Tunnel lining trolley

A technology for lining trolleys and tunnels, used in tunnel lining, tunnel, shaft lining, etc., can solve the problems of inability to automatically open and close, complex formwork support system, low formwork strength, etc., and achieves low labor intensity for workers and anti-floating. The effect of good performance and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

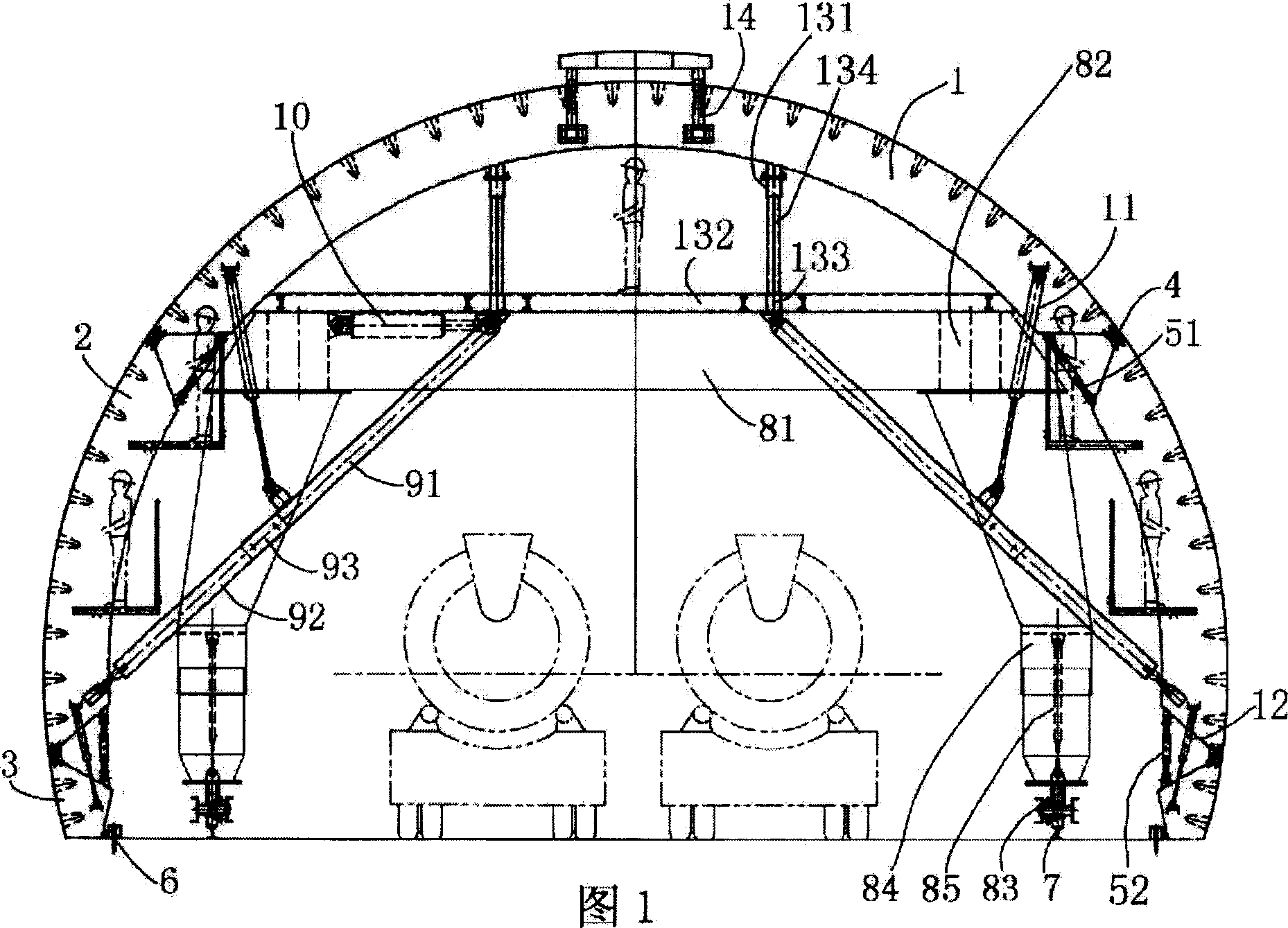

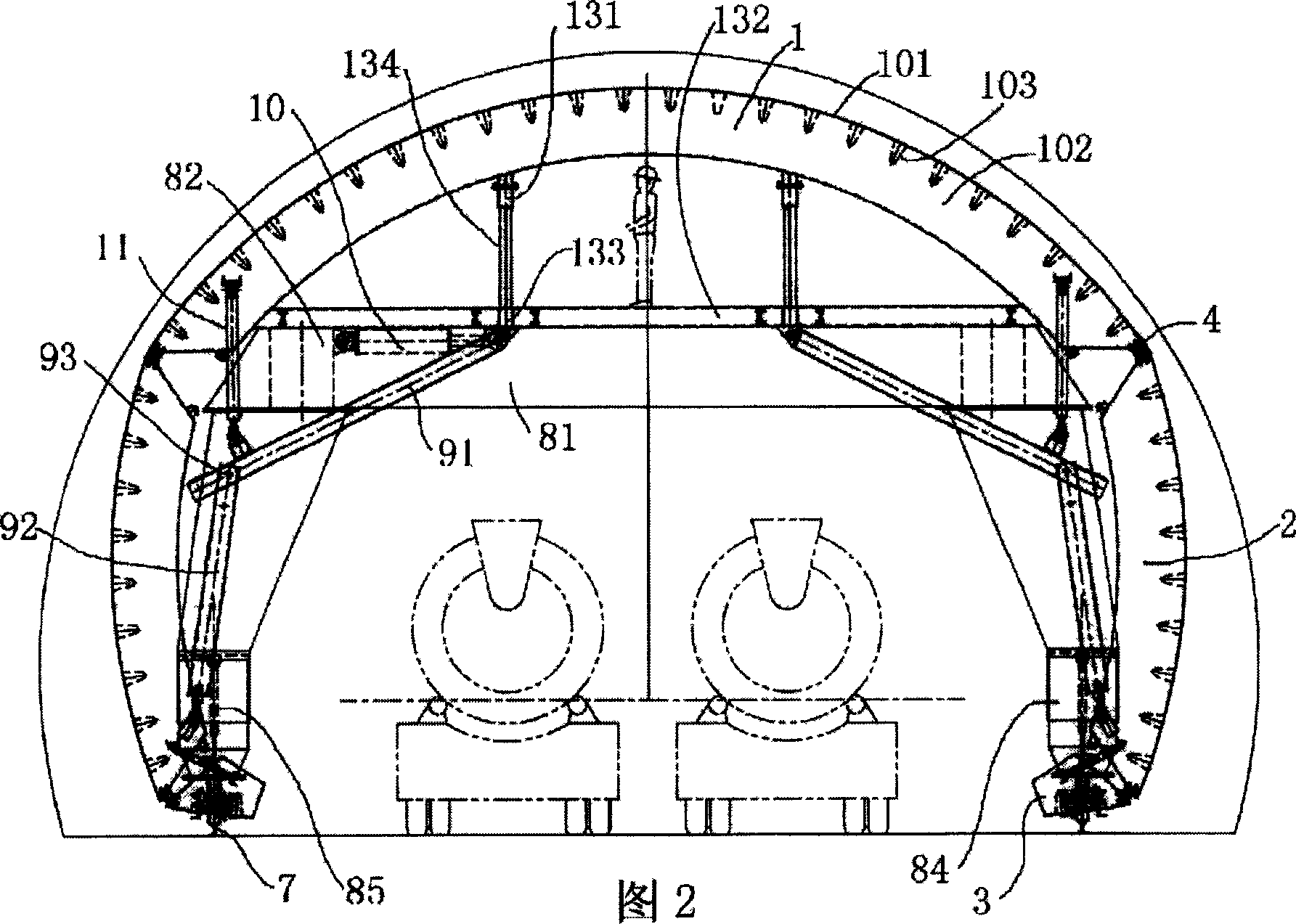

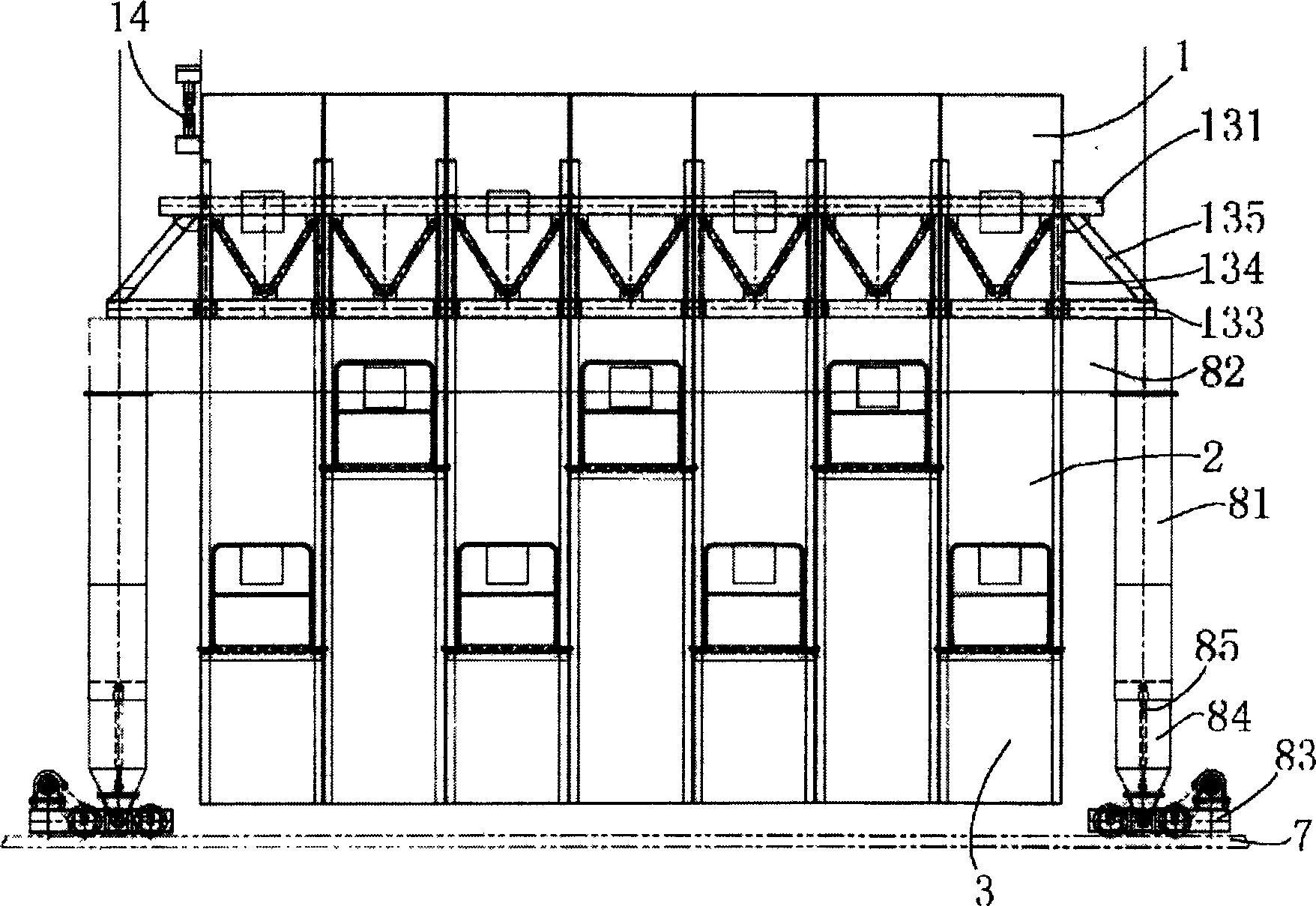

[0026] Embodiment Referring to Figures 1-3, the tunnel lining trolley of the present invention includes a tunnel-shaped formwork, a trolley in the formwork, and a formwork entry and exit system. There is a grouting port on the formwork, and the grouting port is connected to the grouting system. Each set of templates has two observation windows.

[0027] The template is welded by panels 101 , frame plates 102 and ribs 103 .

[0028] see Figure 4 , in order to increase the overall rigidity of the template, reduce the amount of deformation, and reduce the steel consumption of the template, the rib plate 103 of the template is U-shaped. Both sides of the opening are welded to the panel.

[0029] A set of templates includes a top template 1, two side templates 2 and two bottom templates 3, and the cross section of the interface between the top template 1 and the two side templates 2, and between the two side templates 2 and the two bottom templates 3 is bell-shaped. , its outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com