Extrusion units especially for plastics

An extrusion device, plastic technology, applied in the field of manufacturing tubular body, plastic extrusion device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

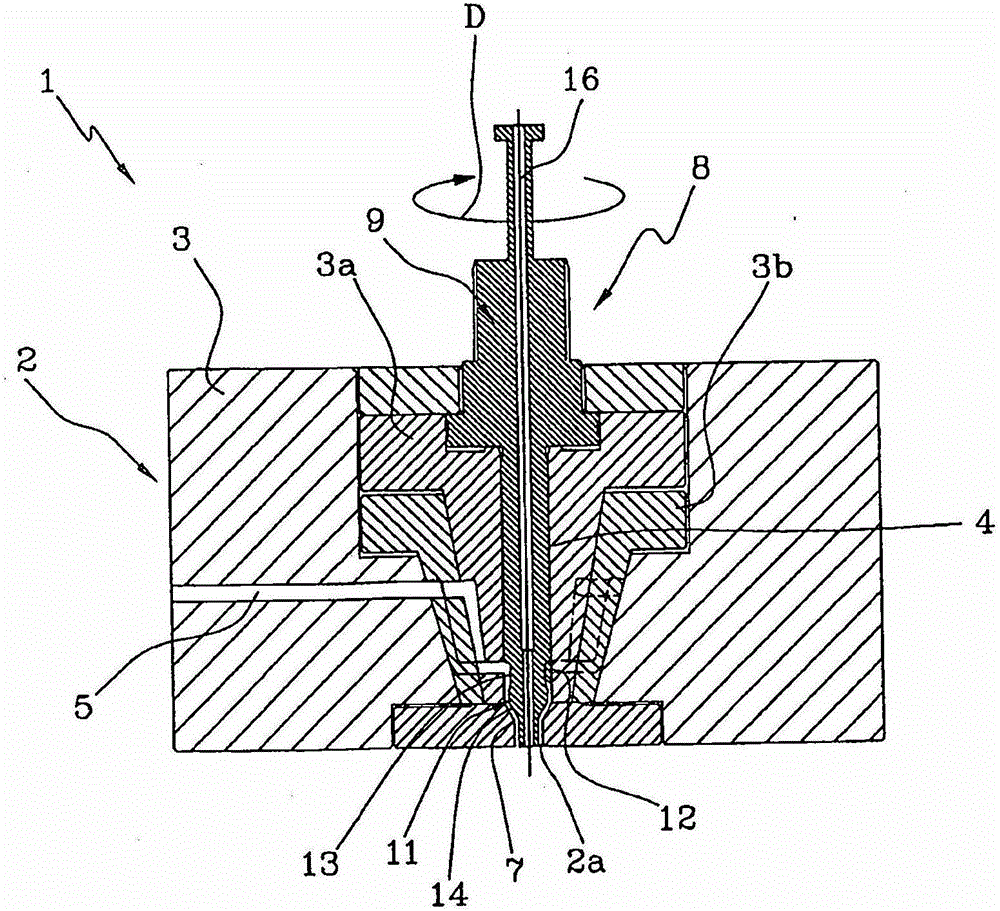

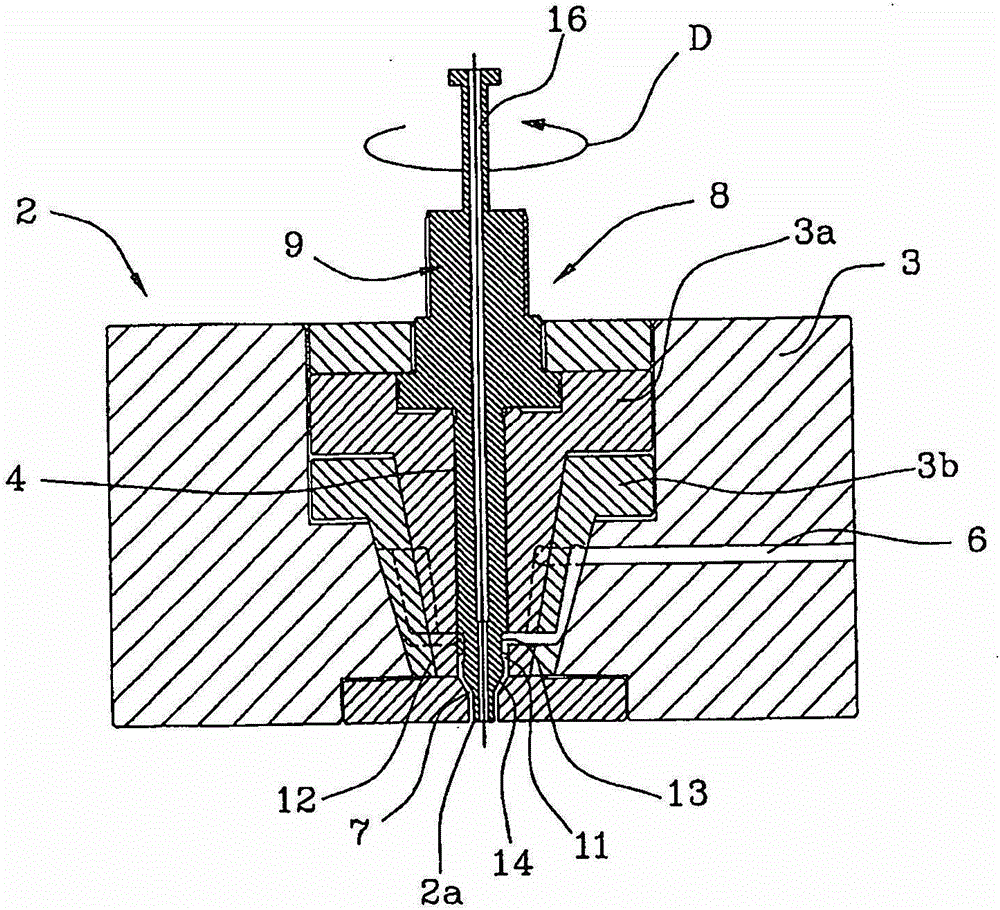

[0040] With particular reference to the drawings, an extrusion device according to the invention has been indicated generally by the reference number 1 .

[0041] In detail, the device 1 comprises, arranged in its lower part, an extrusion head 2 having injection nozzles 2a for delivering at least one plastic M1 , M2 to be extruded.

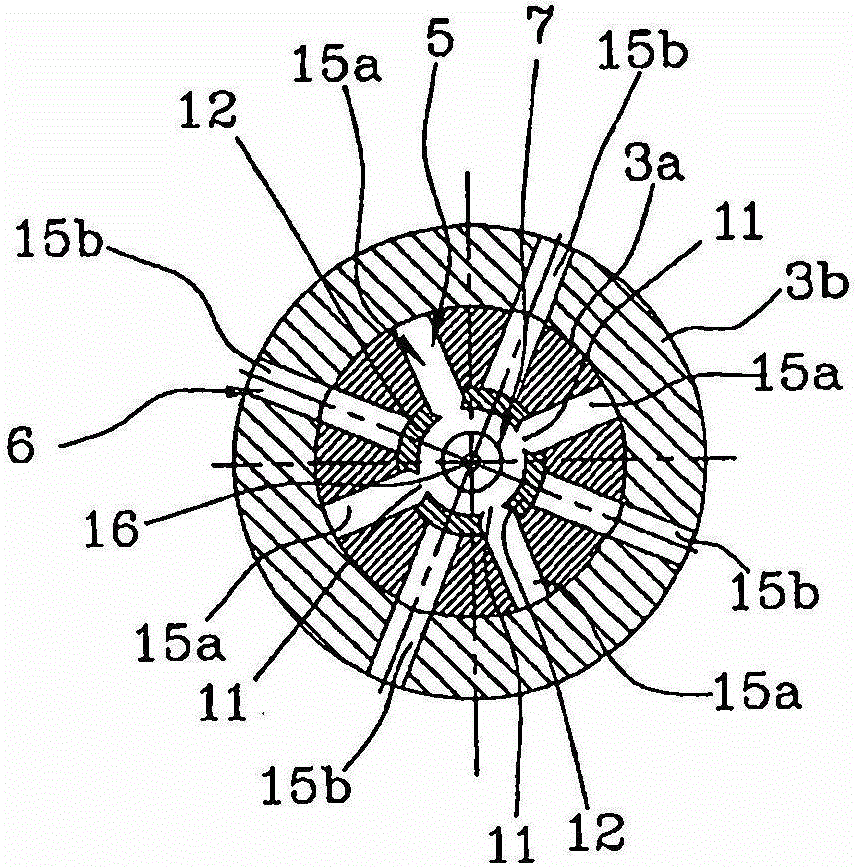

[0042] In particular, refer to figure 1 with 2 , it should be noted that the extrusion head 2 has a support body 3 for a pair of annular parts 3a, 3b, which are coaxial with each other and inserted into each other. The innermost annular portion 3a has a longitudinal cavity 4 delimiting said spray nozzle 2a at its corresponding end. It should be noted that each annular portion 3a, 3b cooperating with said support body 3 defines a corresponding channel for the passage of the plastic to be extruded.

[0043] In particular, as figure 1 As shown in , the innermost annular portion 3a has a first channel 5 for feeding the first plastic material M1 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com