Pneumatic powder conveying gas material separation and decompression device and process

A technology of pneumatic conveying and decompression device, which is used in conveying bulk materials, conveyors, transportation and packaging, etc. It can solve the problem of increasing the impact wear of the inner wall of the launder, the flying leakage of powder raw materials, and reducing the use of launders. life and other problems, to solve the loss of raw materials, avoid flying leakage or leakage, and improve the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

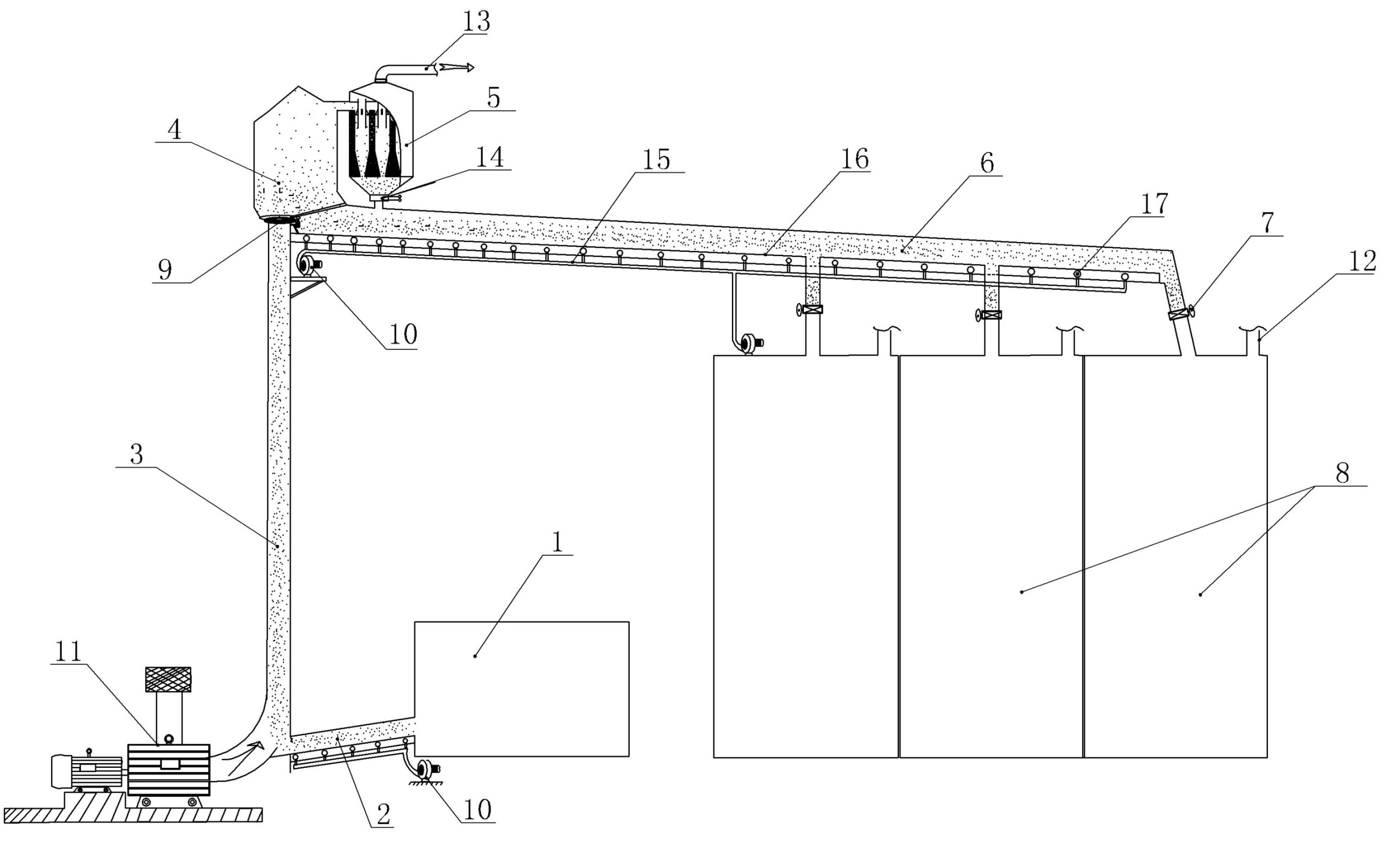

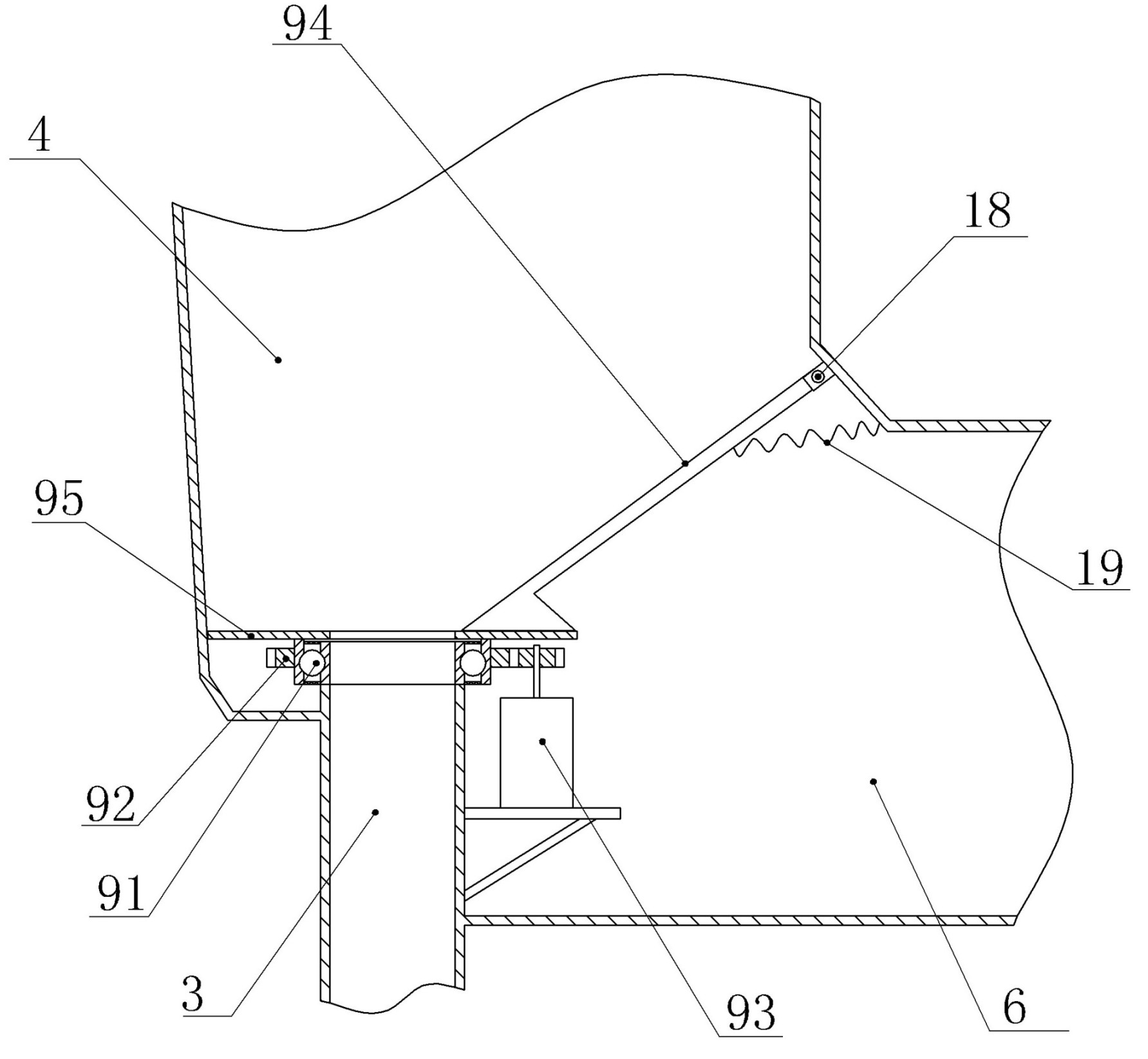

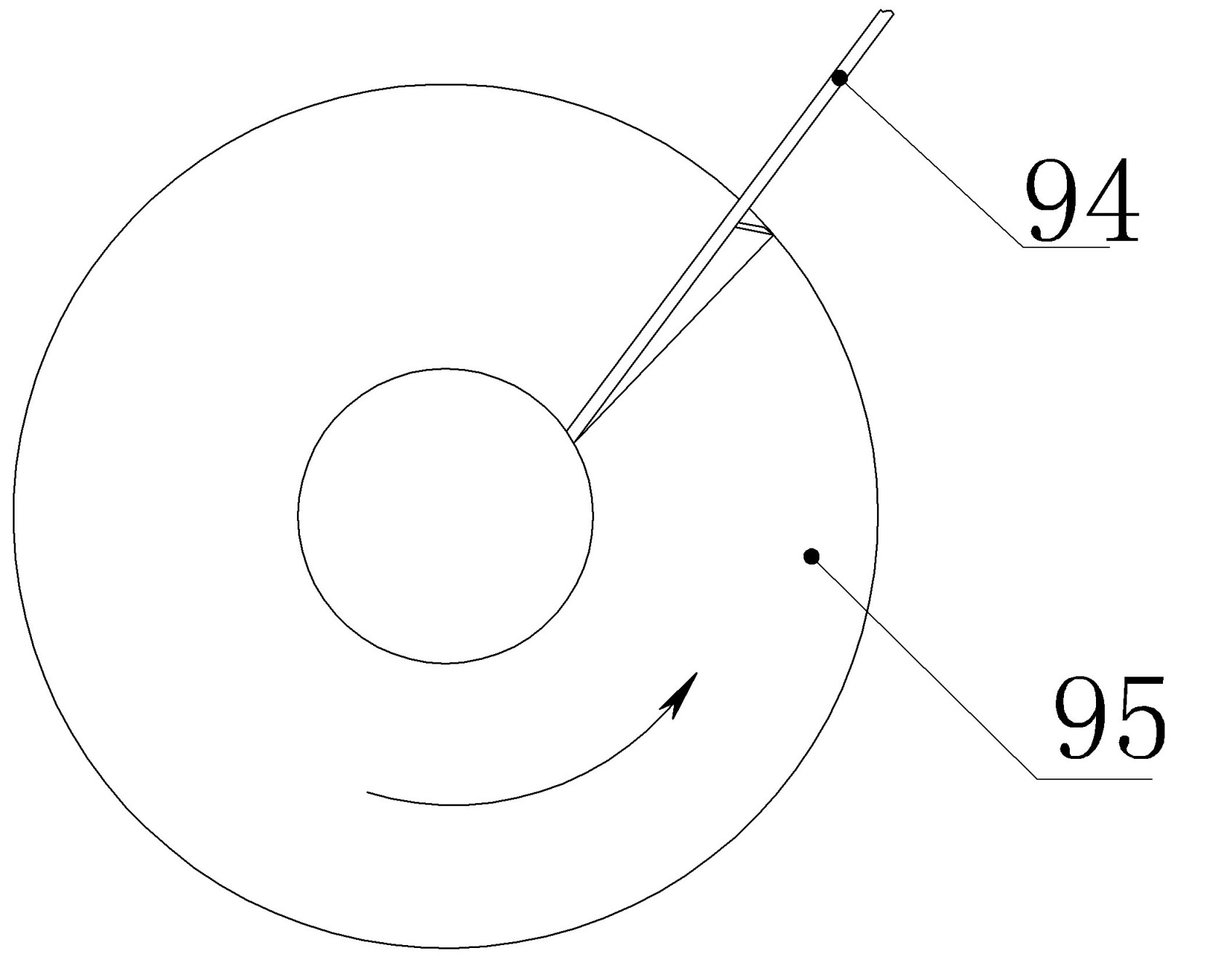

[0032] Embodiment one: see figure 1 — Figure 8 , label 1 is the powder production source, 2 is the feeding chute, 3 is the pneumatic lifting pipeline, 4 is the dust-reducing splitter, 5 is the axial-flow high-efficiency cyclone dust collector, 6 is the tank chute, and 7 is the tank Branch pipe and tank valve, 8 is the powder storage bin, 9 is the feeder, 10 is the axial flow fan, 11 is the Roots blower, 12 is the dust removal exhaust pipe, 13 is the main exhaust pipe (connected with the dust removal and purification system ), 14 is a gravity blanking valve, 15 is a feeding air pipe of a tank launder, 16 is an air material cloth interlayer, 17 is a feeding air valve, 18 is a bearing pin, and 19 is a return spring. 501a and 501b are the upper cylindrical section and the lower conical section of the shell respectively, 502 is the exhaust pipe, 503 is the sealing plate fixedly supported, 504 is the arc guide vane, 505 is the air inlet, 506 is the discharge port , 507 is the tot...

Embodiment 2

[0040] Embodiment two: see figure 1 , a powder pneumatic conveying gas material separation and decompression process, comprising the following steps:

[0041] (1) The powder production source transports the powder raw materials along the feeding trough to the confluence of the lower mouth of the pneumatic lifting pipeline;

[0042] (2) Use the fan to output high-pressure airflow above 100KP to gasify the powder raw material in the lower part of the air lift pipe and then lift it up to the top of the air lift pipe;

[0043] (3) Perform gravity dust reduction and diversion treatment on the high-pressure and high-speed gas material lifted in step (2), forming the buffered mainstream gas and most of the materials that sink due to gravity, and most of the sinking materials fall into the dial The material tray is dialed into the tank chute, and poured into each silo by pneumatic push at the bottom of the chute;

[0044] (4) The mainstream gas formed in step (3) is subjected to cyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com