Municipal waste separation system

A municipal garbage and sorting system technology, applied in the direction of solid separation, solid waste removal, etc., can solve the problems of poor working environment of sorting workers, physical and mental health hazards of operators, and difficulty in guaranteeing sorting quality, so as to improve efficiency, Improve the working environment and realize the effect of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

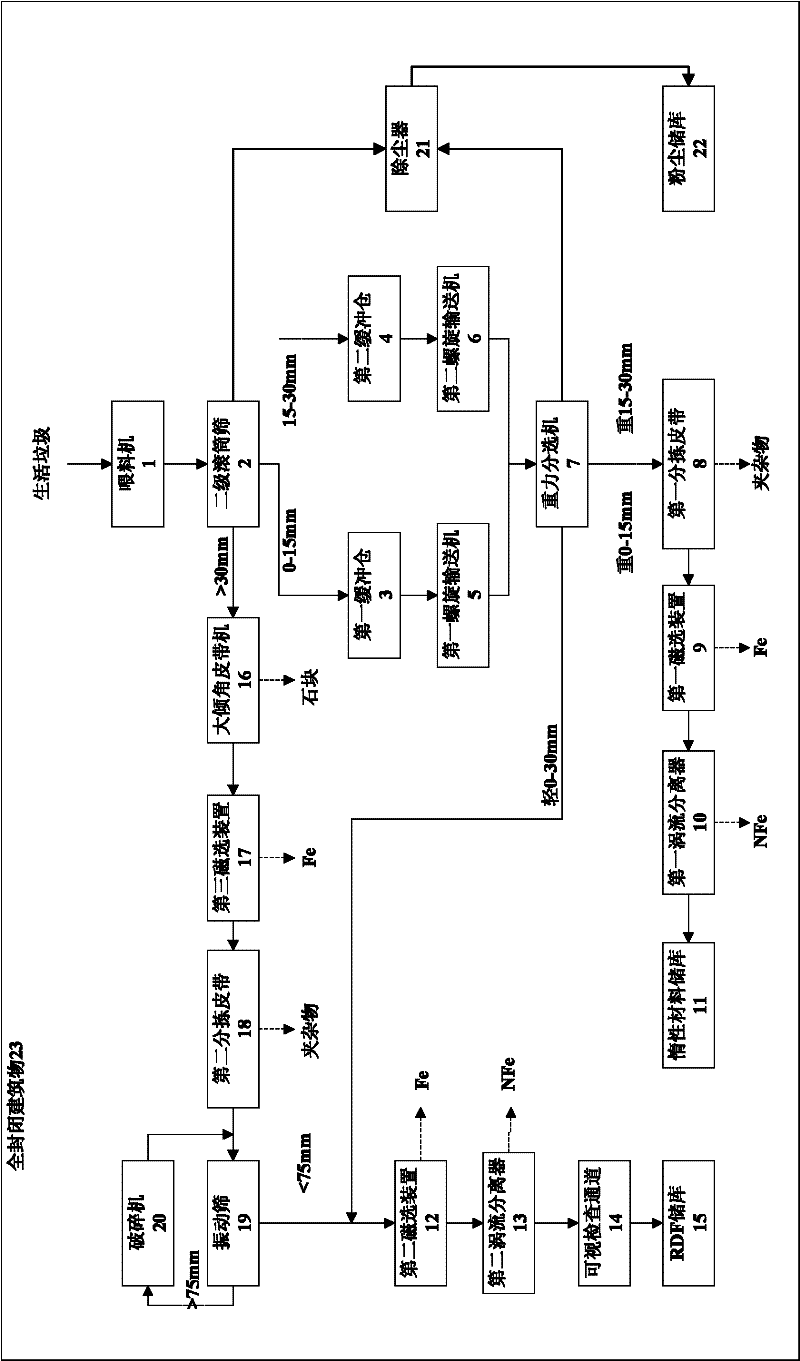

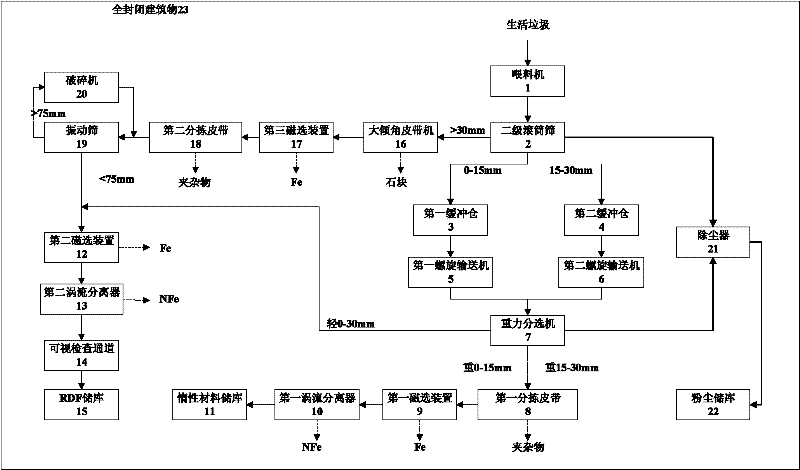

[0015] Such as figure 1 Shown, a kind of municipal refuse sorting system, it comprises feeder 1, secondary drum screen 2, first buffer bin 3, second buffer bin 4, first screw conveyor 5, second screw conveyor 6, Gravity sorter 7, first sorting belt 8, second sorting belt 18, first magnetic separation device 9, second magnetic separation device 12, third magnetic separation device 17, first eddy current separator 10, second Vortex separator 13, inert material storage 11, RDF (refuse-derived fuel) storage 15, high-inclination belt conveyor 16, vibrating screen 19, crusher 20, dust collector 21, dust storage 22, fully enclosed building 23 The input port of the feeder 1 receives the pre-crushed and dried municipal waste, the output port of the feeder 1 is located at the input port of the secondary drum screen 2, and the particle size of the secondary drum screen 2 is less than 15mm. The output port of the undersize is connected with the first buffer bin 3 by a pipeline (that is, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com