Regular metal section adjustable double-end cutting machine

A metal profile, adjustable technology, applied in the direction of metal sawing equipment, metal processing equipment, sawing device, etc., can solve the problems that the stability cannot be guaranteed well, the position is not easy to adjust, and the cutting effect is affected, so as to achieve the best cutting effect Good, good adjustability, not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following specific examples are only explanations of the present invention, and it is not a limitation of the present invention. Those skilled in the art can make modifications without creative contribution to the present embodiment as required after reading this specification, but as long as they are within the rights of the present invention All claims are protected by patent law.

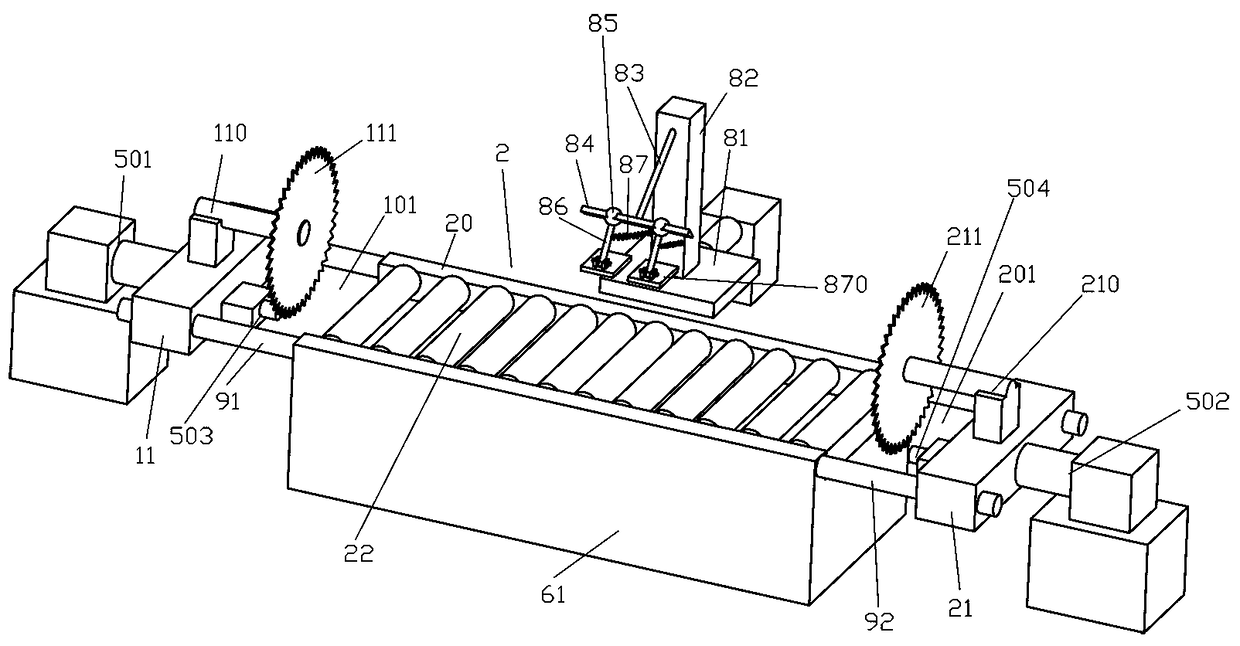

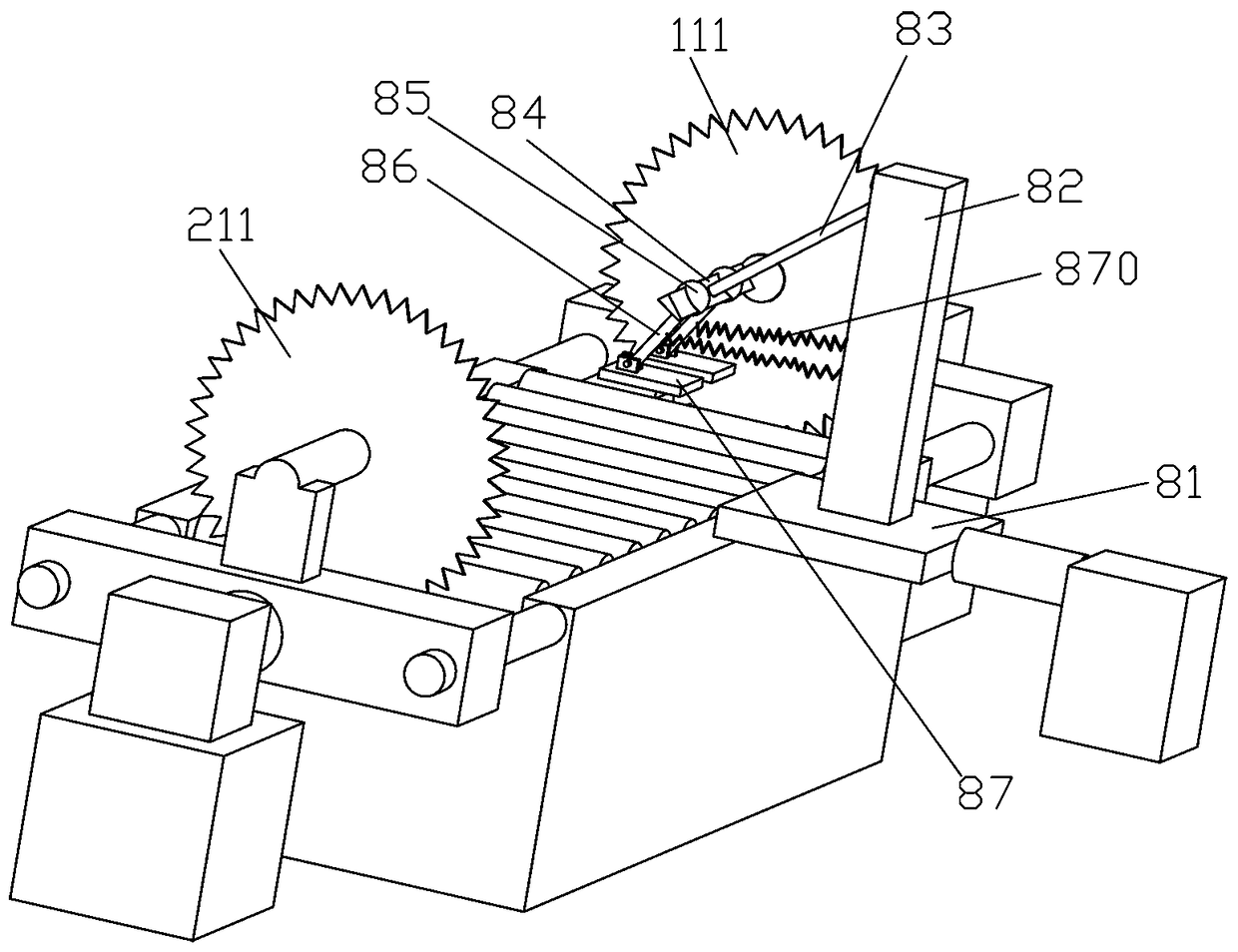

[0017] Examples such as figure 1 , 2 As shown, the adjustable double-head cutting machine for regular metal profiles includes a workbench 61. The upper part of the workbench 61 is equipped with a track 2 for placing metal profiles. The front end of the track 2 is fixed at two left and right intervals and extends forward. The front guide column 91, the rear end of the track 2 is fixed with two left and right rear guide columns 92 that are arranged at intervals and extend backwards, and the front adjustment plate 11 that can move forward and backward is installed on the two front guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com