Driving roller

A technology for driving drums and outer cylinders, which is applied in the direction of electric components, engine components, and engine seals. It can solve problems such as complex structures and poor waterproof performance, and achieve large contact areas, good waterproof performance, and axial movement prevention. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose and technical solution of the present invention clearer, the technical solution of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention.

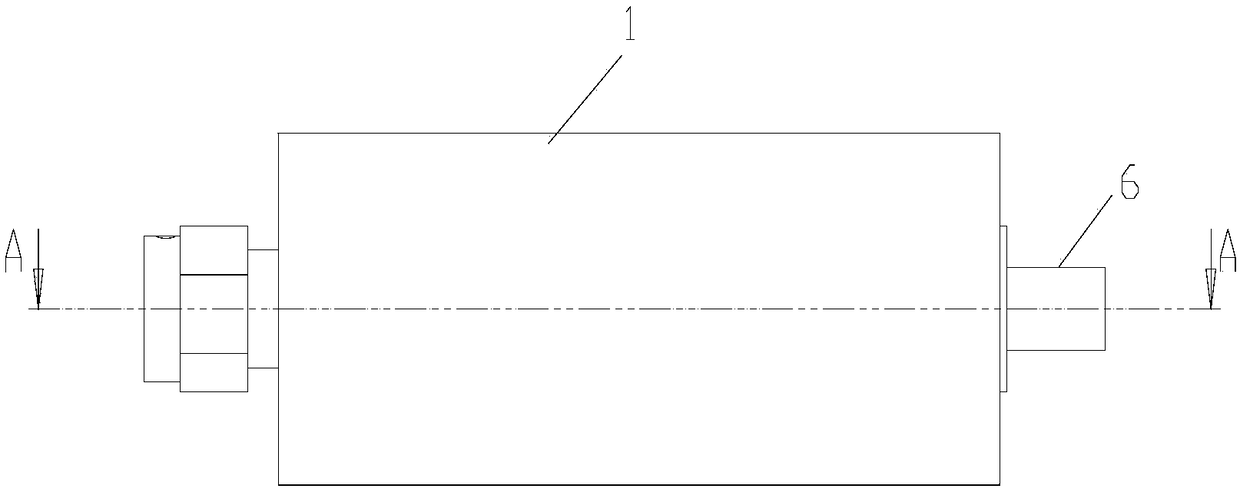

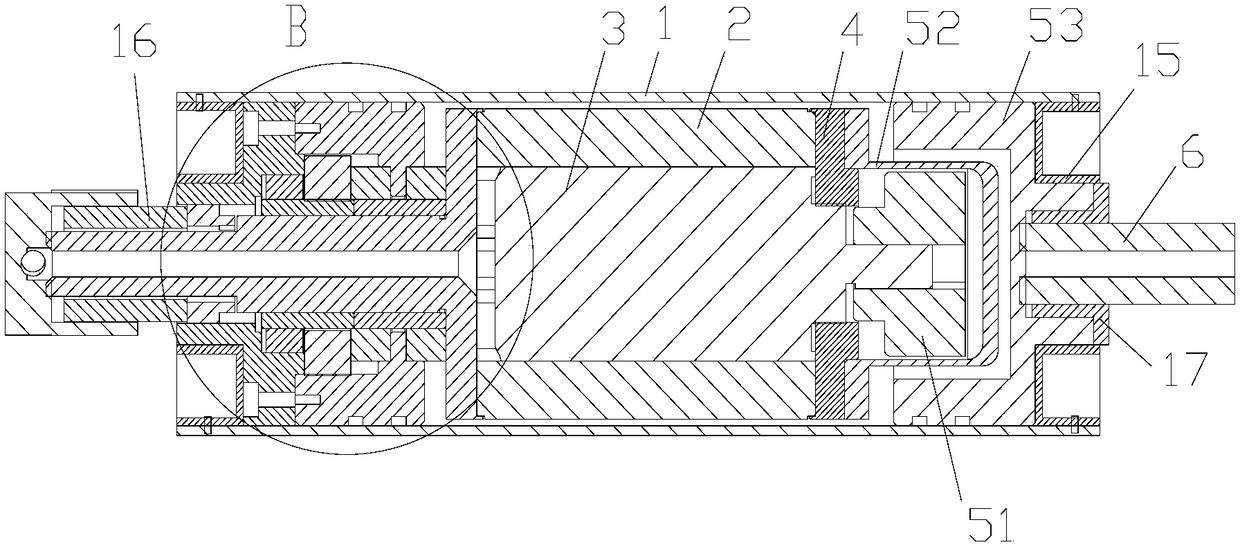

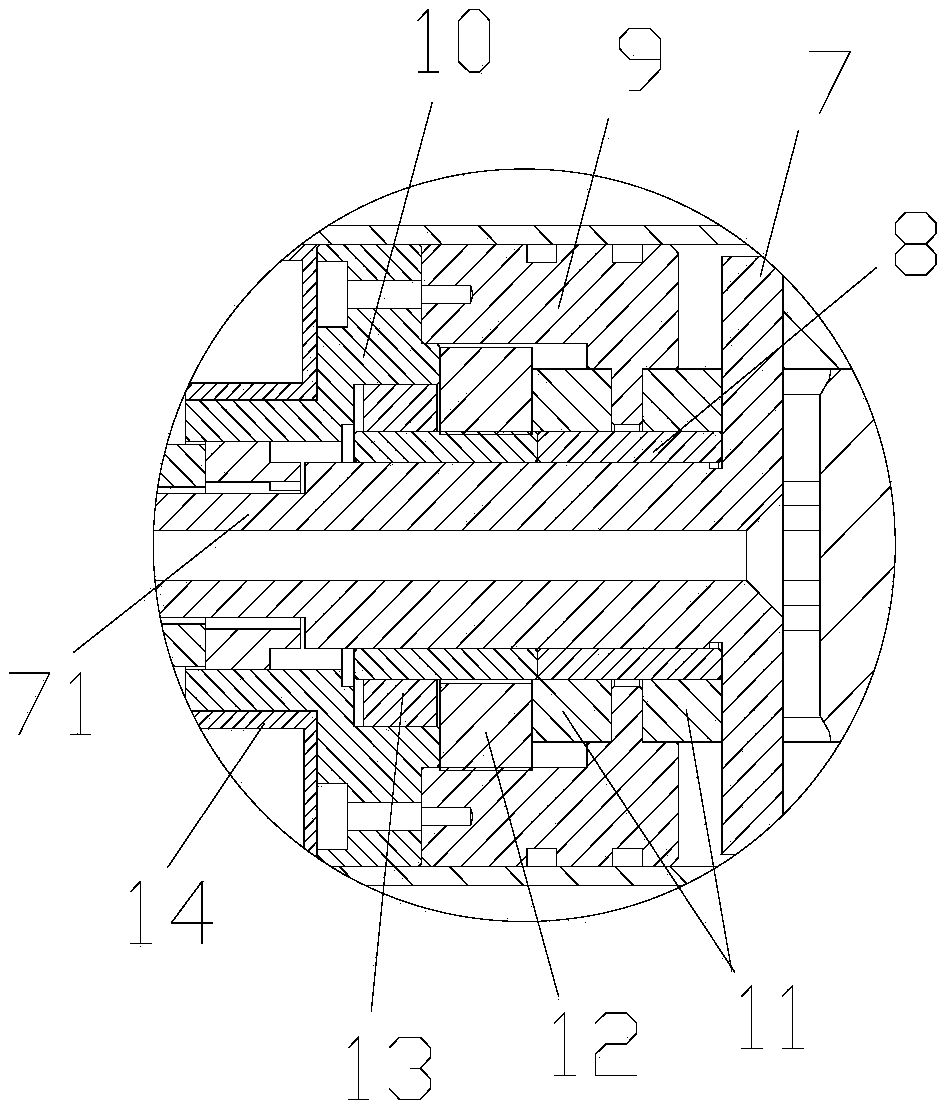

[0030] Such as Figure 1-7 As shown, a driving drum includes an outer cylinder 1 and an inner cylinder 2 arranged in the outer cylinder, a motor 3 is fixedly arranged in the inner cylinder, the output shaft of the motor 3 is sleeved with a first rotating member, and the outer peripheral surface of the first rotating member It is sealed and fixed with the inner wall of the outer cylinder; the other end of the inner cylinder 2 is provided with a second connecting piece, through which the inner cylinder 2 and the outer cylinder 1 are rotatably connected together, and the second connecting piece and the inner cylinder It is tightly connected with the outer cylinder. The motor 3 is a servo motor, which can drive the outer cylinder 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com