Thermal management system of small hydrogen production equipment

A heat management system and hydrogen production equipment technology, applied in the field of heat management systems, can solve problems such as difficulty in low-temperature operation, and achieve the effects of accelerating heat transfer, good transition effect, and accelerating circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

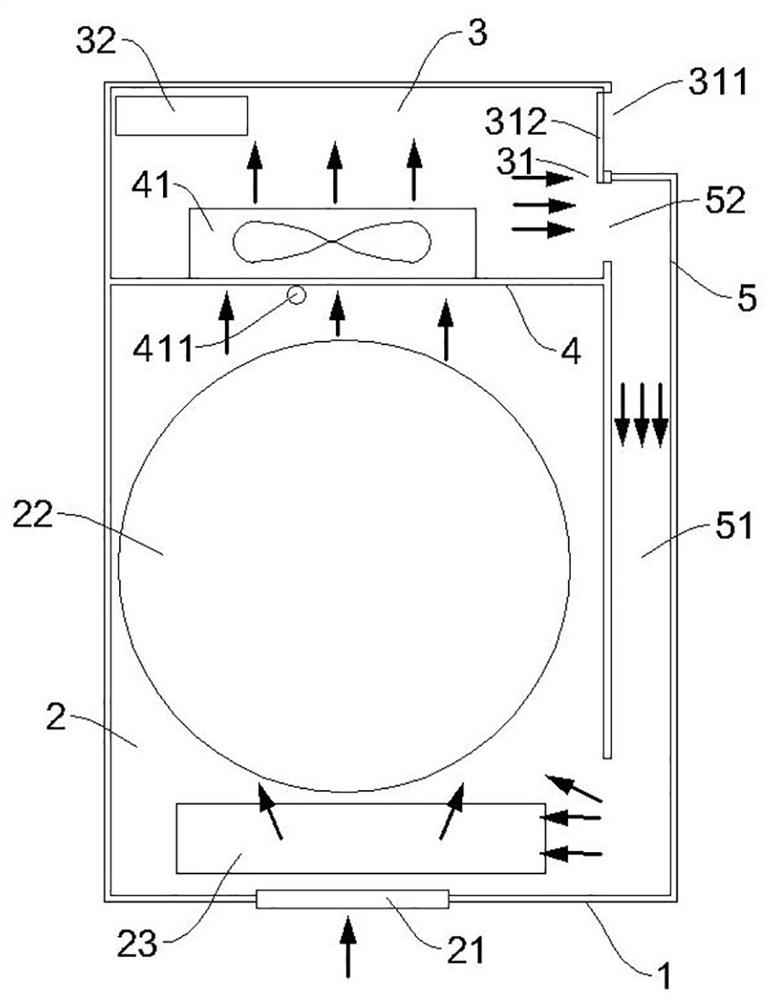

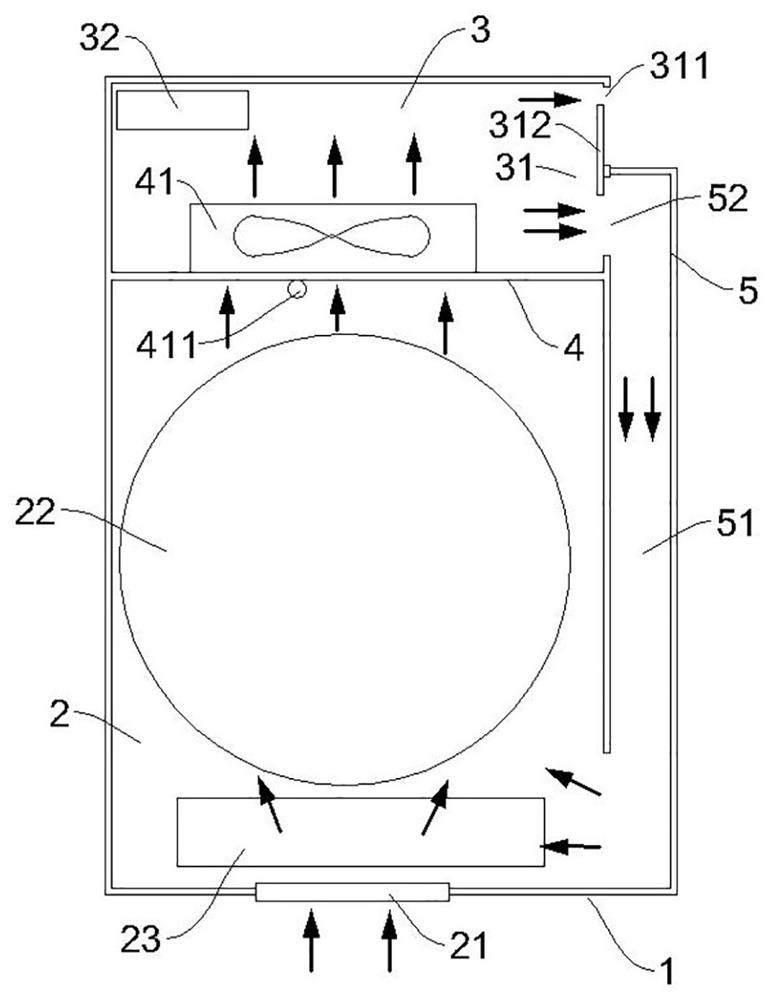

[0034] A thermal management system for small hydrogen production equipment, such as figure 1 As shown, it includes a reaction chamber 2 and a heat distribution chamber 3. The reaction chamber 2 and the heat distribution chamber 3 are based on the outer box 1 and are jointly arranged in the outer box 1, and the reaction chamber 2 and the heat distribution chamber 3 pass through a barrier The plates 4 are separated; the reaction chamber 2 is provided with a fuel tank 22 and a water separation filter component 23 connected to the fuel tank 22 through a pipeline (in this embodiment, the water separation filter component 23 is a water vapor separator, and the The water vapor separator is connected to the hydrogen production pipeline such as the water distribution pipeline and the gas drying pipeline); the fan 41 is installed on the baffle plate 4, and a wall of the reaction chamber 2 opposite to the fan 41 is set There is an air inlet window 21, and the air inlet window 21 is provi...

Embodiment 2

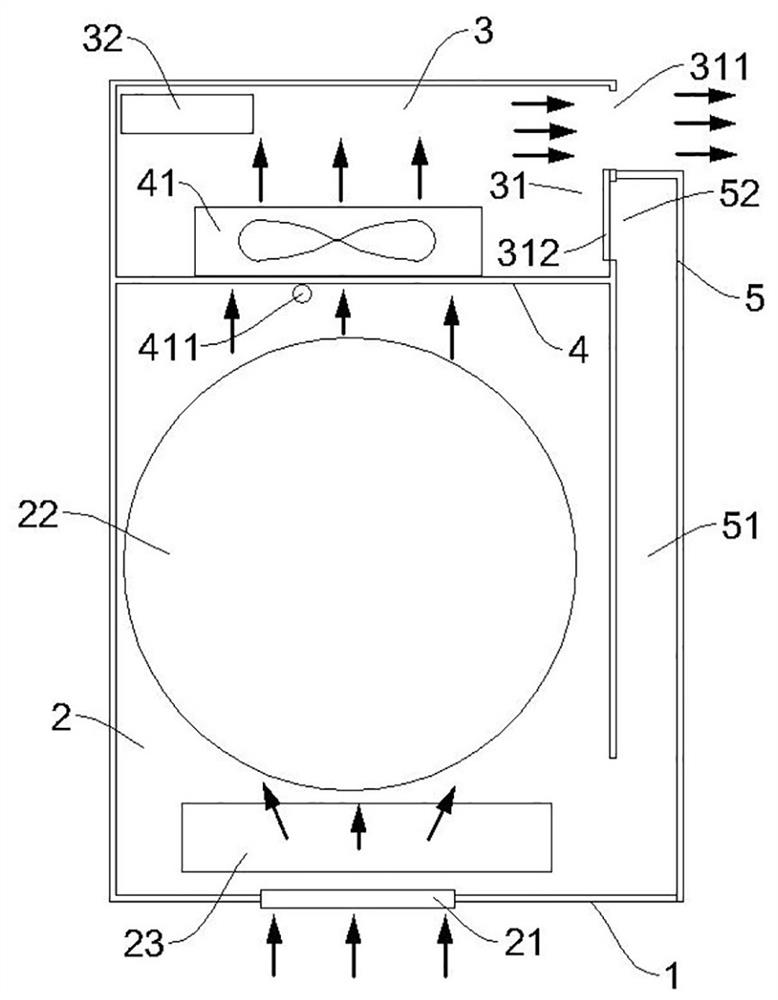

[0043] A thermal management system for small hydrogen production equipment, such as Figure 4 As shown, the basic structure is the same as that of Embodiment 1, the difference is that: this embodiment is also provided with a cooling fin assembly 24 and an air pump 33 on the basis of Embodiment 1; In the right position, the cooling fin assembly 24 includes a plurality of parallel cooling fins; the air pump 33 is arranged in the heat distribution chamber 3 near the air outlet end 31 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com