Centrifugal pumps in parallel jointed series

A centrifugal pump and conjoined technology, applied in the field of parallel conjoined centrifugal water pumps, can solve the problems of large axial thrust, impact wear, damage, etc., achieve performance improvement, eliminate frictional resistance, and reduce hidden dangers of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

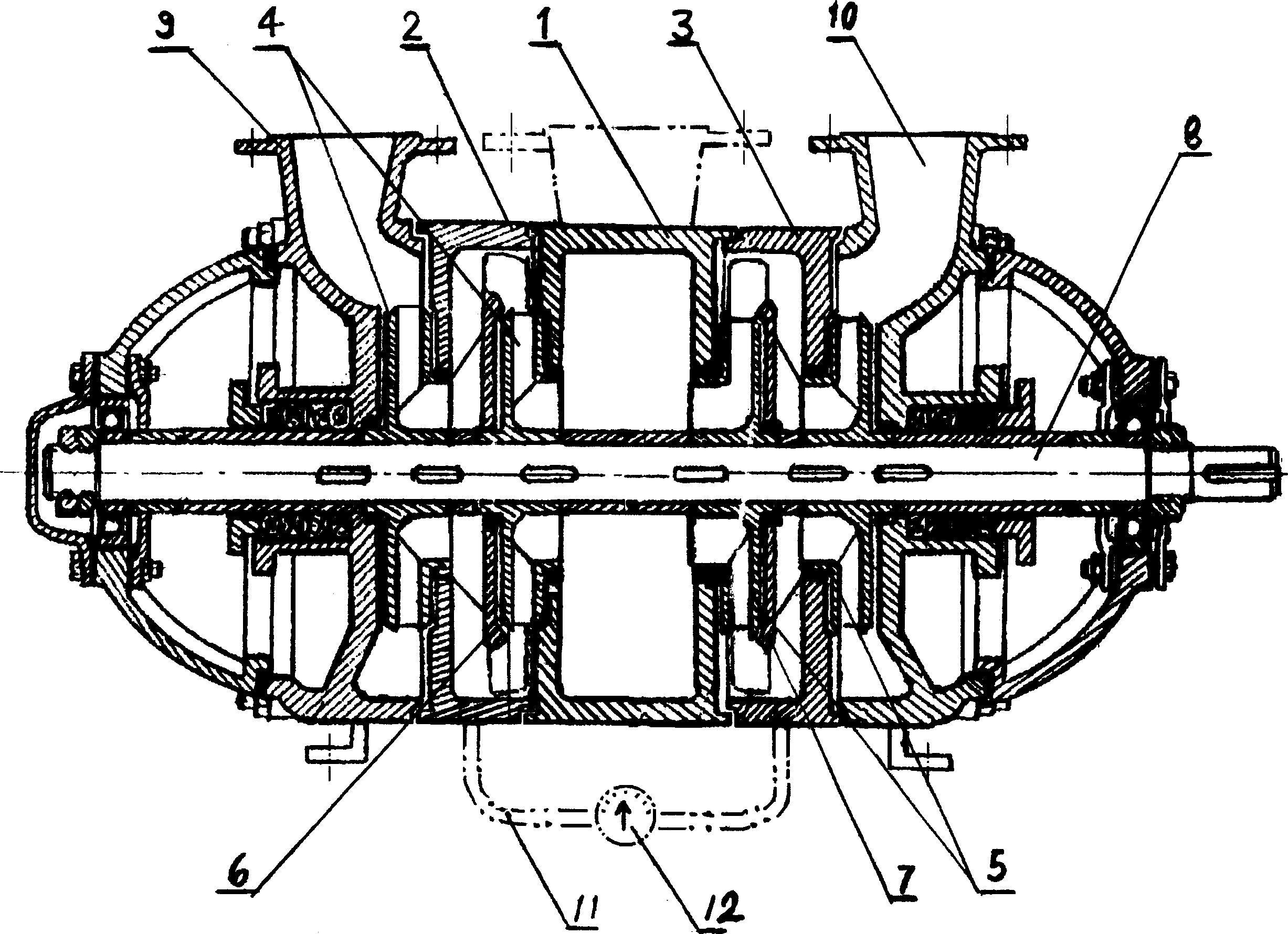

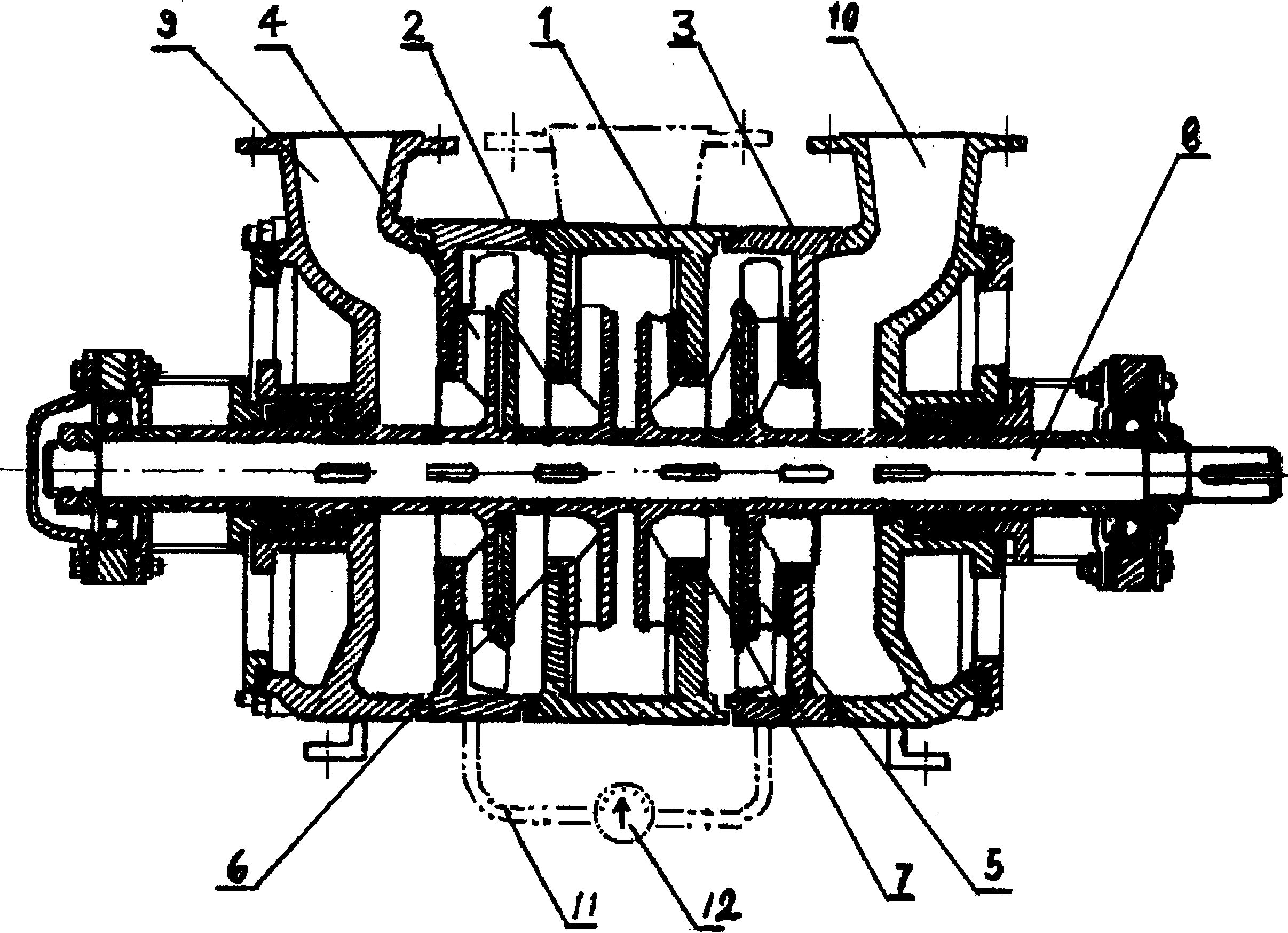

[0009] Embodiment 1, the present invention includes a pump casing, a pump bracket, a pump shaft 8 set on the pump supporting frame and connected to the power device, and a bearing set on the pump shaft and matched with the pump bracket. It is characterized in that it is provided with a water outlet The left water outlet section 9 and the right water outlet section 10 are respectively provided with water outlet chambers around the pump shaft, the left water outlet section 9 is fixedly connected with the left bracket of the pump, the right water outlet section 10 is fixedly connected with the right bracket of the pump, and the left water outlet section 9 and the right water outlet section 10 There are pump shaft mounting holes on the outside of the pump shaft respectively. The outside of the left water outlet section 9 and the right water outlet section 10 form a dynamic seal fit with the pump shaft sleeve set on the pump shaft 8 through the pump shaft installation holes. The left...

Embodiment 2

[0011] Embodiment 2, the left middle section 2 and the right middle section 3 are respectively set between the left water outlet section 9 and the right water outlet section 10 and the water inlet section 1, and the left middle section 2 and the right middle section 3 are provided with a middle section cavity surrounding the pump shaft, and the middle section cavity The pump shaft 8 is sleeved with the left impeller 4 and the right impeller 5 respectively. In the production process, the water inlet section 1 connected to the water pipe should have a cross-sectional area of the water inlet pipe not less than the sum of the cross-sectional areas of the two outlet pipes. The left impeller 4 and the right impeller 5 are respectively installed on the pump shaft 8, the left guide vane 6 and the right guide vane 7 are respectively installed in each middle section, and each middle section and left impeller and guide vane are the same as the D-type pump. The size of the right impelle...

Embodiment 3

[0012] Embodiment 3, the left middle section 2 and the right middle section 3 are respectively set between the left water outlet section 9 and the right water outlet section 10 and the water inlet section 1, and the left middle section 2 and the right middle section 3 are provided with a middle section cavity surrounding the pump shaft, and the middle section cavity One or more left impellers 4 and right impellers 5, and left guide vanes 6 and right guide vanes 7 are set respectively. All the other are with embodiment 2, refer to figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com