Physicochemical comprehensive treatment system for dangerous waste liquid

A comprehensive treatment, waste liquid technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., to achieve good treatment effect, avoid leakage and leakage, and reduce investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

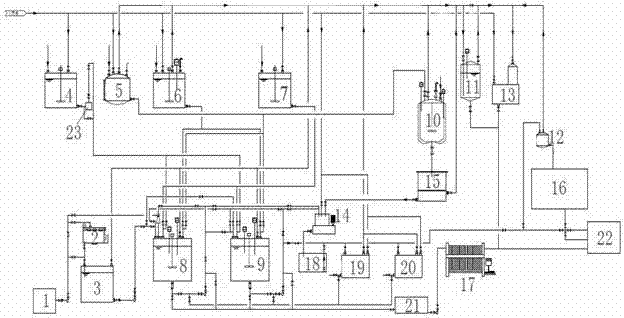

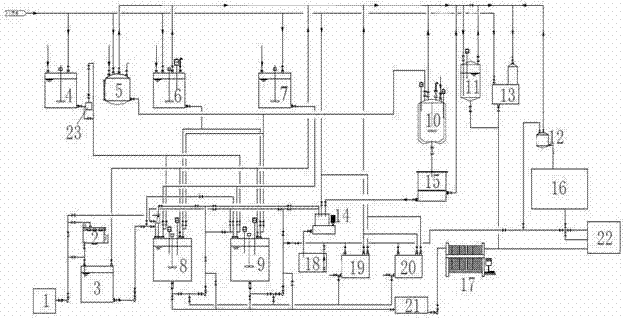

Image

Examples

Embodiment

[0021] Applying the present invention, the hydrofluoric acid waste liquid produced by a certain medical equipment company in Hangzhou is used as the processing object. The fluoride content of the waste liquid (calculated as F-) is 100g / L. The main pollutant is HF, which is strongly acidic and has a gray-green appearance.

[0022] The specific treatment conditions are as follows: the reaction agent is lime milk solution lime / water=27 / 100 (mass ratio), 1:1 hydrochloric acid solution, and the amount of each batch of waste liquid is 0.8m 3 , add lime emulsion 2.5 m 3 After stirring for 15 minutes, pass through hydrochloric acid solution 0.06 m 3 Adjust the pH value (can be adjusted to about pH = 7) to stir for 20 minutes. After the reaction, the viscous waste liquid enters the vertical centrifuge for centrifugal dehydration, the filter cake enters the sludge collection tank or goes to the hazardous waste landfill for safe landfill, and the filtrate enters the middle tank of was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com