Husk crushing and sorting system for walnuts and sorting technology

A sorting system and walnut crushing technology, applied in the direction of shelling, sorting, pod removal, etc., can solve the problems of different impact strength of husks, manual sorting of walnuts, and difficulty in batch shelling processing, etc. The effect of high degree of automation, low labor cost and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

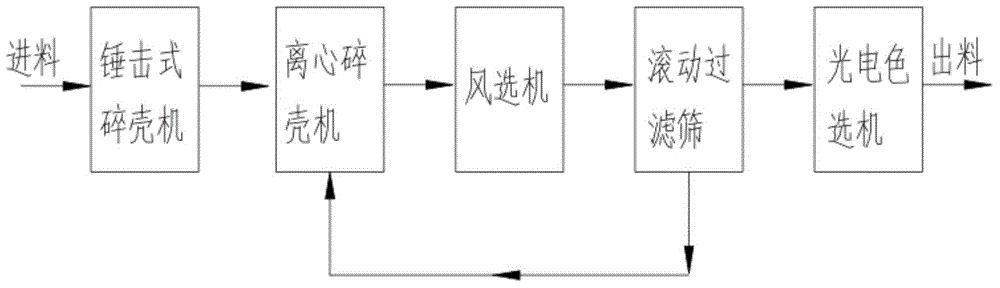

[0033] Such as Figure 1 to Figure 8 As shown, a sorting system for broken walnut shells includes a hammer-type shell breaker, a wind separator, a rolling filter screen, and a photoelectric color sorter that are connected in sequence. A centrifugal shell crusher is provided, and the hammer shell crusher, centrifugal shell crusher, winnowing machine, rolling filter screen and photoelectric color sorter are connected by a chain conveyor belt;

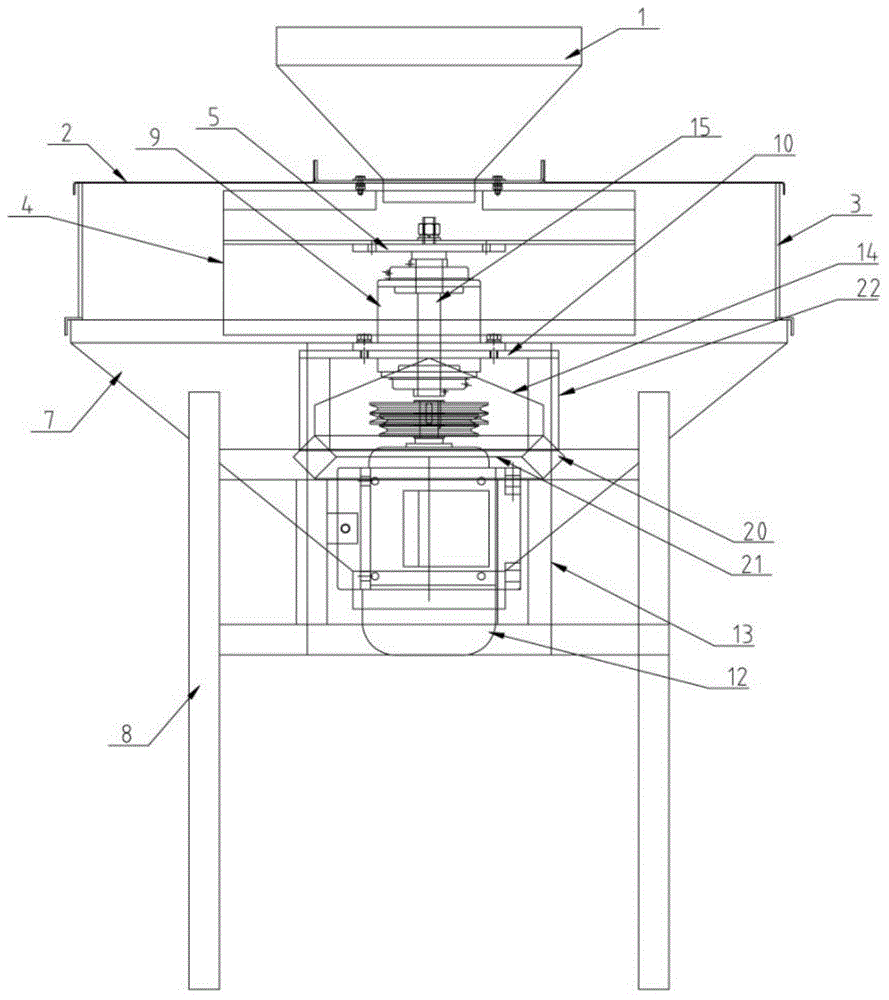

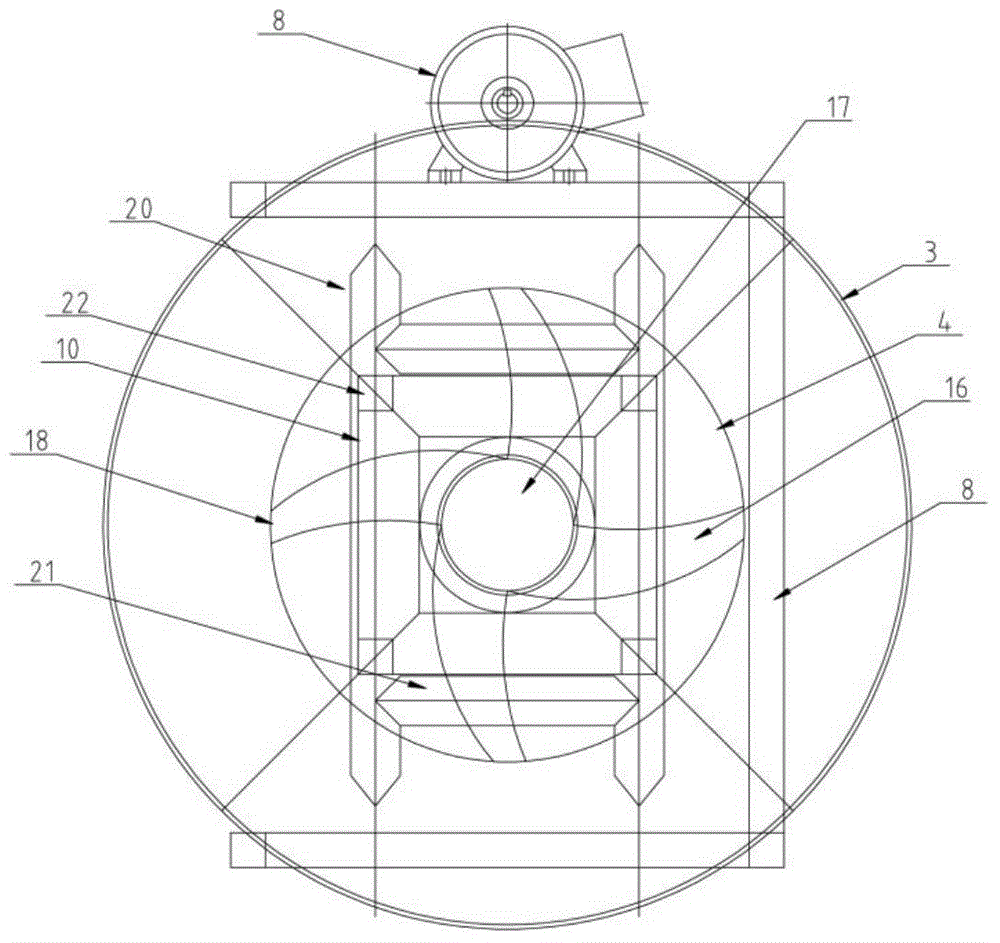

[0034]The centrifugal shell crusher includes a frame 8, a feed hopper 1 and a lower hopper 7, the lower hopper 7 is installed on the frame 8, and a There is a cylinder 3, and also includes a rotating mechanism and a support frame 6. The rotating mechanism includes a turntable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com