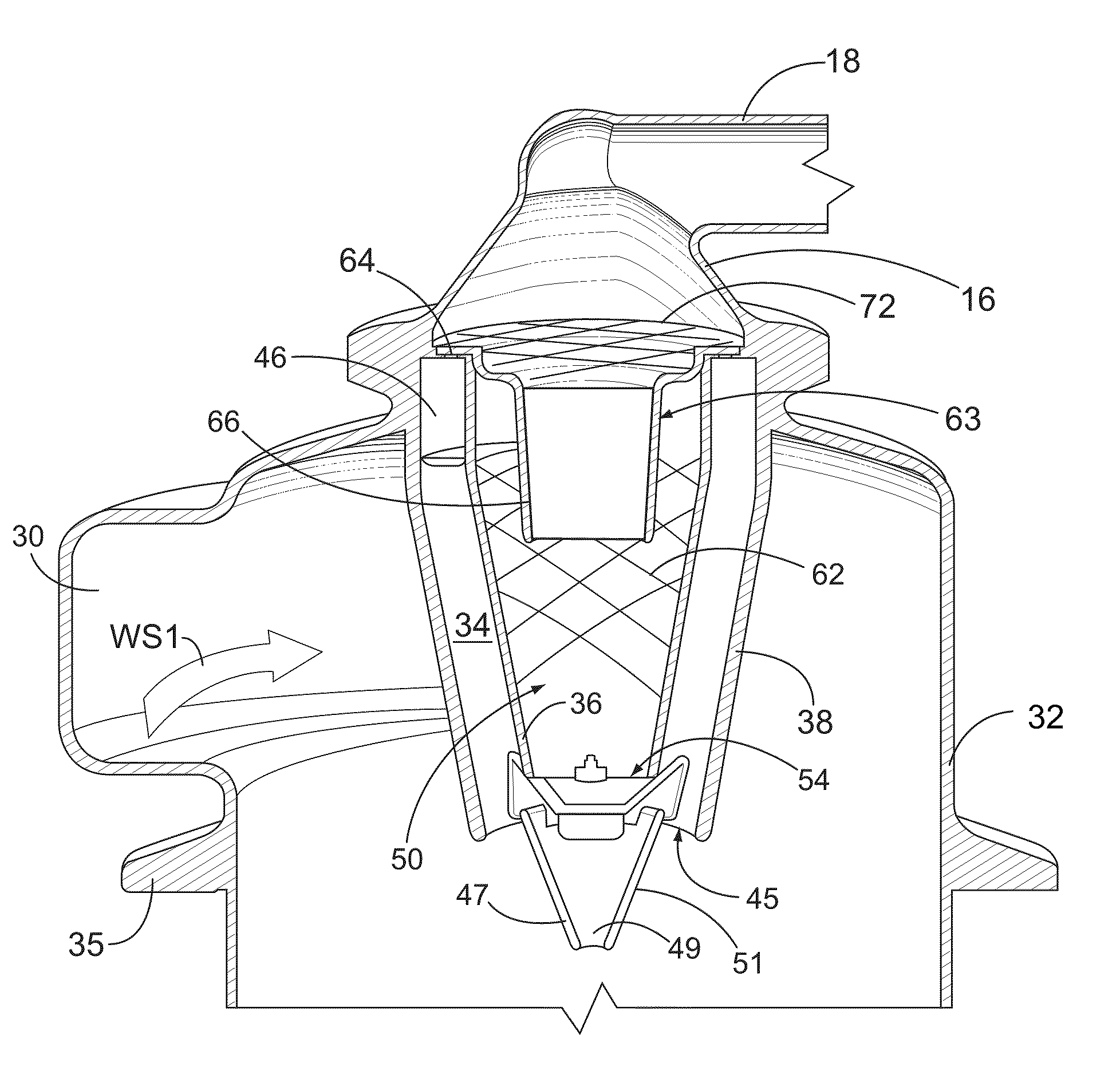

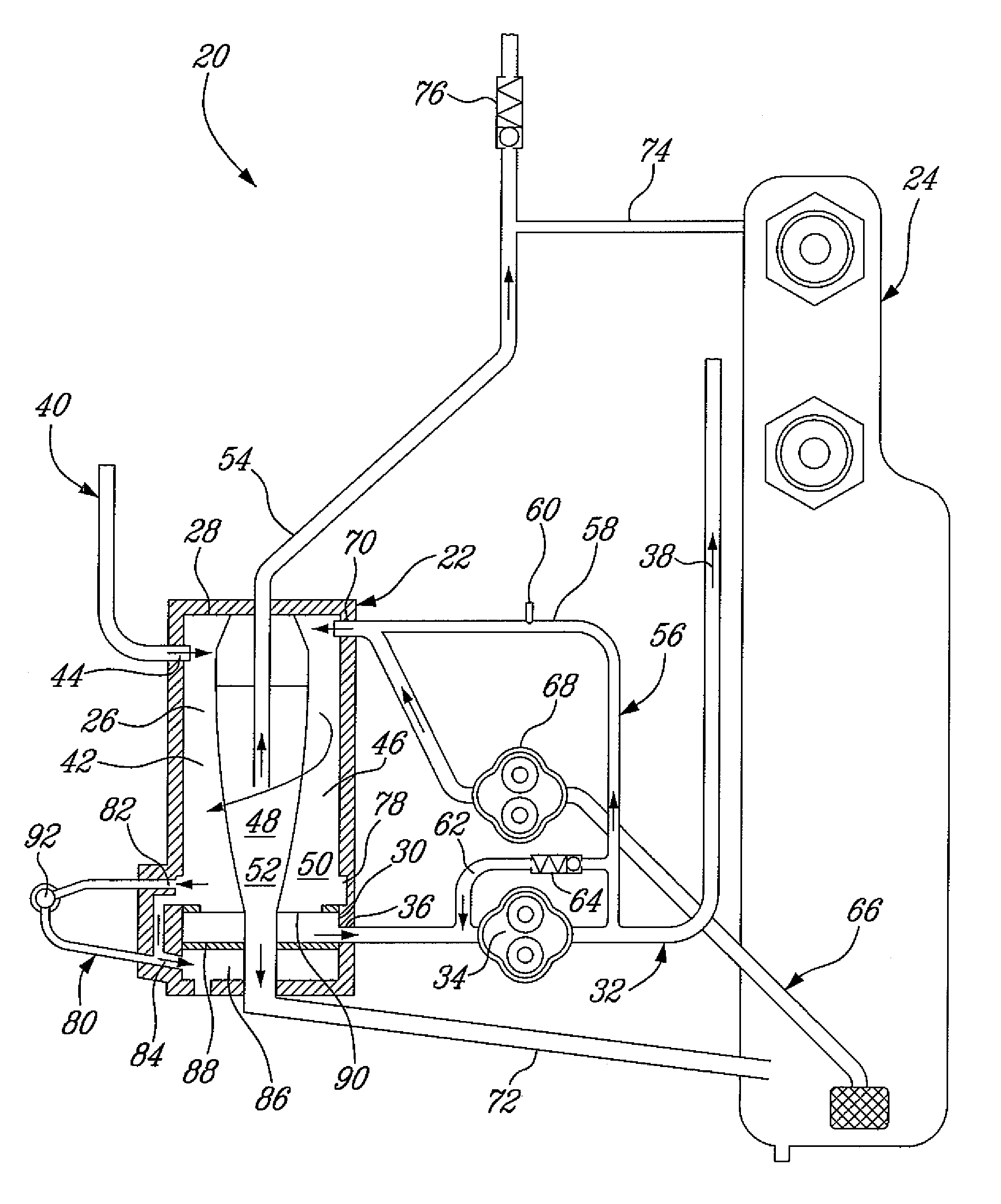

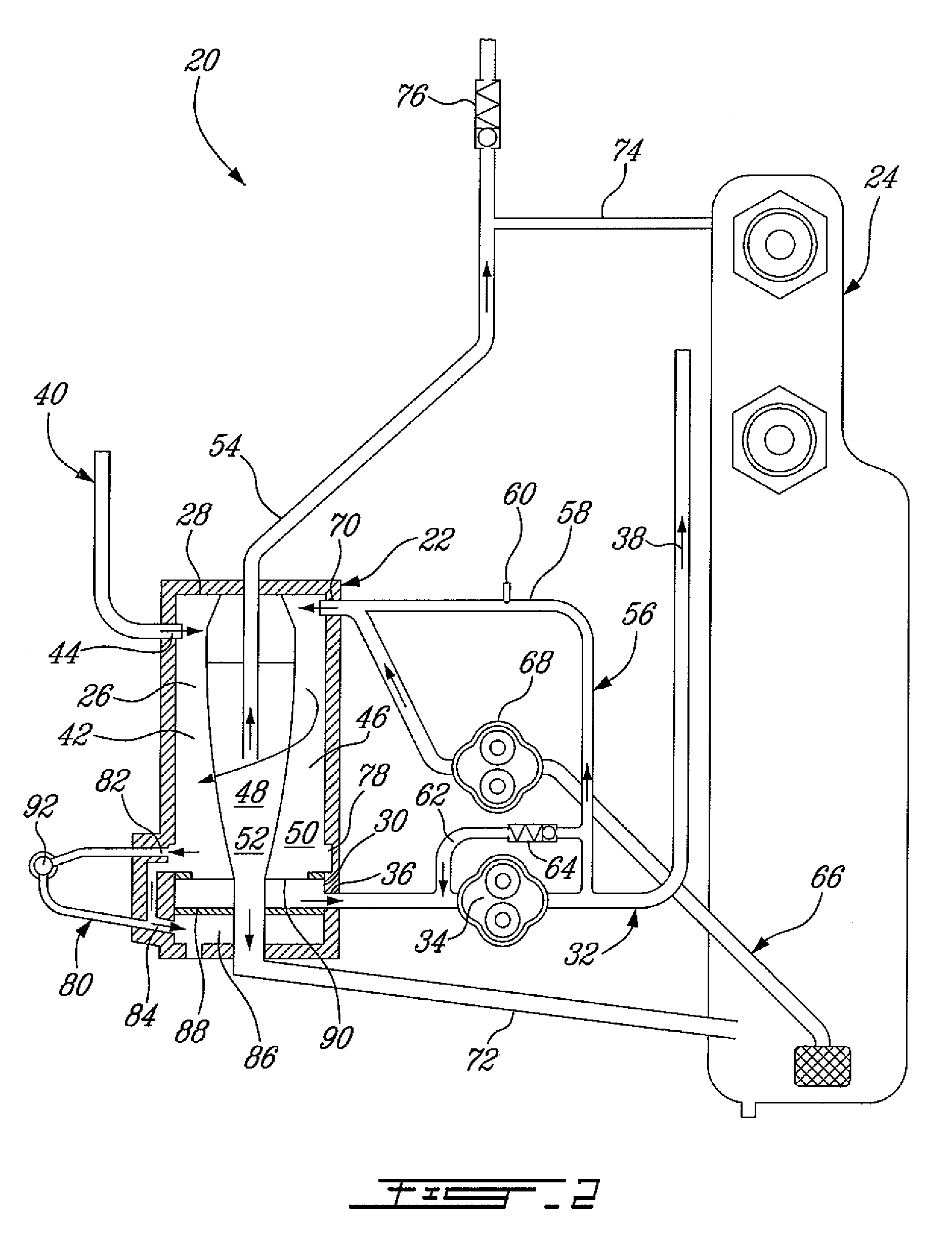

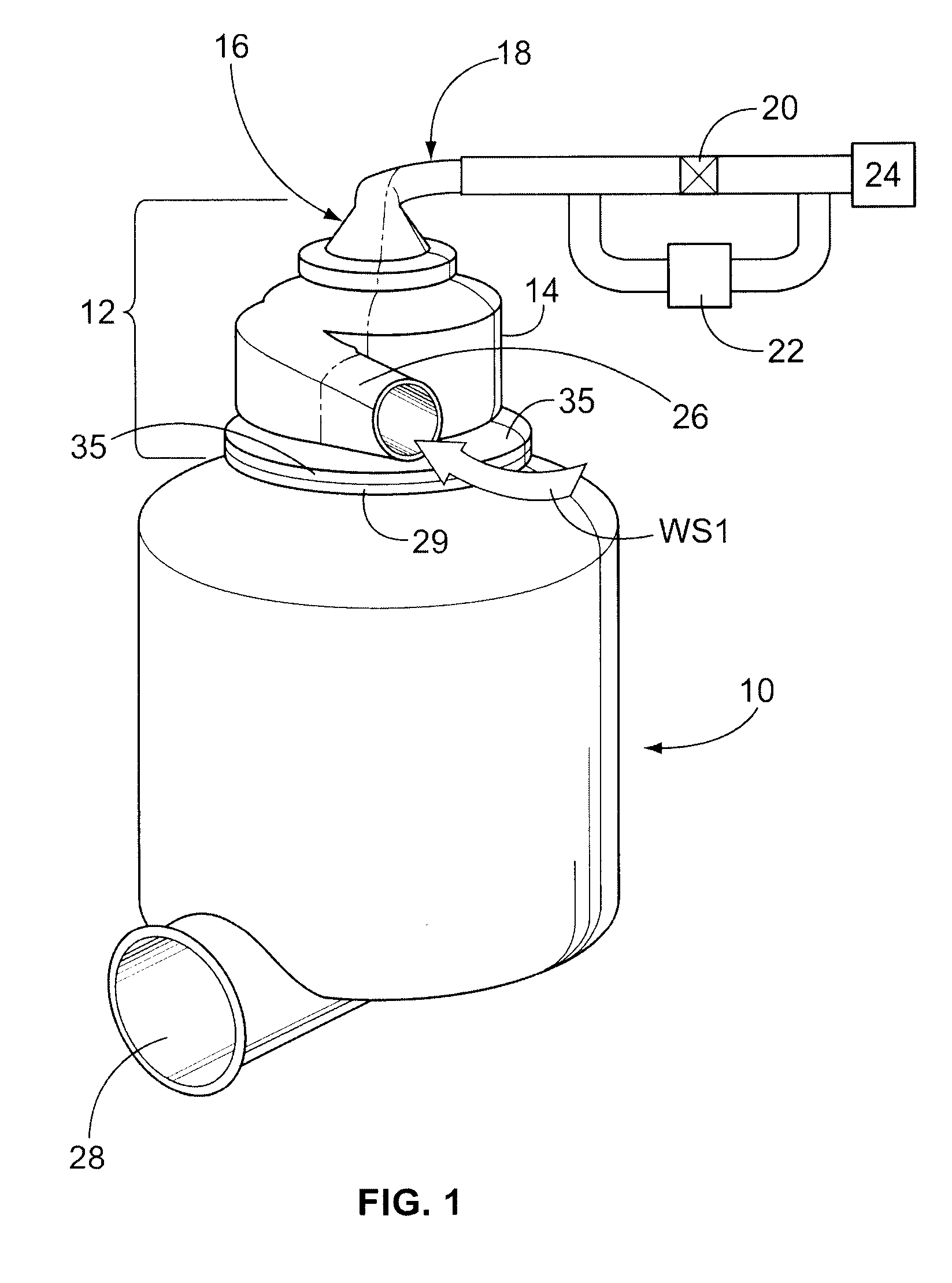

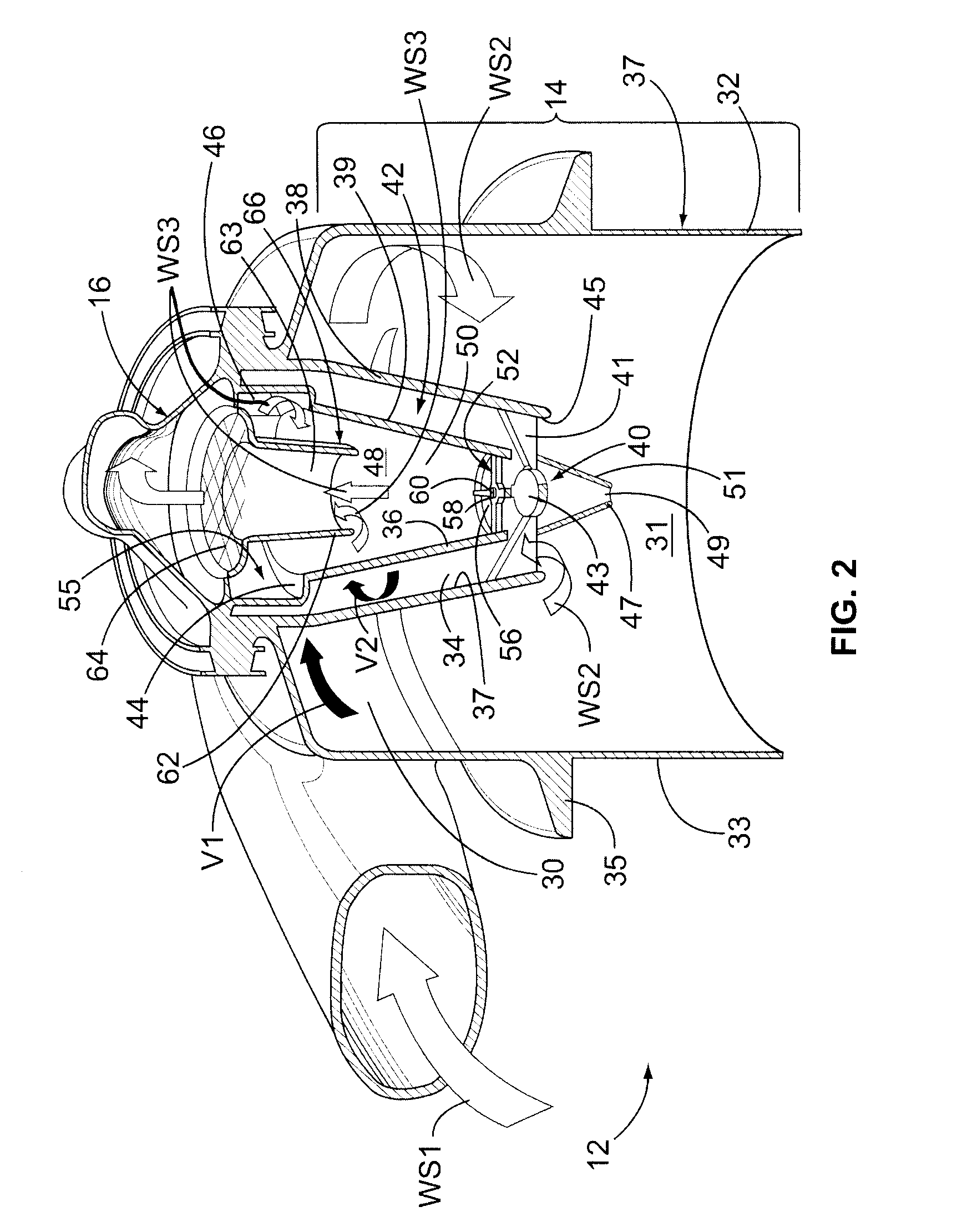

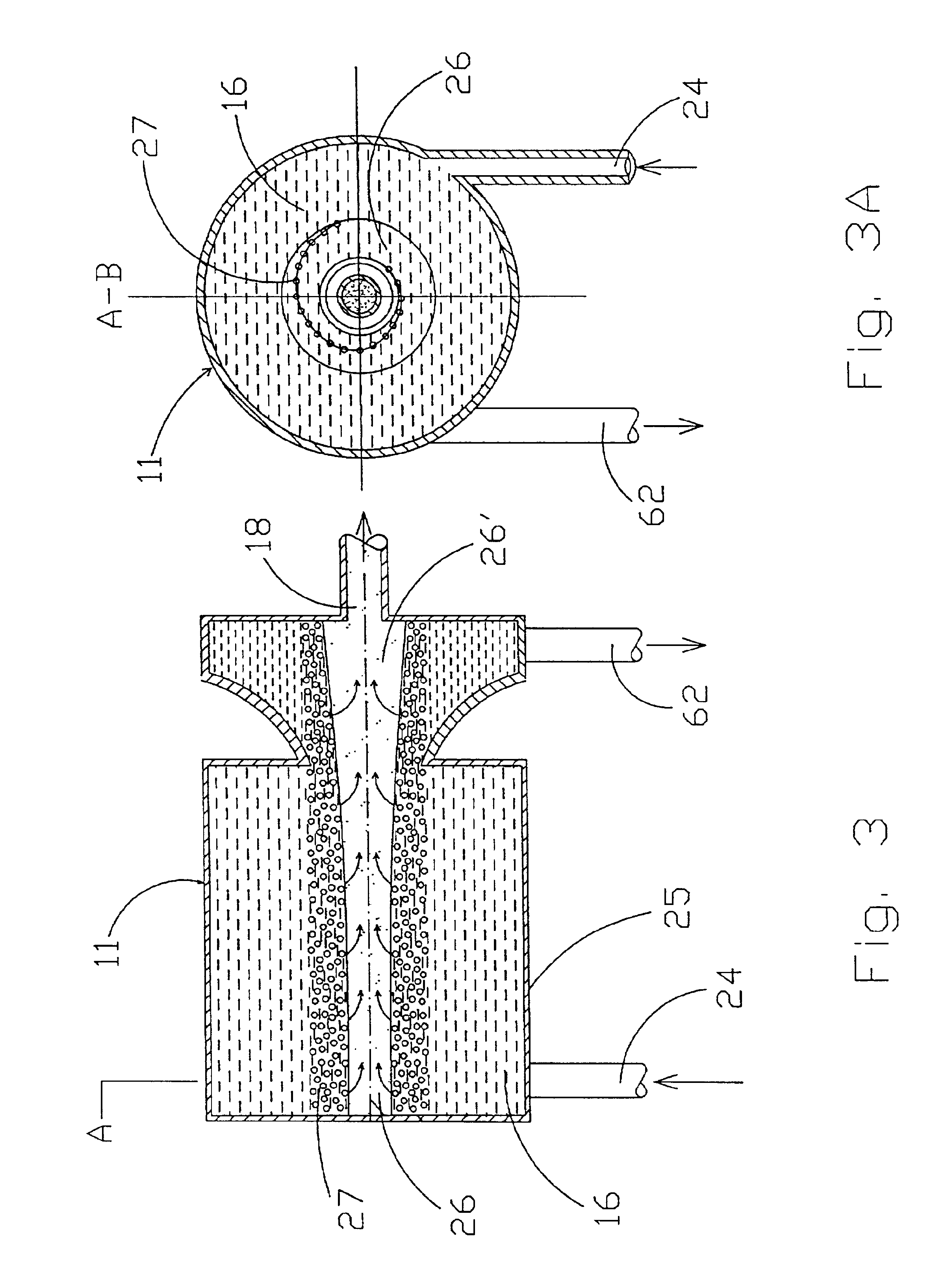

Lubrication system and method, and vortex flow separator for use therewith

An aircraft engine lubrication system has a vortex separator, a first pump line having a first pump, an inlet connected to a separated lubricant area at the outlet end of the separator, and an outlet connectable to the engine. A scavenge line is provided for returning lubricant from the engine to an inlet end of the separator. A lubricant tank is connected in fluid flow communication with the separator by a connection line. A second pump line having a second pump has an inlet connected to the lubricant tank and an outlet connected to the separator for pumping lubricant from the tank to the inlet end of the separator.

Owner:PRATT & WHITNEY CANADA CORP

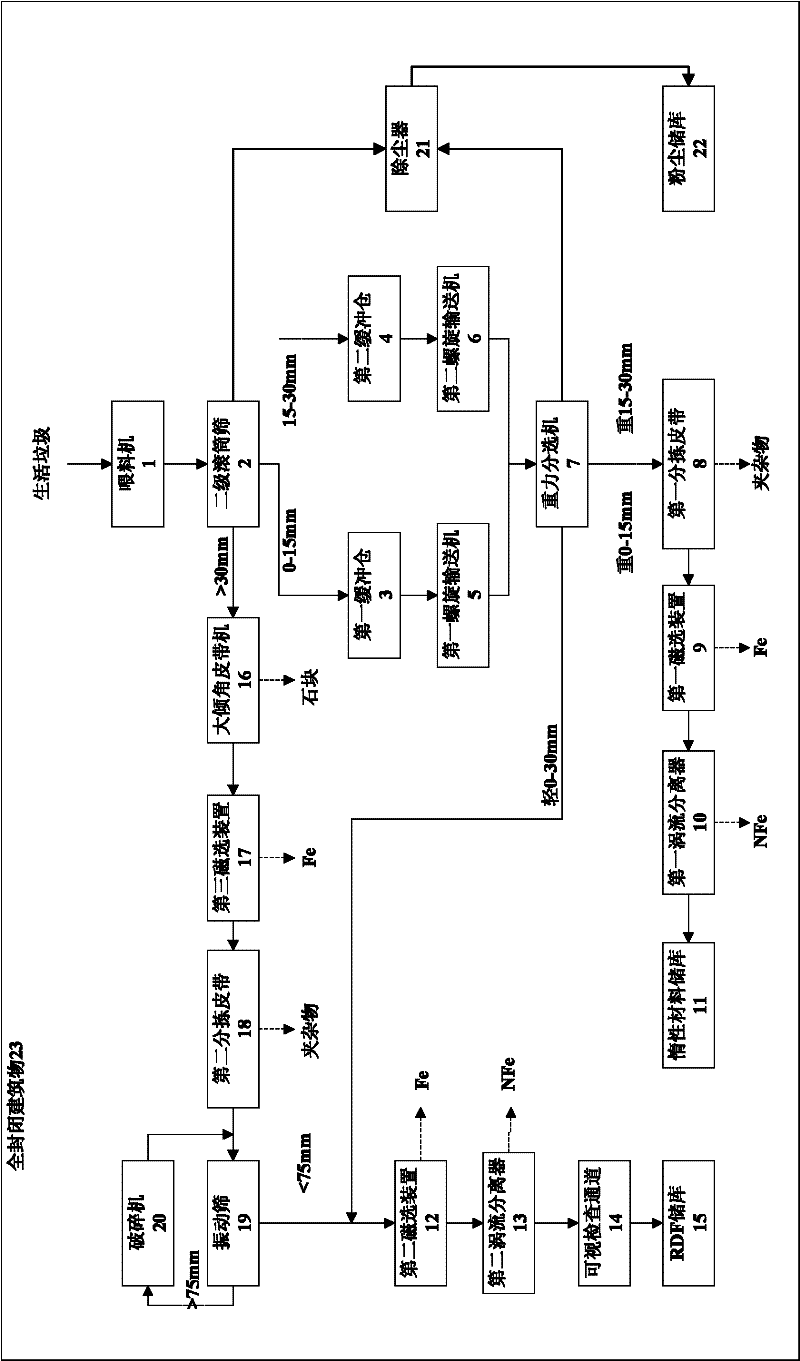

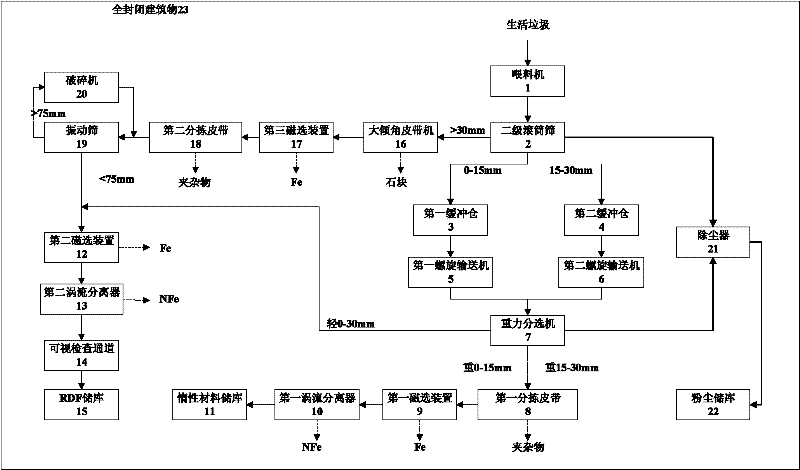

Municipal waste separation system

ActiveCN102189094AEfficient separationImprove working environmentSolid waste disposalSolid separationHazardous substanceEngineering

The invention relates to a municipal waste separation system. The municipal waste separation system is characterized by comprising a feeding machine, a secondary rotary screen, a first buffer bin, a second buffer bin, a first spiral conveyer, a second spiral conveyer, a gravity separator, a first sorting belt, a second sorting belt, a first magnetic separation device, a second magnetic separationdevice, a third magnetic separation device, a first vortex separation device, a second vortex separation device, an inert material storage hall, a resource description framework (RDF) storage hall, alarge-inclination-angle belt machine, a vibrating screen and a crushing machine. The separation system has high sorting efficiency, and can effectively separate combustible substances, insert components, ferrous metal / non-ferrous metal, and harmful substances in the pre-crushed and dried municipal waste to facilitate subsequent comprehensive utilization. The separation process is totally closed,remote operation and control is performed by using a computer, waste is not required to be directly contacted, the working environment of workers is improved, mechanization and automation are realized, and efficiency is improved.

Owner:华新环境工程有限公司

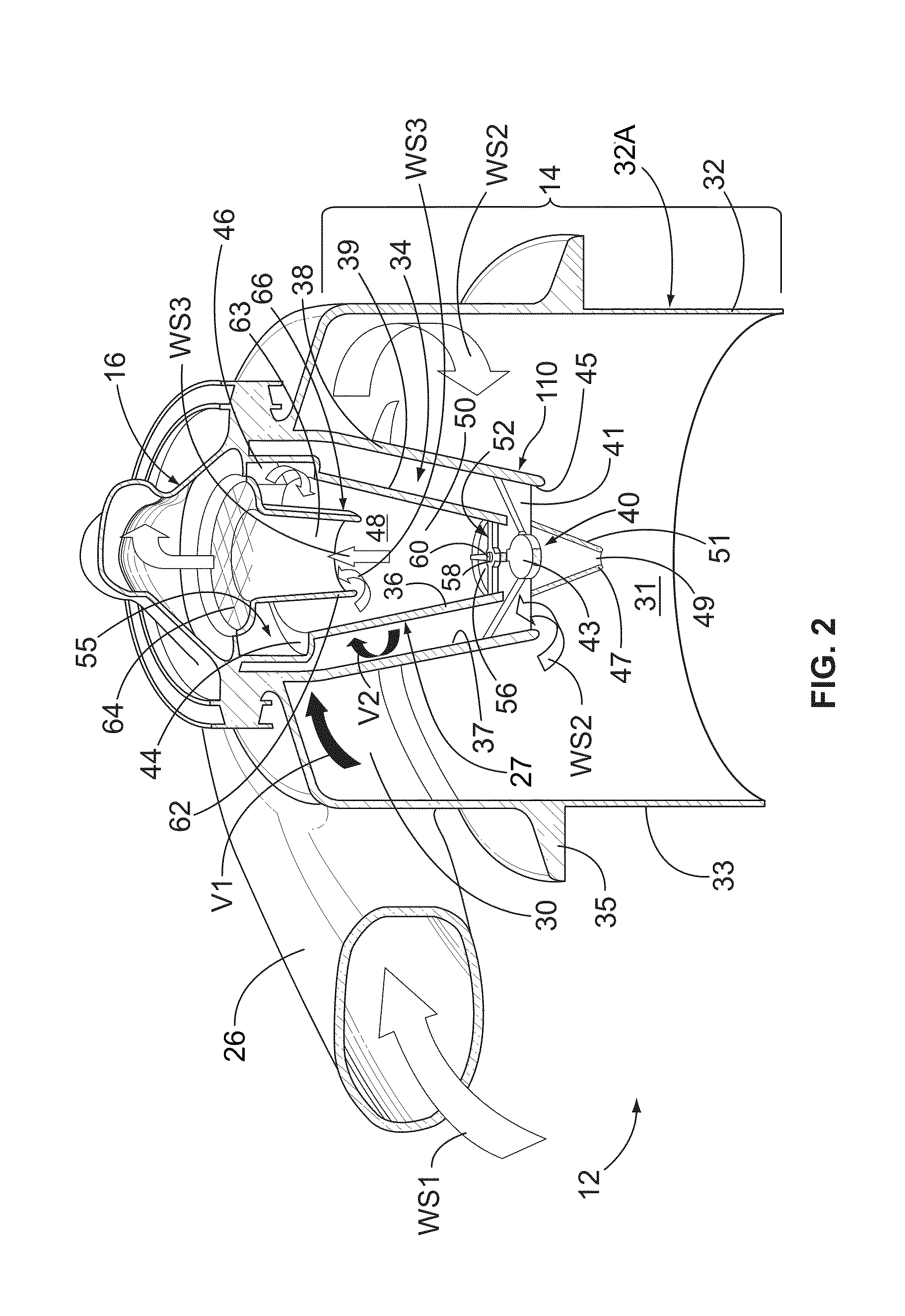

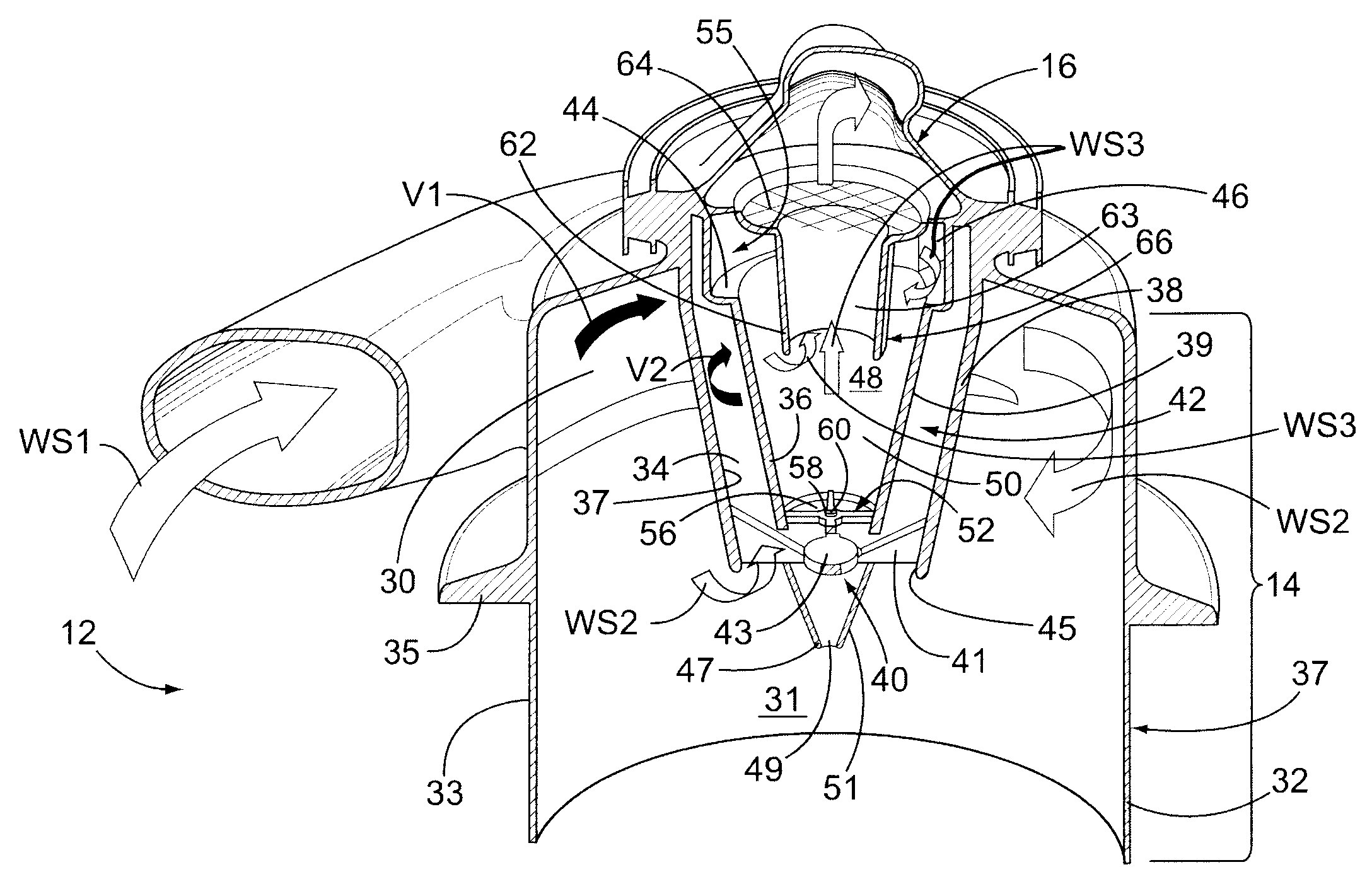

Multiple vortex waste separator apparatus

ActiveUS20100084352A1Combination devicesWater/sewage treatment by centrifugal separationEddy current separatorWaste stream

A multiple vortex separator for drawing a substantially moisture-free airstream from a waste stream having an annular channel defining a first vortex flow path for separating liquid and solid waste from this waste stream and an inverted conical cavity between nested inverted cones defining a second vortex flow path that is isolated from the first vortex flow path for separating additional liquid and solid waste from the waste stream before it exits the vortex separator.

Owner:BE AEROSPACE INCORPORATED

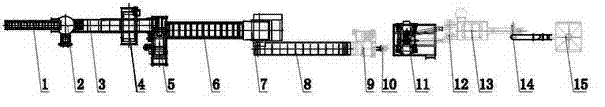

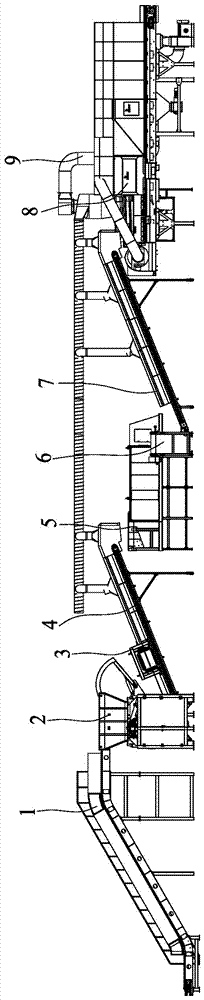

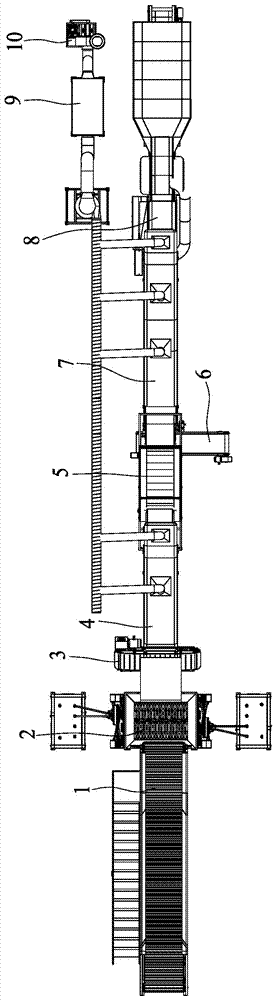

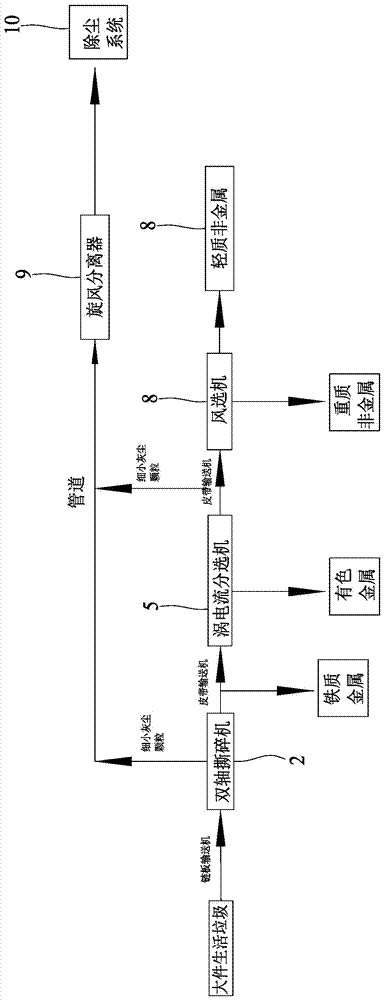

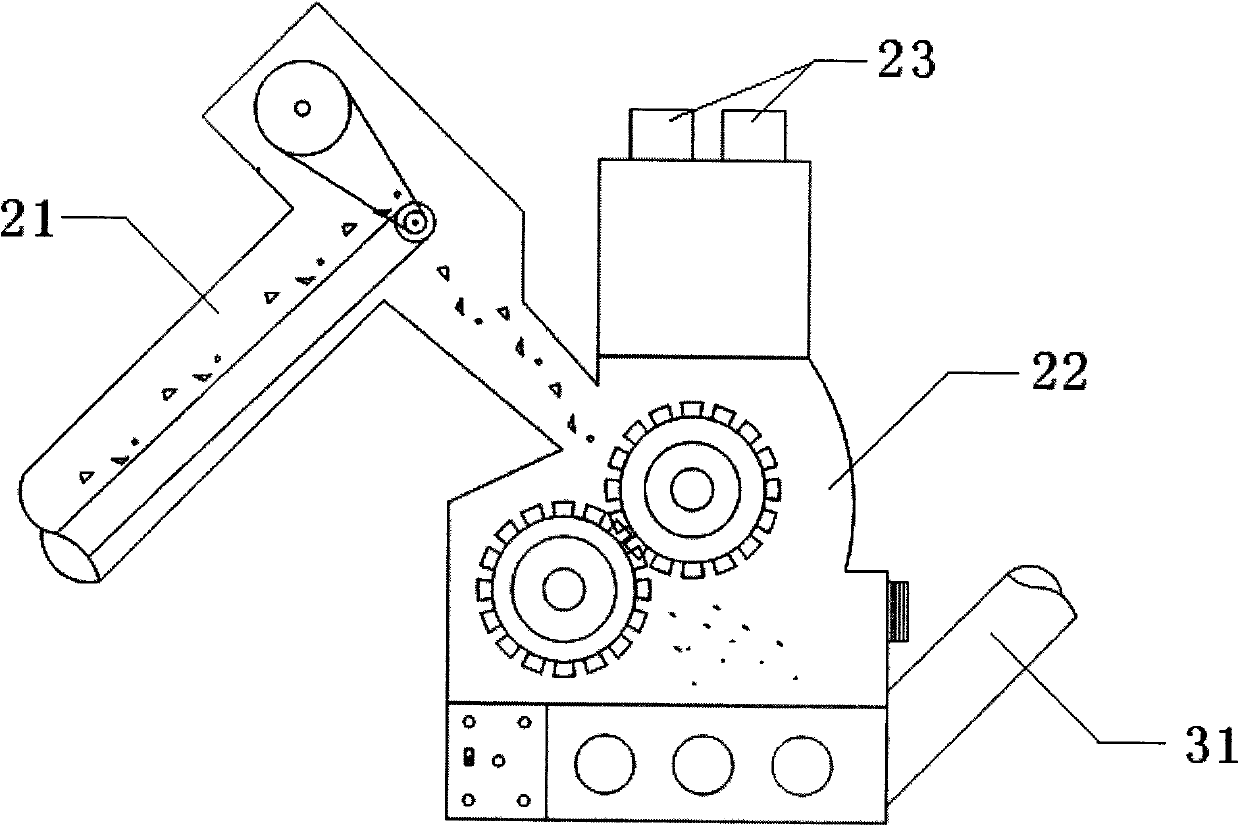

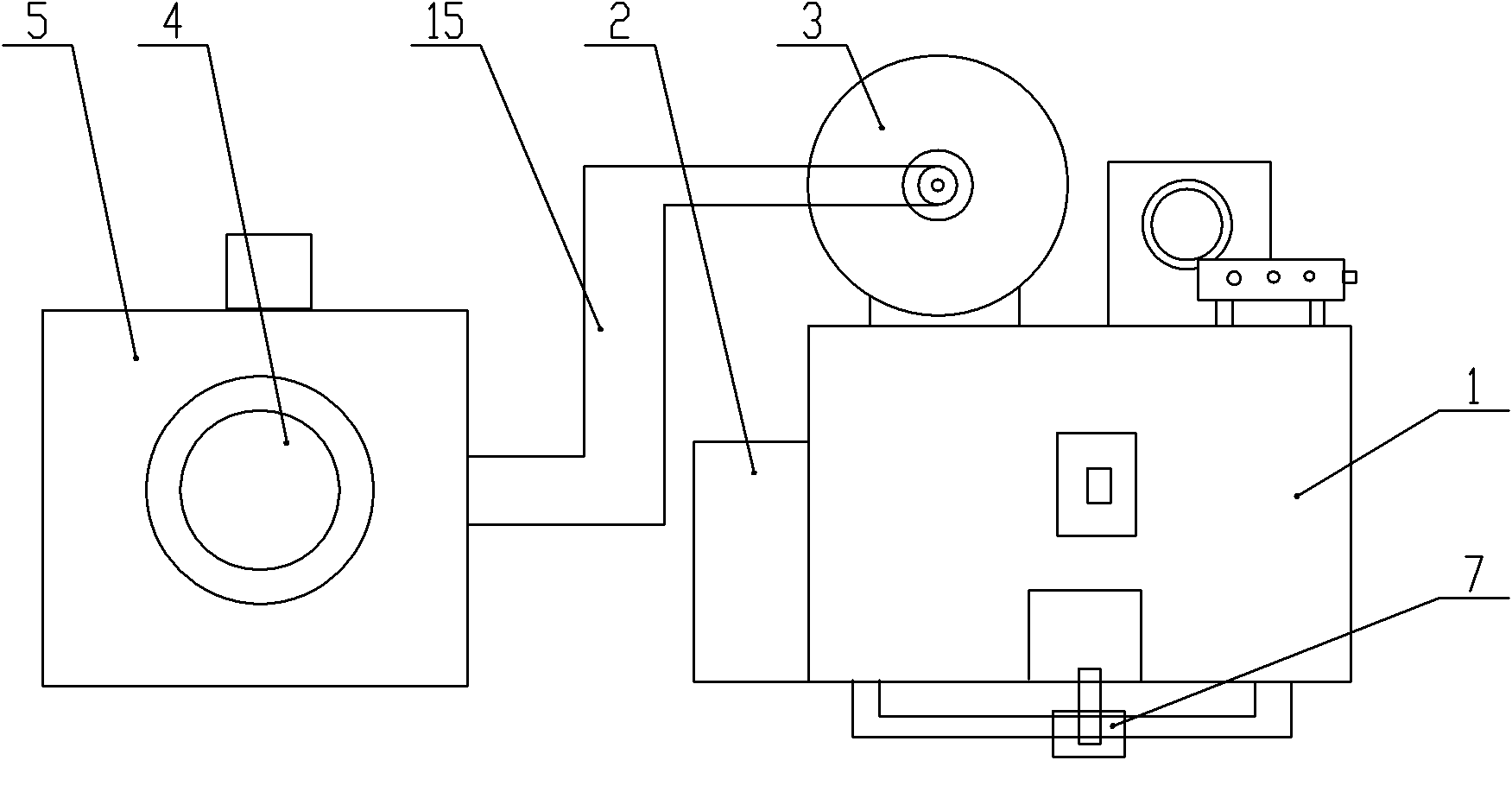

Large-sized garbage crushing and separating equipment and process

PendingCN106903138ASmall sizeRealize automatic sortingTransportation and packagingSolid waste disposalEddy current separatorAir classifier

The invention discloses large-sized garbage crushing and separating equipment and process. The large-sized garbage crushing and separating equipment comprises a chain scraper conveyor, a double-shaft shredder, a first belt conveyor, a magnetic separator, an eddy current separator, a discharged material belt conveyor, a second belt conveyor, an air classifier, a cyclone separator and a dust collector. The chain scraper conveyor, the double-shaft shredder, the first belt conveyor, the eddy current separator, the second belt conveyor and the air classifier are sequentially connected; the magnetic separator is mounted above the first belt conveyor; and the feeding end of the discharged material belt conveyor is connected with non-ferrous metal discharged by the eddy current separator. Large-sized household garbage can be treated by the chain scraper conveyor and the double-shaft shredder, crushed materials can be automatically separated by the magnetic separator and the eddy current separator, and dust produced in the crushing process can be efficiently treated by the cyclone separator and the dust collector, so that no secondary pollution is caused.

Owner:HUANCHUANG XIAMEN TECH

Multiple vortex waste separator apparatus

ActiveUS7998250B2Water/sewage treatment by centrifugal separationCombination devicesEddy current separatorWaste stream

Owner:BE AEROSPACE INCORPORATED

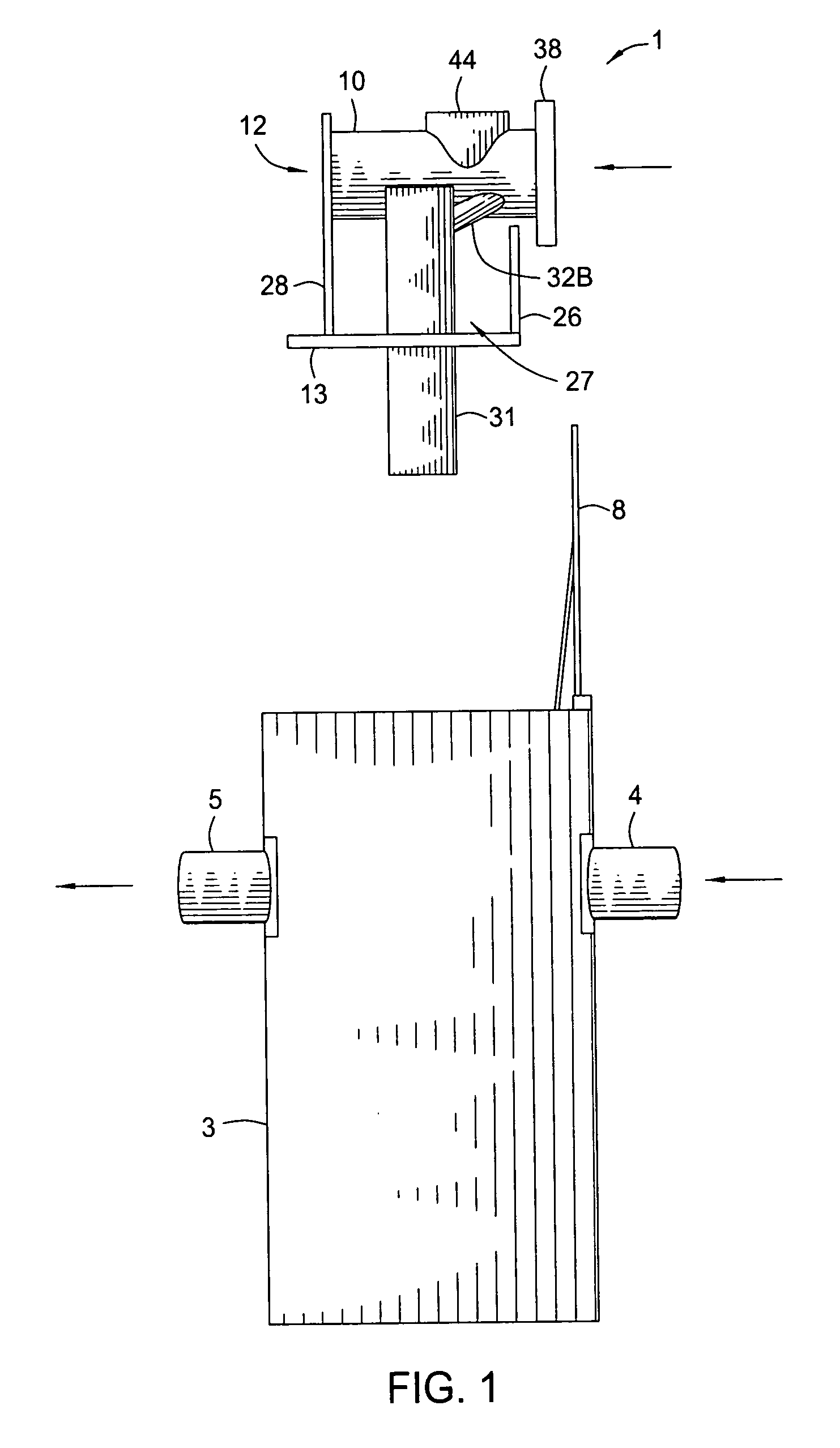

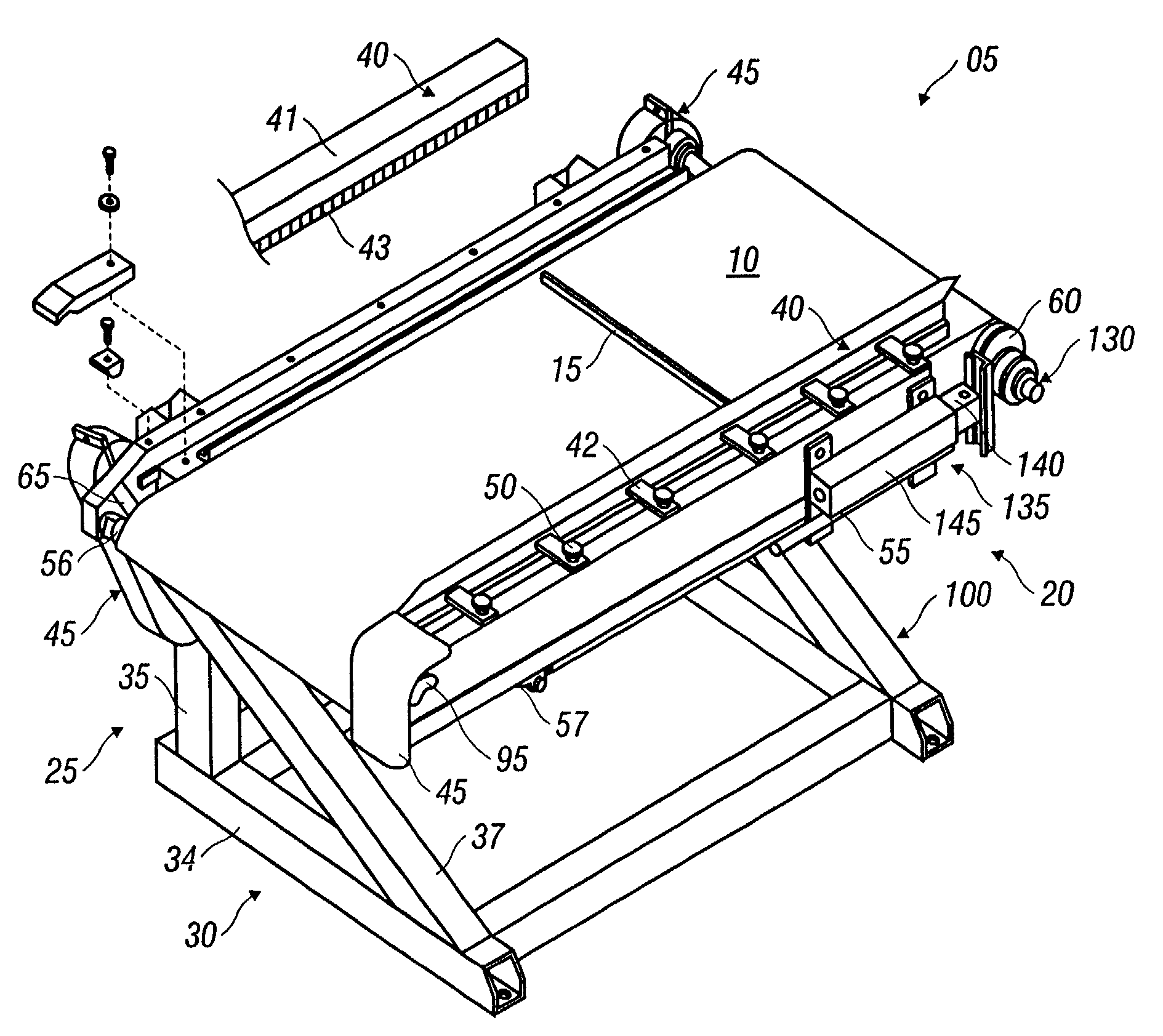

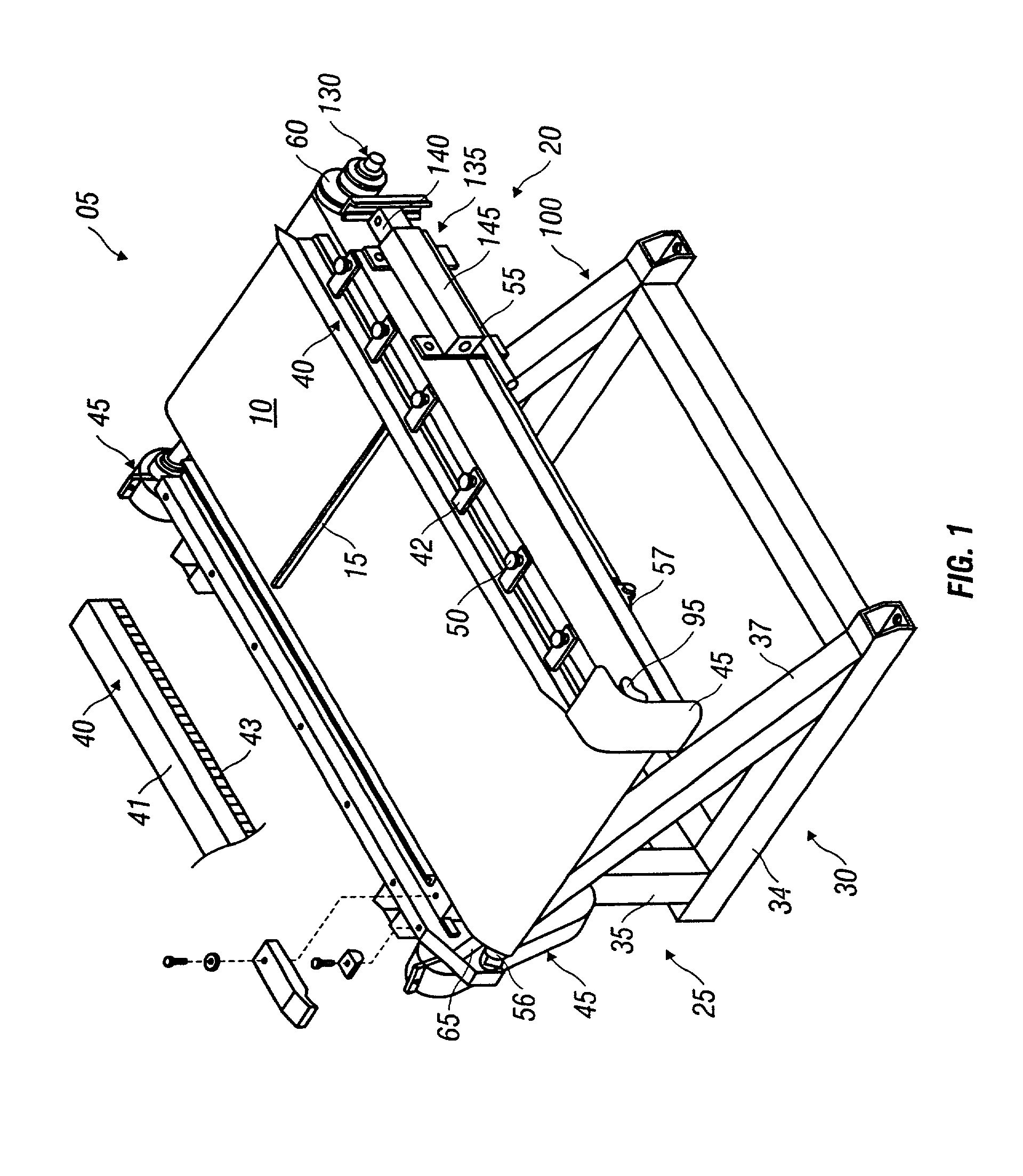

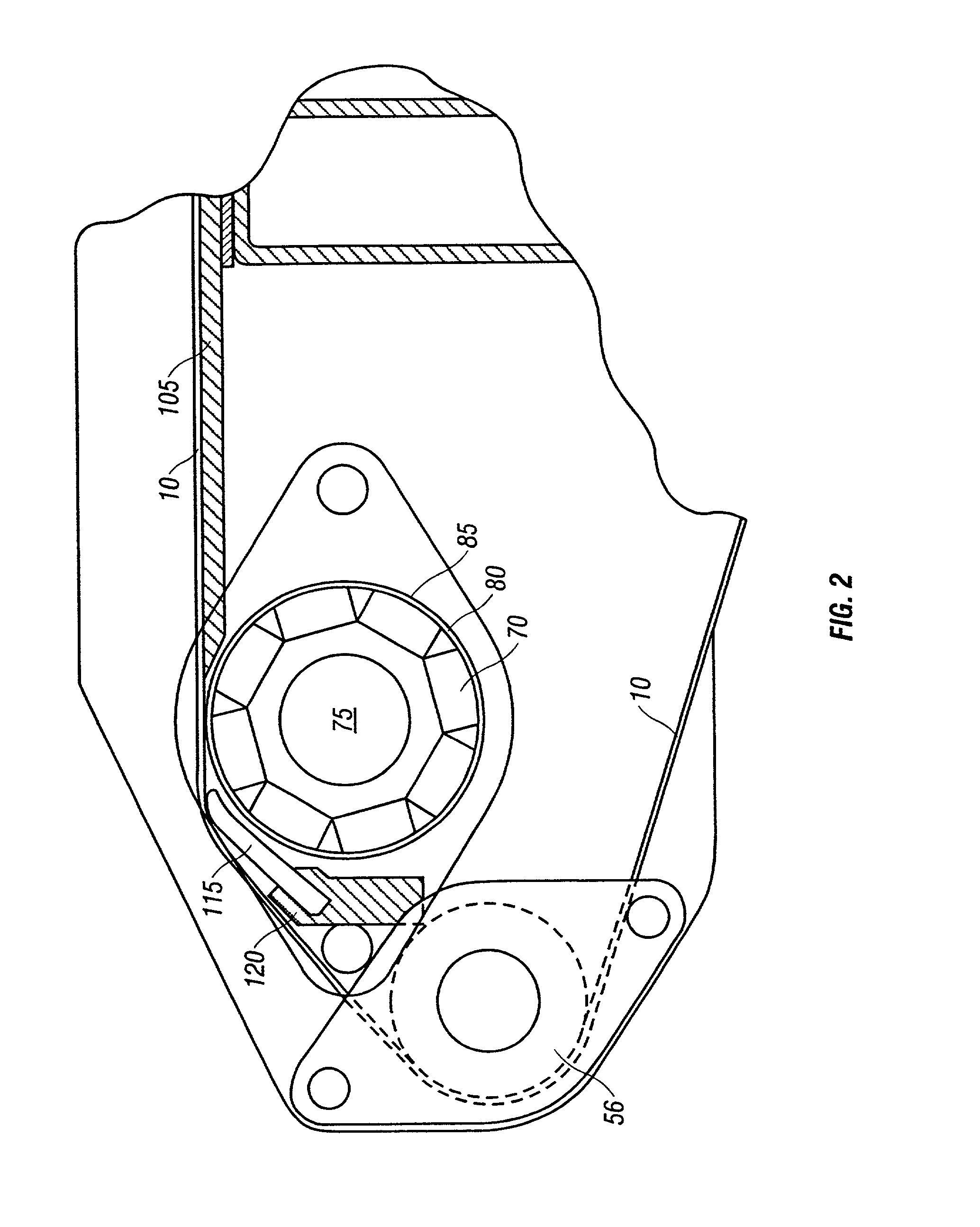

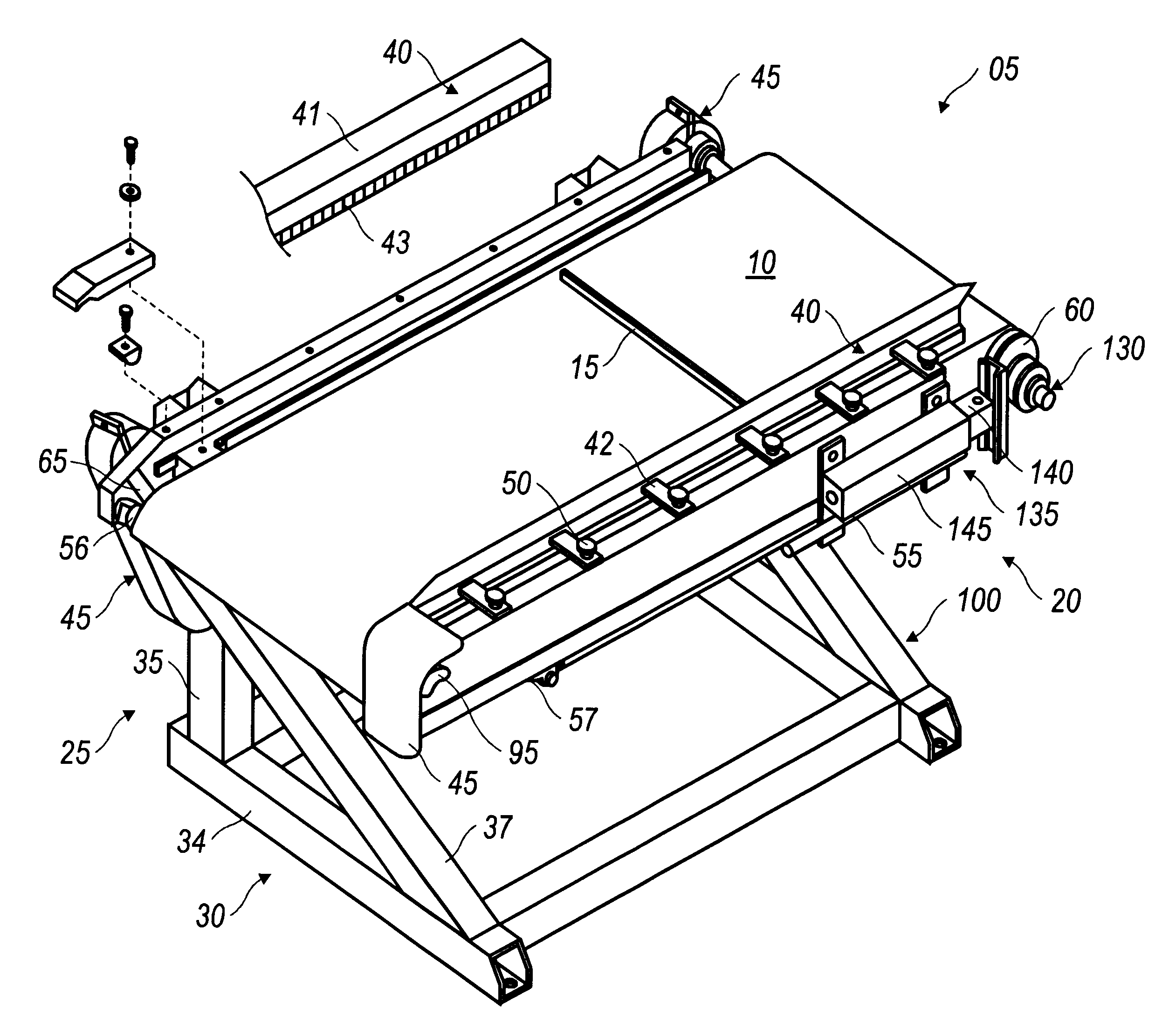

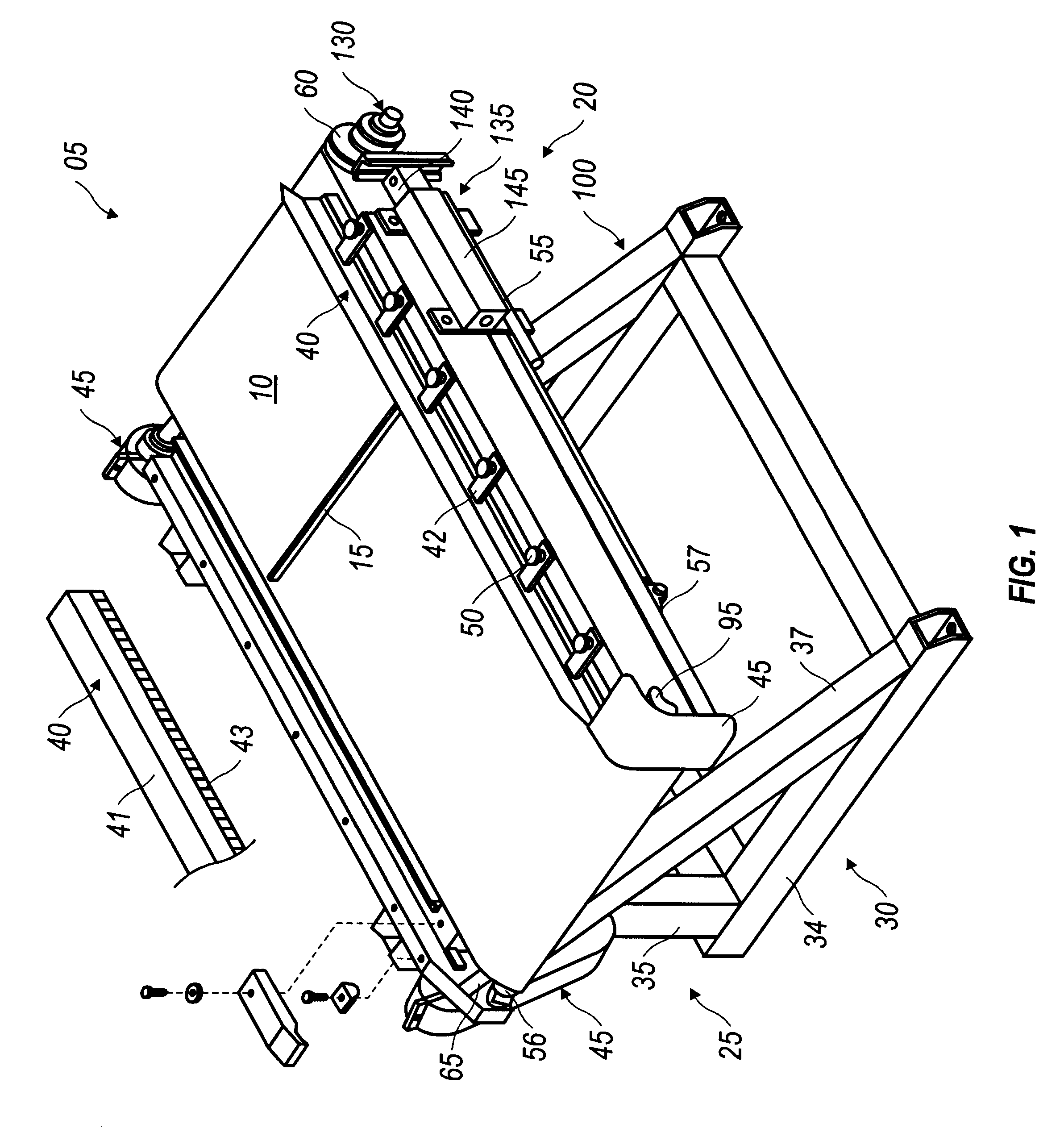

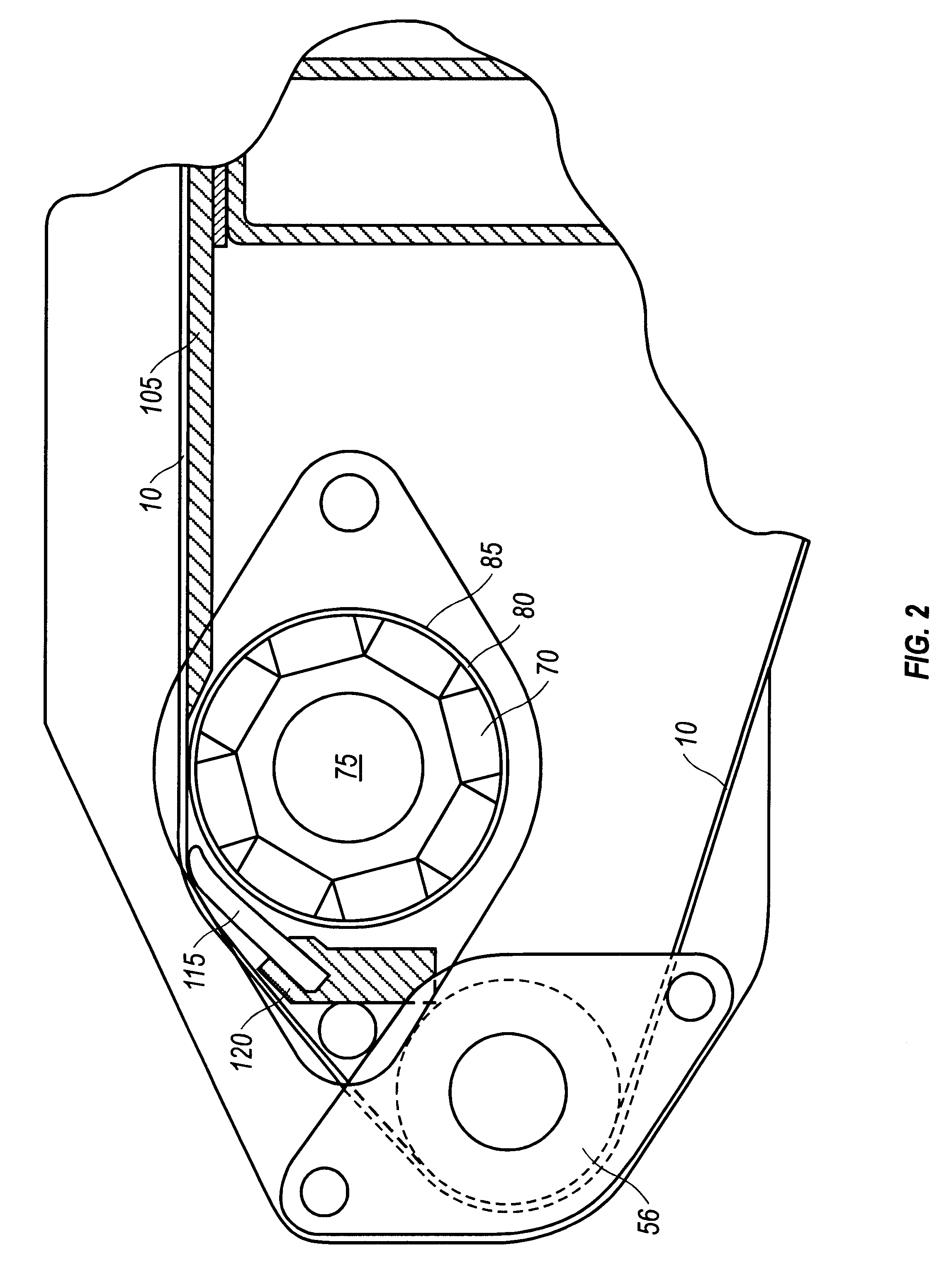

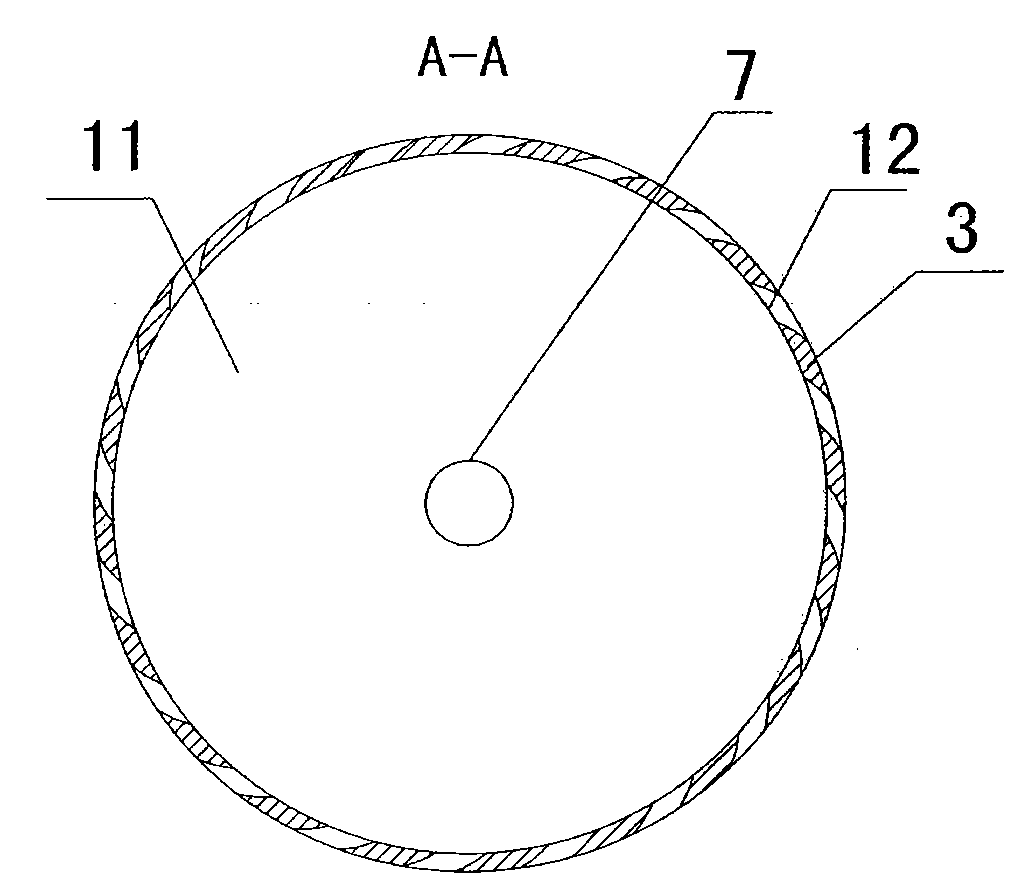

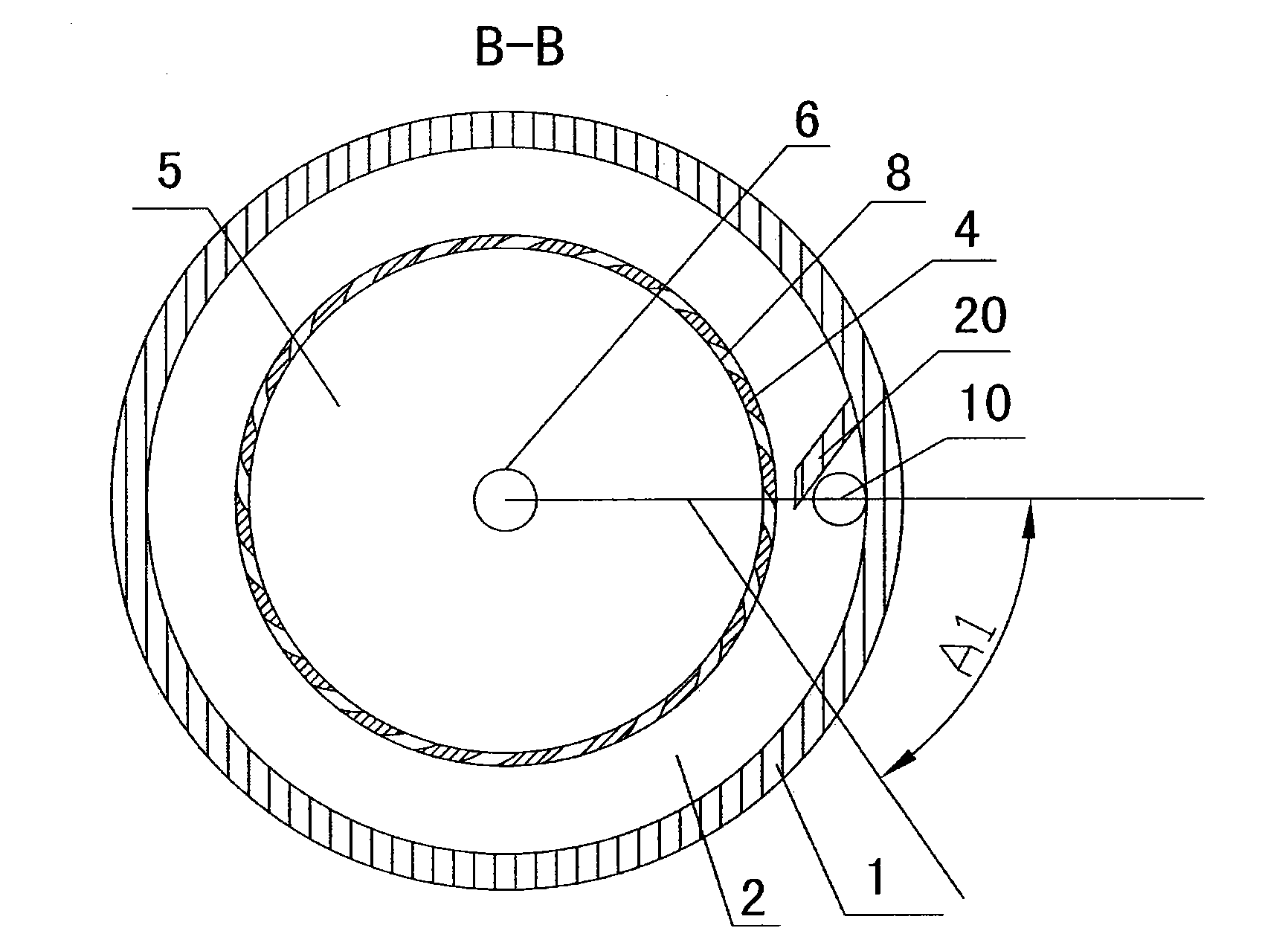

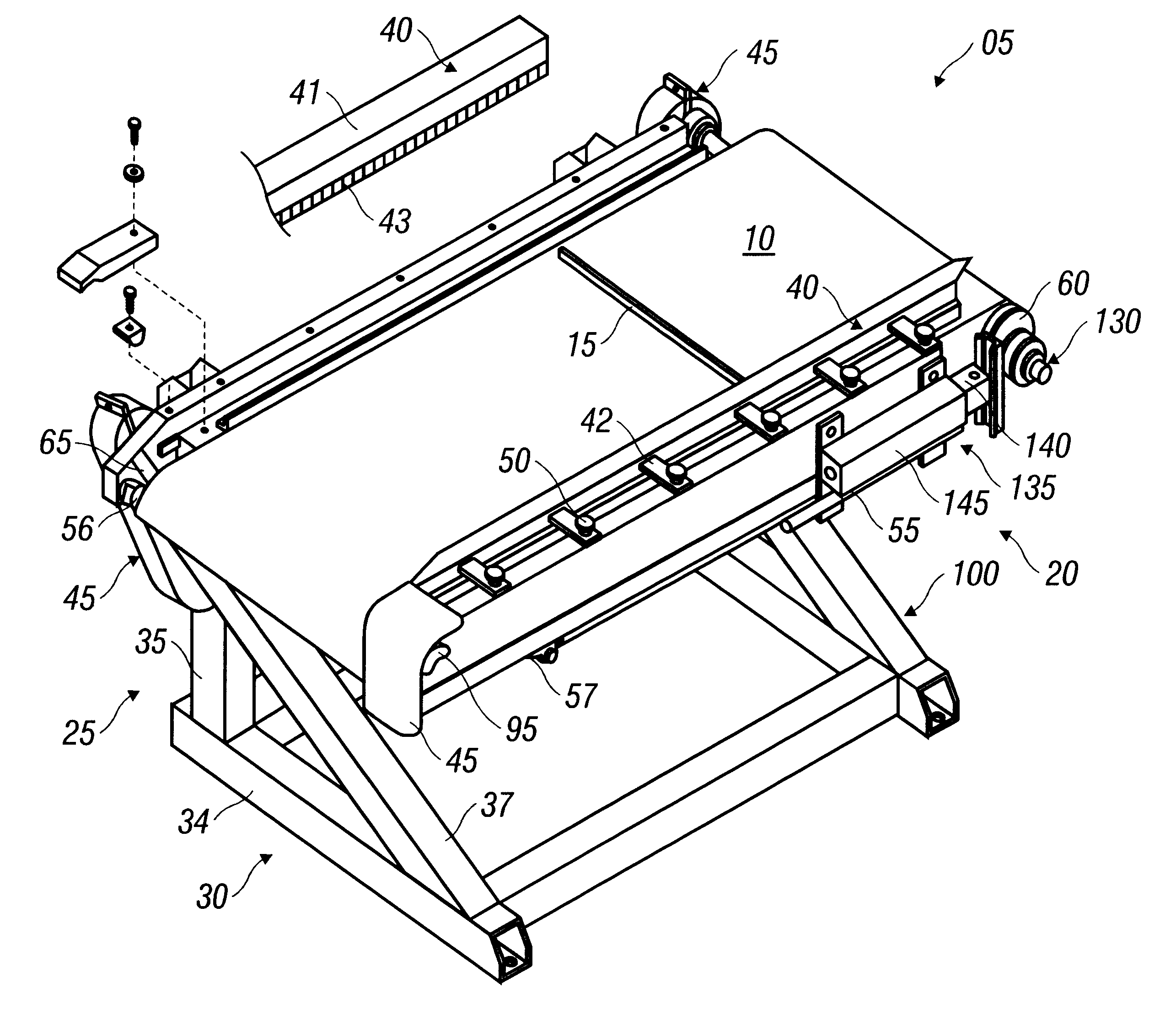

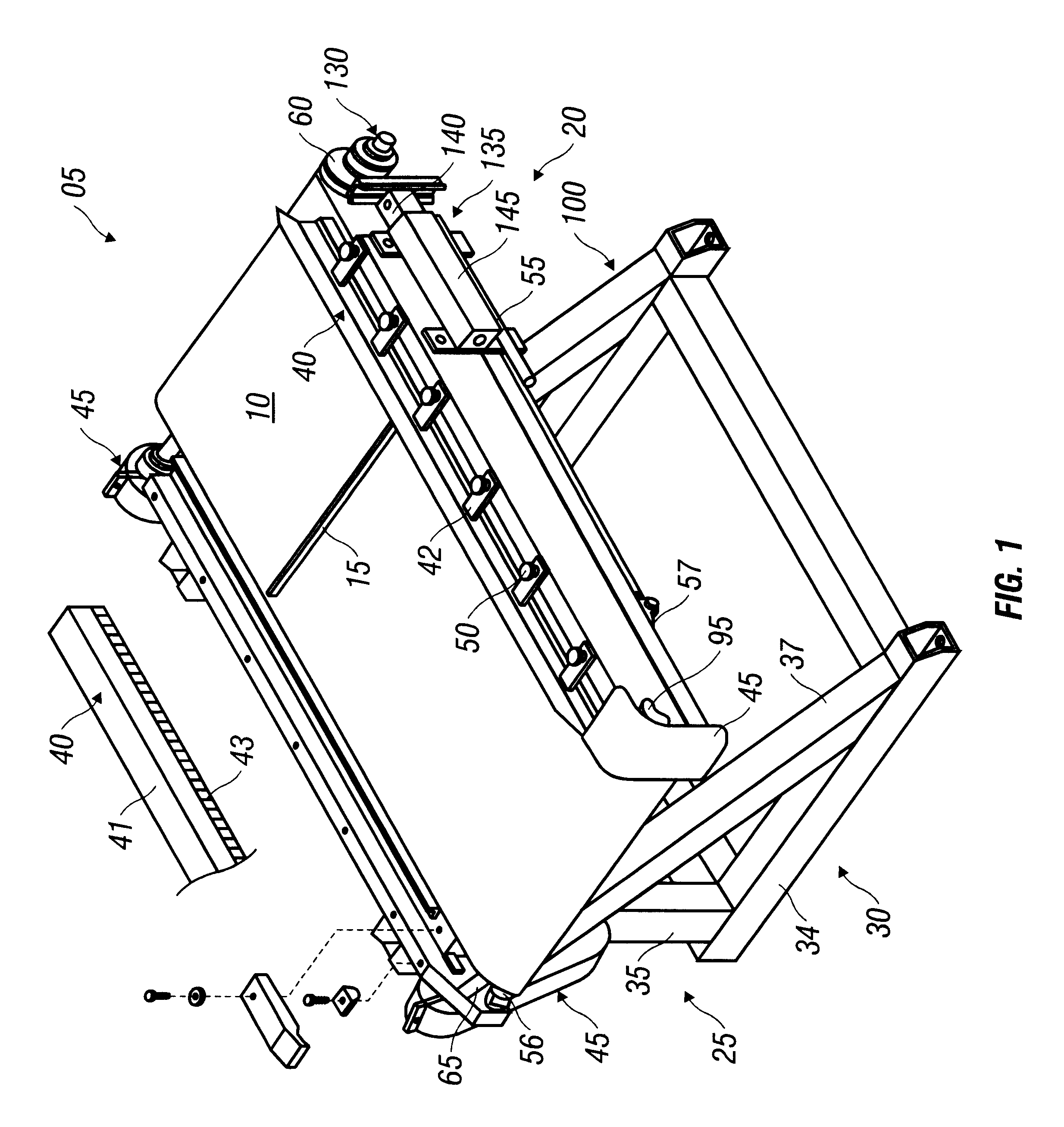

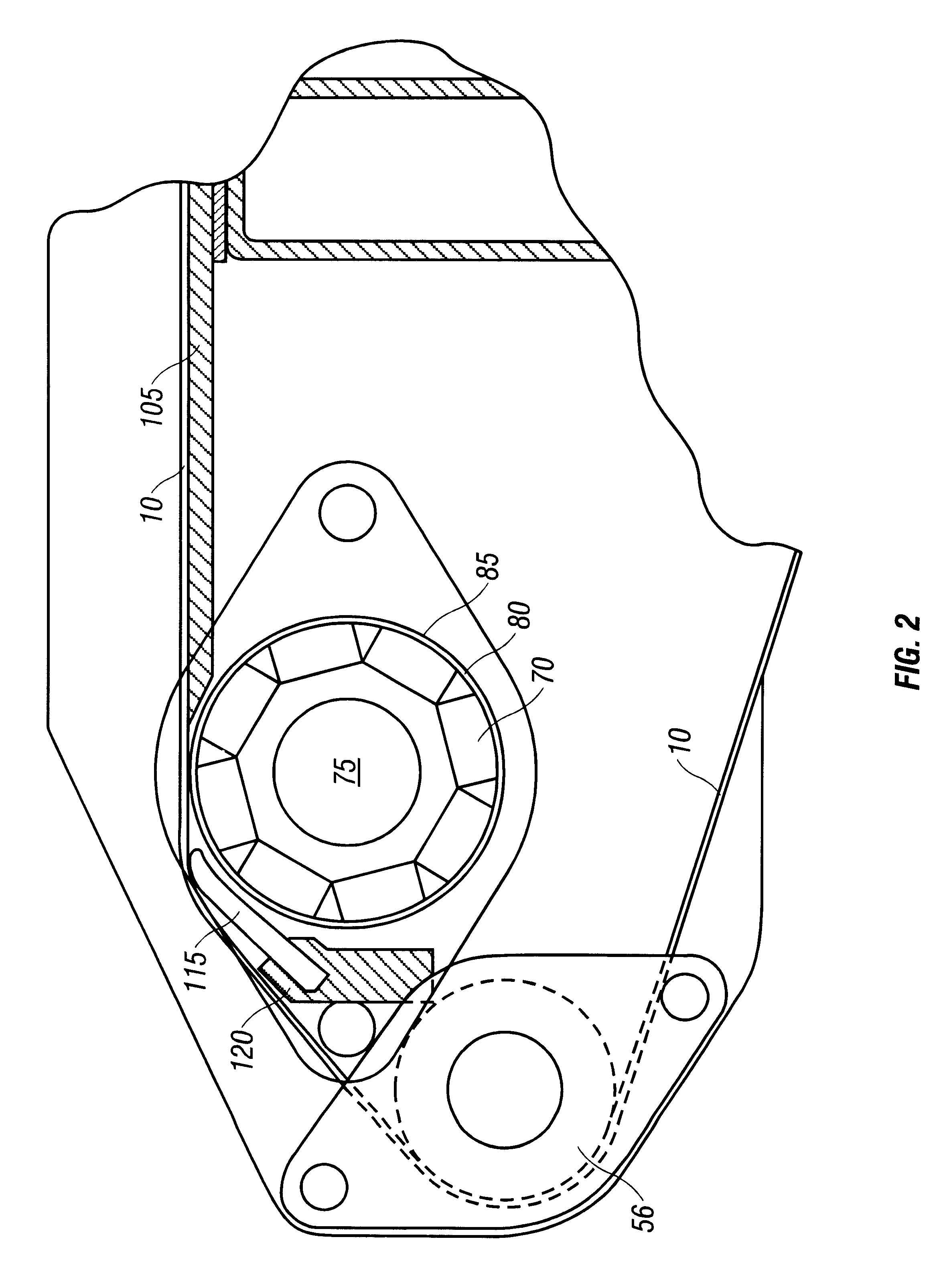

Magnetic separator

An eddy current separator apparatus for separating non-ferrous metals from other materials. The apparatus includes a support frame and a table cantileverly suspended from the frame. An expansion and contraction mechanism is incorporated that is adapted to accept a continuous conveyor belt thereabout. The expansion and contraction mechanism is capable of being configured between an operating configuration and maintenance configuration. A continuous conveyor belt is constructed to be able to be looped about the expansion and contraction mechanism and the table such that the conveyor belt is drawn tight in the operating configuration and slackened in the maintenance configuration. In this manner, the continuous conveyor belt is easily removable from, and installable onto the table in the maintenance configuration. A magnetic rotor is positioned proximate a first side of the continuous conveyor belt and is adapted to generate an eddy current on an opposite second side of the continuous conveyor belt upon rotation for inducing an elevating force in non-ferrous metals for separation from other materials.

Owner:HOWELL BILLY R

Waste battery recycling system and recycling method

ActiveCN104183855AEffective Environmental RecyclingEffective resource recyclingReclaiming serviceable partsBattery recyclingEddy current separatorProcess engineering

The invention discloses a waste battery recycling system and a recycling method. The system and method are as below: the waste dry batteries are subjected to two crushing to obtain components of powdered carbon, paper, film, plastics, carbon rods, iron, zinc and copper; the components are dried and have mercury removed, and sent into a vibration sieve to separate powdered carbon; the remaining components are sent into a vibration sieve in a next device; at the same time a blower and a suction fan are arranged on both sides of the vibration sieve in a line, so that lighter components containing paper, film and plastics are blown into a storage barrel and a space bag, and remaining iron, carbon rods, zinc and copper are sent into a conveyor belt of a magnetic separation device to isolate the iron; the remaining carbon rods, zinc and copper are crushed by a biaxial crusher; the carbon rods are crushed into powdered carbon, which is separated and sent into the space bag; and the remaining zinc and copper are sent into an eddy current separator for separation. The invention can carry out effective and environment-friendly recycling, harmless treatment and recycling on waste batteries, and realizes a self existence and continuously fixed recycling mode of resources.

Owner:深圳市泰力废旧电池回收技术有限公司

System for thermal and catalytic cracking of crude oil

InactiveUS6936230B2Simplify System DesignReduce metal contentThermal non-catalytic crackingCatalytic crackingDistillationVapor generator

In this invention the system and processes for organization of oil refinery from gases and heavy admixtures with a separation of purified oil for fractions obtained in the process of thermal distillation, and thermal and catalytic cracking and subsequent fine separation of products for narrow fractions are presented. The combining of vortex vapor generation processes of preliminary heated oil in the field of inertia forces of rotating liquid with condensation processes of gaseous products at reduced pressure in vortex vapor condensers with cooled walls with utilization of subsequent heating and productions of fuels with narrow fraction composition permits to obtain a high quality product. New types of vortex devices are presented: the vortex separator of oil from water and admixtures, the vortex vapor generator for production of fine vapor fractions, the vortex vapor condenser for condensation of vaporized fractions, the vortex vapor generator in a catalyst layer moving in a boiling layer, which is a catalytic reactor with a regulated contact time between a catalyst and a boiling layer. A two-zone combustion furnace helps to decrease energy spending, improves combustion completeness.

Owner:ZHURIN VIACHESLAV V

Magnetic separator

InactiveUS6478161B2Cost-effective to produceCost-effective to operateConveyorsMagnetic separationEddy current separatorEngineering

An eddy current separator apparatus for separating non-ferrous metals from other materials. The apparatus includes a support frame and a table cantileverly suspended from the frame. An expansion and contraction mechanism is incorporated that is adapted to accept a continuous conveyor belt thereabout. The expansion and contraction mechanism is capable of being configured between an operating configuration and maintenance configuration. A continuous conveyor belt is constructed to be able to be looped about the expansion and contraction mechanism and the table such that the conveyor belt is drawn tight in the operating configuration and slackened in the maintenance configuration. In this manner, the continuous conveyor belt is easily removable from, and installable onto the table in the maintenance configuration. A magnetic rotor is positioned proximate a first side of the continuous conveyor belt and is adapted to generate an eddy current on an opposite second side of the continuous conveyor belt upon rotation for inducing an elevating force in non-ferrous metals for separation from other materials.

Owner:HOWELL BILLY R

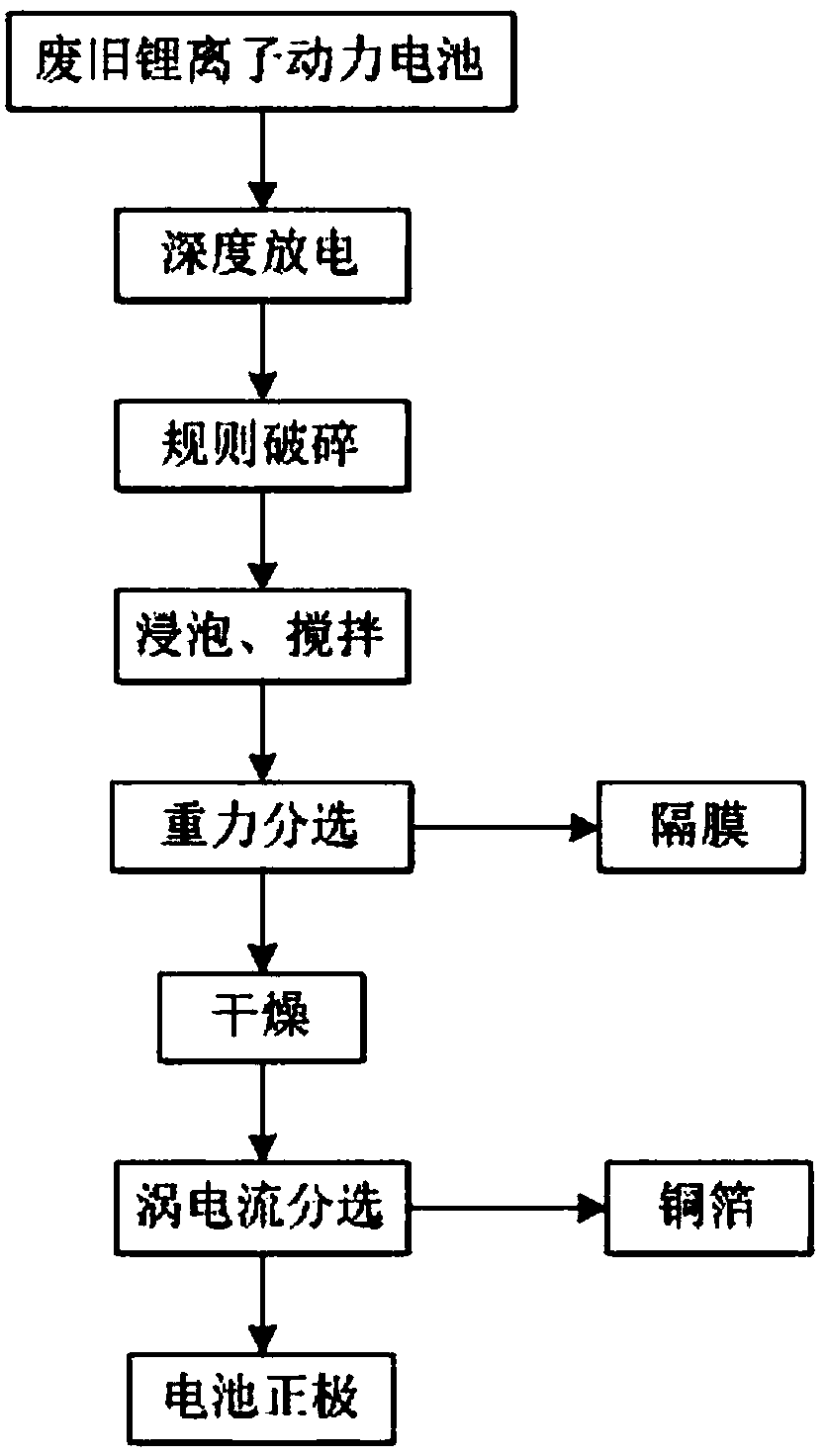

Method for recovering separator, copper foil and battery positive pole from waste lithium-ion power battery

InactiveCN109904545AEasy to separateFacilitate subsequent separation and recoveryWaste accumulators reclaimingBattery recyclingPower batteryLithium

The invention discloses a method for recovering a separator, a copper foil and a battery positive pole from a waste lithium-ion power battery. The method comprises the following steps that (1) discharging of the waste lithium-ion power battery is performed at 15-40 DEG C, and the voltage of the waste lithium-ion power battery is reduced to 0.01-0.5V; (2) the battery after discharging is sheared and broken into a geometrically regular shape by using a shearing crusher; (3) the obtained regular battery fragments are immersed in water and stirred, and after stirring is performed, the regular battery fragments are sieved; (4) the obtained oversize product is placed in a gravity separator, the separator is separated from the copper foil and the battery positive pole, and the separator is recovered; and (5) the obtained copper foil and battery positive pole are dried and then placed in an eddy current separator to separate and recover the copper foil and the battery positive pole. The methodis easy in realization of industrialization, low in recovery cost and high in product recovery rate, and does not pollute the environment.

Owner:有研资源环境技术研究院(北京)有限公司

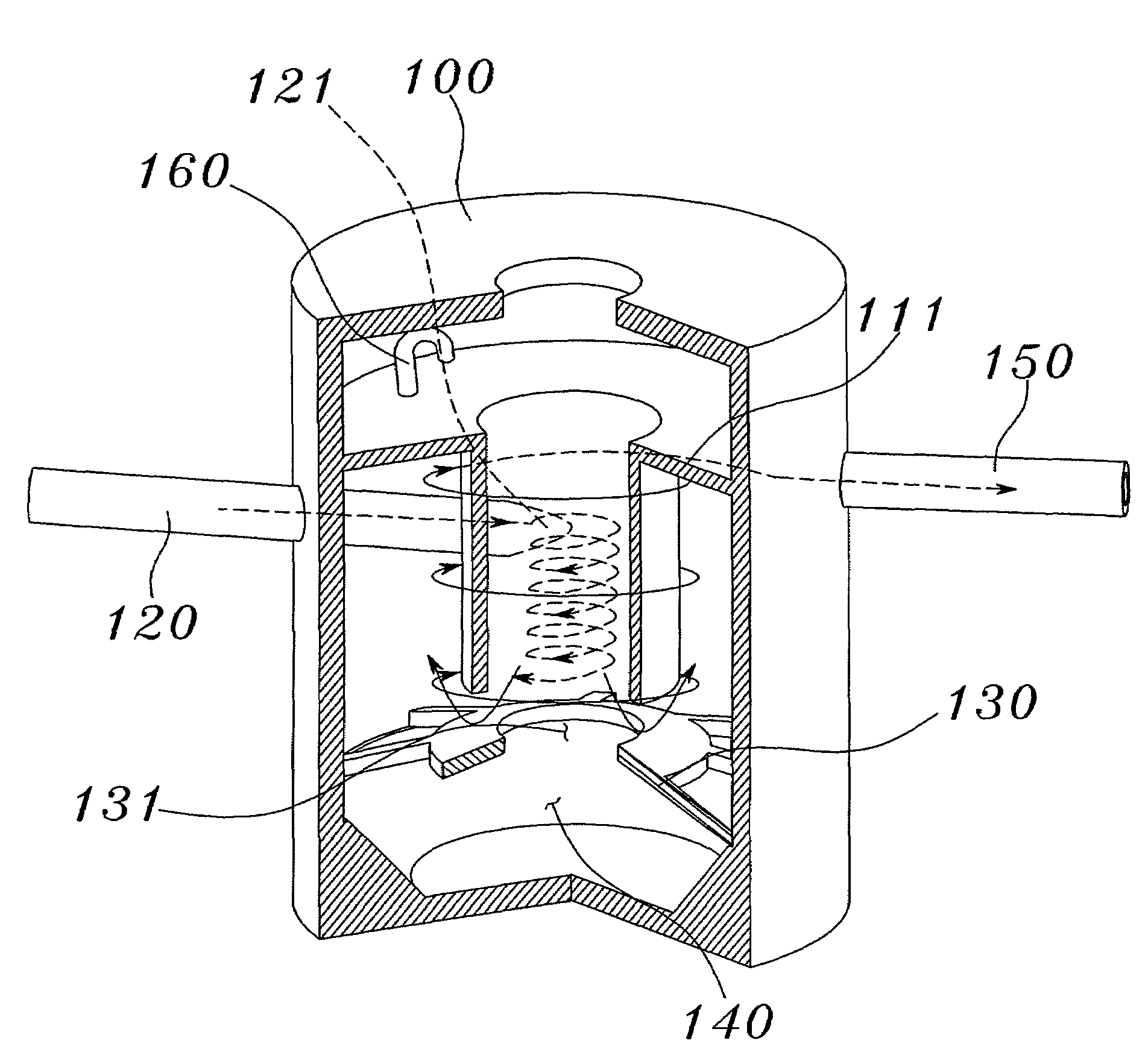

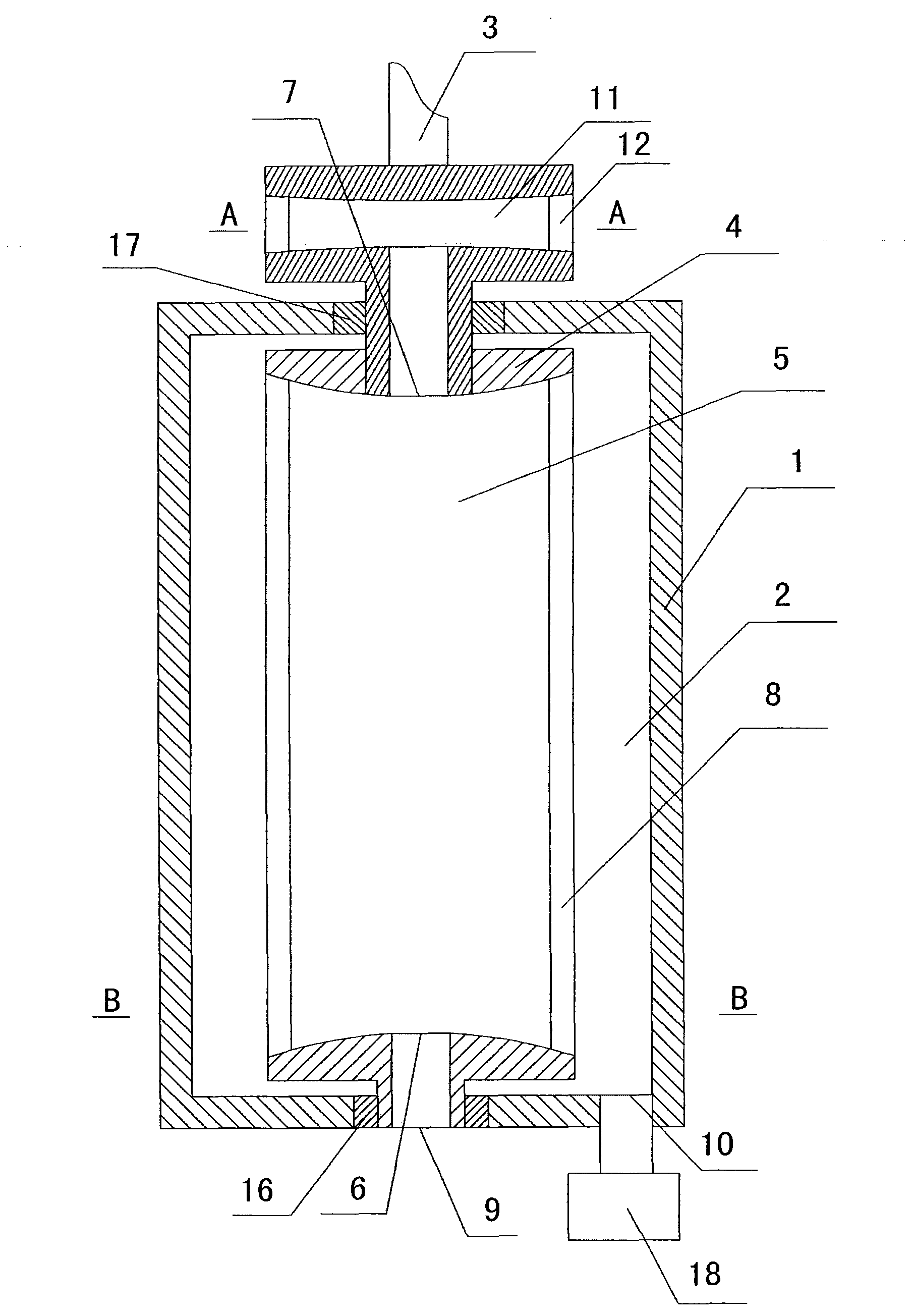

Whirlpool separator

InactiveCN101875027ASolve the emission problemSolve energy problemsCentrifugesWater desalinationChemical industry

A whirlpool separator is composed of a casing and a drive shaft, wherein the casing is internally provided with a casing cavity and the drive shaft; the casing cavity is internally provided with a whirlpool wheel connected with the drive shaft; the whirlpool wheel is internally provided with a whirlpool chamber the middle of which is provided with a whirlpool chamber inlet, and the periphery of the whirlpool chamber is provided with a whirlpool chamber outlet; and the casing cavity is provided with a casing cavity inlet arranged corresponding to the whirlpool chamber inlet, and the casing cavity is provided with a casing cavity outlet. The whirlpool separator in the invention adopts a brand new separation principle and a method, makes full use of circular motion and fluid motion, and utilizes a whirlpool the rotation speed of which increases from the periphery to the center progressively to separate the fluid therein. The invention can be widely applicable to the fields of sewage treatment, refuse treatment, oredressing, sea water desalination, ocean chemical industry, hydrogen production, oxygen production, nano material manufacture, carbon dioxide decomposition, harmful gas decomposition, air conditioning, refrigeration, reactor, oil refining, air purification, dust abatement, dust absorption and the like, can provide inexhaustible clean energy, can thoroughly solve the energy problem and leads to industrial revolution in various industries.

Owner:陈久斌

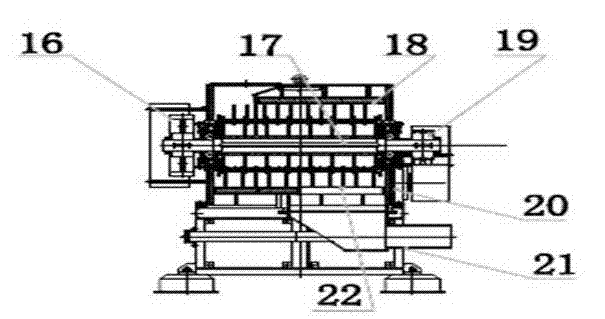

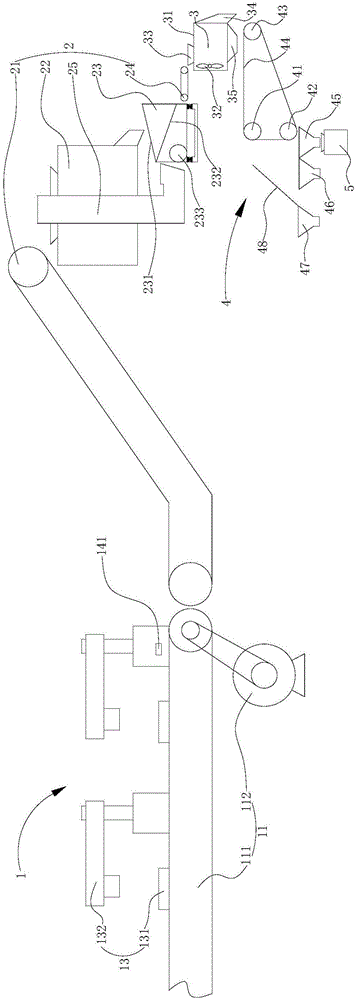

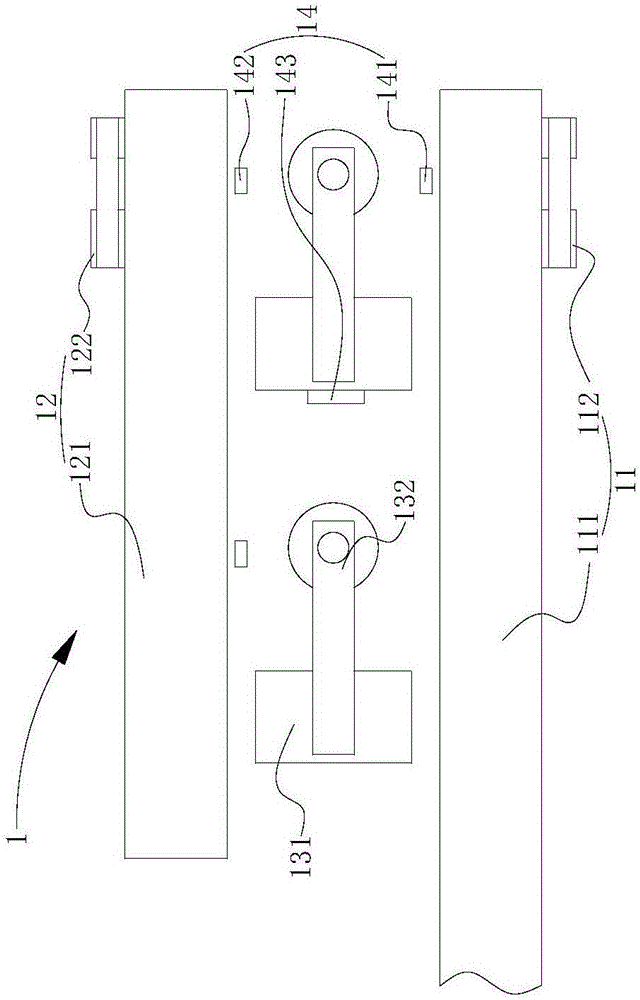

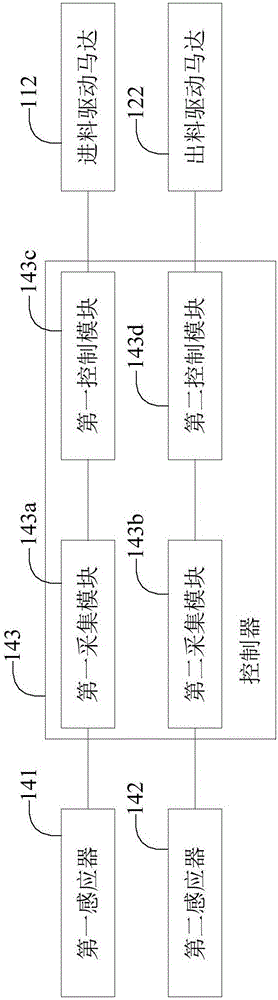

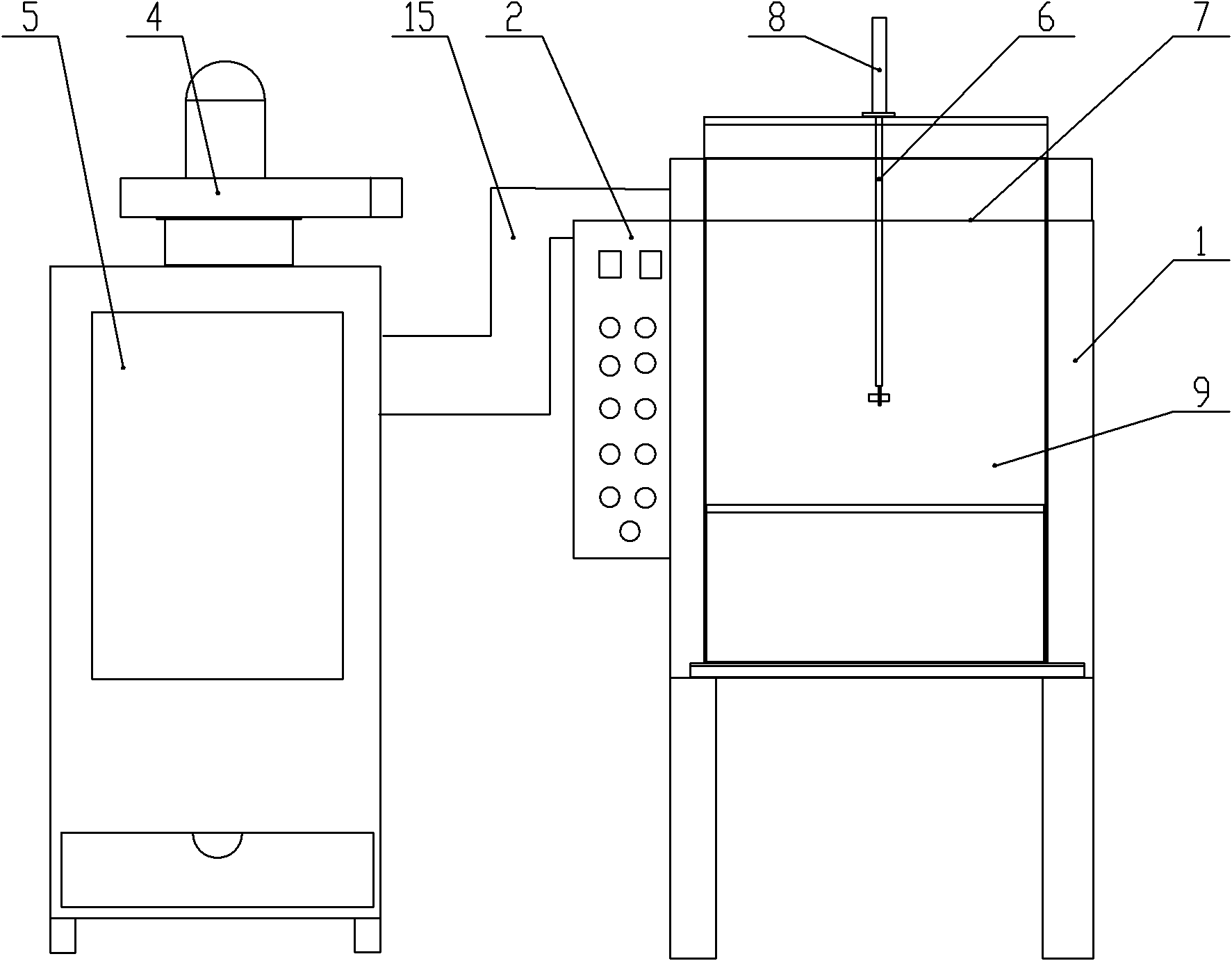

Automatic waste household appliance disassembling system

ActiveCN106824981ASystematizeImprove resource recovery efficiencySolid waste disposalEddy current separatorMagnetic separation

The invention discloses an automatic waste household appliance disassembling system which comprises disassembling lines, a crushing mechanism, a winnowing mechanism, a magnetic separation mechanism and an eddy current separator. The disassembling lines comprise the feeding disassembling line, the discharging disassembling line and at least one disassembling station. The crushing mechanism comprises a feeding conveying belt, a crushing machine, a vibration screen and a discharging conveying belt. The winnowing mechanism comprises a winnowing barrel, a winnowing fan, a winnowing feeding hopper, a first winnowing discharging outlet and a second winnowing discharging outlet. The magnetic separation mechanism comprises a magnetic roller, a driving roller, a driven roller, a magnetic separation belt, a first hopper and a second hopper, and the magnetic separation belt is connected with the second winnowing discharging outlet relative to one end of the driven roller. The eddy current separator is connected with the discharging end of the second hopper. According to the automatic waste household appliance disassembling system, waste household appliances are disposed in sequence through the disassembling lines, the crushing mechanism, the winnowing mechanism, the magnetic separation mechanism and the eddy current separator, systemic and continuous disposal of the waste household appliances is achieved, and the resource recycling efficiency of the waste household appliances is improved.

Owner:HUBEI DONGJIANG ENVIRONMENTAL COMPANY LIMITED

Magnetic separator

InactiveUS6250474B1Cost-effective to produceCost-effective to operateMagnetic separationEddy current separatorEngineering

An eddy current separator apparatus for separating non-ferrous metals from other materials. The apparatus includes a support frame and a table cantileverly suspended from the frame. An expansion and contraction mechanism is incorporated that is adapted to accept a continuous conveyor belt thereabout. The expansion and contraction mechanism is capable of being configured between an operating configuration and maintenance configuration. A continuous conveyor belt is constructed to be able to be looped about the expansion and contraction mechanism and the table such that the conveyor belt is drawn tight in the operating configuration and slackened in the maintenance configuration. In this manner, the continuous conveyor belt is easily removable from, and installable onto the table in the maintenance configuration. A magnetic rotor is positioned proximate a first side of the continuous conveyor belt and is adapted to generate an eddy current on an opposite second side of the continuous conveyor belt upon rotation for inducing an elevating force in non-ferrous metals for separation from other materials.

Owner:HOWELL BILLY R

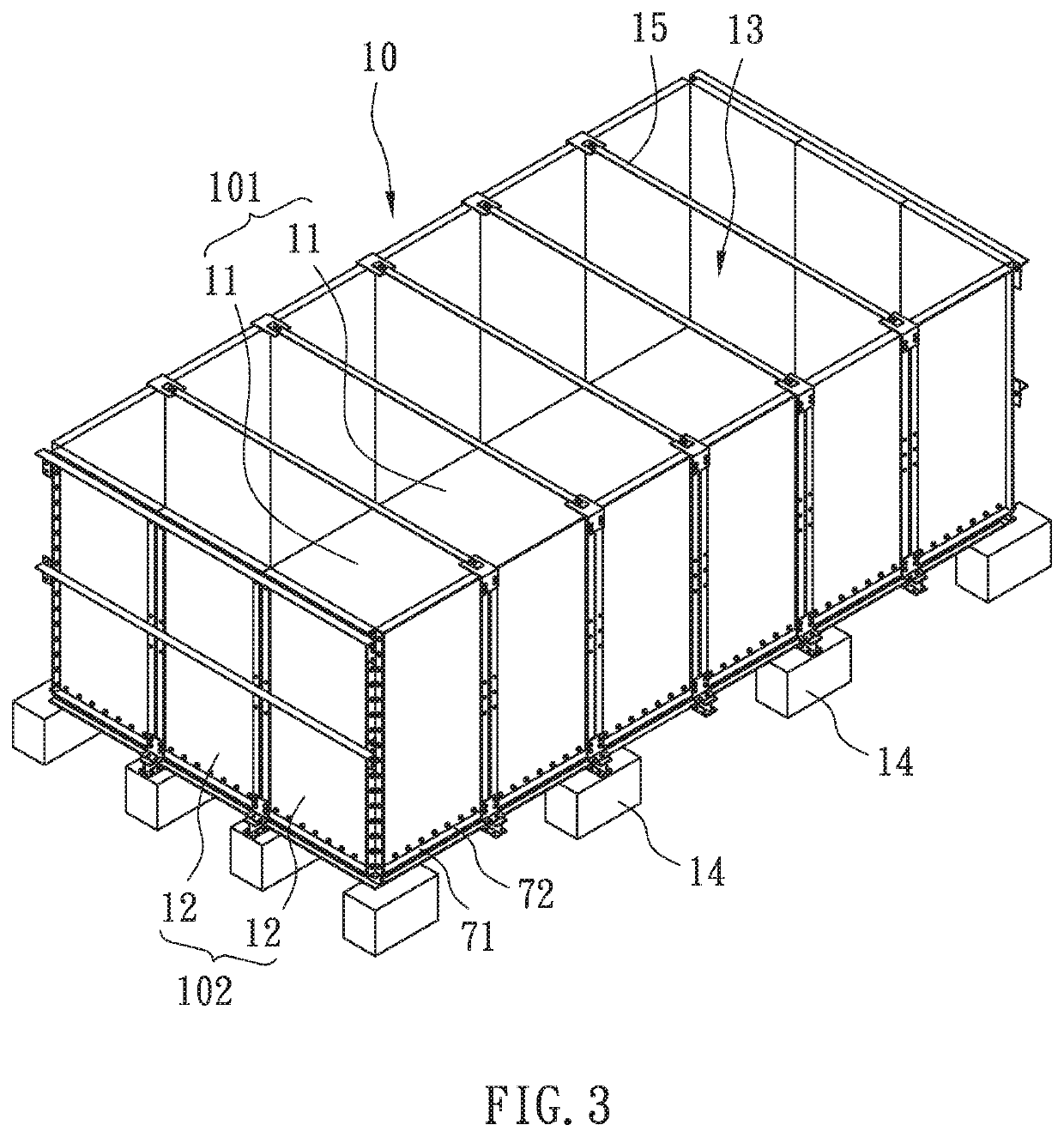

Aquaculture system

InactiveUS20190357503A1Avoid obstructionEasy to cleanWater/sewage treatment by centrifugal separationReversed direction vortexParticulatesShrimp

An aquaculture system contains: a cultivation tank, a vortex separator, a drawing pump, multiple bubble separators, multiple filtering units, an aeration unit, and a collection tank. The cultivation tank includes multiple first plates, multiple second plates, an open accommodation chamber, and a conduit tube. The vortex separator includes an inlet and an outlet. The drawing pump is connected beside the vortex separator and the outlet. Each bubble separator includes a cylindrical container and a micro bubble generating unit. Each filtering unit includes a filtration room, multiple filtering membrane sets, at least one water pipe, multiple dish-shaped bags, and multiple vacuum pumps. The aeration unit includes multiple air supply pipes, and the collection tank is employed to receive residual baits and excrements of little fishes or shrimps and particulate matters from the second discharge orifice of each bubble separator and the filtration room.

Owner:TAIWAN WATER RECYCLE TECH

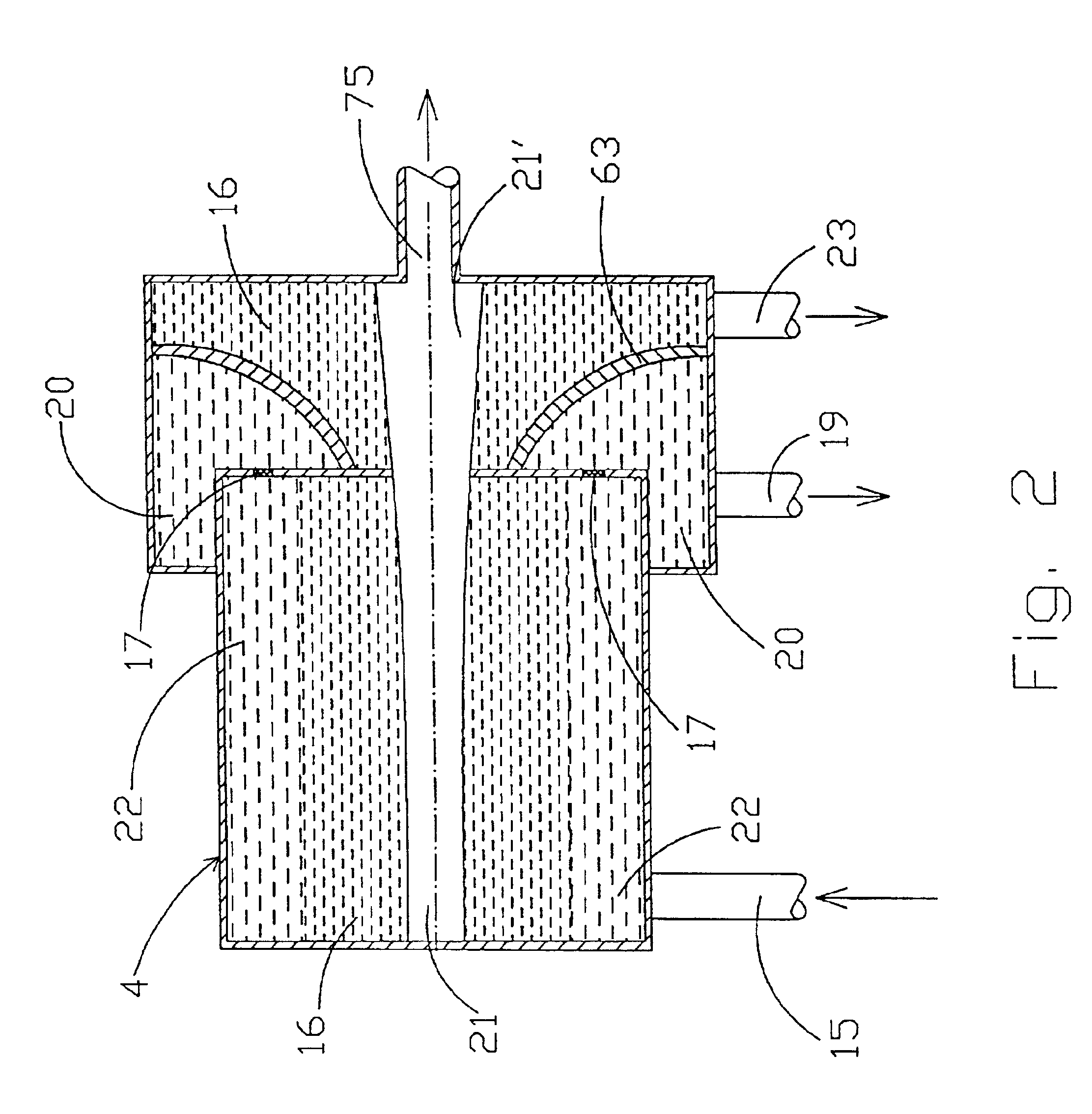

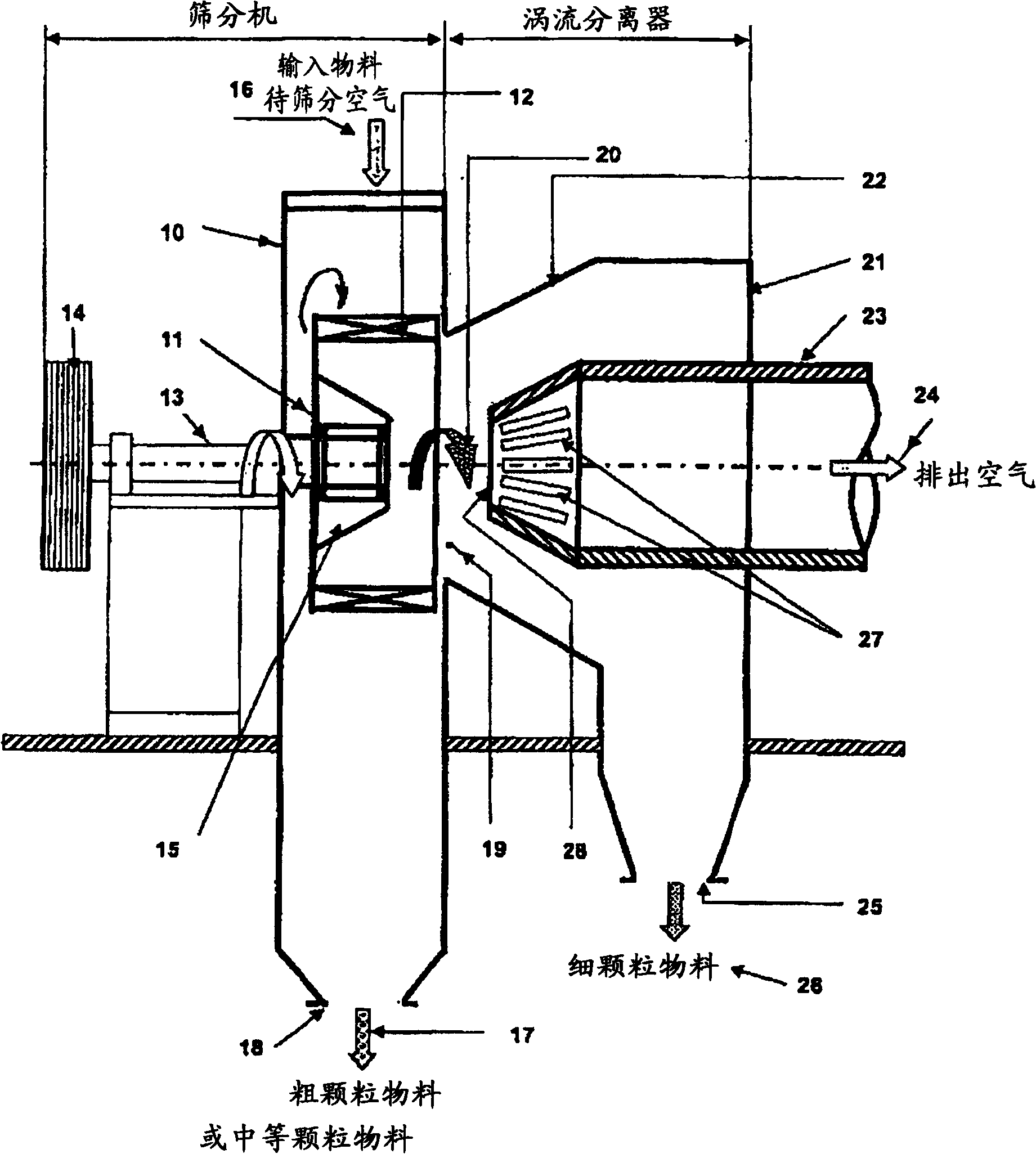

Sieving device for sieving granular material

InactiveCN101291747AEliminate flow resistanceEliminate Flow LossGas current separationVortex flow apparatusCycloneEddy current separator

In order to improve the design of a sieve device for sieving granular material with at least one rotational cage-rotor classifier and with a fines separator connected downstream therefrom, whereby saving space and specific energy demand for operating the entire device. To this end, the invention provides that a cyclone-like cyclone separator (21) is to be directly mounted with the smaller diameter of its housing cone (22) on the sieve housing opening (19) for drawing the flow of sieving gas (20), which flows out with angular momentum energy and which is loaded with the fines, whereby the cage-rotor classifier (10, 11) and the separator (21) form a compact modular unit, and an immersion tube (23) for drawing the flow of sieving gas (24), which is rid of the fines, is to be placed in the center of the cyclone separator (21), and at least one opening (25) for discharging the fines (26); is to be placed on the periphery of the cyclone separator housing (21).

Owner:KHD HUMBOLDT WEDAG GMBH

A novel method and an apparatus in converting unsorted municipal solid waste into geo-polymer pellets/briquettes and geo-polymer bricks/paver blocks

Apparatus and method in converting municipal solid waste into geo-polymer briquettes and geo-polymer bricks comprising bag opener cum crushers, magnetic separators for ferrous and eddy current separators for non-ferrous things; squeezer for removing liquid content; inter particle collision driers for drying; pulverizer for pulverizing, and devolatizing carbonization reactor for carbonisation of combustible MSW to produce solid char with low water content. Solid char is mixed with geo- polymer binding agent / starch / tar / to form combustible pellet / briquette. These highly combustible briquette / pellets have high calorific value. The pellet / briquette is formed by rotating combustible char at high rpm and compaction. Pellet has a water content of less than 5% by weight and fuel value of 5500 to 6500 KCAL This process produces non-combustible geo-polymer brick. The non-combustible MSW separated by a trommel is crushed by inter particle collision crusher and pan mixers mixing with geo-polymer binding agent / fly ash / quarry dust / chips or china clay and moulded.

Owner:NEWAY MSW IP HLDG LLP

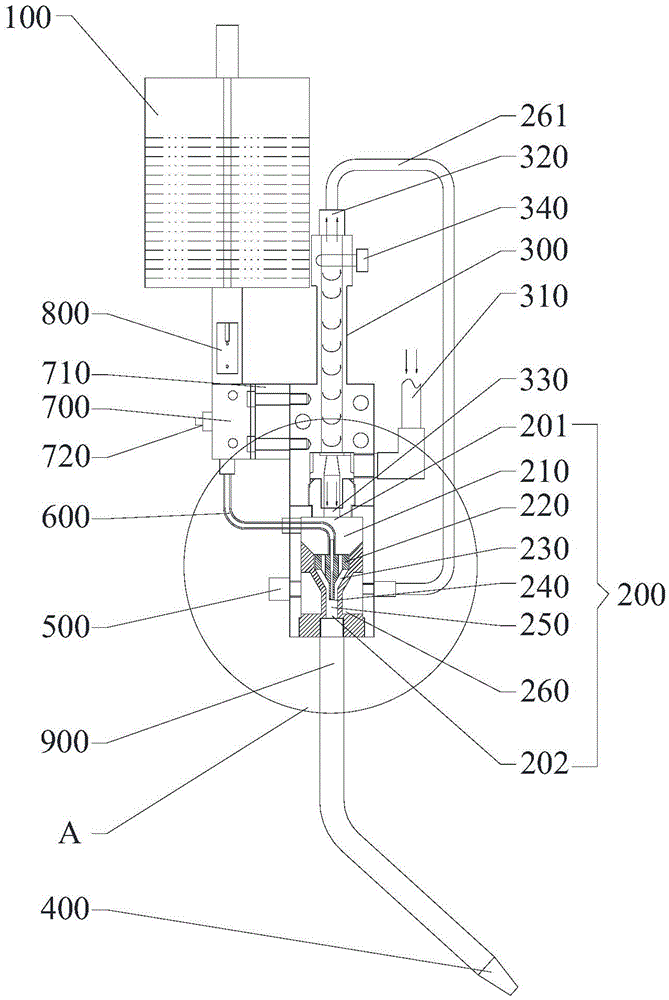

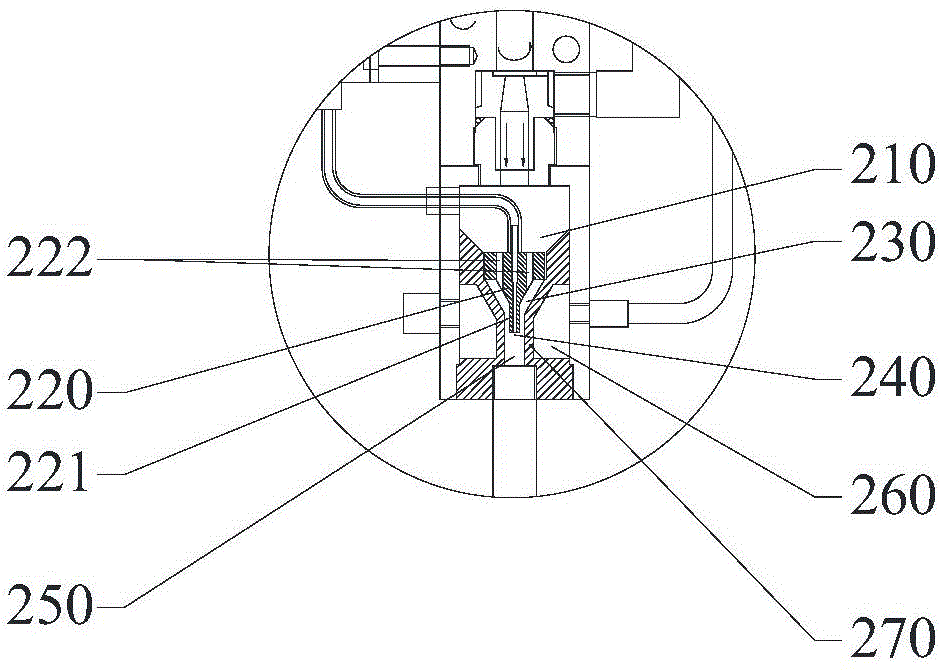

Pneumatic vortex self-priming lubricating and cooling system

InactiveCN104625866AEnsure adequate lubricationSolve the lack of cooling capacityMaintainance and safety accessoriesCold airEddy current separator

The invention provides a pneumatic vortex self-priming lubricating and cooling system in the technical field of devices utilizing compressed air as power. The pneumatic vortex self-priming lubricating and cooling system comprises an oil tank, a vacuum generator, a vortex separator and an air and liquid nozzle, wherein the vacuum generator comprises an input end and an output end, a cold air cavity, a vacuum nozzle, a cold air jet cavity, a jet vacuum cavity and an air-liquid mixing cavity are sequentially arranged between the input end and the output end, the cold air jet cavity is a conical cavity, the vacuum nozzle is provided with an oil injection pipe and a plurality of air flow holes, the oil injection pipe is arranged at the center of the vacuum nozzle, the air flow holes are uniformly arranged around the oil injection pipe, and the oil injection pipe is communicated with the oil tank; the vortex separator is provided with a compressed air input port, a hot air output port and a cold air output port, the cold air output port is communicated with the input end of the vacuum generator, and the air and liquid nozzle is communicated with the output end of the vacuum generator. The pneumatic vortex self-priming lubricating and cooling system takes the air as power, realizes vacuum liquid suction, air-liquid mixing and atomizing, heating for preventing freezing and plugging, so that workpieces and a tool can be sufficiently lubricated and cooled.

Owner:上海寄亚机电模具科技有限公司

Automatic sand blasting processor

InactiveCN101941183AAchieve recyclingReduce use costAbrasive machine appurtenancesAbrasive blasting machinesEddy current separatorSand blasting

The invention relates to an automatic sand blasting processor, which comprises a sand blasting machine body, wherein the sand blasting machine body is fixedly connected with a hydrocyclone separator which is communicated with a deduster through a pipe; and a centrifugal fan is arranged on the top part of the deduster. In the invention, the structure is reasonable and simple; and due to the combination of the hydrocyclone separator, the centrifugal fan and the deduster, the cycling of sand particles is realized, the working efficiency is improved considerably, and enterprise use cost is saved.

Owner:WUXI RISHENG MACHINERY FACTORY

Production device and process for bottle flake recovery, granulation and reutilization

PendingCN112026046AImprove uniformityEnhanced stainabilityPlastic recyclingDomestic articlesFood gradeEddy current separator

The invention relates to the technical field of bottle flake recovery, granulation and reutilization, in particular to a production device and process for bottle flake recovery, granulation and reutilization. The production device is sequentially provided with an eddy current separator and a material separator, and a screw extrusion granulating device respectively communicates with material mixingbin devices through material pipelines. The production process mainly comprises the steps of screening and sorting bottle flakes to remove impurities, then carrying out preheating, heating and dryingand melt granulation, and finally, uniformly mixing cut granules and outputting the granules. The production device and process are characterized in that the fineness degree is high, the defects of high cost, low quality and low output of an existing production system are shielded, and the batch output is greatly improved by means of the process for bottle flake recovery and granulation to facilitate the downstream use; and the cut granules produced by the device and the process can be used for producing downstream high-end products and even food-grade products.

Owner:郑州中远干燥工程有限公司

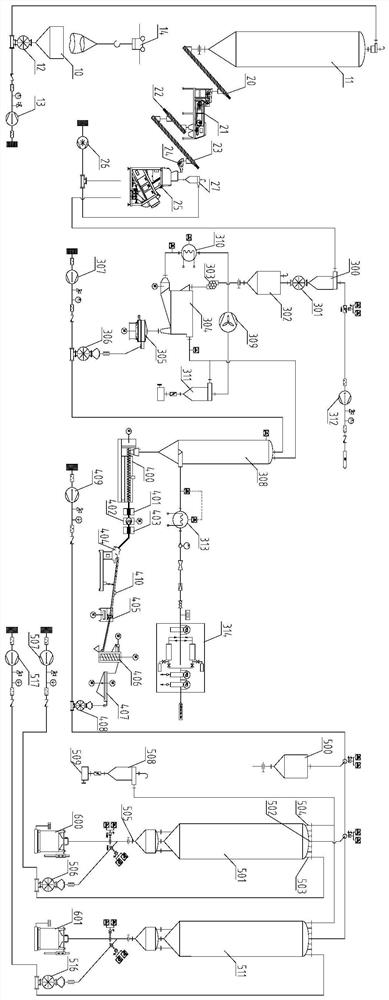

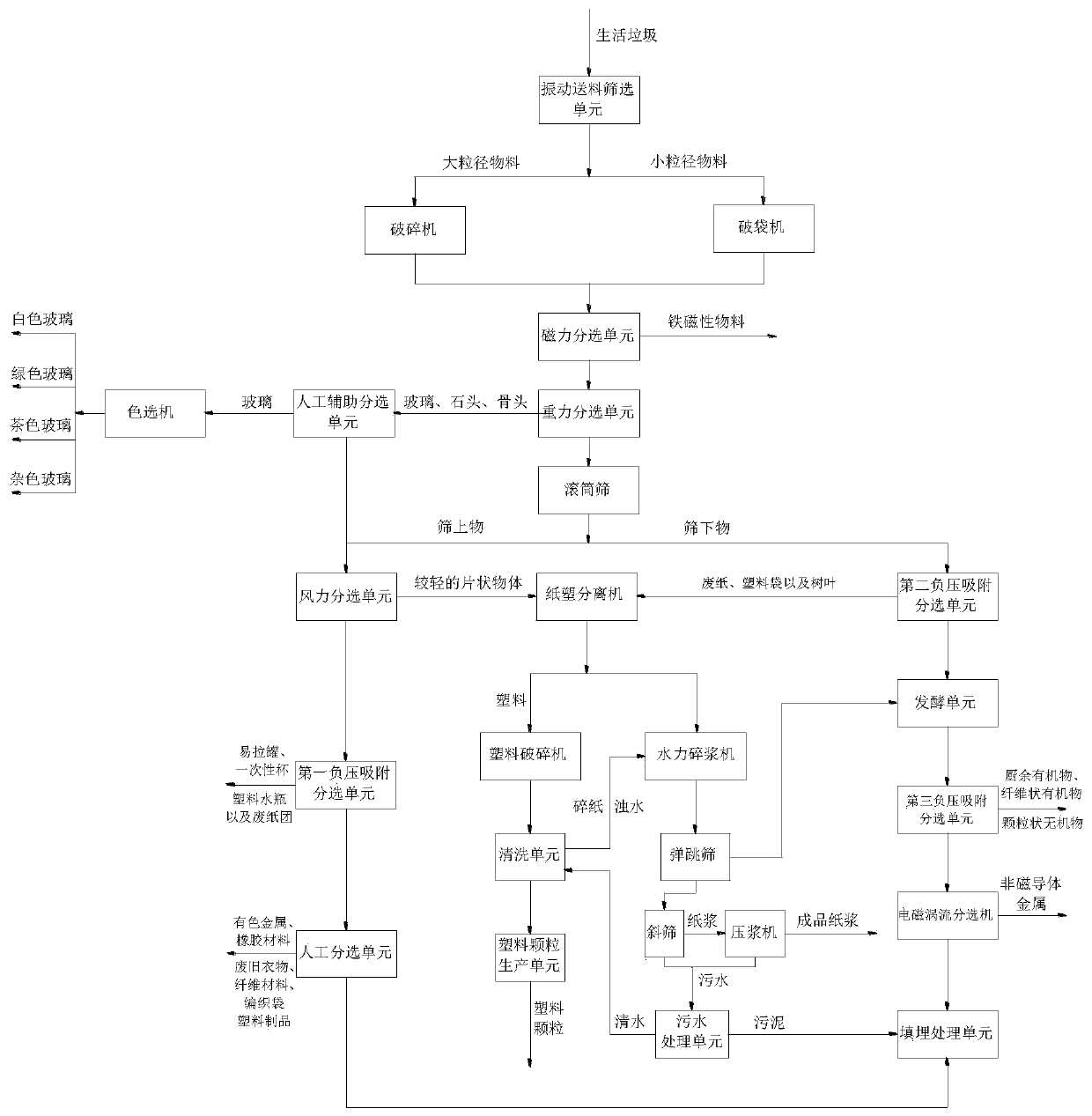

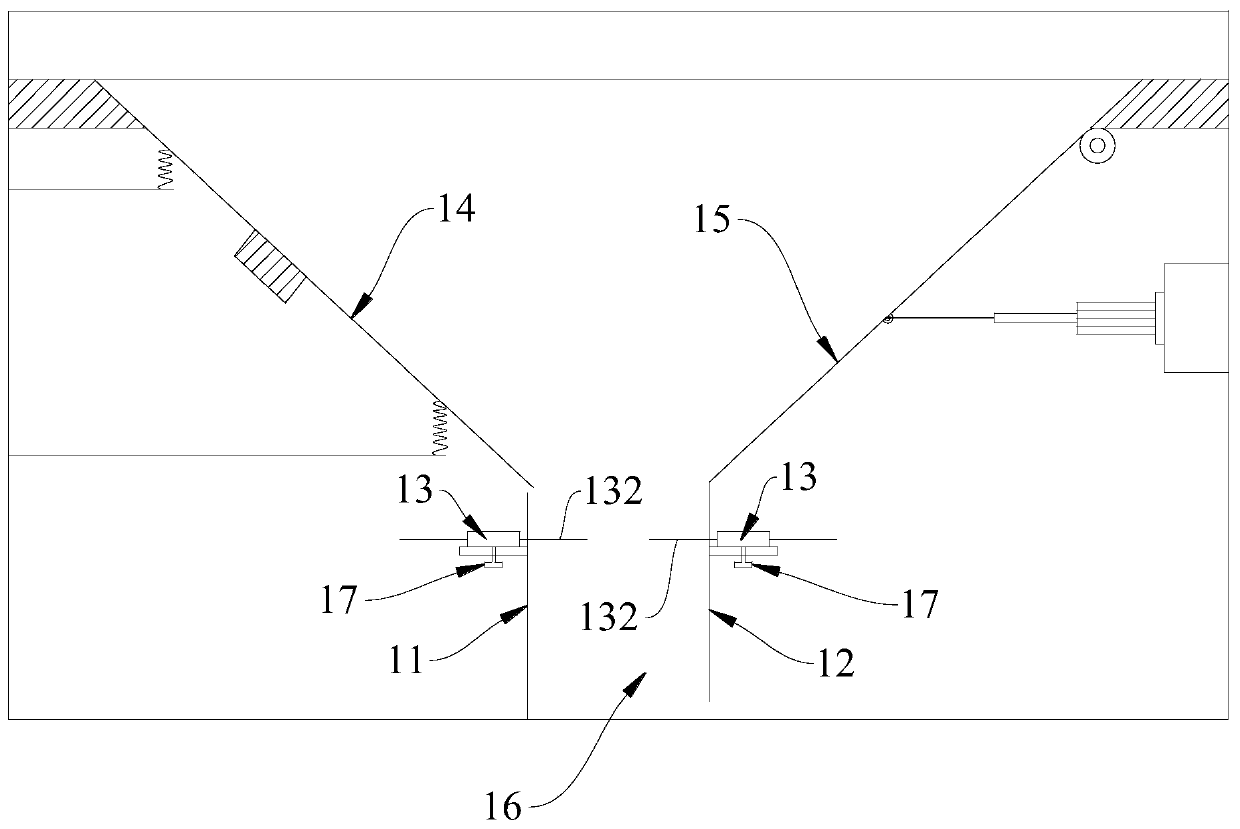

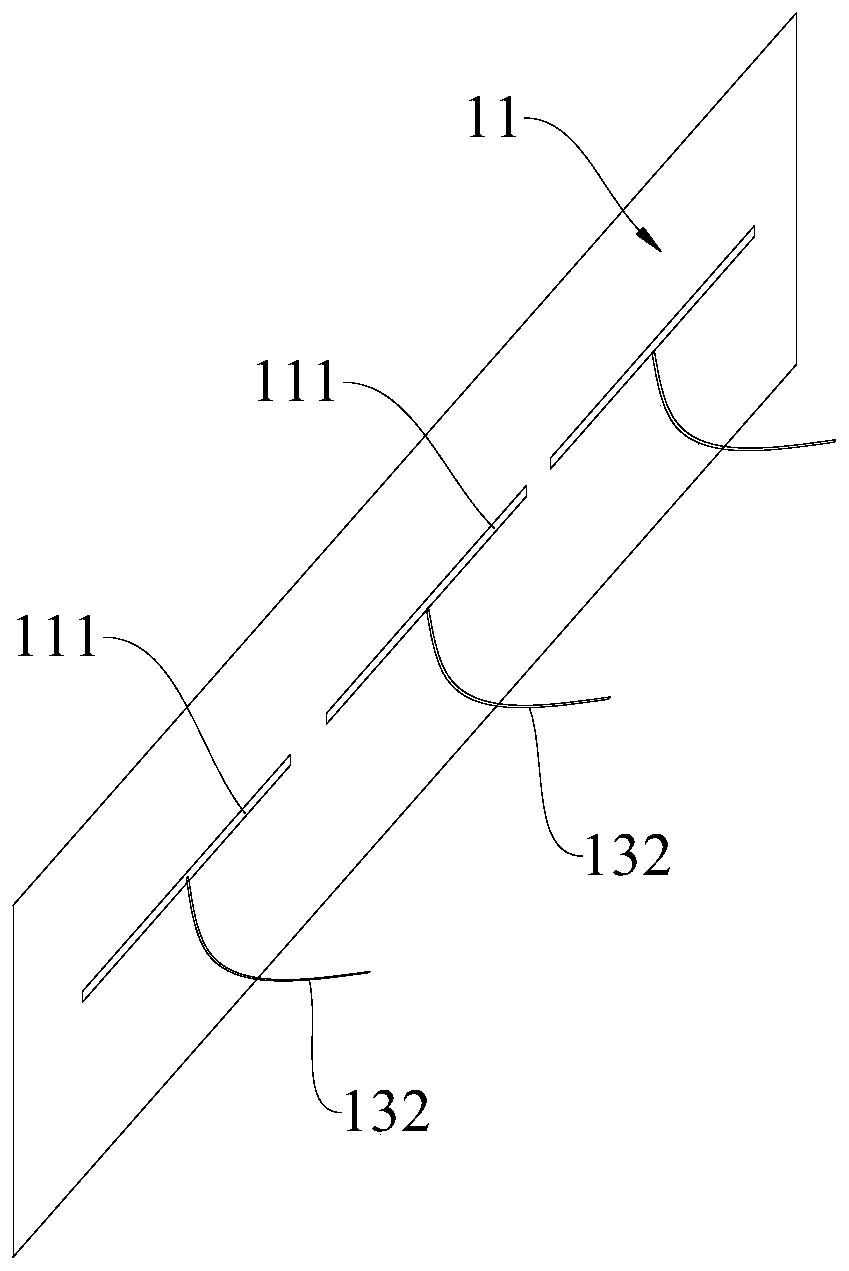

Mechanized classification system and method for household garbage terminals

PendingCN110076176AAccurate classificationEasy to classifySolid waste disposalResource utilizationEddy current separator

The invention discloses a mechanized classification system and method for household garbage terminals. The mechanized classification system for the household garbage terminals comprises a vibration feeding and screening unit, a crushing and bag-breaking unit, a magnetic separation unit, a gravity separation unit, a manual assisted separation unit, a drum screen, a wind separation unit, a first negative pressure adsorption separation unit, a manual separation unit, a second negative pressure adsorption separation unit, a paper-plastic separator, a plastic crushing machine, a cleaning unit, a plastic particle production unit, a hydrapulper, a bounce screen, an inclined screen, a pulp press, a sewage treatment unit, a fermentation unit, a third negative pressure adsorption separation unit, anelectromagnetic eddy current separator and a landfill unit. The mechanized classification method for the household garbage terminals adopts the mechanized classification system for the household garbage terminals for garbage classification. The mechanized classification system and method for the household garbage terminals can carry out accurate terminal classification for the household garbage,and realize reduction emission, harmless treatment and resource utilization.

Owner:广州励美环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com