Single-side surface layer compressed wood and preparation method thereof

A technology for compressing wood and surface layers, which is applied in lamination, lamination devices, wood compression, etc., can solve the problems of difficult control of compressed wood density distribution, affecting wood yield, and unsatisfactory use effects, so as to prevent tile bending deformation and peak dense layer movement, easy control, and the effect of reducing thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

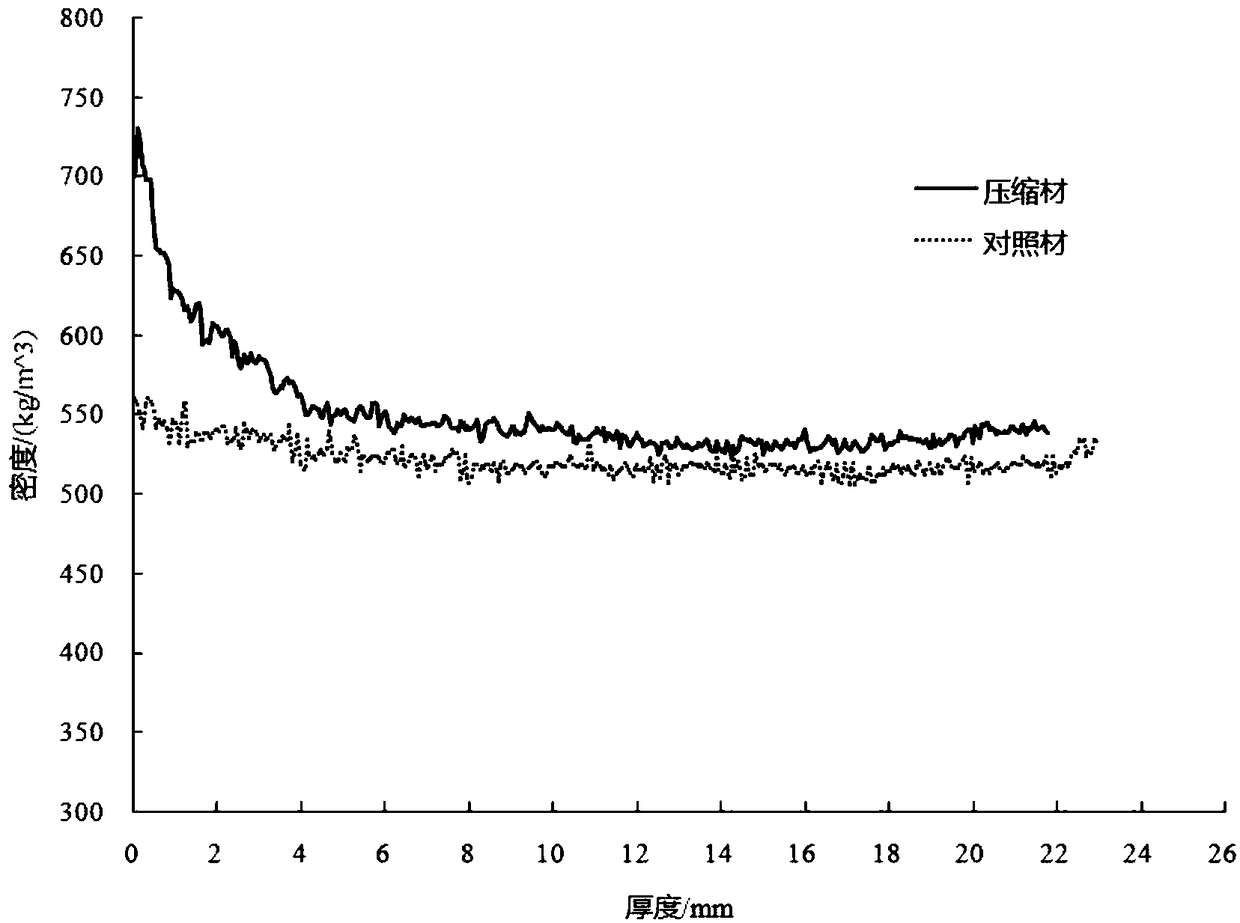

Embodiment 1

[0031] (1) Double-sided planing of Populus tomentosa wood is prepared into a board with a size of 920×120×23.5 mm, which is put into a drying oven and gradually heated to 150° C. to dry to a super dry state;

[0032] (2) Turn on the hot press, raise the temperature of the upper platen (hot plate) to 150°C, and keep the lower platen (cold plate) unheated, and pave the 3 pieces of poplar wood after ultra-high temperature drying neatly in a single row on the cold plate. On the board, a thickness gauge of 21 mm is placed on both sides of the wood;

[0033] (3) closing the press, making the hot plate on the press contact with the poplar wood upper surface, preheating for 90 seconds;

[0034] (4) The pressure of the press is set to 8 MPa, and the wood is compressed to the required thickness at a feed rate of 0.08 mm / s, and then maintained for 120 seconds;

[0035] (5) Reduce the pressure to 1 MPa, and maintain this pressure, the temperature is 150 ° C, and the pressure holding time...

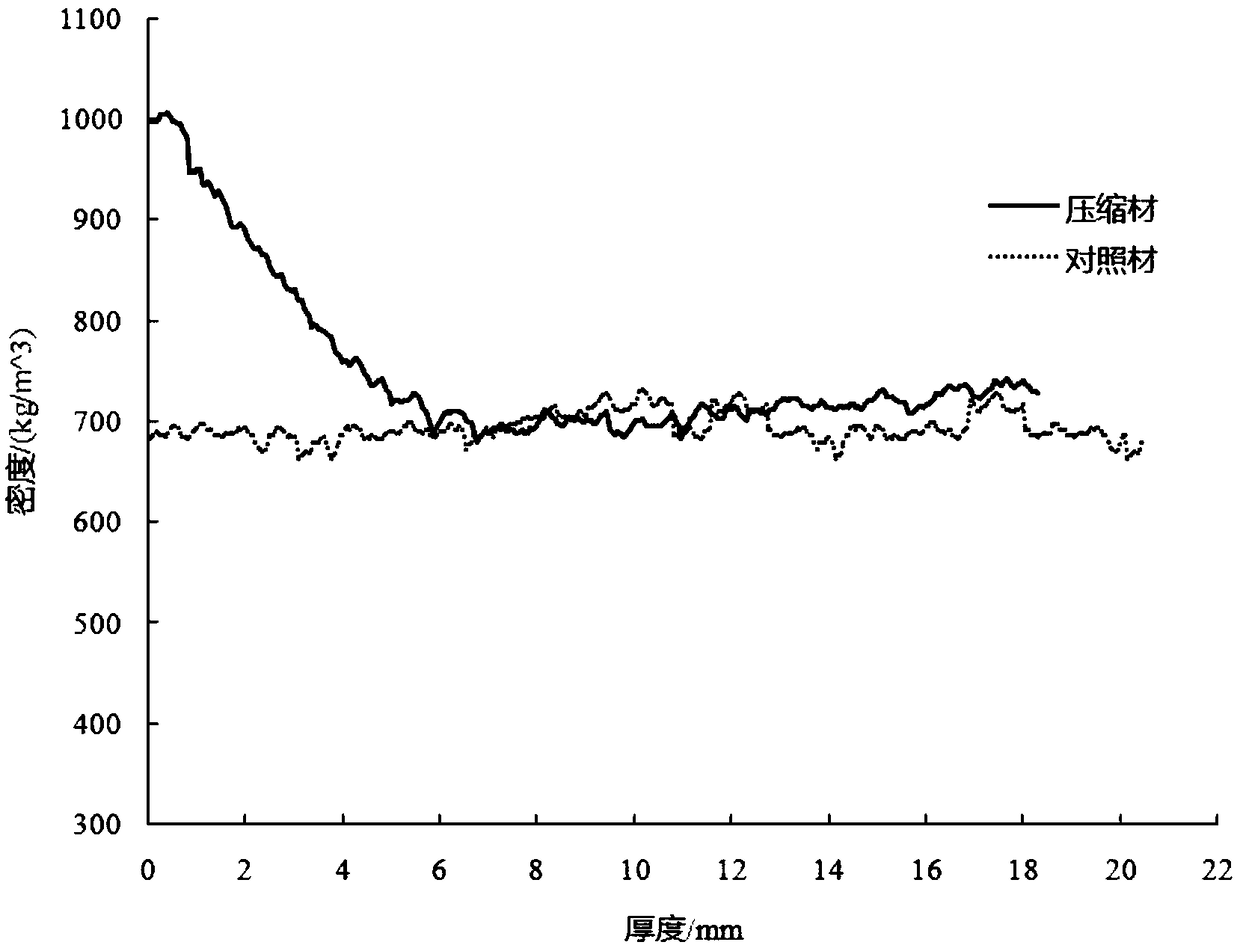

Embodiment 2

[0039] (1) Plane the rubber wood on both sides to prepare a board with a size of 1100×105×20.5 mm, put it into a drying oven and gradually heat it up to 190°C and dry it to a super dry state;

[0040](2) Turn on the hot press, raise the temperature of the upper platen (hot plate) to 190°C, and keep the lower platen (cold plate) unheated, and pave the 3 pieces of rubber wood after ultra-high temperature drying in a single row on the cold plate 18 mm thickness gauges are placed on both sides of the wood;

[0041] (3) Close the press, make the hot plate on the press contact with the upper surface of the rubber wood, and preheat for 120 seconds;

[0042] (4) The pressure of the press is set to 15 MPa, and the wood is compressed to the required thickness at a feed rate of 0.15 mm / s, and then maintained for 250 seconds;

[0043] (5) Reduce the pressure to 3 MPa, and maintain this pressure, the temperature is 190 ° C, and the pressure holding time is 40 minutes;

[0044] (6) The pr...

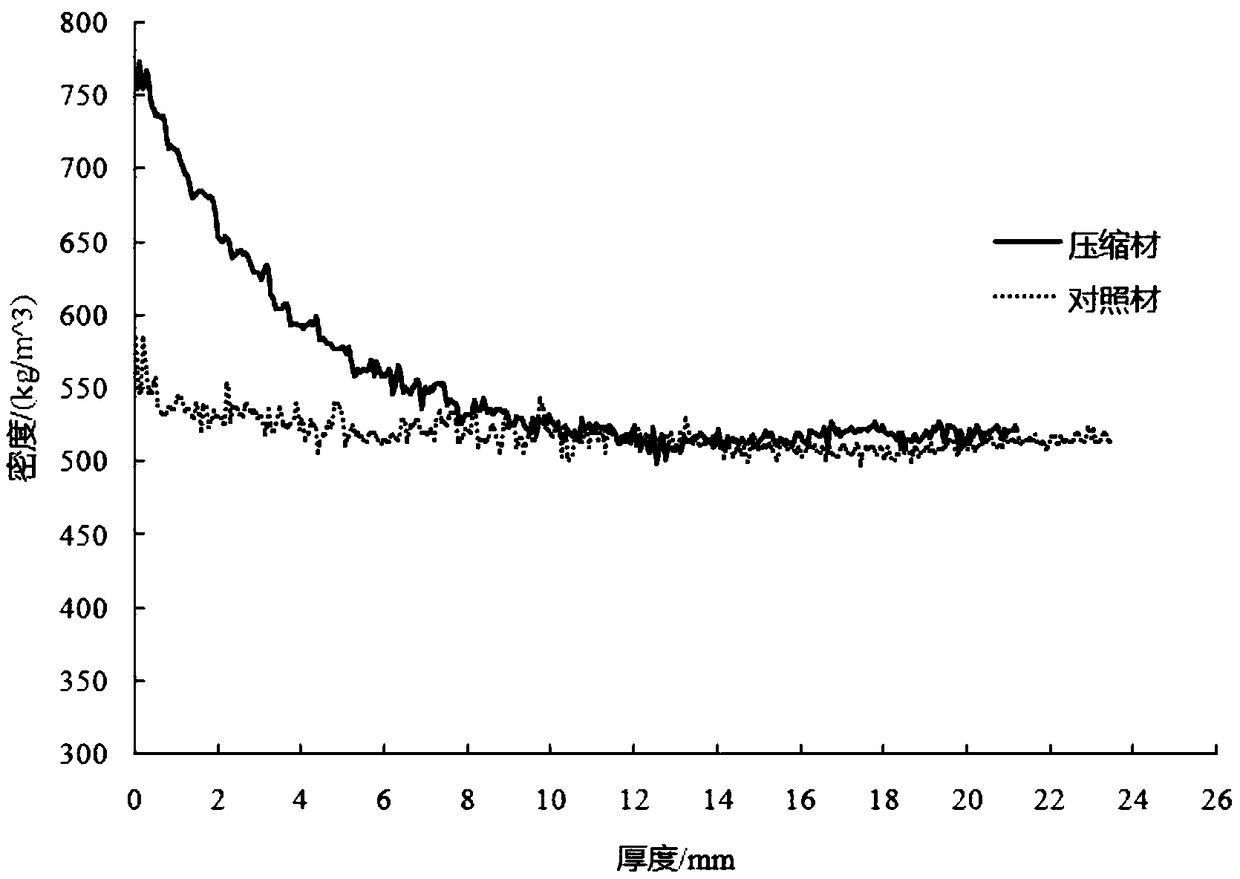

Embodiment 3

[0047] (1) Double-sided planing of Poplar tomentosa wood is prepared into a board with a size of 980×150×23.5 mm, and it is put into a drying oven and gradually heated to 210° C. to dry to a super dry state;

[0048] (2) Turn on the hot press, raise the temperature of the upper platen (hot plate) to 210°C, and keep the lower platen (cold plate) unheated, and pave the 3 pieces of poplar wood after ultra-high temperature drying neatly in a single row on the cold plate. On the board, a thickness gauge of 21 mm is placed on both sides of the wood;

[0049] (3) closing the press, making the hot plate on the press contact with the poplar wood upper surface, preheating for 180 seconds;

[0050] (4) The pressure of the press is set to 12 MPa, and the wood is compressed to the required thickness at a feed rate of 0.18 mm / s, and then maintained for 360 seconds;

[0051] (5) Reduce the pressure to 2 MPa, and maintain this pressure, the temperature is 210 ° C, and the pressure holding ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com