Automatic sand blasting processor

A technology for a processor and a sand blasting machine, applied in the field of sand blasting machines, can solve the problems of reduced impact effect of workpieces, poor recycling effect, reduced work efficiency, etc., and achieve the effects of simple and reasonable structure, saving use cost, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

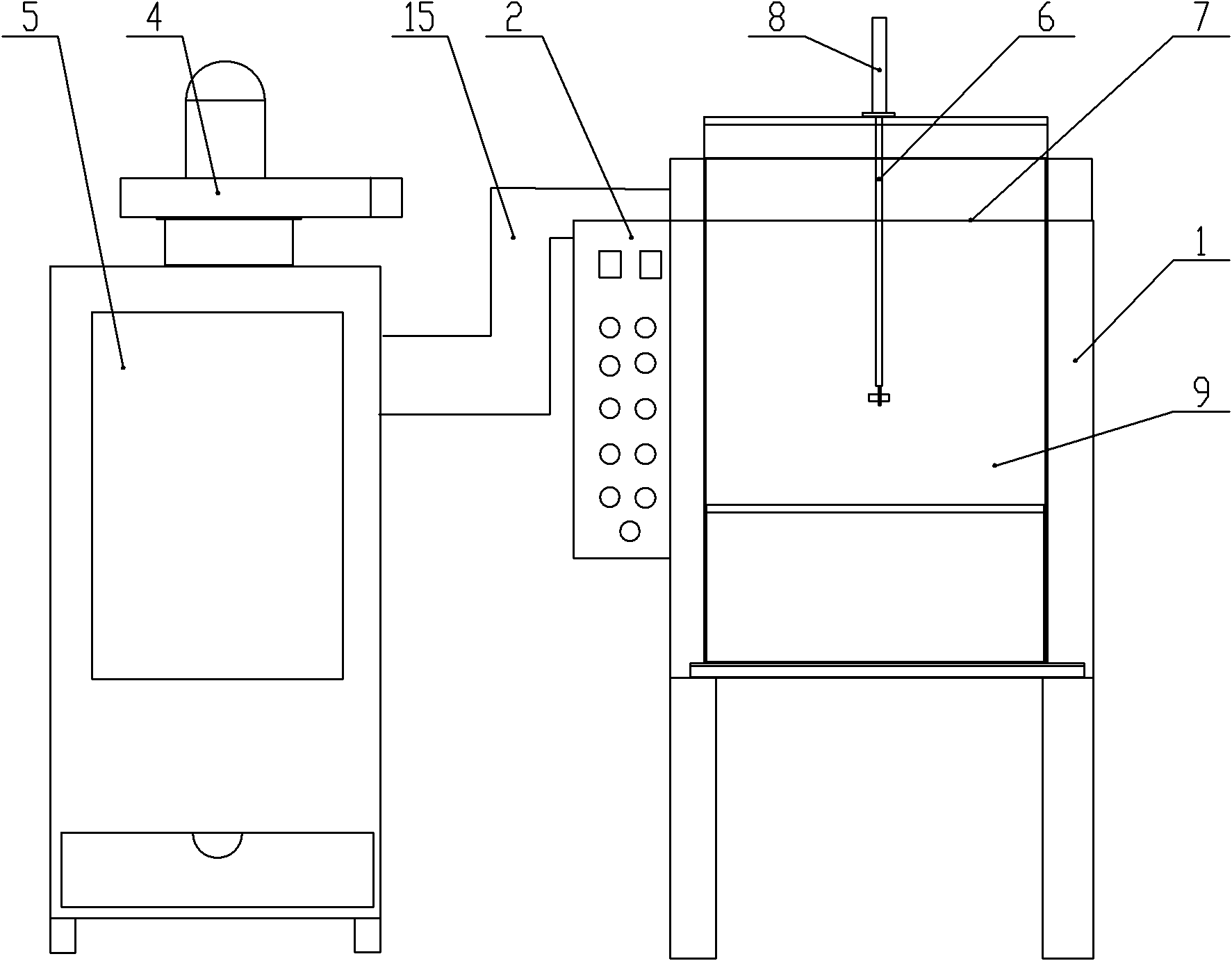

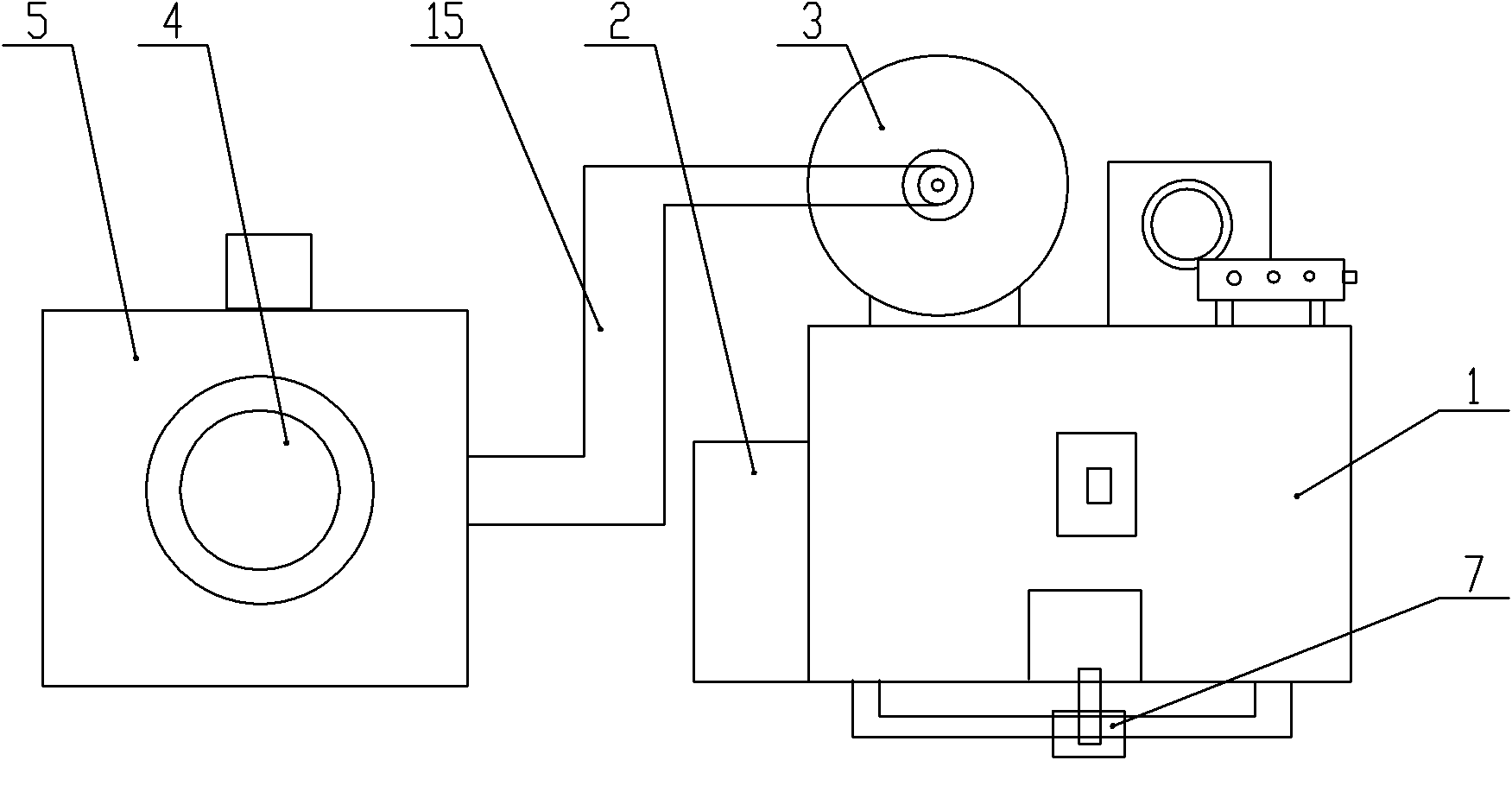

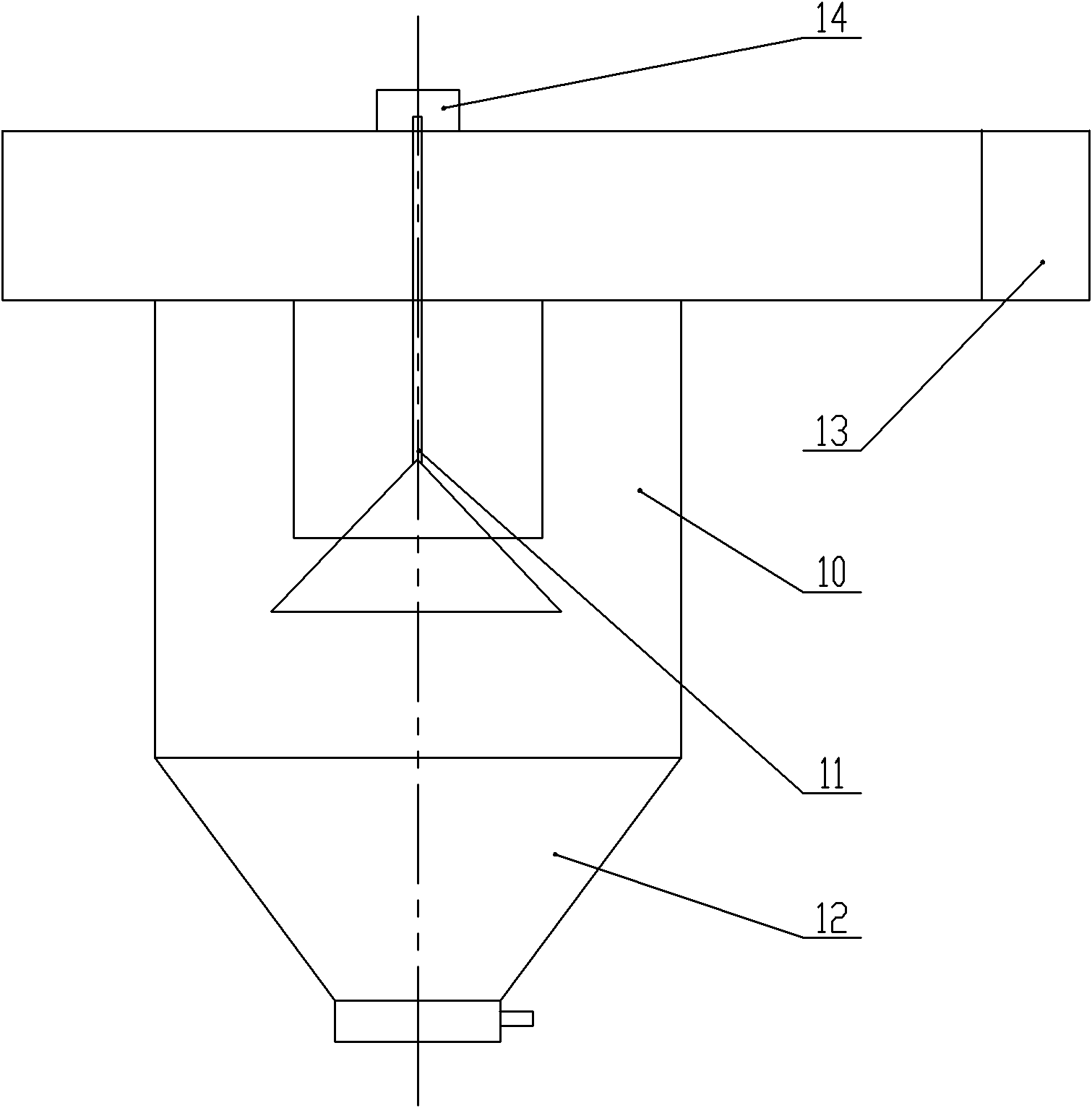

[0012] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0013] Figure 1~Figure 3 Among them, it includes sandblasting machine body 1, electric control box 2, eddy current separator 3, centrifugal fan 4, dust collector 5, sandblasting gun pressing cylinder 6, hatch pressing device 7, rotating device 8, hatch door 9, Eddy current separator housing 10, dust outlet adjusting device 11, material storage box 12, feed inlet 13, dust outlet 14, pipeline 15, etc.

[0014] like figure 1 , figure 2 As shown, the present invention is an automatic sandblasting machine, including a sandblasting machine body 1 . The electric control box 2 is installed on one side of the body 1, and is used to control the operation of each part in the whole machine. The electric control box 2 panel is provided with control buttons such as manual, automatic, emergency stop. The body 1 is composed of a hatch 9, a sandblastin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com