Small automatic garbage sorting device

A garbage sorting and garbage technology, which is applied in the field of small automatic garbage sorting devices, can solve the problems of long maintenance time of the core mechanical component mechanical arm, high research and development cost of garbage sorting devices, and large investment in equipment maintenance funds, etc. The effect of utilizing speed, improving sorting efficiency and quality, improving safety index and separation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be described in detail below with reference to the drawings, but the protection scope of the present invention is not limited to the following embodiments.

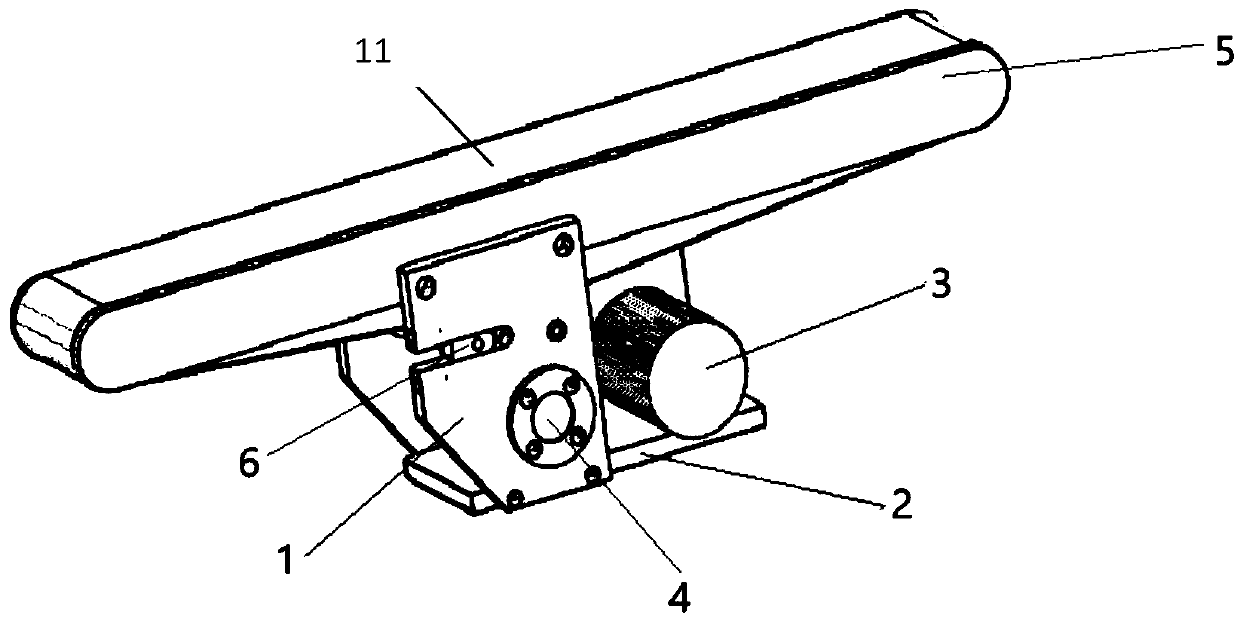

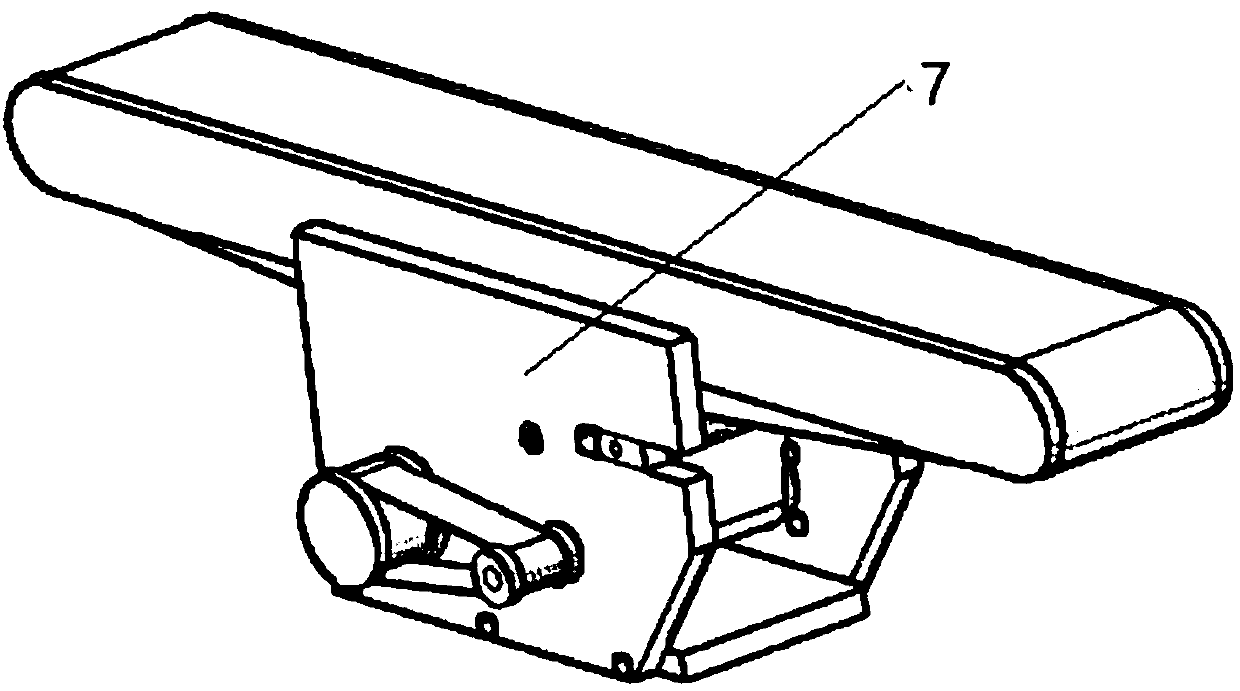

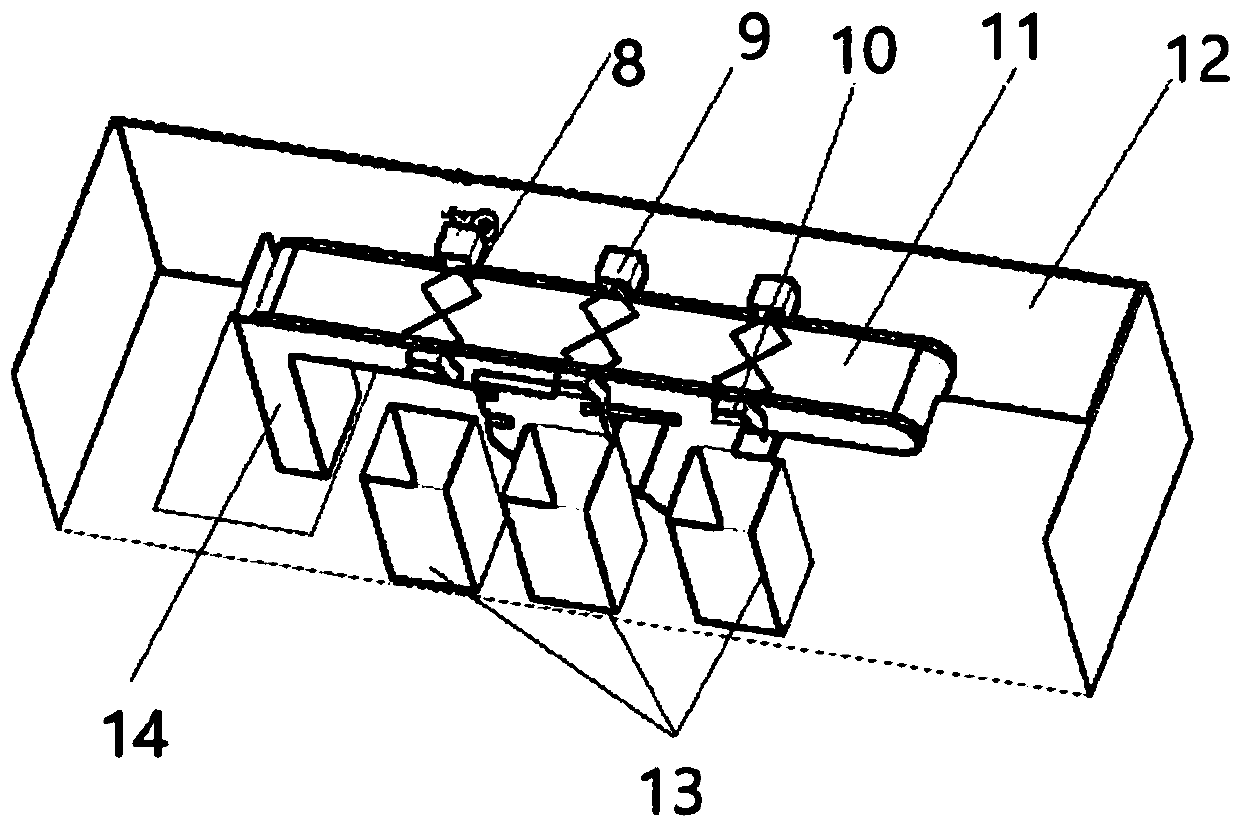

[0028] See attached figure 1 with 2 , A small automatic garbage sorting device, which is a box structure formed by three garbage sorting and recycling units connected in layers from top to bottom, wherein the garbage sorting and recycling unit includes: a rear support frame 1, a base 2 , Drive motor 3, connecting shaft 4, transmission mechanism side plate 5, conveyor belt 11, connecting key 6 and the transmission mechanism of the front support frame 7, and the drive motor 3 is fixed on the front support frame 7, through the transmission of the drive motor 3 The conveyor belt 11 advances at a constant speed, and the rear support frame 1 is respectively connected to the base 2 and the conveyor belt 11 by bolts; three screening mechanisms, namely electromagnetic induct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com