Extensible inspection production equipment for smart cards

A production equipment and card technology, applied in the field of smart card sorting production equipment, can solve the problems of high labor intensity for sorting personnel, difficulty in mass production, and low sorting efficiency, so as to meet the requirements of mass production, excellent performance, The effect of high sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

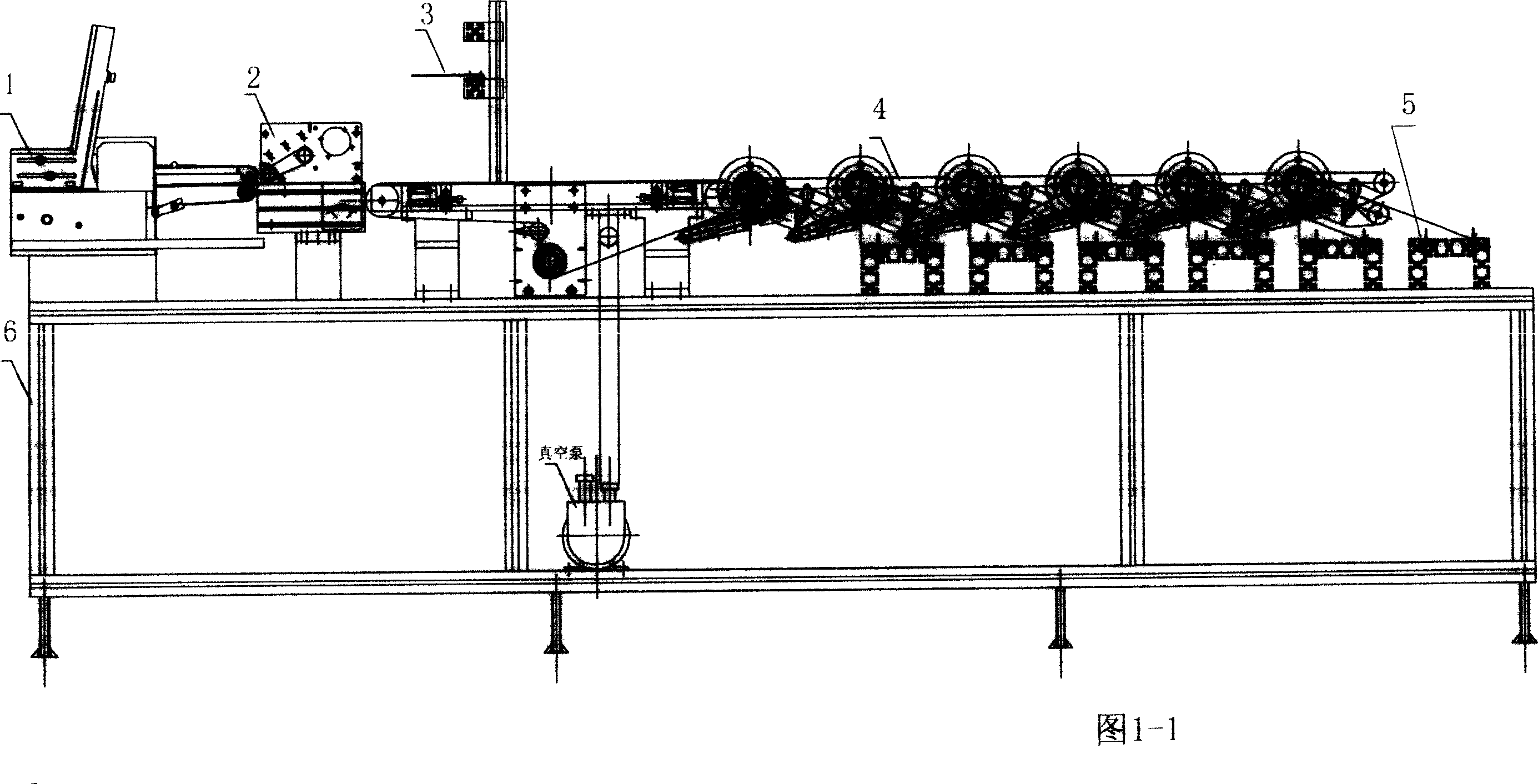

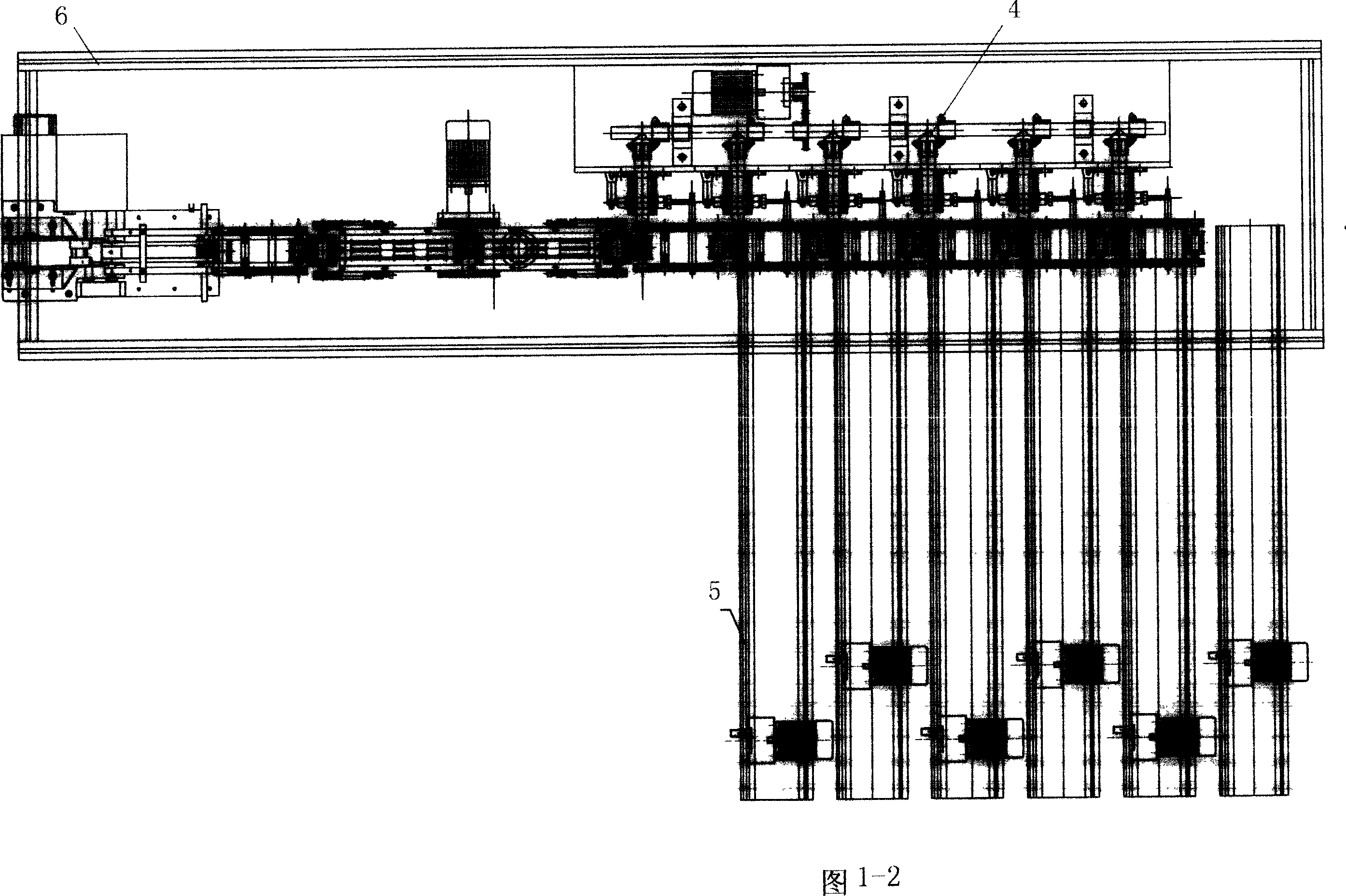

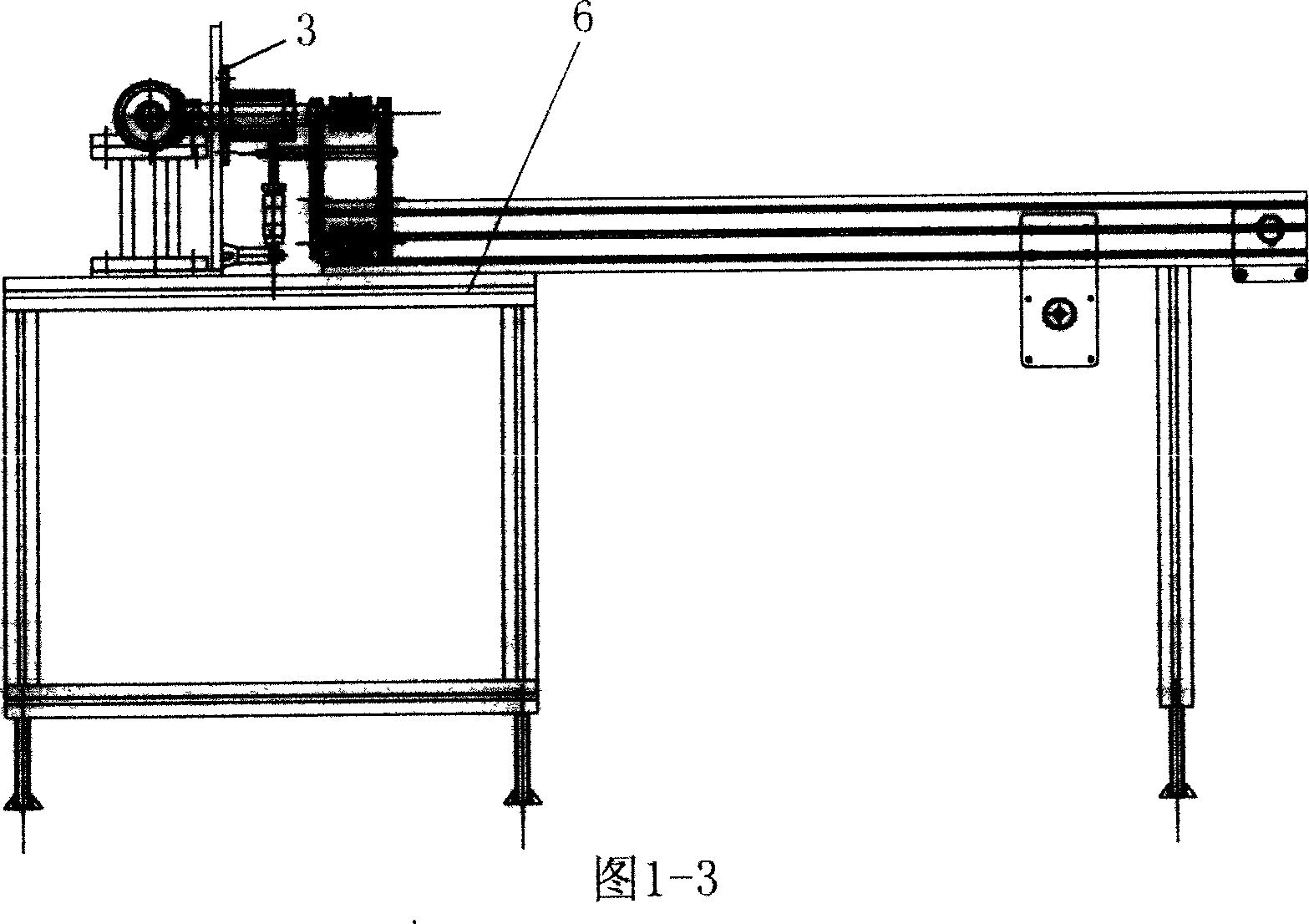

[0028] The schematic diagram of the structure of the present invention is shown in Figure 1, including a card issuing device 1 for sending cards at a frequency, a heavy card rejecting device 2 for rejecting overlapping cards, a detection device 3 for detecting the quality of card surface patterns, and a card issuing device with different surface patterns. Card sorting device 4 for sorting cards, receiving device 5 for stacking the sorted cards, rack 6, among which card issuing device 1, heavy card rejecting device 2, detection device 3, card sorting device 4, and receiving device 5 in sequence Installed on rack 6.

[0029] The above-mentioned card issuing device 1 includes a feed bin 11, a card sending conveyor line 12, a card rubbing wheel 13, a card dividing wheel conveying device 14, and a card feeding motor 15. The feed bin 11 is placed on the side of the card feeding conveyor line 12, and the card feeding conveyor line The active part of 12 is connected with the output sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com