Granular material optical color sorter

A particle material and color sorter technology, applied in sorting and other directions, can solve the problems of limiting the processing capacity of the color sorter, inaccurate judgment of particle color, and inability to distinguish details well, achieving a simple and reliable overall structure and reducing production. Cost, easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

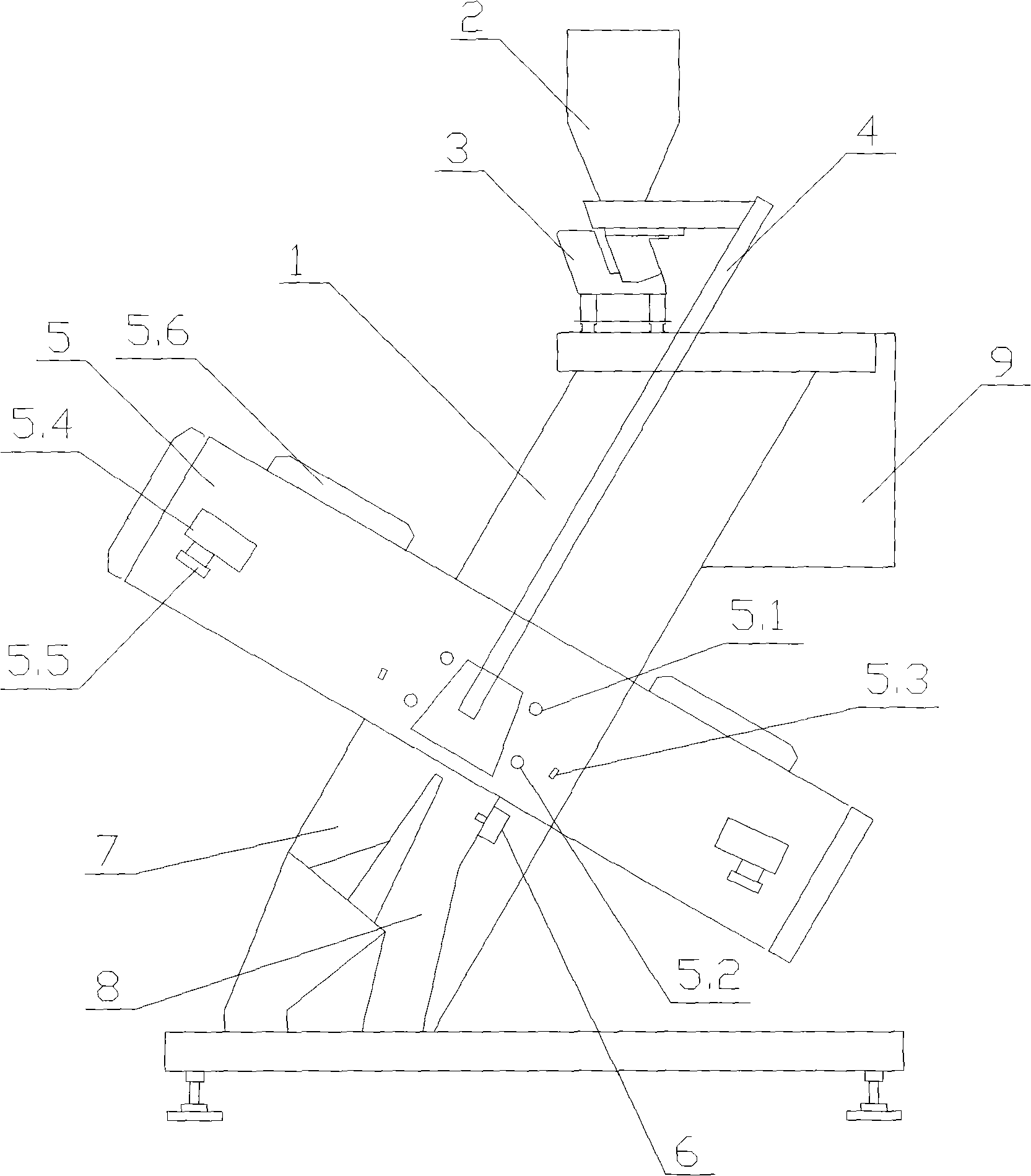

[0017] see figure 1 , the structural frame 1 of the color sorter is the basic structure of the whole machine, used to install other components and ensure their relative positions. The feeding hopper 2 is supported on the top of the structural frame 1 through brackets, and the vibrating feeder 3 is supported on the upper part of the structural frame through support legs with vibration isolation effect, located at the lower end of the feeding hopper 2, and kept in proper alignment with the feeding hopper. Distance, through the control of the feeding hopper 2 and the control of the distance between the two, a certain amount of granular material exists in the vibrating feeder 3 . The unloading chute 4 is obliquely installed on the structural frame 1, and the uppermost end is slightly higher than the discharge opening of the vibrating feeder 3, and an appropriate distance is kept between the discharge opening of the vibrating feeder to achieve sufficient lowering. The amount of ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com