Tobacco grading and sorting device

A grading device and tobacco leaf technology, applied in tobacco, tobacco preparation, application, etc., can solve problems such as low production efficiency, high production cost, and scattered structure, and achieve the effects of reducing labor intensity and improving sorting efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

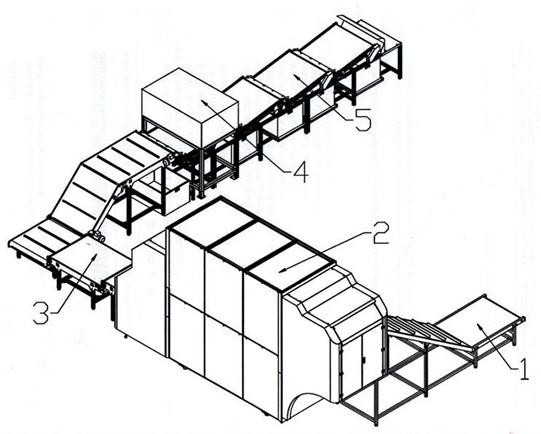

[0007] The embodiment is described in detail in conjunction with the accompanying drawings. In the present invention, a tobacco leaf lifting device 1 is installed on the inlet side of a drum loosening device 2, and a multi-stage belt transmission device 3 is installed at the outlet end of the drum loosening device. The multi-stage belt The placement direction of the last-stage conveyor belt of the transmission device is consistent with or perpendicular to the direction of the previous conveyor belt. An image detection and grading device 4 is installed at the discharge end of the multi-stage belt transmission device. Tobacco classification device 5 is installed at mouth end.

[0008] When working, the collected tobacco leaves are placed on the platform of the tobacco leaf lifting device first, and then enter the tobacco leaf loosening device through lifting transmission, and the individual tobacco leaves that have not been scattered are loosened again by the loosening device thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com