Sieving device for sieving granular material

一种筛分装置、颗粒物料的技术,应用在旋流装置、用气流将固体从固体中分离出来、固体分离等方向,能够解决压力损失等问题,达到消除加速的损失、消除流动阻力和/或压力损失、单位能量要求减少的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

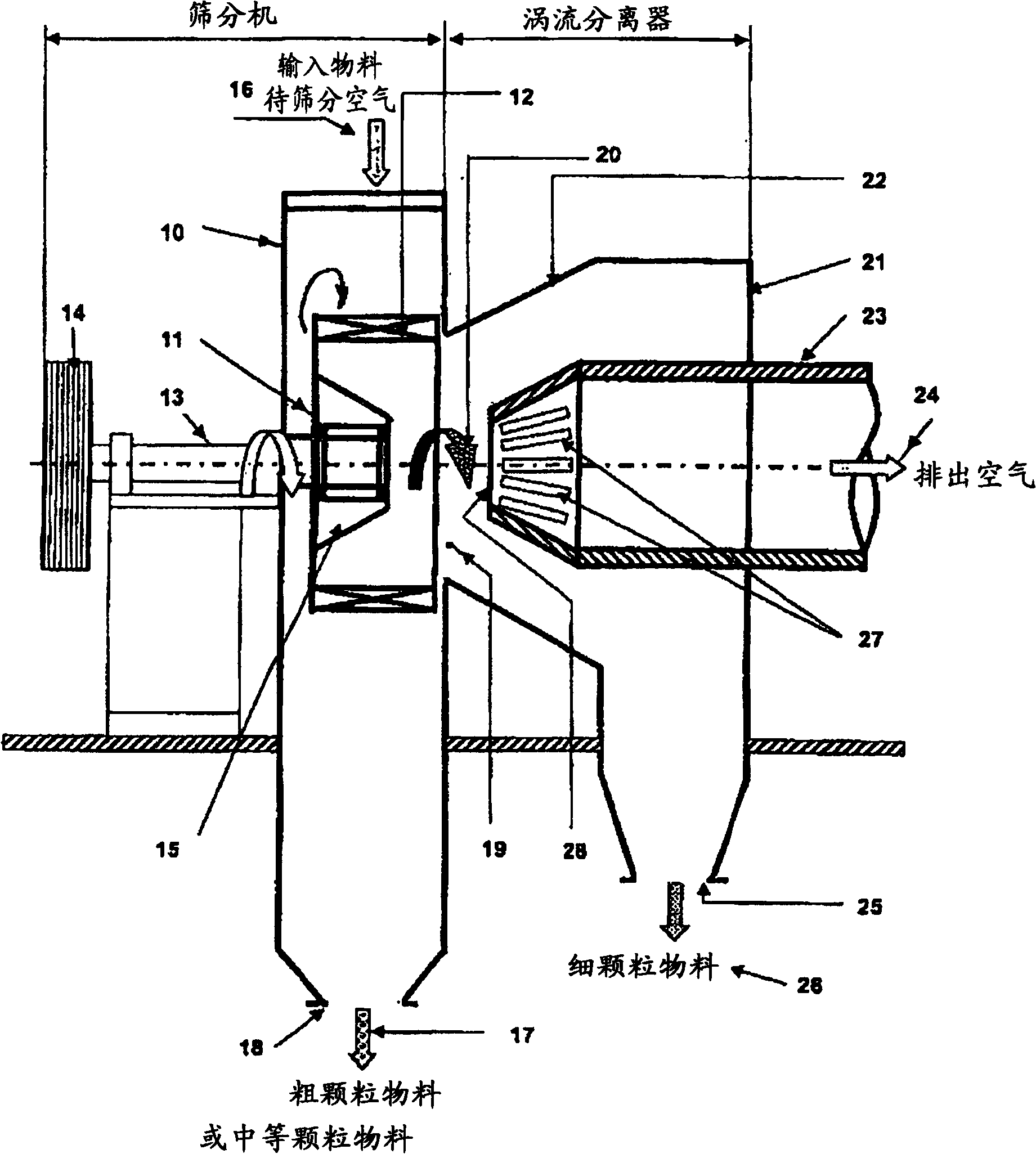

[0013] In the screening machine housing 10, at least one rod-shaped basket 11 is mounted rotatably and cantilevered on an approximately horizontal shaft 13, said rod-shaped basket 11 having eddy current elements 12 distributed over the circumference of the rotor, said shaft Driven by motor 14. The rod basket 11 with its swirl elements 12 can be designed conically or frustoconically instead of cylindrically. A frusto-conical extrusion body 15 can be arranged inside the rod-shaped basket 11 . The granular material to be sieved, for example from a jet mill, is introduced into the sifter housing 10 , suspended in the sifting air flow 16 , where it is accelerated to the peripheral speed of the rotating rod basket 11 . The fine-grained material contained in the input material is conveyed inwards by the air flow against the centrifugal force between the rods 12 of the rod basket 11 and leaves the rod basket centrally together with the sieving air flow, in the case of the shown embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com