Necking type steel bar connecting sleeve, connecting structure thereof and installing method of connecting structure

A technology of steel connection sleeve and installation method, which is applied in the direction of structural elements, building components, building structures, etc., can solve the problems of difficult quality control, hidden dangers of building safety, and high connection strength, so as to improve the accuracy of the assembly position and improve the corrosion resistance. performance, the effect of improving connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

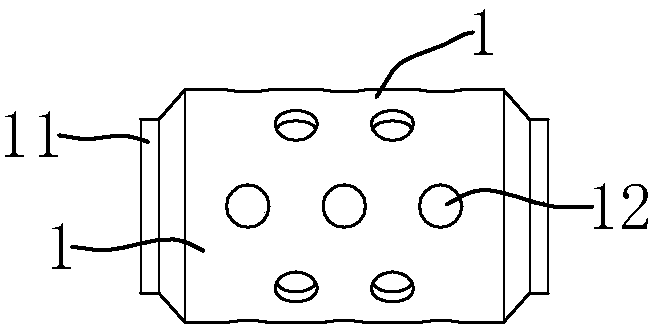

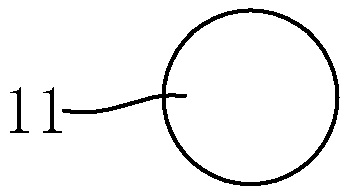

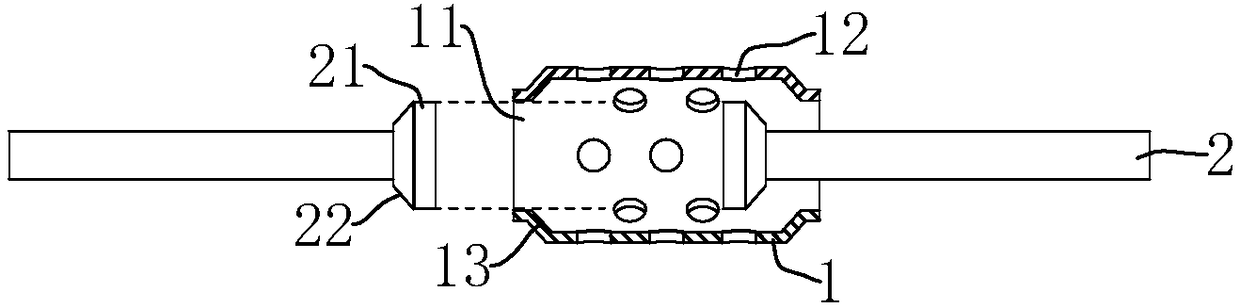

[0103] Necked steel bar connection sleeve and its connection structure, such as figure 1 As shown, the necking-type steel bar connecting sleeve includes a cylinder 1 and a necking 11 integrally connected to both ends of the cylinder 1. Several evenly distributed grouting holes 12 are opened on the cylinder 1 to facilitate the flow of cement slurry into the cylinder 1. inside; combine figure 2 , the necking 11 is a round mouth, the inner wall of the necking 11 is conical, and the larger end of the conical surface faces the inside of the cylinder 1; combined image 3 , the connection structure of the necked steel bar connecting sleeve is composed of the connecting steel bar 2 and the cylinder body 1. One end of the connecting steel bar 2 is embedded and fixed inside the prefabricated slab 3, and the other end is exposed outside the prefabricated slab 3 and far away from the prefabricated slab 3. One end is integrally connected with an expanding head 21, the radial dimension o...

Embodiment 2

[0109] The necking-type steel bar connection sleeve and its connection structure are different from Embodiment 1 in that, as Figure 5 As shown, the constriction 11 is a flat mouth, such as elongated or oval; the enlarged head 21 is a flat head. Taking the ellipse as an example for illustration, the length of the major axis of the ellipse of the expanding head 21 is greater than the length of the minor axis of the ellipse of the constriction 11. Make the elliptical major axis of the enlarging head 21 and the elliptical major axis of the constriction 11 stagger, preferably, the elliptic major axis of the enlarging head 21 is aligned with the elliptical minor axis of the constriction 11, which can limit the enlarging head 21 from the constriction. Port 11 is out of barrel 1 .

[0110] Preferably, as Figure 6 and Figure 7 As shown, a plurality of connecting steel bars 2 can be inserted at both ends of the cylinder body 1, and there can be two. The expanding head 21 is inser...

Embodiment 3

[0112] The necking-type steel bar connection sleeve and its connection structure are different from Embodiment 1 in that, as Figure 8 As shown, anti-skid lines 14 are provided on the inner wall of the cylinder 1 , the anti-slip lines 14 are in the shape of annular grooves, and a plurality of anti-slip lines 14 are evenly distributed along the central axis of the cylinder 1 . After the cement slurry is solidified inside the cylinder 1 to form concrete, the concrete can be embedded in the grooves of the anti-skid lines 14 to improve the connection strength between the inner wall of the cylinder 1 and the inner concrete, and avoid relative sliding between the concrete and the inner wall of the cylinder 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com