A plurality of dry granular ceramic tiles capable of being simultaneously distributed and applied, preparation method and control method thereof

A technology of ceramic tiles and dry granules, which is applied in the field of ceramics, can solve the problem of single dry granule patterns, etc., and achieve the effects of simplifying the process, improving the decorative effect, enhancing the ornamental value and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further detailed below in conjunction with the accompanying drawings:

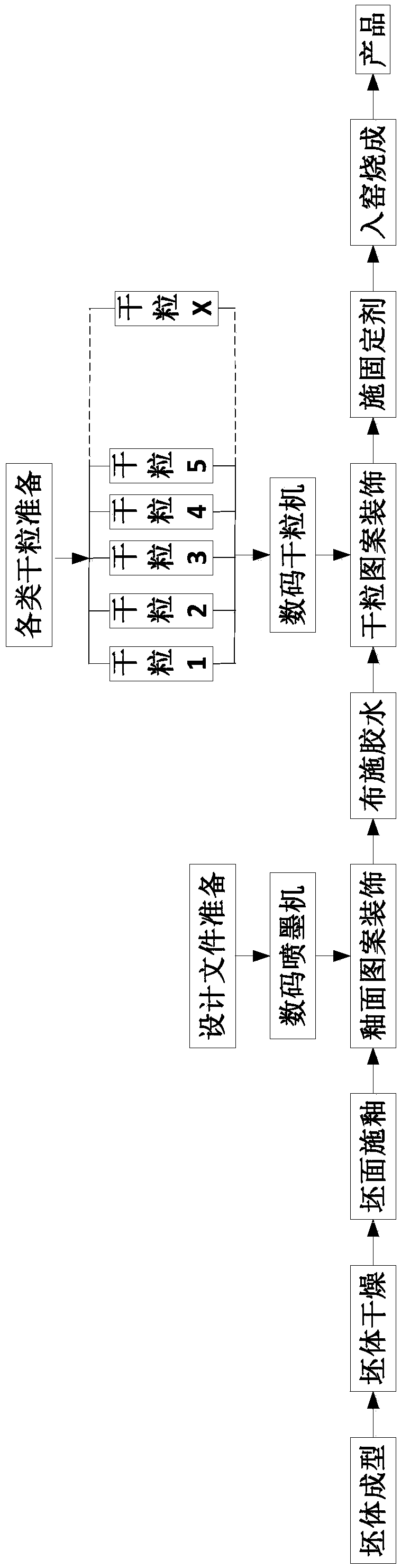

[0033] figure 1 It shows the control flow chart of the present invention that can simultaneously apply a variety of dry ceramic tiles.

[0034] See figure 1 As shown, the control method for simultaneously applying multiple dry ceramic tiles includes the steps of forming a green body, drying the green body, and glazing the green surface, and further includes:

[0035] ⑴ Preparation of design documents;

[0036] ⑵The design file is decorated with glazed patterns through the digital inkjet machine;

[0037] ⑶ Apply glue;

[0038] ⑷ Input the preset parameters, patterns and quantities into the digital drier. The digital drier controls the dosage and effect of different types of dry particles at the same time. All kinds of dry particles are passed through the digital drier. Can give out dry pattern decoration at the same time;

[0039] ⑸Apply fixative and fire into kiln.

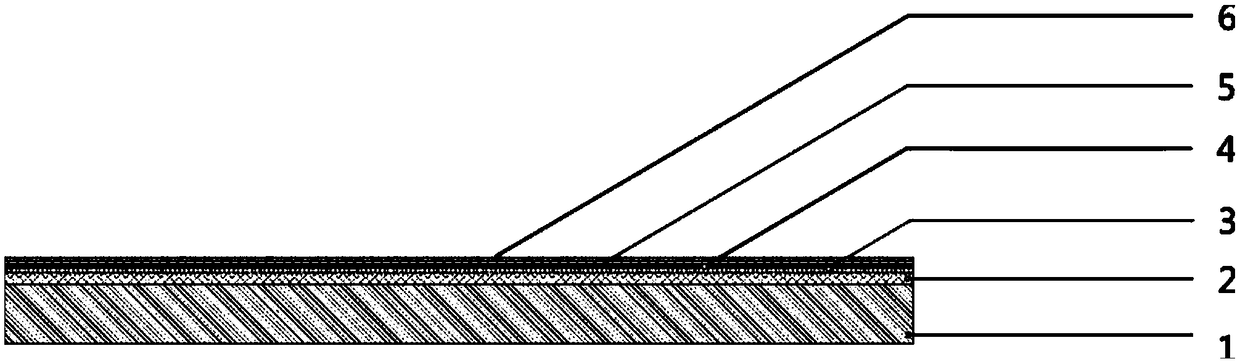

[0040] figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com